-

#1

Руководство пользователя (русский язык)

-

7,2 MB

Просмотры: 9.830

-

#2

Yamaha Phazer FX (Help)

Ребят куплю (или возьму на 3 дня за 3

Заранее спасибо!

-

#3

Re: Yamaha Phazer FX (Help)

С Уважением,

eLoX.

-

#4

Re: Yamaha Phazer FX (Help)

Вот нашел, может кому понадобится

З.Ы. по SERVICE и OWNERS мануалам для PZ50MW 8GP1, вопрос остается открытым….

C Уважением,

eLoX.

-

1,8 MB

Просмотры: 2.262

-

#5

Re: Yamaha Phazer FX (Help)

+ дополнение для моделей 2008….

З.Ы. осталась мануалка …..

С Уважением,

eLoX.

-

15,5 MB

Просмотры: 2.680 -

9,1 MB

Просмотры: 1.396

-

#6

Re: Yamaha Phazer FX (Help)

Ну и ,собственно, мануал

С Уважением,

eLoX.

-

5,9 MB

Просмотры: 2.292

-

#7

Re: Руководство пользователя Yamaha venture MP и вся платформа

Сервисное Руководство. PZ50 07-08

-

9,1 MB

Просмотры: 7.713

-

#8

Re: Руководство пользователя Yamaha venture MP и вся платформа

Полный cервис мануал Yamaha Multi Purpose и Yamaha Phazer

-

22,9 MB

Просмотры: 5.030

-

#9

MAD написал(а):

Руководство пользователя (русский язык)

Не получается скачать, выдает:

Вы не авторизованы для скачивания этого вложения.

Что это значит?

-

#10

Надоели лишние страницы в мануале.

Удалил из сервис мануала Фазера и Мультика французский и норвежский, оставил только английский язык

-

14,8 MB

Просмотры: 861

-

#11

Бюллетень про проблемы с задней передачей

-

1,3 MB

Просмотры: 396

-

#12

Чтоб не забылось, парни меняли

Замена бензонасоса от тойота-лексус:

23220-21130

4-я Красноармейская, 2А

Санкт-Петербург, 190005

Email: info@lenmoto.ru

Телефон: +7 (921) 930-81-18

Телефон: +7 (911) 928-08-06

Компания ЛенМото

Запчасти, аксессуары, экипировка, тюнинг для мотоциклов, скутеров, квадроциклов, снегоходов, багги, гидроциклов, катеров и лодочных моторов.

Подпишитесь на наши новости

Подписаться

- Manuals

- Brands

- Yamaha Manuals

- Offroad Vehicle

- VT700F

- Service manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

SERVICE MANUAL

MANUEL D’ATELIER

INSTRUKTIONSBOK

VX700F

VX700DXF

SX700F

MM700F

VT700F

8CH-28197-J0

(981051)

Related Manuals for Yamaha VT700F

Summary of Contents for Yamaha VT700F

-

Page 1

SERVICE MANUAL MANUEL D’ATELIER INSTRUKTIONSBOK VX700F VX700DXF SX700F MM700F VT700F 8CH-28197-J0 (981051) -

Page 3

NOTICE HOW TO USE THIS MANUAL This manual was written by the Yamaha Motor Com- pany primarily for use by Yamaha dealers and their Particularly important information is distinguished in qualified mechanics. It is not possible to put an entire this manual by the following notations: mechanic’s education into one manual, so it is as-… -

Page 4

AVERTISSEMENT COMMENT UTILISER Ce manuel a été écrit par la Yamaha Motor Company CE MANUEL à l’intention des concessionnaires Yamaha et de leurs mécaniciens qualifiés. Il n’est pas possible de mettre Les informations particulièrement importantes sont toute la formation d’un mécanicien dans un seul repérées par les notations suivantes. -

Page 5

ANMÄRKNING ANVÄNDNING AV Denna handbok som är skriven av Yamaha Motor INSTRUKTIONSBOKEN Company är främst avsedd för Yamaha auktoriserade återförsäljare och reparatörer. En utbildad mekanik- Särskilt viktig information i instruktionsboken har ers erfarenhet kan inte ersättas med instruktioner — märkts på följande sätt: hur fullständiga de än är — i en verkstadshandbok av… -

Page 6

ILLUSTRATED SYMBOLS (Refer to the illustration) INSP INFO Illustrated symbols 1 to 9 are designed as thumb tabs to indicate the chapter’s number and content. 1 General information POWR 2 Periodic inspection and adjustment CHAS 3 Chassis 4 Power train 5 Engine 6 Cooling system 7 Carburetion… -

Page 7

SYMBOLES GRAPHIQUES ILLUSTRERADE SYMBOLER (Voir l’illustration) (Se illustrationen) Les symboles graphiques à servent à repérer De illustrerade symbolerna 1 till 9 har utformats les différents chapitres et à indiquer leur contenu. som ett index för att indikera kapitlets nummer och Renseignements généraux innehåll. -

Page 9

INDEX INDEX INNEHÅLLSFÖRTECKNING GENERAL INFORMATION RENSEIGNEMENTS GENERAUX ALLMÄN INFORMATION INFO PERIODIC INSPECTIONS AND ADJUSTMENT INSPECTIONS ET REGLAGES PERIODIQUES INSP PERIODISK INSPEKTION OCH JUSTERING CHASSIS CHASSIS CHAS CHASSI POWER TRAIN TRAIN DE ROULEMENT POWR DRIVENHET ENGINE MOTEUR MOTOR COOLING SYSTEM SYSTEME DE REFROIDISSEMENT COOL KYLSYSTEM CARBURETION… -

Page 10

CHAPTER 1. POWER TRAIN ……….2-16 GENERAL INFORMATION SHEAVE DISTANCE AND OFFSET ADJUSTMENT ……… 2-16 DRIVE V-BELT ……… 2-18 MACHINE IDENTIFICATION ……1-1 ENGAGEMENT SPEED CHECK ….. 2-20 FRAME SERIAL NUMBER ……1-1 PARKING BRAKE PAD INSPECTION ..2-20 ENGINE SERIAL NUMBER ……. 1-1 PARKING BRAKE ADJUSTMENT … -

Page 11

SKI …………..3-8 BRAKE MASTER CYLINDER VX700/VX700DX/VT700 ……3-8 ASSEMBLY ……….4-37 SX700/MM700 ……….3-9 INSTALLATION ……..4-37 INSPECTION ……….3-10 INSTALLATION SLIDE RAIL SUSPENSION ……4-38 (VX700/VX700DX/VT700) ……3-10 VX700/VX700DX/SX700 ……4-38 VT700 …………4-39 FRONT SUSPENSION ……..3-11 MM700 ………… -

Page 12

CHAPTER 6. HANDLEBAR SWITCH (RIGHT) ….8-7 CARBURETOR SWITCH ……8-8 COOLING SYSTEM MAIN SWITCH ……….. 8-8 LOAD CONTROL RELAY ……8-9 HEAT EXCHANGER ……..6-1 EMERGENCY ENGINE STARTING VX700/VX700DX/SX700/VT700 ….6-1 (VX700/SX700/MM700) ……8-9 MM700 …………6-2 INSPECTION ……….6-3 ELECTRICAL STARTING SYSTEM INSTALLATION ………. -

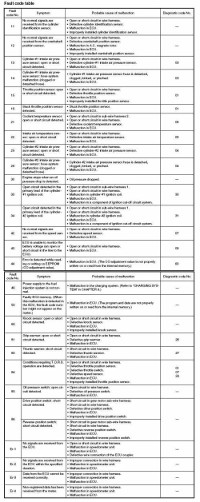

Page 13

PASSENGER GRIP WARMER RELAY (VT700) …………. 8-38 FAULT LOCATION TABLE ……8-39 CHAPTER 9. SPECIFICATIONS GENERAL SPECIFICATIONS ……9-1 MAINTENANCE SPECIFICATIONS ….9-4 ENGINE …………9-4 POWER TRAIN ………. 9-7 CHASSIS ……….9-11 ELECTRICAL ……….. 9-12 HIGH ALTITUDE SETTINGS ….9-14 TIGHTENING TORQUE …… -

Page 14

CHAPITRE 1. CONTROLE DU SYSTEME D’ARRET DU MOTEUR PRIORITAIRE (T.O.R.S.) ..2-14 RENSEIGNEMENTS GENERAUX REGLAGE DU JEU DU CABLE DE STARTER (CHOKE) … 2-15 NUMEROS D’IDENTIFICATION ….1-1 CONTROLE DU SYSTEME NUMERO DE SERIE DU CHASSIS ..1-1 D’ECHAPPEMENT ……… 2-15 NUMERO DE SERIE DU MOTEUR .. -

Page 15

REGLAGE …………. 2-40 CARTER DE CHAINE DE REGLAGE DES CARBURATEURS ..2-40 TRANSMISSION ………. 4-17 REGLAGE DE L’EMBRAYAGE…. 2-47 MODELES SANS MARCHE SELECTION DES PIGNONS ….2-52 ARRIERE ……….4-17 REGLAGE POUR HAUTE ALTITUDE .. 2-58 INSPECTION ……….. 4-18 SUSPENSION AVANT ……2-59 MONTAGE ………. -

Page 16

MOTEUR …………5-3 POMPE A CARBURANT ……7-10 INSPECTION ……….5-4 VX700/VX700DX/VT700 ……7-10 MONTAGE ……….5-4 SX700/MM700 ……… 7-11 INSPECTION ……….. 7-12 CULASSE ET CYLINDRES ……5-6 MONTAGE ……….7-12 DEPOSE …………. 5-8 CHAPITRE 8. INSPECTION ……….5-9 PARTIE ELECTRIQUE MONTAGE ………. -

Page 17

SYSTEME D’ECLAIRAGE ……8-19 PARTIE ELECTRIQUE ……9-12 SCHEMA DE CIRCUIT ……8-19 REGLAGE POUR HAUTE ALTITUDE . 9-14 GUIDE DE DEPANNAGE …… 8-20 COUPLE DE SERRAGE ……9-17 AMPOULE(S) ………. 8-22 CONTACTEUR DE FEU DE ROUTE ..8-22 SPECIFICATIONS GENERALES RELAIS DE PHARE …….. -

Page 18

KAPITEL 1. DRIVENHET ……….. 2-16 INSTÄLLNING AV SKIVAVSTÅND OCH ALLMÄN INFORMATION SIDOFÖRSKJUTNING ……2-16 DRIVREM ……….2-18 MASKINENS IDENTIFIERING ……1-1 KONTROLL AV RAMENS SERIENUMMER ……1-1 INKOPPLINGSHASTIGHETEN ….2-20 MOTORNS SERIENUMMER ….. 1-1 INSPEKTION AV PARKERINGSBROMSENS BROMSKLOTS ……… 2-20 VIKTIG INFORMATION …….. -

Page 19

KAPITEL 3. BROMS …………4-29 BYTE AV BROMKLOTSAR …… 4-30 CHASSI ISÄRTAGNING AV BROMSOK ….4-34 INSPEKTION OCH REPARATION AV STYRNING …………3-1 BROMSOKET ……….. 4-34 VX700/VX700DX/SX700/VT700 ….3-1 BROMSOK ……….4-35 MM700 …………3-2 MONTERING AV BROMSOK ….4-35 INSPEKTION ………. -

Page 20

REKYLSTARTARE ……..5-27 TÄNDSTIFT ……….8-6 DEMONTERING ……..5-28 TÄNDSTIFTSGAP ……..8-6 INSPEKTION ……….5-28 TÄNDSPOLE ……….8-6 INSTALLATION ……..5-29 GASLÅSNINGSSYSTEM (T.O.R.S.) ..8-7 STYRETS OMKOPPLARE (HÖGER) ..8-7 FÖRGASAROMKOPPLARE …… 8-8 KAPITEL 6. HUVUDOMKOPPLARE ……8-8 KYLSYSTEM DRIFTRELÄT ……….8-9 NÖDSTART AV MOTORN VÄRMEVÄXLARE ………. -

Page 21

VARIABELT MOTSTÅND (HANDTAGSVÄRMARE) ……8-36 PASSAGERARHANDTAGETS VÄRMARE (VT700) …………. 8-36 PASSAGERARHANDTAGETS VÄRMAROMKOPPLARE (VT700) … 8-37 MOTSTÅND (VT700) ……. 8-37 RELÄ FÖR PASSAGERARSÄTETS GREPPVÄRMARE (VT700) ….. 8-38 FELUNDERSÖKNINGSTABELL ….8-39 KAPITEL 9. SPECIFIKATIONER ALLMÄNNA SPECIFIKATIONER ….9-1 UNDERHÅLLSSPECIFIKATIONER ….9-4 MOTOR …………9-4 DRIVENHET ………. -

Page 22: General Information

MACHINE IDENTIFICATION INFO GENERAL INFORMATION MACHINE IDENTIFICATION FRAME SERIAL NUMBER The frame serial number is located on the right-hand side of the frame (just SCH1010 below the front of the seat). ENGINE SERIAL NUMBER The engine serial number is located on the right-hand side of the crankcase.

-

Page 23

NUMEROS D’IDENTIFICATION MASKINENS IDENTIFIERING INFO RENSEIGNEMENTS ALLMÄN INFORMATION GENERAUX MASKINENS IDENTIFIERING RAMENS SERIENUMMER NUMEROS D’IDENTIFICATION Chassits serienummer 1 är beläget på chassits NUMERO DE SERIE DU CHASSIS högra sida (strax nedanför sitsens framdel). Le numéro de série du châssis est estampé du côté MOTORNS SERIENUMMER droit de ce dernier, (juste sous l’avant du siège). -

Page 24: Important Information

SCH1070 ALL REPLACEMENT PARTS We recommend using genuine Yamaha parts for all replacements. Use oil and grease recommended by Yamaha for assembly and adjustments. SCH1080…

-

Page 25: Viktig Information

Vi rekommenderar användning av Yamaha original- d’origine pour tous les remplacements. Utiliser les delar för alla byten. Använd olja och fett som rekom- huiles recommandées par Yamaha lors des remonta- menderas av Yamaha vid hopsättning och justering. ges et réglages.

-

Page 26

IMPORTANT INFORMATION INFO GASKETS, OIL SEALS, AND O-RINGS 1. All gaskets, seals, and O-rings should be replaced when an engine is overhauled. All gasket surfaces, oil seal lips, and O-rings must be cleaned. 2. Properly oil all mating parts and bearings during reassembly. Apply grease to the oil seal lips. -

Page 27

INFORMATIONS IMPORTANTES VIKTIG INFORMATION INFO JOINTS, BAGUES D’ETANCHEITE ET PACKNINGAR, OLJEPACKNINGAR JOINTS TORIQUES OCH O-RINGAR 1. Lorsqu’un moteur est révisé, tous les joints, ba- 1. Alla packningar, oljepackningar och O-ringar skall gues d’étanchéité et joints toriques doivent être bytas när motorn repareras. Alla ytor för changés. -

Page 28: Special Tools

SPECIAL TOOLS INFO SPECIAL TOOLS Some special tools are necessary for a completely accurate tune-up and assembly. Using the correct special tool will help prevent damage that can be caused by the use of improper tools or improvised techniques. NOTE: Be sure to use the correct part number when ordering the tool, since the part number may differ according to country.

-

Page 29

OUTILS SPECIAUX SPECIALVERKTYG INFO OUTILS SPECIAUX SPECIALVERKTYG Les outils spéciaux convenables sont nécessaires pour Vissa specialverktyg är nödvändiga för fullkomlig jus- un assemblage et une mise au point complets et précis. tering och hopsättning. Användning av korrekt speci- L’utilisation des outils spéciaux convenables permet- alverktyg hjälper till att förhindra skada som kan upp- tra d’éviter les dommages dus à… -

Page 30

SPECIAL TOOLS INFO FOR ENGINE SERVICE • Piston pin puller P/N: YU-01304 (for U.S.A./Canada) 90890-01304 (for Europe) This tool is used to remove the piston pin. SCH1170 • Rotor holding puller P/N: YU-33270 (for U.S.A./Canada) 90890-01362 (for Europe) This tool is used to remove the magneto rotor. SCH1180 •… -

Page 31

OUTILS SPECIAUX SPECIALVERKTYG INFO POUR LA REPARATION DU MOTEUR FÖR MOTORSERVICE • • Extracteur d’axe de piston Kolvbultsavdragare P/N YU-01304 (E.-U. et Canada) P/N YU-01304 (för USA/Canada) 90890-01304 (Europe) 90890-01304 (för Europa) Cet outil est utilisé pour enlever les axes de piston. Detta verktyg används för att demontera kolvbulten. -

Page 32

SPECIAL TOOLS INFO • Clutch bushing press P/N: YS-42424 This tool is used for removing and installing the post bushings (primary sheave cap bush, sliding sheave bush and torque cam bush). SCH1250 • Track clip installer P/N: YS-91045-A (for U.S.A./Canada) 90890-01721 (for Europe) This tool is used for installing the track clip. -

Page 33

OUTILS SPECIAUX SPECIALVERKTYG INFO • • Poussoir de douille d’embrayage Kopplingsbussningspress P/N YS-42424 P/N YS-42424 Cet outil permet de déposer et de reposer les douilles Detta verktyg används för demontering och montering (poulies primaire et mobile, came de torsion). av postbussningarna (primärremskivans kåpbussning, glidremskivans bussning och vridmomentkammens bussning). -

Page 34

INSP INTRODUCTION/PERIODIC MAINTENANCE TABLE PERIODIC INSPECTION AND ADJUSTMENT INTRODUCTION This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine operation and a longer service life. In addition, the need for costly overhaul work will be greatly reduced. This information applies to machines already in service as well as new machines that are being prepared for sale. -

Page 35

INSP PERIODIC MAINTENANCE TABLE Every Initial Pre- 1 month Seasonally operation Item Remarks check 800 km 3,200 km (Daily) (500 mi) (2,000 mi) (40 hr) (160 hr) Check operation and fluid leakage. Brake and parking brake Adjust free play and/or replace pads if necessary. Replace brake fluid. -

Page 36

INSP INTRODUCTION/ENTRETIENS PERIODIQUES INSPECTIONS ET REGLAGES PERIODIQUES INTRODUCTION Ce chapitre traite de toutes les procédures nécessaires pour effectuer les inspections et réglages préconisés. Si l’on respecte ces procédures d’entretien préventif, on sera assuré d’un fonctionnement satisfaisant et d’une plus longue durée de service de la machine. La nécessité de révisions générales sera ainsi réduite dans une large mesure. -

Page 37

INSP ENTRETIENS PERIODIQUES Chaque Après le Vérifications premier mois Saison ou tous avant Désignation Remarques ou 800 km les 3.200 km utilisation (500 mi) (2.000 mi) (quotidiennes) (40 h) (160 h) Vérifier le fonctionnement et l’étanchéité. Frein et frein de stationne- Ajuster le jeu et/ou remplacer les plaquettes de ment frein si nécessaire. -

Page 38

INSP INLEDNING/TABELL FÖR PERIODISKT UNDERHÅLL PERIODISK INSPEKTION OCH JUSTERING INLEDNING Det här kapitlet innehåller all information som behövs för att utföra de rekommenderade inspektionerna och justeringarna. Dessa skyddande underhållsåtgärder, om de följs, kommer att tillförsäkra tillförlitligare maskin- funktion och ett längre brukbart liv hos maskinen. Behovet av dyra reparationsarbeten kommer dessutom att reduceras kraftigt. -

Page 39

INSP TABELL FÖR PERIODISKT UNDERHÅLL Första månaden eller Varje säsong Kontroll före första eller 3.200 km Detalj Anmärkningar användning 800 km (2.000 miles) (dagligen) (500 miles) (160 timmar) (40 timmar) Kontrollera funktionen och vätskeläckage. Justera spelrummet och/eller byt ut bromsklotsarna Broms/parkeringsbroms om nödvändigt. -

Page 40

INSP SPARK PLUGS ENGINE SPARK PLUGS 1. Remove: • Spark plug caps • Spark plugs 2. Inspect: • Electrodes 1 Damage/wear → Replace the spark plug. • Insulator color 2 SCH2010 3. Measure: • Spark plug gap a Out of specification → Regap. Use a wire thickness gauge. -

Page 41

BOUGIES INSP TÄNDSTIFT MOTEUR MOTOR BOUGIES TÄNDSTIFTET 1. Déposer: 1. Demontera: • • Capuchons de bougie Tändstiftshattar • • Bougies Tändstiftet 2. Inspecter: 2. Inspektera: • • Electrodes Elektroderna 1 Usure/endommagement → Remplacer. Skada/slitage → Byt tändstiften. • • Teinte de la porcelaine Isolatorns färg 2 3. -

Page 42

INSP OIL PUMP OIL PUMP Air bleeding CAUTION: The oil pump and oil delivery line must be bled in the following cases: • Any portion of the oil system has been disconnected. • The machine has been turned on its side. •… -

Page 43

POMPE A HUILE INSP OLJEPUMP POMPE A HUILE OLJEPUMP Purge Avluftning ATTENTION: VIKTIGT: Purger la pompe à huile et les conduits d’huile Oljepumpen och oljetilloppsledningen måste quand: avluftas i följande fall: • • une partie quelconque du circuit d’huile a été När någon del av oljesystemet har kopplats ur. -

Page 44

INSP OIL PUMP 14. Install: • Gasket (bleed bolt) • Bleed bolt 15. Install: • Rear bracket (right) M8 mounting bolt (rear): 33 Nm (3.3 m · kg, 24 ft · lb) M10 mounting bolt (rear): 57 Nm (5.7 m · kg, 41 ft · lb) 16. -

Page 45

POMPE A HUILE INSP OLJEPUMP 14. Installer: 14. Installera: • • Joint (boulon de purge) Packningen (avluftningsskruv) • • Boulon de purge Avluftningsskruven 15.Installer: 15. Installera: • • Support arrière (droit) Bakre fästet (höger) M8 boulon de fixation (arrière): M8 fästbult (bak): 33 Nm (3,3 m ·… -

Page 46

INSP FUEL LINE INSPECTION/COOLING SYSTEM FUEL LINE INSPECTION 1. Remove: • Intake silencer Refer to “FUEL PUMP” in CHAPTER 7. 2. Inspect: • Fuel hose 1 • Fuel delivery hoses 2 Cracks/damage → Replace. 3. Install: SCH2090 • Intake silencer Refer to “FUEL PUMP”… -

Page 47

VERIFICATION DES CONDUITS DE CARBURANT/SYSTEME DE REFROIDISSEMENT INSP INSPEKTION AV BRÄNSLELEDNING/KYLSYSTEM VERIFICATION DES CONDUITS DE INSPEKTION AV BRÄNSLELEDNING CARBURANT 1. Demontera: • 1. Déposer: Insugningsljuddämpare • Silencieux d’admission Vi hänvisar till “BRÄNSLEPUMP” i kapitel 7. Se reporter à “POMPE A CARBURANT” au 2. -

Page 48

INSP COOLING SYSTEM 4. Remove: • Coolant filler cap 1 WARNING Do not remove the coolant filler cap 1 when the engine is hot. Pressurized scalding hot fluid and steam may be blown out, which could cause serious injury. When the engine has cooled, place a thick rag or a towel over the coolant filler cap. -

Page 49

SYSTEME DE REFROIDISSEMENT INSP KYLSYSTEM 4. Déposer: 4. Demontera: • • Bouchon de l’orifice de remplissage du liquide Kylmedlets påfyllningslock 1 de refroidissement VARNING AVERTISSEMENT Tag inte av kylmedlets påfyllningslock 1 när Ne jamais enlever le bouchon de remplissage de motorn är het. -

Page 50

INSP COOLING SYSTEM 9. Disconnect: • Coolant hoses 1 Å VX700/VX700DX/SX700/VT700 ı MM700 10. Drain the coolant. NOTE: Lift up the front of the machine to drain the coolant completely. SCH2150 WARNING Coolant is poisonous. It is harmful or fatal if swallowed. -

Page 51

SYSTEME DE REFROIDISSEMENT INSP KYLSYSTEM 9. Déconnecter: 9. Koppla ur: • • Flexibles de liquide de refroidissement Kylmedelsslangarna 1 Å VX700/VX700DX/SX700/VT700 Å VX700/VX700DX/SX700/VT700 ı MM700 ı MM700 10. Vidanger le liquide de refroidissement. 10.Tappa ur kylmedlet. OBS: N.B.: Soulever l’avant de la motoneige pour vidanger com- Lyft upp maskinens framdel för att tappa ur kylmedlet plètement. -

Page 52

INSP COOLING SYSTEM 18. Inspect: • Gasket (coolant drain bolt) Damage → Replace. 19. Install: • Gasket • Coolant drain bolt 1 Coolant drain bolt 1: 13 Nm (1.3 m · kg, 9.4 ft · lb) SCH2130 20. Install: • Exhaust joint •… -

Page 53

SYSTEME DE REFROIDISSEMENT INSP KYLSYSTEM 18. Inspecter: 18. Inspektera: • • Joint (boulon de vidange) Packning (kylmedlets urtappningsbult) Endommagement → Remplacer. Skada → Byt. 19. Installer: 19. Installera: • • Joint Packning • • Kylmedlets urtappningsbult 1 Boulon de vidange Kylmedlets urtappningsbult 1: Boulon de vidange 13 Nm (1,3 m ·… -

Page 54

INSP COOLING SYSTEM 22. Bleed the air from the cooling system. 23. Inspect: • Cooling system Decrease of pressure (leaks) → Repair as required. Inspection steps: • Attach the cooling system tester 1 to the coolant filler 2. Cooling system tester: 90890-01325, YU-24460-01 •… -

Page 55

SYSTEME DE REFROIDISSEMENT INSP KYLSYSTEM 22. Purger d’air le système de refroidissement. 22. Avlufta kylsystemet. 23. Inspecter: 23. Inspektera: • • Système de refroidissement Kylsystemet Perte de pression (fuites) → Réparer. Minskning i trycket (läckage) → Reparera efter behov. Marche à suivre: Inspektionsåtgärder: •… -

Page 56

INSP COOLING SYSTEM Air bleeding steps: • Lift up the tail of the machine. • Remove the bleed bolt 1 on the heat exchanger. • While slowly adding coolant to the coolant filler, drain the coolant until no more air bubbles ap- pear. -

Page 57

SYSTEME DE REFROIDISSEMENT INSP KYLSYSTEM Marche à suivre: Avluftningsåtgärder: • • Soulever l’arrière de la machine. Lyft upp maskinens baksida. • • Retirer le boulon de purge de l’échangeur de Tag ut avluftningsbulten 1 på värmeväxlaren. • chaleur. Fyll sakta på kylmedel i kylartanken och tillåt •… -

Page 58

COOLING SYSTEM/ INSP CARBURETOR SYNCHRONIZATION • Remove the coolant filler cap and bleed the cooling system again, as described above. No air bubbles → OK. • Add coolant to the specified level. • Pour coolant into the coolant reservoir 3 until the coolant level reaches the “FULL”… -

Page 59

INSP SYSTEME DE REFROIDISSEMENT/SYNCHRONISATION DES CARBURATEURS KYLSYSTEM/SYNKRONISERING AV FÖRGASARE • • Démonter le bouchon de remplissage de liquide Tag av kylmedlets påfyllningslock och avlufta de refroidissement et purger à nouveau le sys- kylsystemet igen, på det sätt som visas i åtgär- tème de refroidissement en suivant les étapes derna ovan. -

Page 60

ENGINE IDLE SPEED ADJUSTMENT/ INSP THROTTLE CABLE FREE PLAY ADJUSTMENT ENGINE IDLE SPEED ADJUSTMENT 1. Adjust: • Engine idle speed Adjustment steps: • Start the engine and let it warm up. • Turn the throttle stop screw 1 in or out until the specified engine idle speed is obtained. -

Page 61

INSP REGLAGE DU REGIME DE RALENTI/REGLAGE DU JEU DE CABLE D’ACCELERATION JUSTERING AV MOTORNS TOMGÅNGSHASTIGHET/JUSTERING AV GASVAJERN REGLAGE DU REGIME DE RALENTI JUSTERING AV MOTORNS 1. Régler: TOMGÅNGSHASTIGHET • Régime de ralenti 1. Justera: • Motorns tomgångshastighet Marche à suivre: •… -

Page 62

THROTTLE CABLE FREE PLAY ADJUSTMENT/ INSP THROTTLE OVERRIDE SYSTEM (T.O.R.S.) CHECK 2. Adjust: • Throttle cable free play Adjustment steps: • Loosen the locknut 1. • Turn the adjusting nut 2 in or out until the specified free play is obtained. Turning in →… -

Page 63

INSP REGLAGE DU JEU DE CABLE D’ACCELERATION/CONTROLE DU SYSTEME D’ARRET DU MOTEUR PRIORITAIRE (T.O.R.S.) JUSTERING AV GASVAJERN/KONTROLL AV GASLÅSNINGSSYSTEMET (T.O.R.S.) 2. Régler: 2. Justera: • • Jeu de câble d’accélération Gasvajerns spelrum Marche à suivre: Justeringsåtgärder: • • Desserrer le contre-écrou Lossa på… -

Page 64

STARTER (CHOKE) CABLE FREE PLAY ADJUSTMENT/ INSP EXHAUST SYSTEM INSPECTION STARTER (CHOKE) CABLE FREE PLAY ADJUSTMENT 1. Measure: • Starter cable free play a Out of specification → Adjust. Starter cable free play a: 0.5 ~ 1.5 mm (0.02 ~ 0.06 in) SCH2340 2. -

Page 65

INSP REGLAGE DU JEU DU CABLE DE STARTER (CHOKE)/CONTROLE DU SYSTEME D’ECHAPPEMENT JUSTERING AV STARTKABELNS (CHOKENS) SPELRUM/INSPEKTION AV AVGASSYSTEMET REGLAGE DU JEU DU CABLE DE JUSTERING AV STARTKABELNS STARTER (CHOKE) (CHOKENS) SPELRUM 1. Mesurer: 1. Mät: • • Jeu du câble de starter Chokevajerns spelrum a Hors spécifications →… -

Page 66

INSP SHEAVE DISTANCE AND OFFSET ADJUSTMENT POWER TRAIN SHEAVE DISTANCE AND OFFSET ADJUSTMENT 1. Open the shroud. 2. Remove: • Drive V-belt guard • Drive V-belt 3. Measure: • Sheave distance a Use the distance gauge. Out of specification → Adjust. Sheave distance a: 267 ~ 270 mm (10.52 ~ 10.62 in) Distance gauge:… -

Page 67

ECARTEMENT DES POULIES ET REGLAGE DU DECALAGE INSP INSTÄLLNING AV SKIVAVSTÅND OCH SIDOFÖRSKJUTNING TRAIN DU ROULEMENT DRIVENHET ECARTEMENT DES POULIES ET INSTÄLLNING AV SKIVAVSTÅND OCH REGLAGE DU DECALAGE SIDOFÖRSKJUTNING 1. Ouvrir le capot. 1. Öppna motorhuven. 2. Déposer: 2. Demontera: •… -

Page 68

INSP SHEAVE DISTANCE AND OFFSET ADJUSTMENT 6. Measure: • Secondary sheave free play (clearance) a Use a thickness gauge. Out of specification → Adjust. Secondary sheave free play (clearance) a: 1.0 ~ 2.0 mm (0.04 ~ 0.08 in) SCH2400 7. Adjust: •… -

Page 69

ECARTEMENT DES POULIES ET REGLAGE DU DECALAGE INSP INSTÄLLNING AV SKIVAVSTÅND OCH SIDOFÖRSKJUTNING 6. Mät: 6. Mesurer: • • Sekundärskivans frigång (rörelsemarginal) a Jeu de la poulie secondaire (écartement) Använd ett tjockleksmätare. Utiliser une jauge d’épaisseur. Motsvarar ej specifikation → Justera. →… -

Page 70

INSP DRIVE V-BELT DRIVE V-BELT WARNING When installing the new V-belt, make sure that it is positioned from 1.5 mm (0.06 in) above the edge of the secondary sheave to –0.5 mm (–0.02 in) below the edge a. If the V-belt is not positioned correctly, the clutch engagement speed will be changed. -

Page 71

COURROIE TRAPEZOIDALE INSP DRIVREM COURROIE TRAPEZOIDALE DRIVREM AVERTISSEMENT VARNING Veiller à placer la nouvelle courroie trapézoïdale Var vid montering av en ny kilrem noga med att de 1,5 mm (0,06 in) au-dessus à –0,5 mm (–0,02 in) remmen placeras mellan 1,5 mm (0,06 in) ovanför en dessous du bord de la poulie secondaire. -

Page 72

INSP DRIVE V-BELT 2. Adjust the position of the V-belt by removing or adding a spacer 1 on each adjusting bolt 2. V-belt position Adjustment More than 1.5 mm (0.06 in) above the Remove a spacer edge From 1.5 mm (0.06 in) above the edge to Not necessary –0.5 mm (–0.02 in) -

Page 73

COURROIE TRAPEZOIDALE INSP DRIVREM 2. Ajuster la position de la courroie trapézoïdale en 2. Justera kilremmens läge genom att ta bort eller ajoutant ou en retirant une entretoise au niveau lägga till ett mellanlägg 1 på var och en av de chacun des boulons de réglage justeringsbultarna 2. -

Page 74

ENGAGEMENT SPEED CHECK/PARKING BRAKE PAD INSP INSPECTION/PARKING BRAKE ADJUSTMENT ENGAGEMENT SPEED CHECK 1. Place the machine on a level surface of hard- packed snow. 2. Check: • Clutch engagement speed Checking steps: • Start the engine, and open the throttle lever gradually. -

Page 75

VERIFICATION DU REGIME D’EMBRAYAGE/CONTROLE DES PLAQUETTES DE FREIN DE STATIONNEMENT/REGLAGE DU FREIN DE INSP STATIONNEMENT KONTROLL AV INKOPPLINGSHASTIGHETEN/INSPEKTION AV PARKERINGSBROMSENS BROMSKLOTS/JUSTERING AV PARKERINGSBROMSEN VERIFICATION DU REGIME KONTROLL AV D’EMBRAYAGE INKOPPLINGSHASTIGHETEN 1. Placer la motoneige sur une surface plane de 1. Placera maskinen på en plan yta av hårt packad neige dure. -

Page 76

BRAKE LEVER ADJUSTMENT (VX700DX/SX700/VT700)/ INSP BRAKE FLUID LEVEL INSPECTION BRAKE LEVER ADJUSTMENT (VX700DX/SX700/VT700) 1. Adjust: • Brake lever position (distance from the grip to the brake lever) Adjustment steps: • Loosen the locknut 1. • While lightly pushing the brake lever in direction a, turn the adjusting bolt 2 by fingers to set the brake SCH2510 lever to the desired position. -

Page 77

REGLAGE DU LEVIER DE FREIN AVANT (VX700DX/SX700/VT700)/ INSP CONTROLE DU NIVEAU DE LIQUIDE DE FREIN JUSTERING AV HANDBROMS (VX700DX/SX700/VT700)/INSPEKTION AV BROMSVÄTSKANS NIVÅ REGLAGE DU LEVIER DE FREIN AVANT JUSTERING AV HANDBROMS (VX700DX/SX700/VT700) (VX700DX/SX700/VT700) 1. Régler: 1. Justera: • • Position du levier de frein Bromsspakens läge (distance entre la manette des gaz et le levier de (avståndet från gashandtaget till bromsspaken) -

Page 78

BRAKE PAD INSPECTION/BRAKE HOSE INSPECTION INSP AIR BLEEDING (HYDRAULIC BRAKE SYSTEM) BRAKE PAD INSPECTION 1. Apply the brake lever. 2. Inspect: • Brake pad Wear indicator 1 nearly contacts the brake disc → Replace as a set. Wear limit a: 4.7 mm (0.19 in) SCH2530 BRAKE HOSE INSPECTION… -

Page 79

CONTROLE DES PLAQUETTES DE FREIN/CONTROLE DE FLEXIBLE DE FREIN/ INSP PURGE D’AIR (CIRCUIT DE FREINAGE HYDRAULIQUE) INSPEKTION AV BROMSKLOTSARNA/INSPEKTION AV BROMSSLANGEN/AVLUFTNING (HYDRAULISKT BROMSSYSTEM) CONTROLE DES PLAQUETTES DE FREIN INSPEKTION AV BROMSKLOTSARNA 1. Actionner le levier de frein. 1. Drag till bromsspaken. 2. -

Page 80

AIR BLEEDING (HYDRAULIC BRAKE SYSTEM)/ INSP DRIVE CHAIN d. Tighten the bleed screws when the brake lever limit has been reached, then release the lever. • Repeat steps (a) to (d) until all of the air bubbles have disappeared from the fluid. •… -

Page 81

PURGE D’AIR (CIRCUIT DE FREINAGE HYDRAULIQUE)/ INSP CHAINE DE TRANSMISSION AVLUFTNING (HYDRAULISKT BROMSSYSTEM)/DRIVKEDJAN d. Serrer les vis de purge quand le levier a atteint d. Drag fast avluftningsskruvarna när bromsspak- la limite de sa course, puis relâcher le levier. ens gräns har nåtts och släpp sedan spaken. •… -

Page 82

INSP DRIVE CHAIN CAUTION: There is a magnet attached to the end of the dipstick. It is used to remove any metal particles that may accumulate in the drive chain housing. Be sure to: • Pull the dipstick out slowly and gently so the metal particles do not fall off the magnet back into the drive chain housing. -

Page 83

CHAINE DE TRANSMISSION INSP DRIVKEDJAN VIKTIGT: ATTENTION: L’extrémité de la jauge est munie d’un aimant. Det sitter en magnet i änden på oljestickan. Den är till för att avlägsna eventuella metallpartiklar Celui-ci permet d’éliminer toutes les particules métalliques qui pourraient s’accumuler dans le som samlats i drivkedjehuset. -

Page 84

INSP DRIVE CHAIN Oil replacement Oil replacement steps: • Place the oil pan under the drain hole. • Remove the oil drain bolt 1 and drain the oil. CAUTION: Be sure to remove any oil from the heat protec- tor. SCH2590 •… -

Page 85

CHAINE DE TRANSMISSION INSP DRIVKEDJAN Changement d’huile Oljebyte Åtgärder för oljebyte: Marche à suivre: • • Placera ett oljetråg under urtappningshålet. Placer un bac à vidange sous l’orifice de vi- • Tag ur oljeurtappningsbulten 1 och tappa ur dange. • oljan. -

Page 86

DRIVE CHAIN/ INSP TRACK TENSION ADJUSTMENT 3. Install: • Battery bracket (VX700DX/VT700) • Battery (VX700DX/VT700) CAUTION: • Connect the positive lead to the battery termi- nal first. • Make sure the battery leads are connected properly. Reversing the leads can seriously damage the electrical system. -

Page 87

CHAINE DE TRANSMISSION/REGLAGE DE LA TENSION DE LA CHENILLE INSP DRIVKEDJAN/JUSTERING AV BANDSPÄNNINGEN 3. Installer: 3. Installera: • • Support de batterie (VX700DX/VT700) Batterifäste (VX700DX/VT700) • • Batterie (VX700DX/VT700) Batteriet (VX700DX/VT700) ATTENTION: VIKTIGT: • • Connecter d’abord le câble positif à la borne de Anslut pluskabeln till batteripolen först. -

Page 88: Track Tension Adjustment

INSP TRACK TENSION ADJUSTMENT 3. Adjust: • Track deflection Adjustment steps: • Place the machine onto a suitable stand to raise the track off of the ground. • Loosen the rear axle nut 1. NOTE: It is not necessary to remove the cotter pin 2. SCH2630 a.

-

Page 89

REGLAGE DE LA TENSION DE LA CHENILLE INSP JUSTERING AV BANDSPÄNNINGEN 3. Régler: 3. Justera: • • Flèche de la chenille Bandets avböjning Marche à suivre: Justeringsåtgärder: • • Placer la motoneige sur un support adéquat, de Placera maskinen på att lämpligt stag så att façon à… -

Page 90

INSP SLIDE RUNNER INSPECTION SLIDE RUNNER INSPECTION 1. Inspect: • Slide runner 1 Cracks/damage/wear → Replace. 2. Measure: • Slide runner thickness a Out of specification → Replace. Slide runner wear limit a: SCH2680 10 mm (0.39 in) 2-28… -

Page 91

VERIFICATION DES PATINS INSP INSPEKTION AV GLIDSKENAN VERIFICATION DES PATINS INSPEKTION AV GLIDSKENAN 1. Inspecter: 1. Inspektera: • • Patin Glidskenan 1 → Sprickor/skada/slitage → Byt. Craquelures/endommagement/usure Rem- placer. 2. Mät: • 2. Mesurer: Glidskenans tjocklek a • Motsvarar ej specifikation → Byt. Epaisseur de patin →… -

Page 92

Studs may catch on an object and pull out of the track, leaving tears and damage around the already weakened area. To minimize possible damage, consult your stud manu- facturer for installation and stud pattern recommen- dations. Yamaha does not recommend track studding. 2-29… -

Page 93

à la mönster. mise en place et l’emplacement correctes des clous. Yamaha rekommenderar inte dubbning av band. Yamaha ne recommande pas l’utilisation de clous. 2-29… -

Page 94

INSP SKI/SKI RUNNER CHASSIS SKI/SKI RUNNER 1. Inspect: • • Ski runner Damage/wear → Replace. SCH2690 Ski runner wear limit a: 8 mm (0.31 in) Plastic ski wear limit b: VX700/VX700DX/VT700: 13 mm (0.51 in) SX700/MM700: 8 mm (0.31 in) SCH2695 CAUTION: To avoid scratching, wearing and damaging the… -

Page 95

SKIS/LONGERONS DE SKI INSP SKIDAN/SKIDSKENAN CHASSIS CHASSI SKIS/LONGERONS DE SKI SKIDAN/SKIDSKENAN 1. Inspecter: 1. Inspektera: • • Skis Skidan • • Longerons de ski Skidskenan → Skada/slitage → Byt. Usure/endommagement Remplacer. Skidskenans slitagegräns a: Limite d’usure du longeron de ski 8 mm (0,31 in) 8 mm (0,31 in) Plastskidans slitagegräns b:… -

Page 96

INSP STEERING SYSTEM STEERING SYSTEM Free play check 1. Check: • Steering system free play Move the handlebar up and down and back and forth. Turn the handlebar slightly to the right and left. Excessive free play → Check that the handle- bar, tie rod ends and relay rod ends are in- SCH2710 stalled securely in position. -

Page 97

DIRECTION INSP STYRSYSTEMET DIRECTION STYRSYSTEMET Inspection du jeu Kontroll av spelrum 1. Vérifier: 1. Kontrollera: • • Jeu du système de direction Styrsystemets spelrum Pousser le guidon en avant, en arrière et vers För styret uppåt och nedåt och fram och till- le haut et le bas. -

Page 98

INSP STEERING SYSTEM/LUBRICATION 3. Adjust: • Ski toe-out Adjustment steps: • Loosen the locknuts (tie-rod) 1. • Turn the tie rods 2 in or out until the specified toe- out is obtained. • Tighten the locknuts (tie-rod) 1. SCH2720 Locknut (rod end) 1: 25 Nm (2.5 m ·… -

Page 99

DIRECTION/GRAISSAGE INSP STYRSYSTEMET/SMÖRJNING 3. Régler: 3. Justera: • • Ouverture des skis Skidornas skränkning Marche à suivre: Justeringsåtgärder: • • Desserrer les contre-écrous (barre d’accouple- Lossa på låsmuttrarna (parallellstag) 1. • ment) Vrid parallellstagen 2 inåt eller utåt tills specifice- •… -

Page 100

INSP LUBRICATION Relay arm (steering) 1. Use a grease gun to inject grease into the nipples 1. Recommended lubricant: ESSO Beacon 325 Grease or Aeroshell Grease #7A SCH2740 Front and rear suspension 1. Use a grease gun to inject grease into the nipples 1. -

Page 101

GRAISSAGE INSP SMÖRJNING Bras relais (direction) Reläarm (styrning) 1. Injecter de la graisse à travers les graisseurs à 1. Använd en fettpistol för att spruta in fett i nipplarna l’aide d’un pistolet graisseur. Lubrifiant recommandé: Rekommenderat smörjmedel: Graisse ESSO Beacon 325 ou ESSO:s Fett Beacon 325 eller Aeroshell n°7A Aeroshell Fett #7A… -

Page 102

INSP HEADLIGHT BEAM ADJUSTMENT ELECTRICAL HEADLIGHT BEAM ADJUSTMENT 1. Place the machine on a level surface. 2. Place the machine in front of a wall at the recom- mended distance D. Refer to the table below. 3. Measure the distance H from the floor to the center of the headlight and place a mark on the SCH2765 wall at that height. -

Page 103

REGLAGE DU FAISCEAU DU PHARE INSP JUSTERING AV STRÅLKASTAREN PARTIE ELECTRIQUE ELEKTRISKT REGLAGE DU FAISCEAU DU PHARE JUSTERING AV STRÅLKASTAREN 1. Placer la machine sur une surface plane. 1. Placera maskinen på en plan yta. 2. Placer le véhicule face à un mur à la distance 2. -

Page 104

INSP BATTERY INSPECTION (VX700DX/VT700) BATTERY INSPECTION (VX700DX/VT700) WARNING Battery fluid is poisonous and dangerous, causes severe burns, etc. Contains sulfuric acid. Avoid contact with skin, eyes or clothing. Antidote: EXTERNAL – Flush with water. INTERNAL – Drink large quantities of water or milk. -

Page 105

INSPECTION DE LA BATTERIE (VX700DX/VT700) INSP INSPEKTION AV BATTERI (VX700DX/VT700) INSPECTION DE LA BATTERIE INSPEKTION AV BATTERI (VX700DX/VT700) (VX700DX/VT700) VARNING AVERTISSEMENT Batterivätska är giftigt och farligt och kan orsaka L’électrolyte de batterie est extrêmement toxique svåra brännskador m.m. Vätskan innehåller sva- et peut causer de graves brûlures. -

Page 106

INSP BATTERY INSPECTION (VX700DX/VT700) Replace the battery if: • Battery voltage will not rise to a specific value or bubbles fail to rise even after many hours of charging. • Sulfation of one or more cells occurs, as indicated by the plates turning white, or an accumulation of material exists in the bottom of the cell. -

Page 107

INSPECTION DE LA BATTERIE (VX700DX/VT700) INSP INSPEKTION AV BATTERI (VX700DX/VT700) Remplacer la batterie dans les cas suivants: Byt ut batteriet i följande fall: • • Après plusieurs heures de charge, la tension de Om batterispänningen inte vill stiga till specifice- la batterie n’atteint pas la valeur spécifiée ou il rat värde eller om bubblorna inte stiger ens efter ne se dégage pas de bulles de gaz. -

Page 108

INSP BATTERY CHARGING (VX700DX/VT700) BATTERY CHARGING (VX700DX/VT700) The battery must be charged properly before using for the first time. This initial charge will prolong the life of the battery. 1. Remove: • Battery WARNING When removing the battery, disconnect the nega- tive lead first. -

Page 109

CHARGE DE LA BATTERIE (VX700DX/VT700) INSP LADDNING AV BATTERI (VX700DX/VT700) CHARGE DE LA BATTERIE LADDNING AV BATTERI (VX700DX/VT700) (VX700DX/VT700) Batteriet måsta laddas upp på korrekt sätt innan det Il convient de charger correctement une nouvelle tas i bruk för första gången. Denna inledande ladd- batterie avant sa première utilisation. -

Page 110

BATTERY CHARGING (VX700DX/VT700)/ INSP FUSE INSPECTION (VX700DX/VT700) 2. Install: • Battery CAUTION: • Connect the positive lead to the battery termi- nal first. • Make sure the battery leads are connected properly. Reversing the leads can seriously damage the electrical system. •… -

Page 111

CHARGE DE LA BATTERIE (VX700DX/VT700)/ INSP VERIFICATION DES FUSIBLES (VX700DX/VT700) LADDNING AV BATTERI (VX700DX/VT700)/INSPEKTION AV SÄKRINGAR (VX700DX/VT700) 2. Installer: 2. Installera: • • Batterie Batteriet VIKTIGT: ATTENTION: • • Connecter d’abord le câble positif à la borne de Anslut pluskabeln till batteripolen först. •… -

Page 112

INSP FUSE INSPECTION (VX700DX/VT700) 2. Replace: • Blown fuse Replacing steps: • Set the main switch to “OFF”. • Install a new fuse of the correct amperage. • Set the main switch to “ON” and verify if the electrical circuit is operational. •… -

Page 113

VERIFICATION DES FUSIBLES (VX700DX/VT700) INSP INSPEKTION AV SÄKRINGAR (VX700DX/VT700) 2. Remplacer: 2. Byt: • • Säkring som har gått Fusible grillé Etapes du remplacement: Åtgärder vid byte: • • Ställ huvudomkopplaren i läget “OFF”. Placer le contacteur à clé sur “OFF”. •… -

Page 114

INSP CARBURETOR TUNING TUNING CARBURETOR TUNING The carburetors are set at the factory to run at temperatures of 0°C ~ –20°C (32°F ~ –4°F) at sea level. If the machine is to be operated under conditions other than those specified above, the carburetors must be properly adjusted. -

Page 115

REGLAGE DES CARBURATEURS INSP INSTÄLLNING AV FÖRGASARE REGLAGE INSTÄLLNING REGLAGE DES CARBURATEURS INSTÄLLNING AV FÖRGASARE Les carburateurs ont été réglés à l’usine pour fonc- Förgasarna är fabriksinställda för att användas vid en tionner à des températures allant de 0°C ~ –20°C temperatur på… -

Page 116

Use the chart in CHAPTER 9 to select main jets according to variations in elevation and temperature. NOTE: These jetting specifications are subject to change. Consult the latest technical information from Yamaha to be sure you have the most up-to-date jetting specifications. Clip… -

Page 117

OBS: données figurant au CHAPITRE 9. Dessa munstycksspecifikationer kan ändras. Slå upp den senaste tekniska informationen från Yamaha för N.B.: Ces spécifications sont sujettes à modification. Con- att se till att Du har de allra nyaste munstycks- sulter la documentation technique Yamaha pour être… -

Page 118

INSP CARBURETOR TUNING Guide for carburetion SCH2815 2-42… -

Page 119

REGLAGE DES CARBURATEURS INSP INSTÄLLNING AV FÖRGASARE Guide pour la carburation Förgasningsguide Å Å Ouverture du papillon d’accélération Gasspällets öppning ı Réglage de moyen régime ı Inställning för medelhastighet Ç Réglage de haut régime Ç Inställning för hög hastighet Î Î… -

Page 120

INSP CARBURETOR TUNING Standard main jet Main jet whose diameter is 10% smaller than standard Main jet whose diameter is 10% larger than standard SCH2820 position position position SCH2825 CAUTION: If the air silencer box is removed from the carbu- retors, the change in pressure in the intake will create a lean mixture that may cause severe engine damage. -

Page 121

REGLAGE DES CARBURATEURS INSP INSTÄLLNING AV FÖRGASARE Å Débit du gicleur principal (1/hr) Å Huvudmunstyckets bränsleflöde (1/timmen) ı Ouverture du papillon d’accélération ı Gasspällets öppning Ç Ouvert à fond Ç Helt öppet A Gicleur standard Standard huvudmunstycke B Gicleur dont le diamètre est inférieur de 10% au Huvudmunstycke vars diameter är 10% mindre än diamètre standard standard… -

Page 122

INSP CARBURETOR TUNING Low-speed tuning The carburetors are built so that low speed tuning can be done by adjusting the pilot mixture screw 2 and throttle stop screw 1. CAUTION: Never run the engine without the air intake si- lencer installed. Severe engine damage may re- sult. -

Page 123

REGLAGE DES CARBURATEURS INSP INSTÄLLNING AV FÖRGASARE Réglage de bas régime Inställning för låg hastighet La mise au point des carburateurs pour la marche à Förgasarna är byggda så att inställningen för låg bas régime s’effectue au moyen de la vis de mélange hastighet kan göras genom att justera tomgångs- de ralenti et de la vis de butée de papillon… -

Page 124

INSP CARBURETOR TUNING Main jet selection chart Spark plug color Diagnosis Remedy Light tan or gray Carburetors are tuned properly. Dry black or fluffy Mixture is too rich. Replace the main jet with the next smaller size. deposits White or light gray Mixture is too lean. -

Page 125

INSP CARBURETOR TUNING Trouble Diagnosis Adjustment • Remove the pilot jet, clean it with compressed air, and Poor performance at Clogged or loose pilot jet mid-range speeds: then install it. • Momentary slow re- • Make sure that the pilot jet is fully tightened. sponse to the throttle •… -

Page 126

INSP REGLAGE DES CARBURATEURS Tableau de sélection de gicleur principal Couleur de bougie Diagnostic Remède Jaune foncé ou gris Carburateurs bien réglés Dépôts noirs secs ou Mélange trop riche Remplacer le gicleur principal par un d’une taille pelucheux plus petite. Blanc ou gris clair Mélange trop pauvre Remplacer le gicleur principal par un d’une taille… -

Page 127

INSP REGLAGE DES CARBURATEURS Problème Diagnostic Réglage • Mauvais rendement à Gicleur de ralenti bouché Retirer le gicleur de ralenti, le nettoyer à l’air com- moyen régime: ou desserré primé, puis le remettre en place. • • Réponse lente aux Veiller à… -

Page 128

INSP INSTÄLLNING AV FÖRGASARE Tabell för val av huvudmunstycke Tändstiftsfärg Diagnos Åtgärd Ljus brunt eller grått Förgasaren är rätt inställd. Torra svarta eller fjuniga Blandningen är för rik. Byt ut huvudmunstycket mot ett som har ett nummer avlagringar lägre. Vitt eller ljus grått Blandningen är för mager. -

Page 129

INSP INSTÄLLNING AV FÖRGASARE Diagnos Justering • Dålig prestanda vid Tilltäppt eller löst sittande Demontera tomgångsmunstycket, rengör det med tryck- medelhastigheter: tomgångsmunstycke luft och installera det. • • Tillfälligt dålig reaktion Se till att tomgångsmunstycket dras fast ordentligt. vid gasning •… -

Page 130

INSP CLUTCH CLUTCH G Green Silver High altitude Pink W White R Red Specifications Model: VX700 ~ 1,000 m 900 ~ 1,500 m 1,400 ~ 2,100 m 2,000 ~ 3,000 m Å Elevation (~ 3,500 ft) (3,000 ~ 5,000 ft) (4,500 ~ 7,000 ft) (6,500 ~ 10,000 ft) 1,600 ±… -

Page 131

REGLAGE DE L’EMBRAYAGE INSP KOPPLING REGLAGE DE L’EMBRAYAGE KOPPLING Haute altitude På hög höjd Caractéristiques Specifikationer Modèle: VX700 Modell: VX700 Å Altitude Å Höjd över havet ı Régime de ralenti ı Motorns tomgångsvarvtal Ç Régime d’embrayage (tr/mn) Ç Inkopplingsvarvtal (varv/min) Î… -

Page 132

INSP CLUTCH G Green R Red O Orange Silver Pink W White Specifications Model: VX700DX ~ 1,000 m 900 ~ 1,500 m 1,400 ~ 2,100 m 2,000 ~ 3,000 m Å Elevation (~ 3,500 ft) (3,000 ~ 5,000 ft) (4,500 ~ 7,000 ft) (6,500 ~ 10,000 ft) 1,600 ±… -

Page 133

REGLAGE DE L’EMBRAYAGE INSP KOPPLING Caractéristiques Specifikationer Modèle: VX700DX Modell: VX700DX Å Altitude Å Höjd över havet ı Régime de ralenti ı Motorns tomgångsvarvtal Ç Régime d’embrayage (tr/mn) Ç Inkopplingsvarvtal (varv/min) Î Régime de variation de rapport (tr/mn) Î Växlingsvarvtal (varv/min) ‰… -

Page 134

INSP CLUTCH G Green R Red Yellow Specifications Model: SX700 ~ 1,000 m 900 ~ 1,500 m 1,400 ~ 2,100 m 2,000 ~ 3,000 m Å Elevation (~ 3,500 ft) (3,000 ~ 5,000 ft) (4,500 ~ 7,000 ft) (6,500 ~ 10,000 ft) 1,600 ±… -

Page 135

REGLAGE DE L’EMBRAYAGE INSP KOPPLING Caractéristiques Specifikationer Modèle: SX700 Modell: SX700 Å Altitude Å Höjd över havet ı Régime de ralenti ı Motorns tomgångsvarvtal Ç Régime d’embrayage (tr/mn) Ç Inkopplingsvarvtal (varv/min) Î Régime de variation de rapport (tr/mn) Î Växlingsvarvtal (varv/min) ‰… -

Page 136

INSP CLUTCH G Green W White Yellow Specifications Model: MM700 ~ 1,000 m 900 ~ 1,500 m 1,400 ~ 2,100 m 2,000 ~ 3,000 m Å Elevation (~ 3,500 ft) (3,000 ~ 5,000 ft) (4,500 ~ 7,000 ft) (6,500 ~ 10,000 ft) 1,600 ±… -

Page 137

REGLAGE DE L’EMBRAYAGE INSP KOPPLING Caractéristiques Specifikationer Modèle: MM700 Modell: MM700 Å Altitude Å Höjd över havet ı Régime de ralenti ı Motorns tomgångsvarvtal Ç Régime d’embrayage (tr/mn) Ç Inkopplingsvarvtal (varv/min) Î Régime de variation de rapport (tr/mn) Î Växlingsvarvtal (varv/min) ‰… -

Page 138

INSP CLUTCH G Green O Orange Pink Specifications Model: VT700 ~ 1,000 m 900 ~ 1,500 m 1,400 ~ 2,100 m 2,000 ~ 3,000 m Å Elevation (~ 3,500 ft) (3,000 ~ 5,000 ft) (4,500 ~ 7,000 ft) (6,500 ~ 10,000 ft) 1,600 ±… -

Page 139

REGLAGE DE L’EMBRAYAGE INSP KOPPLING Caractéristiques Specifikationer Modèle: VT700 Modell: VT700 Å Altitude Å Höjd över havet ı Régime de ralenti ı Motorns tomgångsvarvtal Ç Régime d’embrayage (tr/mn) Ç Inkopplingsvarvtal (varv/min) Î Régime de variation de rapport (tr/mn) Î Växlingsvarvtal (varv/min) ‰… -

Page 140

INSP CLUTCH/GEAR SELECTION The clutch may require tuning depending upon where the machine will be operated and the desired han- dling characteristics. The clutch can be tuned by changing the engagement and shifting speeds. Clutch engagement speed is defined as the engine speed at which the machine first begins to move from a complete stop. -

Page 141

REGLAGE DE L’EMBRAYAGE/SELECTION DES PIGNONS INSP KOPPLING/VAL AV VÄXEL Il pourrait s’avérer nécessaire de reprendre le réglage Det kan hända att kopplingen måste ställas in, de l’embrayage en fonction de la région d’utilisation, beorende på det område där maskinen används och des habitudes du pilote, etc. -

Page 142

INSP GEAR SELECTION 1 Chain and sprocket part number Å Part name ı Teeth & links Ç Part no. Î Standard 18 teeth 89J-17682-80 19 teeth 89J-17682-91 20 teeth 89J-17682-00 VT700 for Europe ‰ Drive sprocket 21 teeth MM700 89J-17682-10 VX700DX/SX700 22 teeth 89J-17682-20… -

Page 143

SELECTION DES PIGNONS INSP VAL AV VÄXEL 1 N° de pièce de la chaîne et des pignons Detaljnummer på kedjor och kedjehjul Å Nom de pièce Å Detaljnamn ı Dents et maillons ı Kuggar & länkar Ç N° de pièce Ç… -

Page 144

INSP GEAR SELECTION 5 Torque cam (secondary sheave spring seat) SCH2850 ı Effects Ç Part no. Î Cam angle ‰ Identification mark Ï Standard 8BV-17604-71 47° 8BV71 VX700/VX700DX/SX700 8BV-17604-51 45° 8BV51 VT700 for U.S.A./Canada MM700 8BV-17604-31 43° 8BV31 VT700 for Europe 8BV-17604-11 41°… -

Page 145

SELECTION DES PIGNONS INSP VAL AV VÄXEL 5 Came de torsion (siège de ressort de poulie Momentkam (sekundärremskivans fjädersätet) Å secondaire) Identifieringsmärke Å Marque d’identification ı Effekter ı Effets Ç Detaljnummer Ç N° de pièce Î Kamvinkel Î Angle de came ‰… -

Page 146

INSP GEAR SELECTION 6 Primary sheave spring SCH2855 ‰ Ó È Ï Ô Î Spring rate Wire Outside Free Ò Standard Ì Color Preload No. of Parts No. N/mm gauge diameter length coils (kg/mm) N (kg) mm (in) mm (in) mm (in) 90501-551L3 19.6 (2.00) -

Page 147

SELECTION DES PIGNONS INSP VAL AV VÄXEL 6 Ressort de poulie primaire Primärremskivans fjäder Å Code de couleur des ressorts Å Färgkod för fjäderidentifiering ı Couleur de la raideur de ressort ı Färg för fjädervärde Ç Couleur de la précharge Ç… -

Page 148

INSP GEAR SELECTION 7 Clutch weights Å Standard 8CH-17605-10 35.32 g VX700/ VX700DX VT700 for U.S.A./Canada SCH2860 8CR-17605-10 38.09 g MM700 VT700 for Europe SCH2861 8DF-17605-10 37.84 g SX700 SCH2863 8DG-17605-00 39.26 g SCH2865 8DJ-17605-00 37.77 g SCH2867 8DN-17605-20 42.09 g SCH2869 2-56… -

Page 149

INSP SELECTION DES PIGNONS VAL AV VÄXEL 7 Poids d’embrayage Kopplingsvikter Å Standard Å Standard 2-56… -

Page 150

INSP GEAR SELECTION 8 Rollers I.D. 9 mm (0.4 in) Å ROLLER with ı OUTSIDE Ç BUSHING Î IDENTIFICATION ‰ Standard Ï EFFECTS BUSHING DIAMETER TYPE (P/N) MARK (Width) PART NUMBER 8CR-17624-00-00 14.5 mm Duralon VX700/ (0.57 in) VX700DX/ MM700/ VT700/ 90380-09245-00 8CR-17624-10-00… -

Page 151

SELECTION DES PIGNONS INSP VAL AV VÄXEL 8 Rouleaux Rullar Å N°/PIECE de ROULEAU et BAGUE Å RULLE med BUSSNING DETALJNUMMER ı DIAMETRE EXTERIEUR ı YTTRE DIAMETER Ç TYPE DE BAGUE (N°/P) Ç BUSSNINGSTYP (P/N) Î MARQUE D’IDENTIFICATION (largeur) Î IDENTIFIERINGSMÄRKE (bredd) ‰… -

Page 152

INSP HIGH ALTITUDE TUNING HIGH ALTITUDE TUNING To attain the best performance in high altitude conditions, carefully tune the snowmobile as outlined below. Check STD settings • Carburetors • Spark plugs Adjust the main jet size according to the chart Test the main jet Not OK Adjust the size of the main jet… -

Page 153: Reglage Pour Haute Altitude

INSP REGLAGE POUR HAUTE ALTITUDE REGLAGE POUR HAUTE ALTITUDE Pour obtenir le meilleur rendement à haute altitude, régler la motoneige comme indiqué ci-dessous. Vérifier les réglages standard. • Carburateurs • Bougies Déterminer la taille de gicleur principal selon le tableau. Tester gicleur principal (rendement et Incorrect Déterminer la taille de gicleur principal.

-

Page 154

INSTÄLLNING FÖR ANVÄNDNING PÅ HÖG HÖJD ÖVER INSP HAVSNIVÅ INSTÄLLNING FÖR ANVÄNDNING PÅ HÖG HÖJD ÖVER HAVSNIVÅ För att få bästa möjliga prestanda på platser som ligger högt över havsnivån skall Du varsamt ställa in snöskotern på det sätt som visas nedan. Kontrollera standardinställningarna •… -

Page 155

INSP… -

Page 156

INSP FRONT SUSPENSION FRONT SUSPENSION Spring preload (VX700/VX700DX/MM700/VT700) 1. Adjust: • Spring preload Adjustment steps: • Turn the adjusting ring 1 to the proper position. Spring adjuster SCH2880 position Softer ← → Harder Preload VX700/VX700DX/VT700: 1 Standard MM700: 3 CAUTION: Be sure that the left and right spring preload is the same. -

Page 157

SUSPENSION AVANT INSP FRÄMRE UPPHÄNGNING SUSPENSION AVANT FRÄMRE UPPHÄNGNING Précontrainte de ressort Fjäderförbelastning (VX700/VX700DX/MM700/VT700) (VX700/VX700DX/MM700/VT700) 1. Régler: 1. Justera: • • Précontrainte de ressort Fjäderförbelastningen Marche à suivre: Justeringsåtgärder: • • Tourner la bague de réglage jusqu’à la posi- Vrid justeringsringen 1 till lämpligt läge. tion désirée. -

Page 158

INSP REAR SUSPENSION REAR SUSPENSION Stopper band 1. Adjust: • Stopper band tension CAUTION: Make sure the left and right sides of the rear suspension stopper band are adjusted evenly. NOTE: This adjustment affects the handling characteristics of the machine. Adjustment steps: •… -

Page 159

SUSPENSION ARRIERE INSP BAKRE UPPHÄNGNING SUSPENSION ARRIERE BAKRE UPPHÄNGNING Sangle d’arrêt Stoppband 1. Régler: 1. Justera: • • Tension de sangle d’arrêt Stoppbandets spänning ATTENTION: VIKTIGT: Veiller à régler de façon identique les côtés gauche Se till att vänster och höger sida på bakre et droite de la sangle d’arrêt de la suspension. -

Page 160

INSP REAR SUSPENSION Spring preload (VX700/VX700DX/MM700/VT700) 1. Adjust: • Spring preload Adjustment steps: • Turn the adjusting ring 1 to the proper position. Spring adjuster SCH2900 position Softer ← → Harder Preload VX700: 1 Å Front Standard VX700DX/MM700/VT700: 3 Spring adjuster position Softer ←… -

Page 161

SUSPENSION ARRIERE INSP BAKRE UPPHÄNGNING Précontrainte de ressort Fjäderförbelastning (VX700/VX700DX/MM700/VT700) (VX700/VX700DX/MM700/VT700) 1. Régler: 1. Justera: • • Précontrainte de ressort Fjäderförbelastningen Marche à suivre: Justeringsåtgärder: • • Tourner la bague de réglage jusqu’à la position Vrid justeringsringen 1 till lämpligt läge. désirée. -

Page 162

INSP REAR SUSPENSION Rear suspension-full rate 1. Adjust: • Full rate adjuster Adjustment steps: Installation position Spring rate Soft Medium Hard and damping SCH2920 Standard NOTE: Be sure to make this adjustment when there is no load (rider or cargo) on the snowmobile. •… -

Page 163

SUSPENSION ARRIERE INSP BAKRE UPPHÄNGNING Réglage général de la suspension arrière Bakre upphängningens fulla värde 1. Régler: 1. Justera: • • Dispositif de réglage de la suspension arrière Fullvärdesjusteraren Marche à suivre: Justeringsåtgärder: Position de Installations- montage läge Constante de Fjädervärde Mjuk Medel… -

Page 164

INSP REAR SUSPENSION Rear suspension position (MM700) 1. Adjust: • Rear suspension position NOTE: Select the rear suspension position according to the snow conditions: a standard; b deep new snow. Bolt (slide rail suspension): 72 Nm (7.2 m · kg, 52 ft · lb) SCH2935 2-63… -

Page 165

SUSPENSION ARRIERE INSP BAKRE UPPHÄNGNING Position de la suspension arrière (MM700) Bakre upphängningens läge (MM700) 1. Régler: 1. Justera: • • Position de la suspension arrière Bakre upphängningens läge N.B.: OBS: Sélectionner la position de la suspension arrière en Välj bakre upphängningens läge enligt gällande snö- förhållande: a normalt;… -

Page 166

CHAS STEERING CHASSIS STEERING VX700/VX700DX/SX700/VT700 Å 10 Nm (1.0 m · kg, 7.2 ft · lb) ı 23 Nm (2.3 m · kg, 17 ft · lb) SCH3010 Order Job name/Part name Q’ty Remarks Handlebar removal Remove the parts in the order listed below. Handlebar cover Plastic band Oil tank breather hose… -

Page 167

DIRECTION CHAS STYRNING CHASSIS DIRECTION VX700/VX700DX/SX700/VT700 Ordre Travail/pièces Qté Remarques Dépose du guidon Déposer les pièces dans l’ordre indiqué ci-contre. Cache-guidon Attache réutilisable Reniflard de réservoir d’huile Coupleur de chauffe-pouce Déconnecter. Coupleur de coupe-circuit du moteur Déconnecter. Coupleur de contacteur de frein Déconnecter. -

Page 168

CHAS STEERING MM700 Å 10 Nm (1.0 m · kg, 7.2 ft · lb) ı 23 Nm (2.3 m · kg, 17 ft · lb) SCH3020 Order Job name/Part name Q’ty Remarks Remove the parts in the order listed below. Handlebar removal Handlebar cover Plastic band… -

Page 169

DIRECTION CHAS STYRNING MM700 Ordre Travail/pièces Qté Remarques Dépose du guidon Déposer les pièces dans l’ordre indiqué ci-con- tre. Cache-guidon Attache réutilisable Reniflard de réservoir d’huile Coupleur de chauffe-pouce Déconnecter. Coupleur de coupe-circuit du moteur Déconnecter. Coupleur de contacteur de frein Déconnecter. -

Page 170

CHAS STEERING Å 23 Nm (2.3 m · kg, 17 ft · lb) ı 25 Nm (2.5 m · kg, 18 ft · lb) Ç 35 Nm (3.5 m · kg, 25 ft · lb) Î 43 Nm (4.3 m · kg, 31 ft · lb) ‰… -

Page 171

DIRECTION CHAS STYRNING Ordre Travail/pièces Qté Remarques Dépose de la colonne de direction et de Déposer les pièces dans l’ordre indiqué ci-con- la barre d’accouplement tre. Moteur Se reporter à “MOTEUR” au CHAPITRE 5. Guidon Goupille fendue Agrafe Biellette intermédiaire Rondelle-frein Support de roulement Roulement… -

Page 172

CHAS STEERING INSPECTION 1. Inspect: • Handlebar 1 (VX700/VX700DX/SX700/VT700) • Handlebar 2 (MM700) • Steering column 3 Bends/cracks/damage → Replace. WARNING Do not attempt to straighten a bent column. SCH3040 This may dangerously weaken the column. 2. Inspect: • Bearings (steering column) 1 •… -

Page 173

DIRECTION CHAS STYRNING INSPECTION INSPEKTION 1. Inspecter: 1. Inspektera: • • Guidon (VX700/VX700DX/SX700/VT700) Styret 1 (VX700/VX700DX/SX700/VT700) • • Guidon (MM700) Styret 2 (MM700) • • Colonne de direction Styrstången 3 Cintrage/craquelures/endommagement → Böjning/sprickor/skada → Byt. Remplacer. VARNING AVERTISSEMENT Gör inga försök att räta ut en böjd styrstång, Ne jamais essayer de redresser une colonne cin- eftersom detta kan försvaga styrstången på… -

Page 174

CHAS STEERING INSTALLATION 1. Install: • Bushings 1 NOTE: Mount the bushing with clearance a to the end of the relay arm 2. a Approx. 1 mm (0.04 in) SCH3090 2. Install: • Tie rod 1 • Locknut 2 • Joints 3 Å… -

Page 175

DIRECTION CHAS STYRNING MONTAGE INSTALLATION 1. Installer: 1. Installera: • • Bagues Bussningar 1 N.B.: OBS: Fäst bussningen med spelrummet a till änden på Monter la bague en veillant à laisser du jeu à l’extrémité du bras relais reläarmen 2. a Environ 1 mm (0‚04 in) Ca 1 mm (0,04 in) 2. -

Page 176

CHAS STEERING 4. Install: • Relay rod 1 NOTE: Make sure that the end of the relay rod with the indentation a is connected to the relay arm. CAUTION: Always use new cotter pins. SCH3130 Nut (relay rod): 35 Nm (3.5 m · kg, 25 ft · lb) 5. -

Page 177

DIRECTION CHAS STYRNING 4. Installer: 4. Installera: • • Biellette intermédiaire Relästången 1 OBS: N.B.: Installer la biellette intermédiaire en veillant à con- Se till att stångänden på reläarmen med inbuktningen a ansluts till reläarmen. necter son extrémité porteuse de l’indentation bras relais. -

Page 178

CHAS STEERING 6. Install: • Handlebar CAUTION: • For SX700/MM700: Be sure the projection on the handlebar is not installed into the area a shown. • Be sure the side of the holder with the small gap b faces forward. SCH3150 •… -

Page 179

DIRECTION CHAS STYRNING 6. Installer: 6. Installera: • • Guidon Styret VIKTIGT: ATTENTION: • • SX700/MM700: För SX700/MM700: S’assurer que la saillie du guidon ne vienne pas Se noga till att utbuktningen på styret inte monteras inom område a på illustrationen. s’insérer dans la zone illustrée. -

Page 180

CHAS VX700/VX700DX/VT700 Å 11 Nm (1.1 m · kg, 8.0 ft · lb) ı 17 Nm (1.7 m · kg, 12 ft · lb) Ç 21 Nm (2.1 m · kg, 15 ft · lb) Î 48 Nm (4.8 m · kg, 35 ft · lb) : 1 ESSO beacon 325 grease or Aeroshell grease #7A… -

Page 181

SKIS CHAS SKIDA SKIS VX700/VX700DX/VT700 Ordre Travail/pièces Qté Remarques Dépose des skis Déposer les pièces dans l’ordre indiqué ci-con- tre. Goupille fendue Butée de ski Collerette Rondelle Support inférieur de colonne de ski Longeron de ski Collerette Couleur: Noir Collerette Couleur: Or Rondelle Levier de ski… -

Page 182

CHAS SX700/MM700 Å 11 Nm (1.1 m · kg, 8.0 ft · lb) ı 21 Nm (2.1 m · kg, 15 ft · lb) ç 48 Nm (4.8 m · kg, 35 ft · lb) : 1 ESSO beacon 325 grease or Aeroshell grease #7A SCH3200… -

Page 183

SKIS CHAS SKIDA SX700/MM700 Ordre Travail/pièces Qté Remarques Dépose des skis Déposer les pièces dans l’ordre indiqué ci-con- tre. Goupille fendue Support inférieur de colonne de ski Butée de ski Collerette Rondelle Longeron de ski Rondelle Poignée de ski Reposer les pièces dans l’ordre inverse de leur dépose. -

Page 184

CHAS INSPECTION 1. Inspect: • Ski 1 • Ski runner 2 • Ski stopper 3 • Ski column lower bracket 4 • Ski handle 5 Wear/cracks/damage → Replace. • Mounting bolt 6 • Collar 7 • Bolts 8 • Collars 9 Wear/damage →… -

Page 185

SKIS CHAS SKIDA INSPECTION INSPEKTION 1. Inspecter: 1. Inspektera: • • Skida 1 • • Longeron de ski Skidskena 2 • • Butée de ski Skidstoppare 3 • • Support inférieur de colonne de ski Skidstångens nedre fäste 4 • •… -

Page 186

CHAS FRONT SUSPENSION FRONT SUSPENSION Å 23 Nm (2.3 m · kg, 17 ft · lb) ı 43 Nm (4.3 m · kg, 31 ft · lb) Ç 48 Nm (4.8 m · kg, 35 ft · lb) Î 50 Nm (5.0 m · kg, 36 ft · lb) ‰… -

Page 187

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING SUSPENSION AVANT Ordre Travail/pièces Qté Remarques Dépose de la suspension avant Déposer les pièces dans l’ordre indiqué ci-con- tre. Se reporter à “SKIS”. Barre d’accouplement Amortisseur Capuchon Bras de direction Colonne de ski Douille Rondelle Barres de commande Collerette Douille… -

Page 188

CHAS FRONT SUSPENSION HANDLING NOTES (SX700) WARNING This shock absorber contains highly compressed nitrogen gas. Before handling the shock absorber read and make sure that you understand the following information. The manufacturer cannot be held responsible for property damage or per- sonal injury that may result from improper han- dling. -

Page 189

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING REMARQUES AU SUJET DE LA ANMÄRKNINGAR BETRÄFFANDE MANIPULATION (SX700) HANTERING (SX700) AVERTISSEMENT VARNING Cet amortisseur contient de l’azote fortement com- Den här stötdämparen innehåller kraftigt kompri- primé. Lire et se conformer à ce qui suit avant de merad kvävgas. -

Page 190

CHAS FRONT SUSPENSION 4. Inspect: • Connecting rod 1 • Stabilizer 2 Cracks/bends/damage → Replace. • Collar 3 Wear/scratches/damage → Replace. SCH3280 5. Inspect: • Front arm 1 Cracks/bends/damage → Replace. SCH3290 3-13… -

Page 191

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING 4. Inspecter: 4. Inspektera: • • Bielle Vevstaken 1 • • Stabilisateur Stabilisatorn 2 Craquelures/déformation/endommagement → Sprickor/böjning/skada → Byt. • Remplacer. Flänsarna 3 • Slitage/sprickor/skada → Byt. Collerette Usure/griffes/endommagement → Remplacer. 5. Inspecter: 5. Inspektera: •… -

Page 192

CHAS FRONT SUSPENSION INSTALLATION 1. Install: • Control rod 1 • Nut 2 • Joint 3 a Set length Å Left hand Ç Ì color ı SCH3300 Set length a angle ‰ Upper 475.5 ± 0.5 mm 93 ± 1° (VX700/VX700DX/ (18.7204 ±… -

Page 193

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING MONTAGE INSTALLATION 1. Installer: 1. Installera: • • Barre de commande Styrstaget 1 • • Ecrou Muttern 2 • • Raccord Leden 3 a Longueur Ställ in längd Å Gauche Å Vänster hand ı Longueur a ı… -

Page 194

CHAS FRONT SUSPENSION 2. Install: • Steering arm 1 NOTE: • Align the punch mark a on the ski column with the punch mark b on the steering arm. • Install sections c without any gaps. Nut (steering arm): 56 Nm (5.6 m · kg, 40 ft · lb) SCH3310 Å… -

Page 195

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING 2. Installer: 2. Installera: • • Bras de direction Styrarmen 1 N.B.: OBS: • • Aligner le repère poinçonné de la colonne de ski Anpassa punsmärket a på skidstången med puns- et le repère poinçonné du bras de direction. -

Page 196

CHAS FRONT SUSPENSION Ski spindle camber Place the unit on a level surface and check the ski spindle camber. DO NOT elevate the front end. 1 Using an angle finder, be sure that the unit sits parallel with the floor. Place the angle finder up against the flat aluminum part of the belly pan. -

Page 197

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING Carrossage de ski Skidspindellutning Vérifier le carrossage de ski en veillant à ce que la Kontrollera skidspindellutningen med snöskotern pla- motoneige soit installée sur une surface de niveau. cerad på en plan yta. Lyft INTE upp framändan. NE JAMAIS surélever l’avant du véhicule. -

Page 198

CHAS FRONT SUSPENSION 4 Install the radius rod onto the trailing arm and tighten the bolt. Tighten the ball joint locknut and apply grease to the ball joint. Repeat the procedure for the other side. SCH3370 CAUTION: When tightening the ball joint locknut, be sure to keep the ball joint outer housing centered with the ball to prevent binding. -

Page 199

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING Fixer la barre intermédiaire de direction au bras 4 Installera styrstången på bogserarmen och dra åt traînant, puis serrer le boulon. Serrer le contre- bulten. Dra åt kulledens låsmutter och stryk fett écrou de la rotule, puis enduire la rotule de på… -

Page 200

CHAS FRONT SUSPENSION Front arm part number SCH3390 ı Caster Ç Control rod Î Shock absorber ‰ ID Å Part number bracket angle b bracket angle c mark d 8DM-2382E-10 (L/H) VX700/VX700DX 25.5° 3° 10° 8DM-2382F-10 (R/H) 8CR-2382E-20 (L/H) SX700 25.5°… -

Page 201

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING N° de pièce de bras avant Främre arm, detaljnummer Å N°de pièce Å Detaljnummer ı Angle de chasse a ı Spindelbultens lutning bakåt a Ç Angle du support de barre de commande b Ç Styrstagsfästets vinkel b Î… -

Page 202

CHAS FRONT SUSPENSION Control rod part number SCH3410 Ç Part Number Î Length a ‰ Angle b 439.5 ± 1 mm (17.3031 ± 0.0394 in) 10.8 ± 0.5° Å Upper 8CR-2384E-20 VX700/VX700DX/ 431.6 ± 1 mm (16.9921 ± 0.0394 in) 10.8 ±… -

Page 203

SUSPENSION AVANT CHAS FRÄMRE UPPHÄNGNING N° de pièce de barre de commande Styrstag, detaljnummer Å Haut Å Övre ı Bas ı Undre Ç N° de pièce Ç Detaljnummer Î Longueur a Î Längd a ‰ Angle b ‰ Vinkel b 3-19… -

Page 204

POWR PRIMARY SHEAVE AND DRIVE V-BELT POWER TRAIN PRIMARY SHEAVE AND DRIVE V-BELT Å : 1st 120 Nm (12.0 m · kg, 85 ft · lb) 2nd 60 Nm (6.0 m · kg, 43 ft · lb) SCH4010 Order Job name/Part name Q’ty Remarks Primary sheave removal… -

Page 205

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM TRAIN DE ROULEMENT POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE Ordre Travail/pièces Qté Remarques Dépose de poulie primaire Déposer les pièces dans l’ordre indiqué ci-con- tre. Courroie trapézoïdale Capuchon borgne Ens. poulie primaire Reposer les pièces dans l’ordre inverse de leur dépose. -

Page 206

POWR PRIMARY SHEAVE AND DRIVE V-BELT Å 6 Nm (0.6 m · kg, 4.3 ft · lb) ı 14 Nm (1.4 m · kg, 10 ft · lb) Ç 19 Nm (1.9 m · kg, 13 ft · lb) Î 200 Nm (20.0 m ·… -

Page 207

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM Ordre Travail/pièces Qté Remarques Démontage de poulie primaire Démonter les pièces dans l’ordre donné ci-contre. Cache de poulie primaire Ressort de poulie primaire Collerette Rouleau Rondelle Collerette Masselotte Rondelle Poulie fixe Pignon mené… -

Page 208

POWR PRIMARY SHEAVE AND DRIVE V-BELT REMOVAL 1. Remove: • Primary sheave assembly 1 NOTE: Use the primary sheave holder 2 and primary sheave puller 3. Primary sheave holder: SCH4030 90890-01701, YS-01880 Primary sheave puller: YS-01881-1, YS-01882-1… -

Page 209

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM DEPOSE DEMONTERING 1. Déposer: 1. Demontera: • • Ens. poulie primaire Primärremskivan 1 N.B.: OBS: Utiliser l’outil de maintien de poulie primaire Använd primärremskivans hållare 2 och primärrem- l’extracteur de poulie primaire skivans avdragare 3. -

Page 210

POWR PRIMARY SHEAVE AND DRIVE V-BELT DISASSEMBLY 1. Remove: • Fixed sheave 1 • Stopper 2 • Sliding sheave 3 • Bushing 4 • Spider 5 SCH4040 Removal steps: • Immerse the primary sheave assembly in 80°C ~ 100°C (176°F ~ 212°F) water for several minutes. •… -

Page 211

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM DEMONTAGE ISÄRTAGNING 1. Déposer: 1. Demontera: • • Poulie fixe Den fasta remskivan 1 • • Butée Stopparen 2 • • Poulie mobile Glidremskivan 3 • • Douille Bussningen 4 • •… -

Page 212

POWR PRIMARY SHEAVE AND DRIVE V-BELT INSPECTION 1. Inspect: • Spider 1 • Sliding sheave 2 • Fixed sheave 3 • Primary sheave cap 4 Cracks/damage → Replace. SCH4080 2. Inspect: • Primary sheave spring 1 Cracks/damage → Replace. 3. Measure: •… -

Page 213

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM INSPECTION INSPEKTION 1. Inspecter: 1. Inspektera: • • Croisillon Spindeln 1 • • Poulie mobile Glidremskivan 2 • • Poulie fixe Den fasta remskivan 3 • • Cache de poulie primaire Primärremskivans kåpa 4 Craquelures/endommagement →… -

Page 214

POWR PRIMARY SHEAVE AND DRIVE V-BELT 5. Inspect: • Weight 1 • Roller 2 • Bushing 3 • Slider 4 • Rivet 5 • Collar Wear/scratches/damage → Replace. SCH4110 Slider inside clearance Min. 0 mm (0 in) Max. 0.3 mm (0.0118 in) Rivet replacement steps: •… -

Page 215

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM 5. Inspecter: 5. Inspektera: • • Masselotte Vikten 1 • • Rouleau Rullen 2 • • Douille Bussningarna 3 • • Coulisse Glidstyckena 4 • • Nitarna 5 Rivet • • Collerette Flänsen Usure/griffes/endommagement →… -

Page 216

POWR PRIMARY SHEAVE AND DRIVE V-BELT ASSEMBLY 1. Install: • Sliding sheave (onto the spider) NOTE: Be sure the sliding sheave match mark (X) is aligned with the spider match mark (X). SCH4150 2. Install: • Fixed sheave (onto the spider) NOTE: •… -

Page 217

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM ASSEMBLAGE MONTERING 1. Installer: 1. Installera: • • Poulie mobile Glidremskivan (sur le croisillon) (på spindeln) N.B.: OBS: Veiller à ce que le repère (X) sur la poulie mobile soit Se till att glidremskivans anpassningsmärke (X) an- aligné… -

Page 218

POWR PRIMARY SHEAVE AND DRIVE V-BELT • Tighten the spider to specification using the bar wrench 3. Spider: 200 Nm (20 m · kg, 145 ft · lb) CAUTION: The spider has a left-handed thread. SCH4190 WARNING • Do not operate the primary sheave until the LOCTITE ®… -

Page 219

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM • • Serrer le croisillon au couple spécifié au moyen Drag fast spindeln till det specificerade de la clé spéciale åtdragningsmomentet med skruvnyckeln 3. Croisillon: Spindel: 200 Nm (20 m · kg, 145 ft · lb) 200 Nm (20 m ·… -

Page 220

POWR PRIMARY SHEAVE AND DRIVE V-BELT 7. Tighten: • Bolts Tightening steps: • Temporarity tighten the bolts 1 ~ 6 in the order shown. Bolt (starter motor driven gear) 1 ~ 6: 19 Nm (1.9 m · kg, 13 ft · lb) SCH4220 NOTE: •… -

Page 221

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM 7. Serrer: 7. Drag fast: • • Boulons Bultarna Marche à suivre: Åtgärder för åtdragning: • • Serrer provisoirement les boulons comme Drag fast bultarna 1 ~ 6 temporärt i den ord- illustré. -

Page 222

POWR PRIMARY SHEAVE AND DRIVE V-BELT INSTALLATION 1. Install: • Primary sheave assembly CAUTION: Be sure to remove any oil or grease from the tapered portion of the crankshaft and spider us- ing a cloth dampened with thinner. SCH4230 2. Apply: •… -

Page 223

POULIE PRIMAIRE ET COURROIE TRAPEZOIDALE POWR PRIMÄRREMSKIVA OCH DRIVREM MONTAGE INSTALLATION 1. Installer: 1. Installera: • • Ens. poulie primaire Primärremskivan ATTENTION: VIKTIGT: Veiller à éliminer tout résidu d’huile ou de graisse Se till att avlägsna all olja och/eller fett från de de la partie conique du vilebrequin et du croisillon koniska delarna på… -

Page 224

POWR SECONDARY SHEAVE SECONDARY SHEAVE Å 64 Nm (6.4 m · kg, 46 ft · lb) SCH4260 Order Job name/Part name Q’ty Remarks Secondary sheave removal Remove the parts in the order listed below. V-belt Washer Shim – Refer to “SHEAVE DISTANCE AND OFFSET ADJUSTMENT”… -

Page 225

POULIE SECONDAIRE POWR SEKUNDÄR REMSKIVA POULIE SECONDAIRE Ordre Travail/pièces Qté Remarques Dépose de la poulie secondaire Déposer les pièces dans l’ordre indiqué ci-con- tre. Courroie trapézoïdale Rondelle Cale – Se reporter à “ECARTEMENT DES POULIES ET REGLAGE DU DECALAGE” au CHAPI- TRE 2. -

Page 226

POWR SECONDARY SHEAVE Å 4 Nm (0.4 m · kg, 2.9 ft · lb) ı 6.5 Nm (0.65 m · kg, 4.6 ft · lb) Ç 10 Nm (1.0 m · kg, 7.2 ft · lb) Î 23 Nm (2.3 m · kg, 17 ft · lb) : 1 ESSO beacon 325 grease or Aeroshell grease #7A SCH4270… -

Page 227

POULIE SECONDAIRE POWR SEKUNDÄR REMSKIVA Ordre Travail/pièces Qté Remarques Démontage de la poulie secondaire Déposer les pièces dans l’ordre indiqué ci-con- tre. Siège de ressort Ressort de poulie secondaire Plateau de poulie secondaire 1 (SX700) Poulie fixe Butée Poulie mobile Plateau de poulie secondaire 2 (SX700) Remonter les pièces dans l’ordre inverse de leur… -

Page 228

POWR SECONDARY SHEAVE DISASSEMBLY WARNING • Use extreme CAUTION when disassembling the secondary sheave since serious injury can occur due to the sudden release of spring ten- sion. Use the sheave compressor to contain the spring tension before removing the nuts (spring seat). -

Page 229

POULIE SECONDAIRE POWR SEKUNDÄR REMSKIVA DEMONTAGE ISÄRTAGNING AVERTISSEMENT VARNING • • Faire très ATTENTION lors du démontage de VIKTIGT: Var ytterst försiktig när Du tar isär den la poulie secondaire, car le ressort, en se déten- sekundära remskivan, eftersom Du kan skada dant soudainement, pourrait occasionner une Dig svårt när fjädern frigörs plötsligt. -

Page 230

POWR SECONDARY SHEAVE 5. Measure: • Ramp shoe thickness a Out of specification → Replace the ramp shoe. Wear limit a: 1.0 mm (0.04 in) SCH4320 ASSEMBLY 1. Install: • Stopper • Sliding sheave Screw (stopper): 6.5 Nm (0.65 m · kg, 4.6 ft · lb) 2. -

Page 231

POULIE SECONDAIRE POWR SEKUNDÄR REMSKIVA 5. Mesurer: 5. Mät: • • Rampskons tjocklek a Epaisseur de butée en plastique Hors spécifications → Remplacer. Motsvarar ej specifikation → Byt ut rampskon. Slitagegräns a: Limite d’usure 1,0 mm (0,04 in) 1,0 mm (0,04 in) ASSEMBLAGE MONTERING 1. -

Page 232

POWR SECONDARY SHEAVE Installation steps: • Hold the spring seat 1 and turn the fixed sheave 2 counterclockwise to the specified angle a. NOTE: The holes in the spring seat should align with the bolts on the sliding sheave. a = (sheave hole number + spring seat hole SCH4350 number) ×… -

Page 233

POULIE SECONDAIRE POWR SEKUNDÄR REMSKIVA Marche à suivre: Installationsåtgärder: • • Maintenir le siège de ressort et tourner la Håll fast fjädersätet 1 och vrid samtidigt de fasta remskivan 2 moturs tills specificerad vinkel a poulie fixe dans le sens inverse des aiguilles d’une montre jusqu’à… -

Page 234

• Measure the secondary sheave clearance again. Repeat these steps until the clearance is within specification. SCH4380 NOTE: Yamaha recommends keeping the original shims. Shims: Part number Thickness 90201-061H1 0.5 mm (0.02 in) 90201-06037 1.0 mm (0.04 in) INSTALLATION 1. -

Page 235

Répéter ces étapes jusqu’à ce que l’écartement OBS: soit conforme aux spécifications. Vi på Yamaha rekommenderar att originalmellan- N.B.: läggen behålls. Yamaha recommande de conserver les cales d’ori- gine. Mellanlägg: Detaljnummer Tjocklek Cales: 90201-061H1 0,5 mm (0,02 in) N°… -

Page 236

POWR DRIVE CHAIN HOUSING DRIVE CHAIN HOUSING WITHOUT REVERSE MODEL Å 16 Nm (1.6 m · kg, 11 ft · lb) ı 24 Nm (2.4 m · kg, 17 ft · lb) Ç 48 Nm (4.8 m · kg, 35 ft · lb) Î… -

Page 237

CARTER DE CHAINE DE TRANSMISSION POWR DRIVKEDJEHUS CARTER DE CHAINE DE TRANSMISSION MODELES SANS MARCHE ARRIERE Ordre Travail/pièces Qté Remarques Dépose du carter de chaîne de trans- Déposer les pièces dans l’ordre indiqué ci-con- mission tre. Etrier de frein Se reporter à “FREINS”. Frein de stationnement Se reporter à… -

Page 238

POWR DRIVE CHAIN HOUSING INSPECTION 1. Inspect: • Drive chain housing 1 • Drive chain housing cover 2 Cracks/damage → Replace. • Oil seals (drive chain housing) Wear/damage → Replace. • Bearings (drive chain housing and cover) 3 Pitting/damage → Replace. SCH4400 •… -

Page 239

CARTER DE CHAINE DE TRANSMISSION POWR DRIVKEDJEHUS INSPEKTION INSPECTION 1. Inspektera: 1. Inspecter: • • Drivkedjehuset 1 Carter de chaîne de transmission • • Kåpa för drivkedjan 2 Couvercle du carter de chaîne de transmission Craquelures/endommagement → Remplacer. Sprickor/skada → Byt. •… -

Page 240

POWR DRIVE CHAIN HOUSING 3. Measure: • 14 link section a of the drive chain 1 2 3 4 5 6 7 8 9 0 A B C D E Using a spring scale, pull on the drive chain with 36 kg (80 lb) of force b. Out of specification →… -

Page 241

CARTER DE CHAINE DE TRANSMISSION POWR DRIVKEDJEHUS 3. Mesurer: 3. Mät: • • Drivkedjans 14-länkarssektion a Longueur de 14 maillons de la chaîne de transmission Använd en fjädervåg till att dra i drivkedjan med en kraft b på 36 kg (80 lb). Tendre la chaîne en appliquant une force de Motsvarar ej specifikation →… -

Page 242

POWR DRIVE CHAIN HOUSING INSTALLATION 1. During installation, pay attention to the following. Å Make sure that the bearing seals face towards the drive chain as shown. ı Properly install the rubber seal onto the drive chain housing, making sure that there are no gaps. Be sure to install the spacers in their original positions, otherwise the brake disc and jackshaft will stick. -

Page 243

CARTER DE CHAINE DE TRANSMISSION POWR DRIVKEDJEHUS MONTAGE MONTERING 1. Respecter les points suivants lors du montage. 1. Observera följande punkter vid montering. Å Diriger les joints de roulement du côté de la chaîne de Å Kontrollera att bärlagerpackningarna är vända mot transmission. -

Page 244

POWR DRIVE CHAIN HOUSING WITH REVERSE MODEL Å 10 Nm (1.0 m · kg, 7.2 ft · lb) ı 13 Nm (1.3 m · kg, 9.4 ft · lb) Ç 16 Nm (1.6 m · kg, 11 ft · lb) Î… -

Page 245

CARTER DE CHAINE DE TRANSMISSION POWR DRIVKEDJEHUS MODELE A MARCHE ARRIERE Ordre Travail/pièces Qté Remarques Dépose du carter de chaîne de trans- Déposer les pièces dans l’ordre indiqué ci-con- mission tre. Batterie Support de batterie Etrier de frein Se reporter à “FREINS”. Frein de stationnement Se reporter à… -

Page 246

POWR DRIVE CHAIN HOUSING Å 10 Nm (1.0 m · kg, 7.2 ft · lb) ı 13 Nm (1.3 m · kg, 9.4 ft · lb) Ç 16 Nm (1.6 m · kg, 11 ft · lb) Î 24 Nm (2.4 m · kg, 17 ft · lb) ‰… -

Page 247

CARTER DE CHAINE DE TRANSMISSION POWR DRIVKEDJEHUS Travail/pièces Ordre Qté Remarques Tendeur de chaîne Rouleau Collerette Ressort Palier Pignon mené de marche arrière Rondelle Pignon mené de marche avant Collerette Pignon de renvoi Pignon menant Chaîne de transmission Collerette Rondelle Plaque Arbre Carter de chaîne de transmission… -

Page 248

POWR DRIVE CHAIN HOUSING INSPECTION 1. Inspect: • Drive chain housing 1 • Drive chain housing cover 2 Cracks/damage → Replace. • Shift fork 3 Pitting/wear/damage → Replace. • Oil seals (drive chain housing) Wear/damage → Replace. SCH4480 • Bearings (drive chain housing and cover) 4 Pitting/damage →… -

Page 249