- Manuals

- Brands

- Siemens Manuals

- Control Systems

- SINUMERIK 802C

- Manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Start-Up 01/2002 Edition

SINUMERIK 802C

Related Manuals for Siemens SINUMERIK 802C

Summary of Contents for Siemens SINUMERIK 802C

-

Page 1

Start-Up 01/2002 Edition SINUMERIK 802C… -

Page 3

Numerical Control System SINUMERIK 802C Installing the Control System Start–Up Installing the Drives Start–Up Update Valid for Technical Appendix Control Software Version SINUMERIK 802C Manual Machine Index 01.2002 Edition… -

Page 4

Trademarks SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr and SIMODRIVEr are registered trademarks of Siemens. Third parties using for their own purposes any other names in this document which refer to trademarks might infringe upon the rights of trademark owners. -

Page 5

The device may only be used for the cases of application, as intended by the Catalog, and only in conjunction with third–party devices and components recommended or approved by Siemens. The proper and safe operation of the product requires transport, storage and installation according to the relevant instructions and qualified operation and maintenance at the prescribed intervals. -

Page 6: Table Of Contents

2-15 Installing and removing the SINUMERIK 802C ……..

-

Page 7

7-132 Default assignment of special data for the “Manual machine” ……7-133 SINUMERIK 802C 6FC5 597–3AA20–0BP2 (01.02) -

Page 8

Table of Contents notice SINUMERIK 802C viii 6FC5 597–3AA20–0BP2 (01.02) -

Page 9: Sinumerik 802C Control System

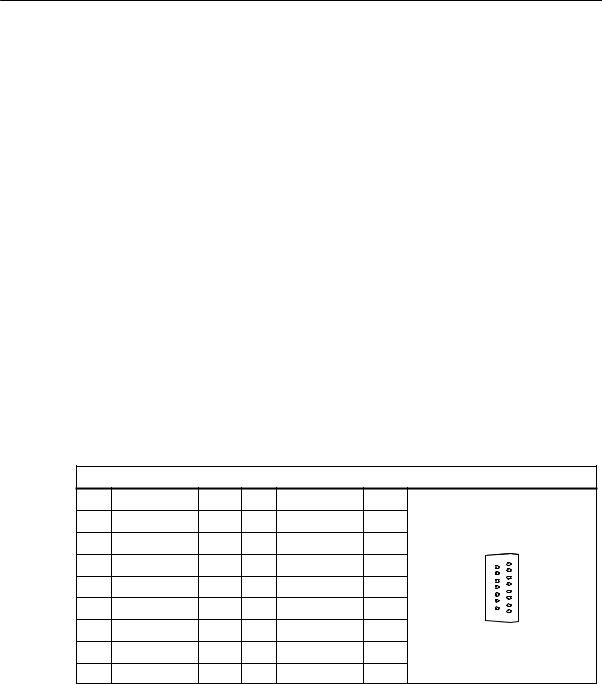

SINUMERIK 802C Control System Components of the SINUMERIK 802C What is SINUMERIK? The SINUMERIK 802C is a microprocessor–controlled numerical control system for simple machine tools with stepper motor drives . Hardware components It consists of the following hardware components: ENC: Control component for a maximum of 3 analog axes and an analog interface for a…

-

Page 10

– PLC software (Programmable Logic Control), executes the integrated PLC user program cyclically. – Integrated PLC user program intended to adjust the SINUMERIK 802C to the machine functions (see also Descrip- tion of Functions “Integrated User Program for SINUMERIK 802C”). SINUMERIK 802C 1-10 6FC5 597–3AA20–0BP2 (01.02) -

Page 11

– Technological machine data files – Programming tool Update diskettes – Update program with operator prompting system – 802C system software, packed, for loading and programming the SINUMERIK 802C via an update program. User data User data are: Machine data Setting data… -

Page 12: Technical Data

SINUMERIK 802C Control System Technical data Technical data Connected load Table 1-1 Connected load Parameter Min. Typ. Max. Unit Supply voltage 20.4 28.8 Ripple Current consumption from 24 V Power dissipation of ENC Power dissipation of OP020 Power dissipation of MCP Power dissipation of DI/O16 Start–up current…

-

Page 13

SINUMERIK 802C Control System Technical data Environmental operating conditions Table 1-4 Environmental operating conditions Parameter 0…55 °C Temperature range Permissible relative humidity 5…95 % without condensation Air pressure 700…1,060 hPa The operating conditions comply with IEC 1131-2. Installation in a housing (e.g. cubicle) is absolutely necessary for operation. -

Page 14

SINUMERIK 802C Control System Technical data SINUMERIK 802C 1-14 6FC5 597–3AA20–0BP2 (01.02) -

Page 15: Installing The Control System

Installing the Control System Installing and removing the SINUMERIK 802C Warning Before performing any installation work, always first make sure that the system is disconnec- ted from the mains! The modules contain electrostatically sensitive devices. It must be ensured that persons without ESD protection never touch printed circuit boards or components when handling operator and machine control panels.

-

Page 16

Installing the Control System Installing and removing the SINUMERIK 802C Warning Before removing the control components, always first make sure that the system is discon- nected from the mains! SINUMERIK 802C 2-16 6FC5 597–3AA20–0BP2 (01.02) -

Page 17

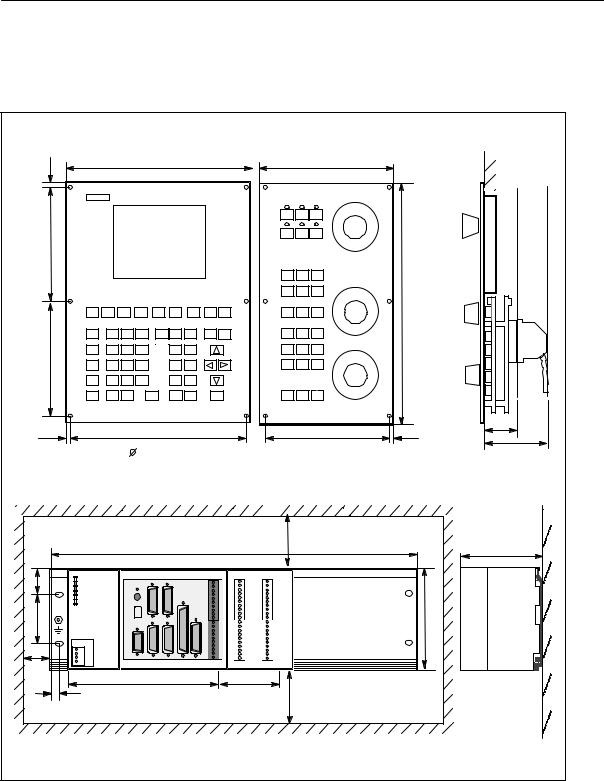

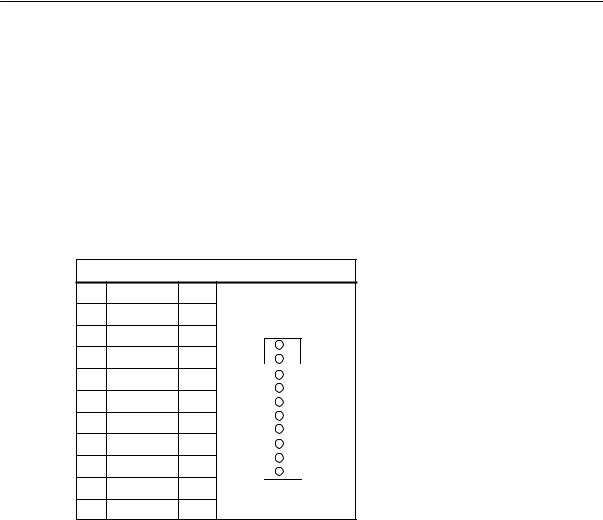

Installing the Control System Installing and removing the SINUMERIK 802C Mounting dimensions The dimensions shown below are important for installing the control components: Ñ Ñ SubD Ñ Ñ Ñ Ñ Mounting Holes X2003 X2005 ENCODER1 ENCODER2 DIAG DC24V X1 RS232… -

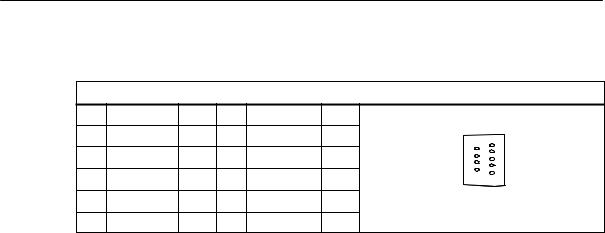

Page 18: Interfaces And Cables

DIAG DC24V X1 RS232 SPINDLE AXIS ENCODER3 X2004 X2006 Fig. 2-2 User interfaces OP020 Rear Rear X1202 X1201 LCD- signal connector X1001 X1002 X1009 Fig. 2-3 Rear of machine control panel and operator panel SINUMERIK 802C 2-18 6FC5 597–3AA20–0BP2 (01.02)

-

Page 19

DI/O X2003 and X2004 10–pin front connector for connecting digital inputs X2005 and X2006 10–pin front connector for connecting digital outputs LEDs 3 LEDs for fault and status displays Operating elements Start–up switch S SINUMERIK 802C 2-19 6FC5 597–3AA20–0BP2 (01.02) -

Page 20

Hand Wheels NC READY Sensor DI/O16 1…16 Wire (0.14…1.5) IN 0..7 IN 8..15 OUT0..7 Wire (0.14…1.5) Actor OUT8..15 1…16 Power Supply Fig. 2-4 SINUMERIK 802C connection diagram 1) Ribbon cable (included in scope of supply) SINUMERIK 802C 2-20 6FC5 597–3AA20–0BP2 (01.02) -

Page 21: Connecting The Individual Components

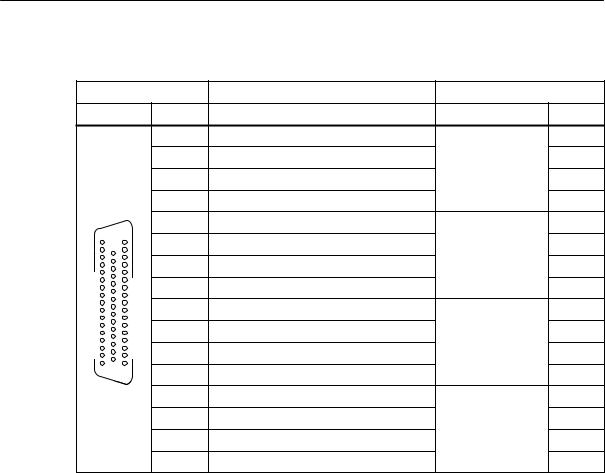

2. Fix the sub–D connector in place using the knurled screws. 2.3.1 Connecting the operator panel Connector pin assignment on the ENC side Operator panel interface Connector designation: OP020 Connector type: 25–pin sub–D plug connector SINUMERIK 802C 2-21 6FC5 597–3AA20–0BP2 (01.02)

-

Page 22

Pin assignment of connector X1009 X1009 Signal Type Pin Signal Type P24_OP M_OP OPD0_N OPD0 OPD1_N OPD1 OPD2_N OPD2 OPD3_N OPD3 OPCP1_N OPCP1 OPCP2_N OPCP2 OPS_N OPTXD_N OPTXD OPRXD_N OPRXD OPCTS_N OPCTS P24_OP M_OP SINUMERIK 802C 2-22 6FC5 597–3AA20–0BP2 (01.02) -

Page 23: Connecting The Feed Drives And The Spindle (X7)

Connector pin assignment on the ENC side Feed drive interface Connector designation: AXIS 1-4 Connector type: 50–pin sub–D plug connector Table 2-3 Pin assignment of connector X7 Pin Signal Type Signal Type Signal Type SINUMERIK 802C 2-23 6FC5 597–3AA20–0BP2 (01.02)

-

Page 24

RF2.1 RF2.2 RF3.1 RF3.2 RF4.1 RF4.2 Signal names Setpoint Reference potential for setpoint RFn.1, RFn.2 Servo enable contact Signal level RS422 Signal type Signal output Axis assignment X axis Y axis Z axis Spindle SINUMERIK 802C 2-24 6FC5 597–3AA20–0BP2 (01.02) -

Page 25

PLC program Signal parameters The setpoint is output as an analog differential signal. Table 2-5 Electrical parameters of the signal outputs for step–switching drives Parameter Unit Voltage range -10.5 10.5 Output current SINUMERIK 802C 2-25 6FC5 597–3AA20–0BP2 (01.02) -

Page 26: Connecting The Measuring Systems (X3 … X6)

Track A (true and negated) B, B_N Track B (true and negated) N, N_N Zero mark (true and negated) P5_MS +5.2 V supply Supply ground Signal level RS422 Signal type Voltage output (supply) 5V input (5V signal) SINUMERIK 802C 2-26 6FC5 597–3AA20–0BP2 (01.02)

-

Page 27: Configuration Of The Rs232 Interface Connection (X8)

The maximum cable length depends on the specifications of the encoder power supply and on the transmission frequency. To provide fault–free operation, make sure that the following values are not exceeded when using preassembled interconnecting cables from SIEMENS: Table 2-8 Maximum cable lengths depending on the encoder power supply…

-

Page 28

Standby output Standby input Ground Signal level RS232 (+ 12 V) Signal type Input Output Voltage output Cable for WinPCIN Table 2-11 Cable for WinPCIN: Pin assignment of the Sub–D connector 9–Pin Name 25–Pin Shield SINUMERIK 802C 2-28 6FC5 597–3AA20–0BP2 (01.02) -

Page 29: Connecting Handwheels (X10)

Two electronic handwheels can be connected which must meet the following requirements: Transmission method: 5 V square–wave (TTL level or RS422) Signals: Track A as true and negated signal (U Track B as true and negated signal (U SINUMERIK 802C 2-29 6FC5 597–3AA20–0BP2 (01.02)

-

Page 30: Connecting Ncready (X20)

Signal names NCRDY_1…2 NC Ready (NCREADY contacts 1…2) Signal type Switching contact NC-READY output Readiness in the form of a relay contact (NO); must be integrated into the EMERGENCY STOP circuit. SINUMERIK 802C 2-30 6FC5 597–3AA20–0BP2 (01.02)

-

Page 31: Connecting The Digital Inputs And Outputs (X2003

2.3.7 Connecting the digital inputs and outputs (X2003 … X2006) Connector pin assignment Interface for the digital inputs Connector designation: X2003, X2004 Connector type: 10–pin plug connector SINUMERIK 802C 2-31 6FC5 597–3AA20–0BP2 (01.02)

-

Page 32

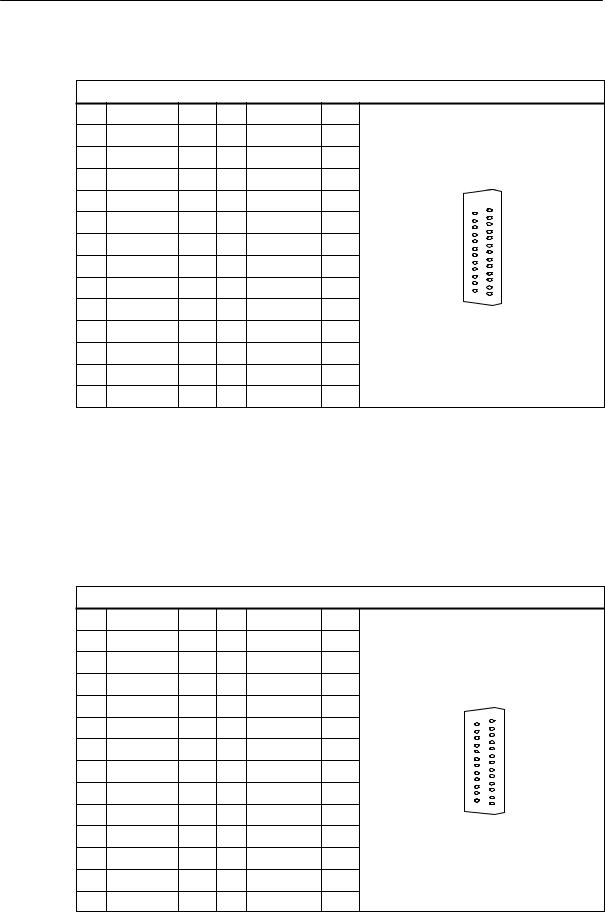

Connecting the individual components Table 2-15 Connector pin assignment X2003 Name Type X2004 Name Type DI10 DI11 DI12 DI13 DI14 DI15 Signal names DI0…15 24 V digital inputs Signal type Voltage input Input (24 V signal) SINUMERIK 802C 2-32 6FC5 597–3AA20–0BP2 (01.02) -

Page 33

Interface for digital outputs Connector designation: X2005, X2006 Connector type: 10–pin plug connector Table 2-17 Connector pin assignment X2005 Name Type 1P24 1M24 X2006 Name Type 2P24 DO10 DO11 DO12 DO13 DO14 DO15 2M24 SINUMERIK 802C 2-33 6FC5 597–3AA20–0BP2 (01.02) -

Page 34

3 “1” signal, output current Simultaneity factor 0.5 per 16 outputs “0” signal, leakage current max. 2 Connecting sensors and actuators X2005 X2003 X2004 X2006 Fig. 2-6 Connecting the digital inputs and outputs SINUMERIK 802C 2-34 6FC5 597–3AA20–0BP2 (01.02) -

Page 35: Enc And Operator Panel Power Supply (X1)

DC 24 V Ground The contacts 2/4 are connected internally in the device. Operator panel The operator panel does not possess a separate power supply connection. It is powered from the ENC via the signal cables. SINUMERIK 802C 2-35 6FC5 597–3AA20–0BP2 (01.02)

-

Page 36: Grounding

Shielded signal cable DI/O16 X2003 X2005 ENCODER1 ENCODER2 DIAG DC24V X1 RS232 SPINDLE AXIS ENCODER3 X2004 X2006 to chassis Grounding bar Fig. 2-7 Grounding diagram for MCP/OP020 installation in a cubicle or machine SINUMERIK 802C 2-36 6FC5 597–3AA20–0BP2 (01.02)

-

Page 37

LCD signal- connector Shielded signal cable DI/O16 X2003 X2005 ENCODER1 ENCODER2 DIAG DC24V X1 RS232 ENCODER3 SPINDLE AXIS X2004 X2006 to chassis Grounding bar Fig. 2-8 Grounding diagram for MCP/OP020 installation in a panel SINUMERIK 802C 2-37 6FC5 597–3AA20–0BP2 (01.02) -

Page 38: Leds And Operating Elements On The Enc

This LED indicates various diagnosis states. Under normal operating conditions, this LED flashes 1:1. Start–up switch (S3) This rotary switch is intended to assist start–up. Position 0: Normal operation Positions 1-4: Start–up cf. also Section 4.2, Table 4-2 SINUMERIK 802C 2-38 6FC5 597–3AA20–0BP2 (01.02)

-

Page 39: Installing The Drives

Installing the Drives Lesehinweis Manufacturer documentation of the drives SINUMERIK 802C 3-39 6FC5 597–3AA20–0BP2 (01.02)

-

Page 40

Installing the Drives SINUMERIK 802C 3-40 6FC5 597–3AA20–0BP2 (01.02) -

Page 41: Start-Up

Installation notes are to be found in Chapter LEERER MERKER. The control system with its components has powered up without errors. Start-up sequence The SINUMERIK 802C can be strated up as follows: 1. Check whether the ENC has powered up. 2. PLC start–up 3.

-

Page 42: Access Levels

Access levels Protection levels The SINUMERIK 802C provides a protection level concept for enabling data areas. The pro- tection levels range from 0 to 7 whereby 0 is the highest and 7 the lowest level. The control system comes with default passwords for protection levels 2 and 3. If necessary these passwords can be changed by the appropriate authorized person.

-

Page 43: Structure Of Machine Data (Md) And Setting Data (Sd)

Depending on the MD SCALING_SYSTEM_IS_METRIC, the physical units of the MD are set as follows: MD10240 = 1 MD10240 = 0 mm/min in/min in/s in/s mm/rev in/rev If no physical units are applicable to the MD, the field contains a ”-”. SINUMERIK 802C 4-43 6FC5 597–3AA20–0BP2 (01.02)

-

Page 44: Handling Machine Data

An internal data backup should be carried out if the control system has been switched off for more than 50 hours (at least 10 min/day with controller ON). It is recommended to carry out internal data saving whenever important data changes have been made. SINUMERIK 802C 4-44 6FC5 597–3AA20–0BP2 (01.02)

-

Page 45

2. Files are read in or read out by areas. The following user data can be selected as indivi- dual files: Data – Machine data – Setting data – Tool data – R parameters – Zero offset – Compensation data (LEC) Part programs Standard cycles SINUMERIK 802C 4-45 6FC5 597–3AA20–0BP2 (01.02) -

Page 46: Turning On And Booting The Control System

Power–up with default machine data (user data determined by the software version) System software update Power–up with saved data PLC stop Reserve Assigned Assigned The switch position comes into effect with next power–up and is displayed on the screen when the control system powers up. SINUMERIK 802C 4-46 6FC5 597–3AA20–0BP2 (01.02)

-

Page 47

Booting with saved data (Start-up switch position 3) Result The user data backed-up on the permanent memory are loaded into the user memory. Contrast control See User’s Guide “Operation and Programming” SINUMERIK 802C 4-47 6FC5 597–3AA20–0BP2 (01.02) -

Page 48: Boot Messages

4. Replace the hardware components. ERROR BOOT 5. Inform the hotline if necessary. ERROR NO BOOT2 ERROR NO SYSTEM ERROR LOAD NC NO SYSTEM-LOADER ERROR LOAD NC CHECKSUM-ERROR ERROR LOAD NC DECOMPRESS-ERROR ERROR LOAD NC INTERNAL-ERROR 1 SINUMERIK 802C 4-48 6FC5 597–3AA20–0BP2 (01.02)

-

Page 49: Starting Up The Plc

The PLC is a store–programmable logic controller for simple machines. It has no hardware of its own and is used as a software PLC in the SINUMERIK 802C control system. The task of the PLC is to control machine–related functional sequences.

-

Page 50

1 and 1,000. Check the response by pressing the axis direction keys. Reference Point is not supported. Standard user program The control system comes with the SAMPLE user program for simple turning machines, which is stored in the permanent memory. SINUMERIK 802C 4-50 6FC5 597–3AA20–0BP2 (01.02) -

Page 51: Start-Up Modes Of The Plc

The hardware start–up switch “PLC STOP” (position 4) is active immediately. The priority of the power–up modes activated via the softkeys on the ope- rator panel is higher than that of the hardware start–up switches. SINUMERIK 802C 4-51 6FC5 597–3AA20–0BP2 (01.02)

-

Page 52: Plc Alarms

SELF–CLEARING: The alarm is cleared because the cause resulting in the alarm has been eliminated or does not exist any longer. Desired alarm responses are defined for each alarm in the PLC. By default, the PLC uses the SHOWALARM response (bit0 – bit5 = 0). SINUMERIK 802C 4-52 6FC5 597–3AA20–0BP2 (01.02)

-

Page 53

‘’1600xxxx’’ in sub–range 0 (1 –> 0 edge). The remaining user alarms are cleared by the PLC after detecting the respective cancel condi- tion. If the alarm is still present, the alarm occurs again. SINUMERIK 802C 4-53 6FC5 597–3AA20–0BP2 (01.02) -

Page 54

Bit3 = 1: EMERGENCY STOP Bit4 = 1: PLC Stop Bit5 = Reserved Cancel criteria: Bit6 + bit7 = 0: SELF–CLEARING alarm (default) Bit6 = 1 : CANCELCLEAR alarm Bit7 = 1 : POWERONCLEAR alarm SINUMERIK 802C 4-54 6FC5 597–3AA20–0BP2 (01.02) -

Page 55

700031 0 0 ‘’ ’’ // 32nd user alarm, the text is assigned by the user Number The alarm text must be here. Comment line (does not appear in the dialog window of the Operator Panel) SINUMERIK 802C 4-55 6FC5 597–3AA20–0BP2 (01.02) -

Page 56: Machine Control Panel (Mcp) Layout

The user can use the keys 1 – 6 and the associated LEDs (the same applies to keys 1 … 6) for his own purposes. The keys 16–24 should be used as axis keys (see sample program SAMPLE). The program- mer can assign the axis keys depending on his particular machine type. SINUMERIK 802C 4-56 6FC5 597–3AA20–0BP2 (01.02)

-

Page 57: Plc Programming

The PLC user program is created using the PLC 802 Programming Tool. The Documentation “S7–200 Automation System, System Manual“ describes how this tool is operated for S7–200. The PLC 802 Programming Tool is to be understood as a subset of this Documentation. SINUMERIK 802C 4-57 6FC5 597–3AA20–0BP2 (01.02)

-

Page 58

In any case, the PLC 802 Programming tool manages one project (logic operations, symbols and comments). The download function is intended to store all important information of a pro- ject in a control system. SINUMERIK 802C 4-58 6FC5 597–3AA20–0BP2 (01.02) -

Page 59

ACCU AC0 … AC3 Table 4-8 Generating the addresses for the V range (see user interface) Type Code Range No. Subrange Offset Addressing (DB No.) (Channel/ Axis No.) symbolic (00–79) (00–99) (0–9) (000–999) (8–digit) SINUMERIK 802C 4-59 6FC5 597–3AA20–0BP2 (01.02) -

Page 60

Flags with defined ONE signal SM 0.1 Initial position: first PLC cycle ‘1’, following cycles ‘0’ SM 0.2 Buffered data lost – applicable only to the first PLC cycle (‘0’ data o.k., ‘1’ – data lost) SINUMERIK 802C 4-60 6FC5 597–3AA20–0BP2 (01.02) -

Page 61: Instruction Set

A detailed description of the instructions is to be found in the help system of the PLC 802 Pro- gramming Tool (Help > Contents and Index, “SIMATIC LAD Instructions”) and in the Docu- mentation “S7–200 Automation System, CPU22x System Manual. SINUMERIK 802C 4-61 6FC5 597–3AA20–0BP2 (01.02)

-

Page 62

≥ b close And Byte . a t b open > =B Or Byte . Load Byte 3 a ≤ b close And Byte 3 a u b open < =B Or Byte 3 SINUMERIK 802C 4-62 6FC5 597–3AA20–0BP2 (01.02) -

Page 63

≥ b close And RWord . a t b open > =R Or RWord . Load RWord 3 a ≤ b close And RWord 3 a u b open < =R Or RWord 3 SINUMERIK 802C 4-63 6FC5 597–3AA20–0BP2 (01.02) -

Page 64

VW, T, C, IW, QW, MW, AC,Constant, LW Count Down If C = 0, Cnt Down: (CD) Cxxx Value Reset: (R) Cxxx: C0 – 31 Preset: (PV) VW, T, C, IW, QW, MW, AC, Constant, LW SINUMERIK 802C 4-64 6FC5 597–3AA20–0BP2 (01.02) -

Page 65

If EN = 1, Enable: EN MUL_R VD, ID, QD, MD, AC, Constant, LD Divide b = a x b Out: VD, ID, QD, MD, AC, LD b = b ÷ a Real Numbers SINUMERIK 802C 4-65 6FC5 597–3AA20–0BP2 (01.02) -

Page 66

VW, T, C, IW, QW, MW, AC, LW Invert DWord If EN = 1, Enable: EN INV_DW VD, ID, QD, MD, AC, Constant, LD a = /a Out: VD, ID, QD, MD, AC, LD SINUMERIK 802C 4-66 6FC5 597–3AA20–0BP2 (01.02) -

Page 67

Label marker for the Label: WORD: 0–127 jump. Conditional Return If EN = 1, exit the Enable: EN from Subroutine subroutine. Conditional End If EN = 1, END ter- Enable: EN minates the main scan. SINUMERIK 802C 4-67 6FC5 597–3AA20–0BP2 (01.02) -

Page 68: Programm Organization

A PLC cycle can be a multiple of the control–internal interpolation cycle (IPO cycle). The ma- chine manufacturer must set the PLC cycle according to his/her own requirements (see ma- chine data “PLC_IPO_TIME_RATIO”). The ratio IPO/ PLC of 1:1 is the fastest possible cyclic processing. SINUMERIK 802C 4-68 6FC5 597–3AA20–0BP2 (01.02)

-

Page 69: Data Organization

The user program can be analyzed or checked for errors using the following methods: PLC Status menu (PCU) Status list menu (PCU) PLC 802 Programming Tool (see Help menu > Contents and Index, “Debugging” or docu- mentation “S7–200 Automation System”, Section “Testing and Monitoring Your Program”) SINUMERIK 802C 4-69 6FC5 597–3AA20–0BP2 (01.02)

-

Page 70: Plc Applications «Download/Upload/Copy/Compare

Programming Tool 802 WinPCIN (binary file) PT PLC 802 Download/ Upload/ Compare Permanent 802D memory project PLC user PLC machine texts data Toolbox application WINPCIN Series start–up Fig. 4-5 PLC applications in the control system SINUMERIK 802C 4-70 6FC5 597–3AA20–0BP2 (01.02)

-

Page 71

The programmer can use the first comment line in the program title of the PLC 802 Pro- gramming Tool for his own additional information in the version display (see “View Proper- ties“). SINUMERIK 802C 4-71 6FC5 597–3AA20–0BP2 (01.02) -

Page 72: User Interface

Technology Setting Overview The SINUMERIK 802C is supplied with the default machine data as a control system for tur- ning machines (2 axes, 1 spindle). If you wish to set another technology (e.g. milling), the rele- vant machine data file must be loaded from the tool box into the control system.

-

Page 73: Commissioning

Commissioning Commissioning Initializing the control system Turn on the control system. The SINUMERIK 802C will load the standard machine data automatically. 4.7.1 Entering the general machine data Overview To make your work easier, the most important machine data of the individual subranges are listed.

-

Page 74

Auxiliary function value (aux. fct. no. in channel): 0…49 22550 New tool compensation for M function Setting data Default- Number Explanation Value 41110 Jog feedrate 41200 Spindle speed 42000 Start angle 42100 Dry run feedrate 5000 SINUMERIK 802C 4-74 6FC5 597–3AA20–0BP2 (01.02) -

Page 75: Starting Up The Axes

Starting up the axes Overview The SINUMERIK 802C has up to three stepper motor feedrate axes (X, Y and Z). The stepper motor drive signals are output at connector X7 for the: X axis at pins 1–3 (PULS1, DIR1 and EN1) Y axis at pins 4–6 (PULS2, DIR2 and EN2) and for the…

-

Page 76

Reciprocation time for M3 direction 35450 Reciprocation time for M4 direction 35510 Feedrate enable for spindle stopped 36000 Exact positioning coarse 0.04 (only SPOS) 36010 Exact positioning fine 0.01 (only SPOS) 36020 Delay exact positioning fine (only SPOS) SINUMERIK 802C 4-76 6FC5 597–3AA20–0BP2 (01.02) -

Page 77

Denominator resolver gearbox (encoder no. Enc. revs Enc. revs 31060 Numerator load gearbox (control parameter set no.): 0…5 Motor revs Motor revs 31050 Denominator load gearbox (control parameter no.): 0…5 Load revs Load revs SINUMERIK 802C 4-77 6FC5 597–3AA20–0BP2 (01.02) -

Page 78

Example 2 for encoder matching: Spindle with rotary encoder on motor (2,048 pulses), internal multiplication = 4, 2 speed sta- ges exist: Gear stage 1: Motor/spindle = 2.5/1 Gear stage 2: Motor/spindle = 1/1 SINUMERIK 802C 4-78 6FC5 597–3AA20–0BP2 (01.02) -

Page 79

2: Encoder external Encoder markings per re- Steps per encoder revolu- 31020 2048 volution (encoder no.) tion 31030 Pitch of leadscrew Leadscrew pitch Denominator load gear- Load gear transmission 31050 box (control parameter ratios no.): 0…5 SINUMERIK 802C 4-79 6FC5 597–3AA20–0BP2 (01.02) -

Page 80

36010 Exact positioning fine 0.01 Exact stop fine Delay exact positioning 36020 Positioning dealy time fine Maximum velocity/speed Threshold velocity for ”axis/spindle stopped” “Axis at standstill” 36060 Threshold velocity for 0.013889 “Spindle at standstill” SINUMERIK 802C 4-80 6FC5 597–3AA20–0BP2 (01.02) -

Page 81

If an exact adjustment is carried out, it is possible to sacrifice of a compensating chuck for tapping. At least, higher spindle speeds/smaller compensation paths can be achieved. SINUMERIK 802C 4-81 6FC5 597–3AA20–0BP2 (01.02) -

Page 82

POSCTRL_GAIN[n] for spindle and axis must be converted accordingly: 1000 = POSCTRL_GAIN[n] –––––– spindle spindle 1000 = POSCTRL_GAIN[n] –––––– axis axis When using further gear stages with G331/G332, the adaptation must also be carried out in these parameter blocks. SINUMERIK 802C 4-82 6FC5 597–3AA20–0BP2 (01.02) -

Page 83

The falsification of axis travel due to mechanical backlash can be compensated (cf. Technical Manual “Description of Functions“). Funktion The axis–specific actual value is corrected by the backlash compensation value (MD32450 BACKLASH) with each change of the traversing direction. SINUMERIK 802C 4-83 6FC5 597–3AA20–0BP2 (01.02) -

Page 84

In the NC, set MD: ENC_COMP_ENABLE(0)=0. This is the only way to load the compen- sation table. The compensation values for the machine axes are entered into the NC memory by means of a part program (see also example in the Manual “Description of Functions“) SINUMERIK 802C 4-84 6FC5 597–3AA20–0BP2 (01.02) -

Page 85: Starting Up The Spindle

Starting up the spindle Overview With the SINUMERIK 802C, the spindle is a subfunction of the entire axis functionality. The machine data of the spindle are therefore to be found under the axis machine data (from MD35000). For this reason, data have to be entered for the spindle, too; these data are descri- bed for axis start-up.

-

Page 86

“Speed is changed” 38032000 Bit 3 “Set gear stage” 39032000 bits 0 to 2 “Positioning mode” 39032002 bit 5 “Oscillating through PLC”38032002 bit 4 “Oscillating mode” 39032002 bit 6 “Control mode” 39032002 bit 7 SINUMERIK 802C 4-86 6FC5 597–3AA20–0BP2 (01.02) -

Page 87: Completing The Start-Up

If the machine manufacturer uses the password ”EVENING” for access level 2 during the start–up work, the password must be changed. – Press the softkey Change passw. – Enter the new password and press OK to confirm. – Note the password in the Manufacturer Documentation. SINUMERIK 802C 4-87 6FC5 597–3AA20–0BP2 (01.02)

-

Page 88: Cycle Start-Up

These data can be selected in the Services menu by pressing the Data outp./data…soft- key. 2. Load all files of the selected technology path from the toolbox diskette into the control sy- stem via the V24 interface. 3. Carry out POWER ON. 4. Reload the recovered data. SINUMERIK 802C 4-88 6FC5 597–3AA20–0BP2 (01.02)

-

Page 89: Series Machine Start-Up

– The control system is brought to “RESET with rebooting” three times during and at the end of data transfer. On completion of error-free data transfer, the control system is completely configured and ready to operate. SINUMERIK 802C 4-89 6FC5 597–3AA20–0BP2 (01.02)

-

Page 90

Start-Up Commissioning Series machine start-up file The series machine start-up file contains: machine data R parameters display and alarm text files display machine data PLC user program main programs subroutines cycles SINUMERIK 802C 4-90 6FC5 597–3AA20–0BP2 (01.02) -

Page 91: Sinumerik 802C

4. Power On —> control system changes to the update condition. Various patterns appear on the screen. 5. After the patterns on the display of the SINUMERIK 802S have disappeared, start the transfer on the PC/PG. SINUMERIK 802C 5-91 6FC5 597–3AA20–0BP2 (01.02)

-

Page 92

2. Carry out POWER ON for slave control system –––> control system changes to the up- date condition. Various patterns appera on the screen. 3. After the patterns on the screen have disappeared, switch on the master control system on the slave control. 3 data blocks are transferred. SINUMERIK 802C 5-92 6FC5 597–3AA20–0BP2 (01.02) -

Page 93: Update

Error when erasing the FLASH memory Check diskette Error when writing to the FLASH memory Inconsistent data (incomplete or faulty) SINUMERIK Update without programming the code FLASH 802S completed (no data received, transfer not started) UPDATE NO DATA SINUMERIK 802C 5-93 6FC5 597–3AA20–0BP2 (01.02)

-

Page 94: Technical Appendix

Foreground language Power On Byte $MM_DISPLA Y_RESOLUTION Decimal Display resolution Power On Byte $MM_USER_CLASS_WRITE_T OA_GEO Decimal User class Write tool geometry Immediately Byte $MM_USER_CLASS_WRITE_T OA_WEAR Decimal User class Write tool wear data Immediately Byte SINUMERIK 802C 6-94 6FC5 597–3AA20–0BP2 (01.02)

-

Page 95

PPI address of the NCK POWER ON BYTE $MM_V24_PPI_ADDR_MMC Decimal PPI address of the HMI POWER ON BYTE $MM_V24_PPI_MODEM_ACTIVE Decimal Modem active Immediately BYTE $MM_V24_PPI_MODEM_BAUD Decimal Modem baud rate Immediately BYTE $MM_V24_PPI_MODEM_P ARITY Decimal Modem parity Immediately BYTE SINUMERIK 802C 6-95 6FC5 597–3AA20–0BP2 (01.02) -

Page 96: General Machine Data

User data (Hex) Alarm bit 0 … 31 POWER ON 0xFF BYTE 6.1.3 Channel-specific machine data Number MD Name Unit Name, Miscellaneous Activated HW / function Standard value Minimum value Maximum value D type User class SINUMERIK 802C 6-96 6FC5 597–3AA20–0BP2 (01.02)

-

Page 97: Axis-Specific Machine Data

_always 0, 0 BYTE 30350 SIMU_AX_VDI_OUTPUT Output of axis signals with simulation axes POWER ON _always BOOLEAN 30600 FIX_POINT_POS mm, de- Fixed-value positions of axis with G75 (position no.) POWER ON grees _always DOUBLE SINUMERIK 802C 6-97 6FC5 597–3AA20–0BP2 (01.02)

-

Page 98

RESET rev/min _always 2000. plus DOUBLE 32070 CORR_VELO Axis velocity for handwheel override, ext. ZO, cont. dressing, distance control RESET _always plus DWORD 32100 AX_MOTION_DIR Traversing direction (not control direction) POWER ON _always DWORD SINUMERIK 802C 6-98 6FC5 597–3AA20–0BP2 (01.02) -

Page 99

Approach reference point in minus direction RESET _always BOOLEAN 34020 REFP_VELO_SEARCH_CAM mm/min, Reference point approach velocity RESET rev/min _always 5000.0 plus DOUBLE 34030 REFP_MAX_CAM_DIST mm, deg. Maximum distance to reference cam RESET _always 10000.0 plus DOUBLE SINUMERIK 802C 6-99 6FC5 597–3AA20–0BP2 (01.02) -

Page 100

SPIND_VELO_LIMIT rev/min Maximum spindle speed POWER ON _always 10000 plus DOUBLE 35110 GEAR_STEP_MAX_VELO rev/min Maximum speed for gear change (gear stage no.): 0..5 NEW CONF _always 500, 500, 1000, 2000, 4000, plus DOUBLE 8000 SINUMERIK 802C 6-100 6FC5 597–3AA20–0BP2 (01.02) -

Page 101

DOUBLE 35410 SPIND_OSCILL_ACCEL rev/s^2 Acceleration during reciprocating NEW CONF _always DOUBLE 35430 SPIND_OSCILL_START_DIR – Starting direction during reciprocation RESET 0–2: As last direction of rotation (zero–speed M3) M3 direction M4 direction _always BYTE SINUMERIK 802C 6-101 6FC5 597–3AA20–0BP2 (01.02) -

Page 102

2nd software limit switch plus RESET _always 100000000 DOUBLE 36200 AX_VELO_LIMIT mm/min, Threshold value for velocity monitoring NEW CONF rev/min (control parameter set no.): 0…5 _always 11500., 11500., 11500., plus DOUBLE 11500., … SINUMERIK 802C 6-102 6FC5 597–3AA20–0BP2 (01.02) -

Page 103: Setting Data

HW / function Standard value Minimum value Maximum value D type User class 41110 JOG_SET_VELO mm/min Axis speed for JOG Immediately _always plus DOUBLE 41200 JOG_SPIND_SET_VELO rev/min Speed for spindle JOG mode Immediately _always plus DOUBLE SINUMERIK 802C 6-103 6FC5 597–3AA20–0BP2 (01.02)

-

Page 104

Progr. spindle speed limitation G26 Immediately _always 1000 plus DOUBLE 43230 SPIND_MAX_VELO_LIMS rev/min Spindle speed limitation with G96 Immediately _always plus DOUBLE 52011 STOP_CUTCOM_STORE Alarm response for TRC and feedforward stop Immediately BOOLEAN SINUMERIK 802C 6-104 6FC5 597–3AA20–0BP2 (01.02) -

Page 105: Plc User Interface Signals

60 s clock (alternating ‘0’ for 30 s, then ‘1’ for 30 s) SM 0.5 1 s clock (alternating ‘0’ for 0.5 s, then ‘1’ for 0,5 s) SM 0.6 PLC cycle clock (alternating one cycle ‘0’, then one cycle ‘1’) SINUMERIK 802C 6-105 6FC5 597–3AA20–0BP2 (01.02)

-

Page 106: Retentive Data Area

Technical Appendix PLC user interface signals Note All empty user interface fields in the following tables are Reserved for SIEMENS and may neither be written, nor evaluated by the user! All fields with a “0” contain the value “logic =”.

-

Page 107: Nck Signals

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 EMER- GENCY 27000000 STOP STOP active 27000001 27000002 Drive ready Ambient tempera- alarm 27000003 ture ture present present alarm SINUMERIK 802C 6-107 6FC5 597–3AA20–0BP2 (01.02)

-

Page 108: Channel Signals

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Activate Activate Activate dry run Single 32000000 feed Block Activate Activate Referenc- 32000001 Program Test Activate Skip 32000002 Block 32000003 SINUMERIK 802C 6-108 6FC5 597–3AA20–0BP2 (01.02)

-

Page 109

Axis 2 in WCS 32001004 Traversing keys Rapid Traversing Feed Activate handwheel traverse key lock override – Stop Axis 2 in WCS 32001005 Machine function continu- 1000 INC 100 INC 10 INC 1 INC 32001006 32001007 SINUMERIK 802C 6-109 6FC5 597–3AA20–0BP2 (01.02) -

Page 110

Reset active aborted stopped waiting running NCK alarm with alarm 33000004 All axes All axes stop of ma- stop of ma- channel– chining stopped refer- specific present enced present 33000005 33000006 33000007 SINUMERIK 802C 6-110 6FC5 597–3AA20–0BP2 (01.02) -

Page 111

1 INC 33001006 33001007 Axis 3 in WCS 33001008 Traversing command Handwheel active plus minus Axis 3 in WCS 33001009 Active machine function continu- 1000 INC 100 INC 10 INC 1 INC 33001010 33001011 SINUMERIK 802C 6-111 6FC5 597–3AA20–0BP2 (01.02) -

Page 112

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Dynamic M functions 25001000 Dynamic M functions 25001001 Dynamic M functions 25001002 Dynamic M functions 25001012 25001013 SINUMERIK 802C 6-112 6FC5 597–3AA20–0BP2 (01.02) -

Page 113: Axis/Spindle Signals

Interface PLC –––––> NCK Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Feed override 380×0000 Axes/ 380×0001 Override Position Follow–up spindle enabled encoder 1 mode lock SINUMERIK 802C 6-113 6FC5 597–3AA20–0BP2 (01.02)

-

Page 114

Signals to spindle [r/w] Data block Interface PLC –––––> NCK Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Gear is Actual gear stage 38032000 changed (spindle) Spindle feed SINUMERIK 802C 6-114 6FC5 597–3AA20–0BP2 (01.02) -

Page 115

390×0007 Signals from axis 3900…3903 Signals from axis [r] Data block Interface NCK –––––> PLC Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 390×1000 (axis) SINUMERIK 802C 6-115 6FC5 597–3AA20–0BP2 (01.02) -

Page 116: Signals From/To Mmc

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Dry run 17000000 feed (MMC –––> selected selected PLC) Program Feed test override 17000001 selected for rapid traverse (MMC ––> PLC) selected Select 17000002 Skip SINUMERIK 802C 6-116 6FC5 597–3AA20–0BP2 (01.02)

-

Page 117

19001002 (MMC –––> PLC) 19001003 Axis number for handwheel 1 (MMC –––> Machine PLC) axis 19001004 Axis number for handwheel 2 (MMC –––> Machine PLC) axis 19001005 (MMC –––> PLC) 19001006 (MMC –––> PLC) SINUMERIK 802C 6-117 6FC5 597–3AA20–0BP2 (01.02) -

Page 118: Machine Control Panel Signals (Mcp Signals)

10000005 ”0” ”0” ”0” Control signals to MCP 1100 [r/w] Signals to MCP Interface PLC –––––> MCP Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 SINUMERIK 802C 6-118 6FC5 597–3AA20–0BP2 (01.02)

-

Page 119: Plc Machine Data

Signals from NCK [r] Data block Interface NCK –––––> PLC Byte 45001000 Hex value (BYTE) 45001001 Hex value (BYTE) 45001002 Hex value (BYTE) 45001003 Hex value (BYTE) 45001030 Hex value (BYTE) 45001031 Hex value (BYTE) SINUMERIK 802C 6-119 6FC5 597–3AA20–0BP2 (01.02)

-

Page 120: User Alarm

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Activation of alarm no. 16000000 700007 700006 700005 700004 700003 700002 700001 700000 Activation of alarm no. 16000001 SINUMERIK 802C 6-120 6FC5 597–3AA20–0BP2 (01.02)

-

Page 121

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Feed Read–in NC start lock disable inhibited 16002000 PLC– NOT– of all axes STOP 16002001 16002002 16002003 SINUMERIK 802C 6-121 6FC5 597–3AA20–0BP2 (01.02) -

Page 122

Data block Interface PLC –––––> MMC Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 570×0000 Axis actual value (REAL) 570×0004 Axis distance to go (REAL) SINUMERIK 802C 6-122 6FC5 597–3AA20–0BP2 (01.02) -

Page 123: Application Note: Unipolar Spindle Control

Application note: unipolar spindle control General With SINUMERIK 802C, the spindle speed setpoint is generally output in the range from –10V through +10V (S… M3 or M4). A setpoint output with positive polarity only (0V through +10V) and an additional direction signal, as it is required for unipolar frequency converters, can be realized via appropriate programming in the NC part program and in the PLC user program (additionally, two M commands for switching the direction signal and M3 for starting rotation).

-

Page 124

Technical Appendix Application note: unipolar spindle control This sheet has been left empty for your notes. SINUMERIK 802C 6-124 6FC5 597–3AA20–0BP2 (01.02) -

Page 125: Manual Machine

PG, PC or laptop with operative WinPCIN program (if not yet installed, install it from the Toolbox) CD ROM with up–to–date toolbox for Sinumerik 802S/C MM At least software version 03.01.06–802S/C or higher must be installed on the Sinumerik 802S/C (otherwise, the operating system must be updated). SINUMERIK 802C 7-125 6FC5 597–3AA20–0BP2 (01.02)

-

Page 126: Loading The Software

Use the WinPCIN software to start the transfer of the file “manmach.arc” from the Toolbox CD ROM (in some cases, first the file has to be copied to the hard disk, as not every WinPCIN version can access a CD ROM drive). SINUMERIK 802C 7-126 6FC5 597–3AA20–0BP2 (01.02)

-

Page 127

(depending on the amount of data). At the completion of this process, the relevant machine data and – in some cases – also the standard PLC program must be adapted accordingly, depending on the hardware confirgura- tion. SINUMERIK 802C 7-127 6FC5 597–3AA20–0BP2 (01.02) -

Page 128: Switching The User Interface

ManMach_3DIO.ptp: designed as described in Section 7.8 (with I/O modules) Switching the user interface From “Manual Machine” to Siemens standard: To switch to the Siemens standard user interface, proceed as follows (always start from the 2nd extension of the basic menu): Press the key to call the password input screenform.

-

Page 129: Additional Machine Data

Manual Machine Additional machine data In the Siemens standard user interface: Press the key to call the main selection screenform. Press the “Diagnosis” function key. Press the key to extend the function key bar. Press the “Language changeover” function key to switch to the alternative language.

-

Page 130: Operation Without Machine Control Panel (Mcp)

Pin 5 DI 11 I 1.4 X2004 Pin 6 DI 12 I 1.5 X2004 Pin 7 DI 13 I 1.6 Spindle jogging key X2004 Pin 8 DI 14 I 1.7 X2004 Pin 9 DI 15 SINUMERIK 802C 7-130 6FC5 597–3AA20–0BP2 (01.02)

-

Page 131

Pin 9 DI 15 All inputs marked with a * possess an inverted logics, i.e. their meanings refer to the signal status “LOW”, and with all of the remaining inputs to the signal status “HIGH”. SINUMERIK 802C 7-131 6FC5 597–3AA20–0BP2 (01.02) -

Page 132: Assignment Of The Digital Outputs:

O 3.3 X2006 Pin 5 DO 11 O 3.4 X2006 Pin 6 DO 12 O 3.5 X2006 Pin 7 DO 13 O 3.6 X2006 Pin 8 DO 14 O 3.7 X2006 Pin 9 DO 15 SINUMERIK 802C 7-132 6FC5 597–3AA20–0BP2 (01.02)

-

Page 133: Default Assignment Of Special Data For The «Manual Machine»

MD 12010 $MN_OVR_FACTOR_AX_SPEED[8] MD 12010 $MN_OVR_FACTOR_AX_SPEED[9] MD 12010 $MN_OVR_FACTOR_AX_SPEED[10] 0.95 MD 12010 $MN_OVR_FACTOR_AX_SPEED[11] MD 12010 $MN_OVR_FACTOR_AX_SPEED[12] 1.05 MD 12010 $MN_OVR_FACTOR_AX_SPEED[13] MD 12010 $MN_OVR_FACTOR_AX_SPEED[14] MD 12010 $MN_OVR_FACTOR_AX_SPEED[15] MD 12010 $MN_OVR_FACTOR_AX_SPEED[16] MD 12010 $MN_OVR_FACTOR_AX_SPEED[17] MD 12010 $MN_OVR_FACTOR_AX_SPEED[18] SINUMERIK 802C 7-133 6FC5 597–3AA20–0BP2 (01.02)

-

Page 134

MD 12050 $MN_OVR_FACTOR_RAPID_TRA[9] MD 12050 $MN_OVR_FACTOR_RAPID_TRA[10] 0.95 MD 12050 $MN_OVR_FACTOR_RAPID_TRA[11] MD 12050 $MN_OVR_FACTOR_RAPID_TRA[12] MD 12050 $MN_OVR_FACTOR_RAPID_TRA[13] MD 12050 $MN_OVR_FACTOR_RAPID_TRA[14] MD 12050 $MN_OVR_FACTOR_RAPID_TRA[15] MD 12050 $MN_OVR_FACTOR_RAPID_TRA[16] MD 12050 $MN_OVR_FACTOR_RAPID_TRA[17] MD 12202 $MN_PERMANENT_FEED[0] MD 12202 $MN_PERMANENT_FEED[1] 1000 SINUMERIK 802C 7-134 6FC5 597–3AA20–0BP2 (01.02) -

Page 135

MD 35040 $MA_SPIND_ACTIVE_AFTER_RESET[AX4] MD 35160 $MA_SPIND_EXTERN_VELO_LIMIT[AX4] Setting data: MD 41110 $SN_JOG_SET_VELO MD 41120 $SN_JOG_REV_SET_VELO MD 41130 $SN_JOG_ROT_AX_SET_VELO MD 41200 $SN_JOG_SPIND_SET_VELO MD 42100 $SC_DRY_RUN_FEED MD 42440 $SC_FRAME_OFFSET_INCR_PROG MD 42442 $SC_TOOL_OFFSET_INCR_PROG MD 43300 $SA_ASSIGN_FEED_PER_REV_SOURCE[AX4] R parameters: R[4] SINUMERIK 802C 7-135 6FC5 597–3AA20–0BP2 (01.02) -

Page 136

Manual Machine Default assignment of special data for the “Manual machine” SINUMERIK 802C 7-136 6FC5 597–3AA20–0BP2 (01.02) -

Page 137

ENC and operator panel power supply (X1), 2-35 Encoder matching to spindles, 4-77 Spindel data, Spindle modes, 4-85 Grounding, 2-36 Updating the System Software, 5-91 Grounding diagram, 2-36 Installing and Dismantling the SINUMERIK 802C, 2-15 SINUMERIK 802C Index-137 6FC5 597–3AA20–0BP2 (01.02) -

Page 138

Index notice SINUMERIK 802C Index-138 6FC5 597–3AA20–0BP2 (01.02) -

Page 139

Suggestions SIEMENS AG Corrections A&D MC BMS for Publication/Manual: Postfach 3180 SINUMERIK 802C D–91050 Erlangen (Tel. +49 180 / 5050 – 222 [Hotline] Fax +49 9131 / 98 – 2176 [Documentation] Mailto: motioncontrol.docu@erlf.siemens.de) Manufacturer Documentation Start-Up From Order No.: 6FC5597-3AA20-0BP2… -

Page 141

SINUMERIK 802S and 802C Document Structure General Documentation: Catalog SINUMERIK 802S SINUMERIK 802C Turning, Milling User Manual: Operation and Programming SINUMERIK 802S SINUMERIK 802S SINUMERIK 802C SINUMERIK 802C Turning Milling User Manual: Diagnostics Guide SINUMERIK 802S SINUMERIK 802C Turning, Milling Technical Manual: Start–Up… -

Page 142

Siemens AG Automatisierungs- und Antriebstechnik Motion Control Systems © Siemens AG 2002 Postfach 3180, D – 91050 Erlangen Subject to change without prior notice Bundesrepublik Deutschland Order No.: 6FC5597-3AA20-0BP2 Printed in the Federal Republic of Germany www.ad.siemens.de…

Start-Up 01/2002 Edition

SINUMERIK 802C

SINUMERIK 802C

Start–Up

|

Valid for |

|

|

Control |

Software Version |

|

SINUMERIK 802C |

3 |

01.2002 Edition

Numerical Control System 1

Installing the Control System 2

Index

11.02 6FC5298-6CA00-0AG3

|

3ls |

SINUMERIK Documentation |

Printing history

Brief details of this edition and previous editions are listed below.

IThe status of each edition is shown by the code in the ”Remarks” column.

Status code in the “Remarks” column:

A . . . . . New documentation.

B . . . . . Unrevised reprint with new Order No. C . . . . . Revised edition with new status.

If actual changes have been made on the page since the last edition, this is indicated by a new edition coding in the header on the page.

|

Edition |

Order–No. |

Remark |

|

04.00 |

6FC5597-3AA20-0BP2 |

A |

|

01.02 |

6FC5597-3AA20-0BP2 |

C |

This Manual is included on the documentation on CD–ROM (DOCONCD)

Edition Order–No. Remark

C

Trademarks

SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr and SIMODRIVEr are registered trademarks of Siemens. Third parties using for their own purposes any other names in this document which refer to trademarks might infringe upon the rights of trademark owners.

This publication was produced with Interleaf V 7

The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Offenders will be liable for demages. All rights, including rights created by patent grant or registration of utility model or design, are reserved.

Siemens AG 2002. All rights reserved.

Other functions not described in this documentation might be executable in the control. This does not, however, represent an obligation to supply such functions with a new control or when servicing.

We have checked that the contents of this document correspond to the hardware and software described. Nonetheless, differences might exist and therefore we cannot guarantee that they are completely identical. The information contained in this document is, however, reviewed regularly and any necessary changes will be included in the next edition. We welcome suggestions for improvement.

Subject to change without prior notice.

|

Bestell-Nr. 6FC5597-3AA20-0BP2 |

Siemens–Aktiengesellschaft |

|

Printed in the Federal Republic of Germany |

Safety notices

This Manual contains notices intended to ensure your personal safety and to avoid material damage. The notices are highlighted by a warning triangle and, depending on the degree of hazard, represented as shown below:

Danger

!indicates that loss of life, severe personal injury or substantial material damage will result if the appropriate precautions are not taken.

Warning

!indicates that loss of life, severe personal injury or substantial material damage may result if the appropriate precautions are not taken.

Caution

!indicates that minor personal injury or material damage may result if the appropriate precautions are not taken.

Caution

without a warning triangle means that a material damage can occur if the appropriate precautions are not taken.

Attention

means that an undesirede event or status can occur if the appropriate note is not observed.

Note

is used to draw your special attention to an important information on the product, the handling of the product or the corresponding part of the documentation.

Qualified personnel

Start–up and operation of a device may only be carried out by qualified personnel. Qualified personnel as referred to in the safety notices provided in this Manual are persons who are authorized to start up, ground and tag devices, systems and circuits according to the relevant safety standards.

Usage as per intended purpose

Please observe the following:

Warning

!The device may only be used for the cases of application, as intended by the Catalog, and only in conjunction with third–party devices and components recommended or approved by Siemens.

The proper and safe operation of the product requires transport, storage and installation according to the relevant instructions and qualified operation and maintenance at the prescribed intervals.

|

SINUMERIK 802C |

v |

|

6FC5 597–3AA20–0BP2 (01.02) |

Table of Contents

Table of Contents

|

1 |

SINUMERIK 802C Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

|

|

1.1 |

Components of the SINUMERIK 802C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

|

|

1.2 |

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-12 |

|

|

2 |

Installing the Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-15 |

|

|

2.1 |

Installing and removing the SINUMERIK 802C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-15 |

|

|

2.2 |

Interfaces and cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-18 |

|

|

2.3 |

Connecting the individual components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-21 |

|

|

2.3.1 |

Connecting the operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-21 |

|

|

2.3.2 |

Connecting the feed drives and the spindle (X7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-23 |

|

|

2.3.3 |

Connecting the measuring systems (X3 … X6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-26 |

|

|

2.3.4 |

Configuration of the RS232 interface connection (X8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-27 |

|

|

2.3.5 |

Connecting handwheels (X10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-29 |

|

|

2.3.6 |

Connecting NCREADY (X20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-30 |

|

|

2.3.7 |

Connecting the digital inputs and outputs (X2003 … X2006) . . . . . . . . . . . . . . . . . . . . . . . . . |

2-31 |

|

|

2.4 |

ENC and operator panel power supply (X1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-35 |

|

|

2.5 |

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-36 |

|

|

2.6 |

LEDs and operating elements on the ENC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-38 |

|

|

3 |

Installing the Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-39 |

|

|

4 |

Start-Up |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-41 |

|

4.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-41 |

|

|

4.1.1 |

Access levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-42 |

|

|

4.1.2 |

Structure of machine data (MD) and setting data (SD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-43 |

|

|

4.1.3 |

Handling machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-44 |

|

|

4.1.4 |

Data saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-44 |

|

|

4.2 |

Turning on and booting the control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-46 |

|

|

4.2.1 |

Boot messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-48 |

|

|

4.3 |

Starting up the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-49 |

|

|

4.3.1 |

Commissioning of the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-49 |

|

|

4.3.2 |

Start–up modes of the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-51 |

|

|

4.3.3 |

PLC alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-52 |

|

|

4.3.4 |

Machine control panel (MCP) layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-56 |

|

|

4.3.5 |

PLC programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-57 |

|

|

4.3.6 |

Instruction set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-61 |

|

|

4.3.7 |

Programm organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-68 |

|

|

4.3.8 |

Data organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-69 |

|

|

4.3.9 |

Interface to the control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-69 |

|

|

4.3.10 |

Testing and monitoring the user program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-69 |

|

|

4.4 |

PLC applications “Download/Upload/Copy/Compare” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-70 |

|

|

4.5 |

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-72 |

|

|

4.6 |

Technology Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-72 |

|

|

4.7 |

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-73 |

|

|

4.7.1 |

Entering the general machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-73 |

|

|

4.7.2 |

Starting up the axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-75 |

|

|

4.7.3 |

Starting up the spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-85 |

|

|

4.7.4 |

Completing the Start–Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-87 |

|

|

4.7.5 |

Cycle start–up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-88 |

|

|

4.8 |

Series machine start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-89 |

|

vi |

SINUMERIK 802C |

|

6FC5 597–3AA20–0BP2 (01.02) |

Table of Contents

|

5 |

Software Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-91 |

|

|

5.1 |

Updating the system software using a PC/PG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-91 |

|

|

5.2 |

Updating the system software incl. user data without using a PC/PG . . . . . . . . . . . . . . . . . . |

5-92 |

|

|

5.3 |

Update errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-93 |

|

|

6 |

Technical Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-94 |

|

|

6.1 |

List of machine and setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-94 |

|

|

6.1.1 |

Display machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-94 |

|

|

6.1.2 |

General machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-96 |

|

|

6.1.3 |

Channel-specific machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-96 |

|

|

6.1.4 |

Axis-specific machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-97 |

|

|

6.1.5 |

Setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-103 |

|

|

6.2 |

PLC user interface signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-105 |

|

|

6.2.1 |

Address ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-105 |

|

|

6.2.2 |

Retentive data area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-106 |

|

|

6.2.3 |

NCK signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-107 |

|

|

6.2.4 |

Channel signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-108 |

|

|

6.2.5 |

Axis/spindle signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-113 |

|

|

6.2.6 |

Signals from/to MMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-116 |

|

|

6.2.7 |

Machine control panel signals (MCP signals) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-118 |

|

|

6.2.8 |

PLC machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-119 |

|

|

6.2.9 |

User alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-120 |

|

|

6.3 |

Application note: unipolar spindle control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-123 |

|

|

7 |

Manual Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-125 |

|

|

7.1 |

Hardware and software requirements for the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-125 |

|

|

7.2 |

Loading the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-126 |

|

|

7.3 |

Switching the user interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-128 |

|

|

7.4 |

Switching the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-128 |

|

|

7.5 |

Additional machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-129 |

|

|

7.6 |

Input limitations with regard to the user interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-129 |

|

|

7.7 |

Operation without machine control panel (MCP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-130 |

|

|

7.8 |

I/O assignment in the standard PLC program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-130 |

|

|

7.8.1 |

Assignment of the digital inputs: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-130 |

|

|

7.8.2 |

Assignment of the digital outputs: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-132 |

|

|

7.9 |

Default assignment of special data for the “Manual machine” . . . . . . . . . . . . . . . . . . . . . . . . |

7-133 |

|

SINUMERIK 802C |

vii |

|

6FC5 597–3AA20–0BP2 (01.02) |

Table of Contents

notice

|

viii |

SINUMERIK 802C |

|

6FC5 597–3AA20–0BP2 (01.02) |

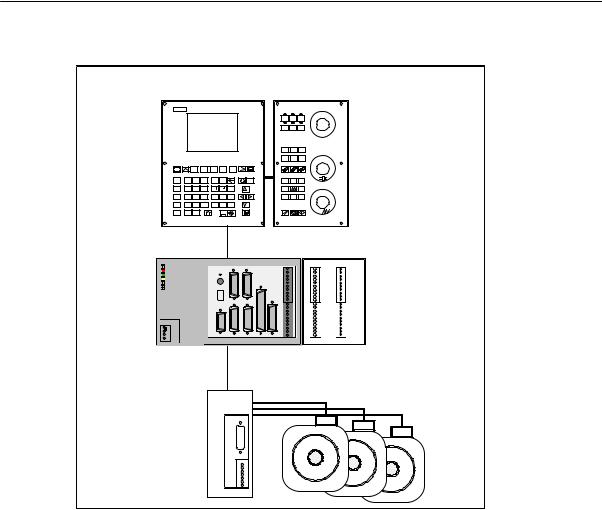

|

SINUMERIK 802C Control System |

1 |

1.1Components of the SINUMERIK 802C

What is SINUMERIK?

The SINUMERIK 802C is a microprocessor–controlled numerical control system for simple machine tools with stepper motor drives .

Hardware components

It consists of the following hardware components:

SENC: Control component for a maximum of 3 analog axes and an analog interface for a main spindle drive (ENC = Economical Numerical Control)

SOP020: NC operator panel with graphics display and keyboard

SMCP: machine control panel

SDI/O16: 16 binary inputs/outputs each extendable to max. 64 by using 4 modules

|

SINUMERIK 802C |

1-9 |

|

6FC5 597–3AA20–0BP2 (01.02) |

SINUMERIK 802C Control System

1.1Components of the SINUMERIK 802C

OP020 MCP

|

INC JOG |

REF |

|||||||||||

|

AUTO SBL |

MDA |

|||||||||||

|

M |

||||||||||||

|

N |

X |

Y |

Z |

T |

D |

VM |

+X |

% |

||||

|

G E |

7 > |

8 |

9 + |

K |

Pg |

-Z |

+Z |

|||||

|

F O |

4 < |

5 |

6 |

LA _ |

P |

R |

-X |

|||||

|

S Q |

1 |

2 |

3 = |

AF U B V C W |

Pg |

|||||||

|

M H |

0 |

$ |

INS |

% |

||||||||

|

ENCODER1ENCODER2 |

X10 |

X2003 |

X2005 |

|||||||||

|

X3 |

X4 |

MPG |

IN |

OUT |

||||||||

|

ERR |

L+ |

|||||||||||

|

0 |

0 |

|||||||||||

|

POK |

S2 |

1 |

1 |

|||||||||

|

DIAG |

S3 |

2 |

2 |

|||||||||

|

3 |

3 |

|||||||||||

|

4 |

4 |

|||||||||||

|

5 |

5 |

|||||||||||

|

D15 |

6 |

6 |

||||||||||

|

7 |

7 |

|||||||||||

|

M |

M |

|||||||||||

|

L+ |

||||||||||||

|

8 |

8 |

|||||||||||

|

9 |

9 |

|||||||||||

|

10 |

10 |

|||||||||||

|

DC24V X1 |

11 |

11 |

||||||||||

|

12 |

12 |

|||||||||||

|

13 |

13 |

|||||||||||

|

PE |

14 |

14 |

||||||||||

|

15 |

15 |

|||||||||||

|

M |

M |

M |

||||||||||

|

L+ |

||||||||||||

|

M |

RS232ENCODER3SPINDLEAXIS |

OPI |

DI |

X2004 |

X2006 |

|||||||

|

X2 |

X5 |

X6 |

X7 |

X8 |

X20 |

|||||||

|

ENC |

DI/O |

External analog drive

Fig. 1-1 SINUMERIK 802C hardware components (example configuration)

Software components

The SINUMERIK 802C comprises the following software components, which can be ordered:

SSystem software on the permanent flash memory of the ENC

–Boot software,

loads the remaining system software from the permanent memory into the user memory (DRAM) and starts the system.

–MMC software (Man Machine Communication), implements all operating functions

–NCK software (NC Kernel)

implements all NC functions. This software controls an NC channel with a maximum of 3 movement axes and a spindle.

–PLC software (Programmable Logic Control), executes the integrated PLC user program cyclically.

–Integrated PLC user program

intended to adjust the SINUMERIK 802C to the machine functions (see also Description of Functions “Integrated User Program for SINUMERIK 802C”).

|

1-10 |

SINUMERIK 802C |

|

6FC5 597–3AA20–0BP2 (01.02) |

SINUMERIK 802C Control System

1.1 Components of the SINUMERIK 802C

SToolbox

–WinPCIN transfer program for a PC/PG (programming device) to transfer user data and programs

–Text manager

–Cycle kit for loading into the control system using WinPCIN

–User program library

–Technological machine data files

–Programming tool

SUpdate diskettes

–Update program with operator prompting system

–802C system software, packed, for loading and programming the SINUMERIK 802C via an update program.

User data

User data are:

SMachine data

SSetting data

STool data

SR parameters

SZero offsets

SCompensation data

SPart programs

SStandard cycles

Data saving

Modified user data are saved for at least 50 h after power off or power failure. After then, they might get lost.

Warning

!To avoid data loss, the operator must carry out data saving (see Section 4.1.4).

|

SINUMERIK 802C |

1-11 |

|

6FC5 597–3AA20–0BP2 (01.02) |

SINUMERIK 802C Control System

1.2Technical data

1.2Technical data

Connected load

|

Table 1-1 |

Connected load |

|||||||

|

Parameter |

Min. |

Typ. |

Max. |

Unit |

||||

|

Supply voltage |

20.4 |

28.8 |

V |

|||||

|

Ripple |

3.6 |

Vss |

||||||

|

Current consumption from 24 V |

1 |

A |

* |

|||||

|

Power dissipation of ENC |

15 |

W |

||||||

|

Power dissipation of OP020 |

7 |

W |

||||||

|

Power dissipation of MCP |

— |

|||||||

|

Power dissipation of DI/O16 |

7 |

W |

** |

|||||

|

Start–up current |

2.6 |

A |

||||||

|

* |

Basic configuration of ENC, |

further DI/O16 |

connected |

|||||

|

OP020, MCP and DI/O16, all |

will increase by 0.05 A each. |

|||||||

|

outputs open, |

** |

at nominal load |

||||||

|

current consumption for any |

Weight

|

Table 1-2 |

Weight |

|

|

Component |

Weight [g] |

|

|

ENC component |

900 g |

|

|

DI/O16 component |

350 g |

|

|

OP020 component |

1,800 g |

|

|

MCP component |

1,200 g |

|

Dimensions

|

Table 1-3 |

Component dimensions |

|

|

Component |

Dimensions HxWxD [mm] |

|

|

ENC component |

125 x 200 x 118 |

|

|

DI/O component |

125 x 80 x 118 |

|

|

OP020 component |

300 x 250 x 50 |

|

|

MCP component |

300 x 170 x 50 |

|

|

1-12 |

SINUMERIK 802C |

|

6FC5 597–3AA20–0BP2 (01.02) |

SINUMERIK 802C Control System

1.2 Technical data

Environmental operating conditions

|

Table 1-4 |

Environmental operating conditions |

|

|

Parameter |

||

|

Temperature range |

0…55 °C |

|

|

Permissible relative humidity |

5…95 % without condensation |

|

|

Air pressure |

700…1,060 hPa |

|

The operating conditions comply with IEC 1131-2.

Installation in a housing (e.g. cubicle) is absolutely necessary for operation.

Transport and storage conditions

|

Table 1-5 |

Transport and storage conditions |

|

|

Parameter |

||

|

Temperature range |

Transport: -40…70 °C |

|

|

Storage: –20 … 55 °C |

||

|

Permissible relative air humidity |

5…95 % without condensation |

|

|

Air pressure |

700…1,060 hPa |

|

|

Transport height |

-1,000…3,000 m |

|

|

Free fall in transport package |

v 1,200 mm |

|

Protective quality and degree of protection

Class of protection I to IEC 536.

No PE terminal required.

Foreign matter and water protection to IEC 529.

Sfor ENC and DI/O16: IP 20

Sfor OP020 and MCP: IP 54 front

IP 00 rear

|

SINUMERIK 802C |

1-13 |

|

6FC5 597–3AA20–0BP2 (01.02) |

SINUMERIK 802C Control System

1.2Technical data

|

1-14 |

SINUMERIK 802C |

|

6FC5 597–3AA20–0BP2 (01.02) |

|

Installing the Control System |

2 |

2.1Installing and removing the SINUMERIK 802C

Warning

!Before performing any installation work, always first make sure that the system is disconnected from the mains!

The modules contain electrostatically sensitive devices.

It must be ensured that persons without ESD protection never touch printed circuit boards or components when handling operator and machine control panels.

Approach

Prior to installation, the machine control panel can be provided with a spindle override switch and an emergency stop button. If these are not required, the openings must be covered with the supplied self–adhesive covers.

1.Mount the spindle override switch.

2.Install the operator panel and the machine control panel.

3.Connect the panel using ribbon cable.

4.Install the DIN rail.

5.Connect the ENC and DI/O components.

Note

If you want to connect several DI/O16 components, it may be necessary to remove the right– hand connector from the housing.

6. Slide the components onto the DIN rail, tilt it down and screw it tight.

Removing the control system

The control components are removed as described above in the reverse order.

|

SINUMERIK 802C |

2-15 |

|

6FC5 597–3AA20–0BP2 (01.02) |

Installing the Control System

2.1 Installing and removing the SINUMERIK 802C

Warning

!Before removing the control components, always first make sure that the system is disconnected from the mains!

|

2-16 |

SINUMERIK 802C |

|

6FC5 597–3AA20–0BP2 (01.02) |

Installing the Control System

2.1Installing and removing the SINUMERIK 802C

Mounting dimensions

The dimensions shown below are important for installing the control components:

|

8 |

250 |

170 |

||||||||

|

142 |

||||||||||

|

300 |

||||||||||

|

SubD |

||||||||||

|

142 |

A |

|||||||||

|

F |

||||||||||

|

8 |

234 |

154 |

45 |

|||||||

|

8 |

||||||||||

|

80 |

||||||||||

|

Mounting |

4,8 |

|||||||||

|

482 |

40 |

|||||||||

|

120 |

||||||||||

|

32,5 |

ENCODER1 |

ENCODER2 |

X10 |

X2003 |

X2005 |

|||||

|

IN |

OUT |

|||||||||

|

X3 |

X4 |

MPG |

L+ |

|||||||

|

ERR |

||||||||||

|

0 |

0 |

|||||||||

|

POK |

1 |

1 |

||||||||

|

DIAG |

2 |

2 |

||||||||

|

3 |

3 |

|||||||||

|

4 |

4 |

|||||||||

|

5 |

5 |

|||||||||

|

6 |

6 |

|||||||||

|

57,2 |

7 |

7 |

125 |

|||||||

|

9 |

9 |

|||||||||

|

M |

M |

|||||||||

|

L+ |

||||||||||

|

8 |

8 |

|||||||||

|

10 |

10 |

|||||||||

|

DC24V X1 |

11 |

11 |

||||||||

|

12 |

12 |

|||||||||

|

13 |

13 |

|||||||||

|

20 |

L+ |

14 |

14 |

|||||||

|

M |

15 |

15 |

||||||||

|

L+ |

M |

M |

||||||||

|

M |

RS232 |

ENCODER3 |

SPINDLE |

AXIS |

OPI |

DI |

||||

|

X2 |

X5 |

X6 |

X7 |

X8 |

X20 |

X2004 |

X2006 |

|||

|

200 |

80 |

|||||||||

|

15 |

||||||||||

|

40 |

Fig. 2-1 Mounting dimensions for SINUMERIK 802C

|

SINUMERIK 802C |

2-17 |

|

6FC5 597–3AA20–0BP2 (01.02) |

Installing the Control System

2.2Interfaces and cables

2.2Interfaces and cables

Position of the interfaces and front panel elements

|

ECU |

DI/O16 |

|||||||

|

ENCODER1 ENCODER2 |

X10 |

X2003 |

X2005 |

|||||

|

X3 |

X4 |

MPG |

IN |

OUT |

||||

|

ERR |

L+ |

|||||||

|

0 |

0 |

|||||||

|

POK |

S2 |

1 |

1 |

|||||

|

DIAG |

S3 |

2 |

2 |

|||||

|

3 |

3 |

|||||||

|

4 |

4 |

|||||||

|

5 |

5 |

|||||||

|

D15 |

6 |

6 |

||||||

|

7 |

7 |

|||||||

|

M |

M |

|||||||

|

L+ |

||||||||

|

8 |

8 |

|||||||

|

9 |

9 |

|||||||

|

10 |

10 |

|||||||

|

DC24V X1 |

11 |

11 |

||||||

|

12 |

12 |

|||||||

|

13 |

13 |

|||||||

|

PE |

14 |

14 |

||||||

|

15 |

15 |

|||||||

|

M |

||||||||

|

M |

M |

|||||||

|

L+ |

||||||||

|

M |

RS232 |

ENCODER3 |

SPINDLE |

AXIS |

OPI |

DI |

X2004 |

X2006 |

|

X2 |

X5 |

X6 |

X7 |

X8 |

X20 |

Fig. 2-2 User interfaces

|

MCP |

OP020 |

|

|

Rear |

Rear |

|

|

X1202 |

CFL |

|

|

X1201 |

||

|

LCDsignal |

||

|

X1001 X1002 X1009 |

connector |

Fig. 2-3 Rear of machine control panel and operator panel

|

2-18 |

SINUMERIK 802C |

|

6FC5 597–3AA20–0BP2 (01.02) |

Installing the Control System

2.2 Interfaces and cables

Interfaces

ENC

SX1 power supply terminals (DC24V)

4–pin screw–type terminal block for connecting the 24 V load power supply

SX2 RS232 interface (V24)

9–pin sub–D plug connector

SX3 to X5 measuring system interfaces (ENCODER)

three 15–pin sub–D plug connectors for connecting incremental position encoders (RS422)

SX6 spindle interface (SPINDLE)

9–pin sub–D socket for connecting a spindle drive with analog interface

SX7 drive interface (AXIS)

50–pin sub–D socket connector for connecting the power sections for a maximum of four analog drives including spindle

SX8 operator terminal interface (OPI)

25–pin D–Sub female connector for connecting the operator terminal

SX10 handwheel interface (MPG)

10–pin front connector for connecting the handwheels

SX20 digital inputs (DI)

10–pin front connector for connecting the NC READY relay

DI/O

SX2003 and X2004

10–pin front connector for connecting digital inputs

SX2005 and X2006

10–pin front connector for connecting digital outputs

LEDs

3 LEDs for fault and status displays

Operating elements

Start–up switch S

|

SINUMERIK 802C |

2-19 |

|

6FC5 597–3AA20–0BP2 (01.02) |

Installing the Control System

2.2Interfaces and cables

Connecting cables

The components are wired up as shown in the Connection Diagram 2-4. For the cables required, please refer to the diagram below.

|

DC24V |

X1 |

L+ |

||||||||

|

M |

Wire (1.0…2.5) |

|||||||||

|

ECU |

||||||||||

|

Machine |

||||||||||

|

RS232 |

Control |

|||||||||

|

X2 |

Panel |

|||||||||

|

RS232 |

Op. Panel |

|||||||||

|

1) |

||||||||||

|

OPI |

flat or round |

|||||||||