- Manuals

- Brands

- Siemens Manuals

- Control Systems

- SINUMERIK 802C

Manuals and User Guides for Siemens SINUMERIK 802C. We have 3 Siemens SINUMERIK 802C manuals available for free PDF download: Manual, Technical Manual, Diagnostics Manual

Siemens SINUMERIK 802C Manual (142 pages)

Brand: Siemens

|

Category: Control Systems

|

Size: 0.76 MB

Table of Contents

-

Table of Contents

6

-

1 SINUMERIK 802C Control System

9

-

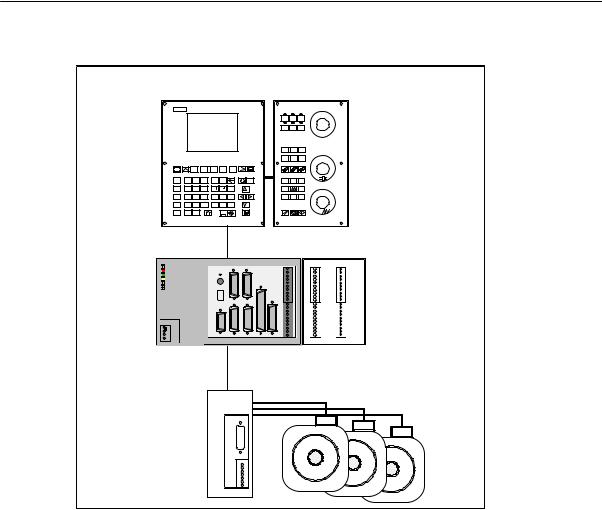

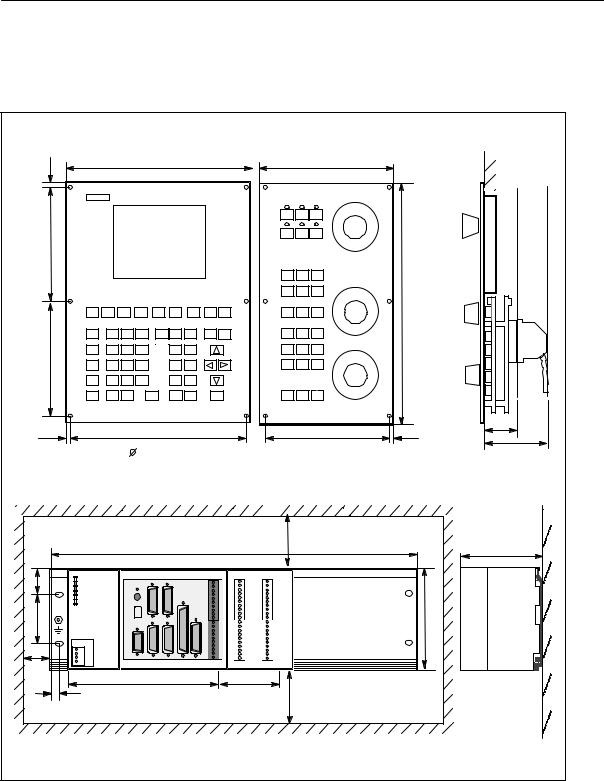

Components of the SINUMERIK 802C

9

-

Technical Data

12

-

-

2 Installing the Control System

15

-

Installing and Removing the SINUMERIK 802C

15

-

Interfaces and Cables

18

-

Connecting the Individual Components

21

-

Connecting the Operator Panel

21

-

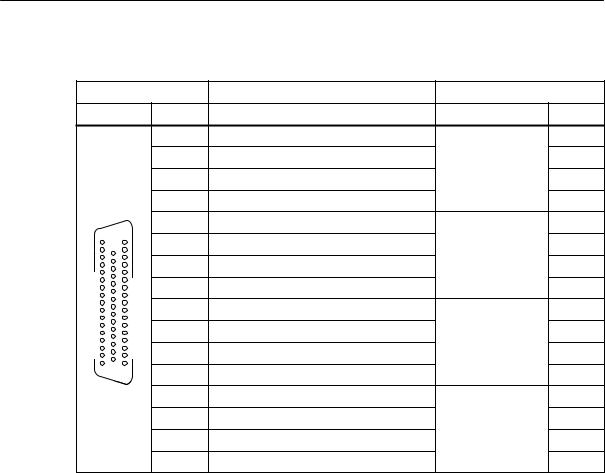

Connecting the Feed Drives and the Spindle (X7)

23

-

Connecting the Measuring Systems (X3 … X6)

26

-

Configuration of the RS232 Interface Connection (X8)

27

-

Connecting Handwheels (X10)

29

-

Connecting NCREADY (X20)

30

-

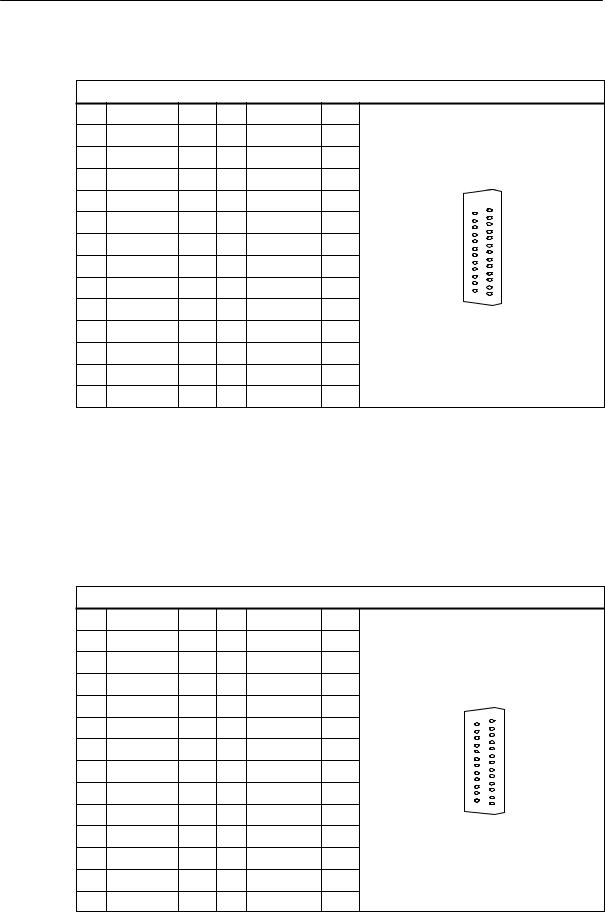

Connecting the Digital Inputs and Outputs (X2003

31

-

ENC and Operator Panel Power Supply (X1)

35

-

Grounding

36

-

Leds and Operating Elements on the ENC

38

-

-

3 Installing the Drives

39

-

4 Start-Up

41

-

General

41

-

Access Levels

42

-

Structure of Machine Data (MD) and Setting Data (SD)

43

-

Handling Machine Data

44

-

Data Saving

44

-

Turning on and Booting the Control System

46

-

Boot Messages

48

-

Starting up the PLC

49

-

Commissioning of the PLC

49

-

Start-Up Modes of the PLC

51

-

PLC Alarms

52

-

Machine Control Panel (MCP) Layout

56

-

PLC Programming

57

-

Instruction Set

61

-

Programm Organization

68

-

Data Organization

69

-

Interface to the Control System

69

-

Testing and Monitoring the User Program

69

-

PLC Applications «Download/Upload/Copy/Compare

70

-

User Interface

72

-

Technology Setting

72

-

Commissioning

73

-

Entering the General Machine Data

73

-

Starting up the Axes

75

-

Starting up the Spindle

85

-

Completing the Start-Up

87

-

Cycle Start-Up

88

-

Series Machine Start-Up

89

-

Update

93

-

-

6 Technical Appendix

94

-

General Machine Data

96

-

Axis-Specific Machine Data

97

-

Setting Data

103

-

PLC User Interface Signals

105

-

Retentive Data Area

106

-

NCK Signals

107

-

Channel Signals

108

-

Axis/Spindle Signals

113

-

Signals From/To MMC

116

-

Machine Control Panel Signals (MCP Signals)

118

-

PLC Machine Data

119

-

User Alarm

120

-

Application Note: Unipolar Spindle Control

123

-

-

7 Manual Machine

125

-

Loading the Software

126

-

Switching the User Interface

128

-

Additional Machine Data

129

-

Operation Without Machine Control Panel (MCP)

130

-

Assignment of the Digital Outputs:

132

-

Default Assignment of Special Data for the «Manual Machine»

133

-

-

Advertisement

Siemens SINUMERIK 802C Technical Manual (130 pages)

Start-Up

Brand: Siemens

|

Category: Controller

|

Size: 1.1 MB

Table of Contents

-

Table of Contents

7

-

1 SINUMERIK 802C Base Line Control System

9

-

Components of the SINUMERIK 802C Base Line

9

-

Technical Data

11

-

-

2 Installing the Control System

13

-

Installing and Dismantling the SINUMERIK 802C Base Line

13

-

Interfaces and Cables

16

-

Connecting the Individual Components

20

-

Connecting the Feed Drives and the Spindle (X7)

20

-

Connecting the Measuring Systems (X3

23

-

Configuration of the RS232 Interface Connection (X2)

24

-

Connecting Handwheels (X10)

26

-

Connecting NCREADY (X20)

27

-

Connecting the Digital Inputs (X100

29

-

Power Supply for CNC (X1)

33

-

Leds and Other Elements on CNC

34

-

-

3 Installing the Drives

37

-

4 Start-Up

39

-

General

39

-

Access Levels

40

-

Structure of Machine Data (MD) and Setting Data (SD)

41

-

Handling of Machine Data

42

-

Data Saving

42

-

Turning on and Booting the Control System

44

-

Boot Messages

46

-

Starting up the PLC

47

-

Commissioning of the PLC

48

-

Start-Up Modes of the PLC

49

-

PLC Alarms

50

-

Machine Control Panel Area Layout

54

-

PLC Programming

56

-

Instruction Set

59

-

Program Organization

66

-

Data Organization

67

-

Interface to the Control System

67

-

Testing and Monitoring the User Program

67

-

PLC Applications «Download/Upload/Copy/Compare

68

-

User Interface

70

-

Technology Setting

70

-

Commissioning

71

-

Entering the General Machine Data

71

-

Starting up the Axes

73

-

Starting up the Spindle

82

-

Completing the Start-Up

84

-

Cycle Start-Up

84

-

Series Machine Start

85

-

-

5 Software Update

87

-

Updating the System Software Using a PC

87

-

Update Errors

88

-

-

6 Technical Appendix

89

-

List of Machine and Setting Data

89

-

Display Machine Data

90

-

General Machine Data

92

-

Channel-Specific Machine Data

93

-

Axis-Specific Machine Data

94

-

Setting Data

103

-

PLC User Interface Signals

104

-

Address Ranges

104

-

Retentive Data Area

105

-

CNC Signals

106

-

Channel Signals

108

-

Axis/Spindle Signals

115

-

Signals From/To MMC

118

-

Machine Control Panel Signals (MCP Signals)

120

-

PLC Machine Data

121

-

User Alarm

123

-

Unipolar Spindle

125

-

Siemens SINUMERIK 802C Diagnostics Manual (115 pages)

Brand: Siemens

|

Category: Control Systems

|

Size: 0.51 MB

Table of Contents

-

Table of Contents

7

-

Overview of NCK Alarms

10

-

Cycle Alarms

88

-

PLC Alarms

93

-

Action List

96

-

Glossary / Abbreviations

105

-

Abbreviations

105

-

Glossary

111

-

Advertisement

Advertisement

Related Products

-

Siemens SINUMERIK 808D

-

Siemens SINUMERIK 808D sl

-

Siemens SINUMERIK 802S

-

Siemens Sinumerik 801

-

Siemens SINUMERIK 840DiE

-

Siemens SINUMERIK 840DE SL

-

Siemens SINUMERIK 828D sl

-

Siemens YASKAWA 830DI

-

Siemens SINUMERIK 840DE pl

-

Siemens SINUMERIK 810DE

Siemens Categories

Controller

Control Unit

Industrial Equipment

Washer

Switch

More Siemens Manuals

Diagnostics Guide 01/02 Edition

SINUMERIK 802S/802C

SINUMERIK 802S

SINUMERIK 802C

Diagnostics Guide

Valid as from

Control system

SINUMERIK 802S

SINUMERIK 802C

01.2002 Edition

Software version

3

3

Alarms

1

Glossary / Abbreviations

2

3ls

SINUMERIK Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column:

A . . . . . New documentation

B . . . . . Unrevised reprint with new Order No.

C . . . . . Revised edition with new status.

If factual changes have been made on the page since the last edition, this is indicated by a new edition

coding in the header on that page.

Edition

02.99

04.00

01.02

Order No.

6FC5598–2AA20–0BP0

6FC5598–2AA20–0BP1

6FC5598–3AA20–0BP2

Remarks

A

C

C

This manual is part of the documentation on CD-ROM (DOCONCD)

Edition

Order No.

Remarks

11.02

6FC5298-6CA00–0BG3

C

Trademarks

SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr,SIMODRIVEr and

MOTION-CONNECTr are Siemens trademarks. All other product and system names are registered

trademarks of their respective owners and must be treated accordingly.

Further information is available on the Internet under:

http://www.ad.siemens.de/sinumerik

This publication was produced with WinWord V7 and

Designer V 6.0

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authorization.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design,

are reserved.

We have checked that the contents of this publication agree with the

hardware and software described herein. Nonetheless, differences

might exist and therefore we cannot guarantee that they are

completely identical. The information given in this publication is

reviewed at regular intervals and any corrections that might be

necessary are made in the subsequent printings. Suggestions for

improvement are welcome at all times.

Subject to change without prior notice.

Siemens AG 2002. All rights reserved.

Order No. 6FC5598–3AA20–0BP2

Printed in the Federal Republic of Germany

Siemens–Aktiengesellschaft

01.02

Preface

The present description is intended as a manual for the machine tool operator

so that he can:

-

assess special events when operating the machine correctly

-

learn the response of the equipment on special events

-

use the provided possibilities to continue work after the special event

-

follow the notes referring him to documentation with further information.

Scope

This Description includes the alarms that may occur in the following areas: NC

kernel (NCK), cycles and PLC.

Further alarms provided from the MMC area (Man Machine Communication)

can also occur. They are announced to the user in self-explaining alarm lines

on the operator panel. They are not subject of the Diagnostic Instructions. For

special cases in conjunction with the integrated PLC refer to literature on the

SIMATIC S7-300 system.

Sorting

The alarms are sorted in the Diagnostic Instructions by ascending alarm numbers with spaces between them.

Safety

Danger

Please check the situation of the equipment carefully using the description of

the particular alarm occurred. Eliminate the causes of occurrence of the alarm

and acknowledge it as specified. Inattention could cause damage to machine,

workpiece, stored settings and - under certain circumstances - to your health.

NCK alarms

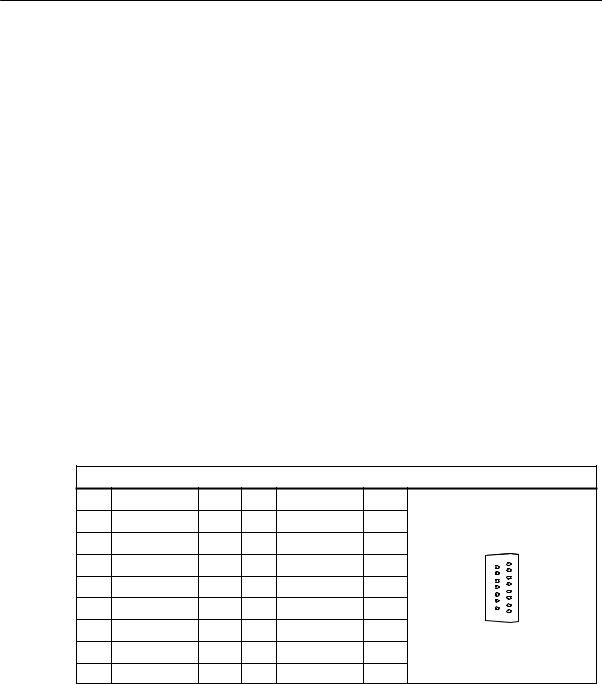

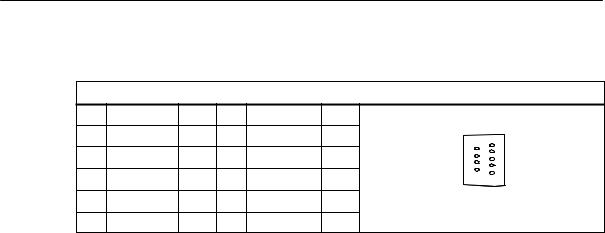

Table 1_1

Alarm number ranges

000 000 - 009 999

General alarms

010 000 - 019 999

Channel alarms

020 000 - 029 999

Axis/spindle alarms

030 000 - 099 999

Functional alarms

060 000 - 064 999

SIEMENS cycle alarms

065 000 - 069 999

User cycle alarms

070 000 - 079 999

Manufacturer and OEM compile cycles

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

v

01.02

MMC

alarms/messages

611D alarms

Table 1_2

Alarm number ranges (continued)

100 000 - 100 999

Basic system

101 000 - 101 999

Diagnosis

102 000 - 102 999

Services

103 000 - 103 999

Machine

104 000 - 104 999

Parameters

105 000 - 105 999

Programming

106 000 - 106 999

Reserve

107 000 - 107 999

OEM

MMC0

110 000 - 110 999

reserved

120 000 - 120 999

reserved

Table 1_3

Alarm number ranges (continued)

300 000 - 399 999

PLC

alarms/messages

Table 1_4

Alarm number ranges (continued)

400 000 - 499 999

General alarms

700 000 - 799 999

User range

6FC5598-3AA20-0BP2

vi

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

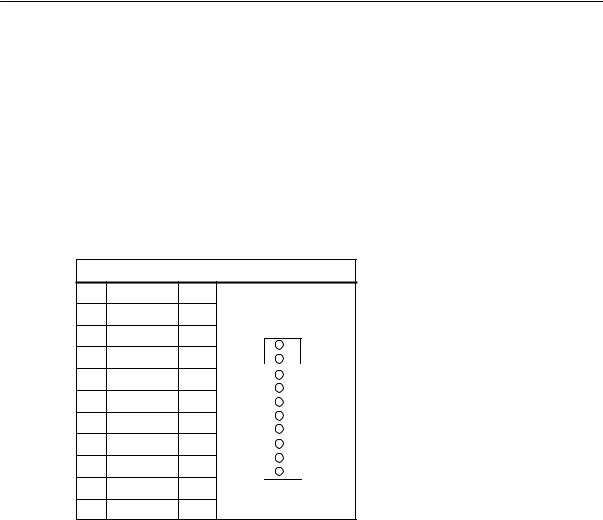

Contents

ALARMS

1-9

1.1

Overview of NCK Alarms

1-10

1.2

Cycle Alarms

1-88

1.3

PLC Alarms

1-93

1.4

Action List

1-96

GLOSSARY / ABBREVIATIONS

2-105

2.1

Abbreviations

2-105

2.2

Glossary

2-111

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

vii

01.02

6FC5598-3AA20-0BP2

viii

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

Alarms

1

System errors

The alarms listed in the following are system errors indicating internal error

conditions. The internal error number displayed together with the error message provides the developer with important information on error cause and

error location.

These system errors will not be described in detail. As far as they occur on the

delivered control systems at all, please contact the following hotline, specifying

alarm number, alarm text and internal system error number contained in

the error message:

Hotline Germany

Siemens AG, A&D techsupport

Telephone: 0180 50 50-222

Mailto:

[email protected]

Helpline

Telephone: 0049 180 50 50 111

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-9

1 Alarms

1.1

01.02

Overview of NCK Alarms

1 002

System error %1

Explanation

%1 = System error number

This alarm refers you to internal error conditions, which in conjunction with

the error number contained in the error message provide information on the

error cause and the error location.

Response

Alarm display.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

1 003

Alarm pointer for this self-clearing alarm %1 is zero

Explanation

%1 = Alarm number

The address used by the operating system for self-clearing alarms (zero

pointer) is not permitted for use in the system.

Response

Alarm display.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

1 004

Alarm reaction from nck alarm is false projected

Explanation

%1 = incorrect alarm number

The alarm response configured by the operating system is incorrect.

Response

Alarm display

Interface signals are set

NC not ready for operation.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Power ON

1 005

Operating system error %1

Explanation

%1 = Operating system error

This alarm indicates that the operating system has detected a severe error in the

system.

Response

Alarm display.

Interface signals are set.

NC not ready for operation.

6FC5598-3AA20-0BP2

1-10

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

NC Start inhibited.

NC Stop at alarm.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Power ON

1 010

Channel %1 system error %2

Explanation

%1 = Channel number

%2 = System error number

This alarm refers you to internal error conditions, which in conjunction with

the error number contained in the error message provide information on the

error cause and the error location.

Response

Alarm display.

Interface signals are set.

NC not ready for operation.

NC Start inhibited.

NC Stop at alarm.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Power ON

1 011

Channel %1 %3 system error %2

Explanation

%1 = Channel number

%2 = System error number

%3 = Channel parameter: Block number, label

This alarm refers you to internal error conditions, which in conjunction with

the error number contained in the error message provide information on the

error cause and the error location.

Response

Alarm display.

Interface signals are set.

Interpreter stop.

NC Start inhibited.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

1 012

Channel %1 system error %2

Explanation

%1 = Channel number

%2 = System error number

This alarm refers you to internal error conditions, which in conjunction with

the error number contained in the error message provide information on the

error cause and the error location.

Response

Alarm display.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-11

1 Alarms

01.02

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

1 014

Channel %1 system error %2

Explanation

%1 = Channel number

%2 = System error number

This alarm refers you to internal error conditions, which in conjunction with

the error number contained in the error message provide information on the

error cause and the error location.

Response

Alarm display.

Interface signals are set.

NC Stop at alarm.

NC Start inhibited.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

1 015

Channel %1 axis %2 system error %3

Explanation

%1 = Channel number

%2 = Axis number

%3 = System error number

This alarm refers you to internal error conditions, which in conjunction with

the error number contained in the error message provide information on the

error cause and the error location.

Response

Alarm display.

Interface signals are set.

Channel not ready for operation.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

1 016

Channel %1 axis %2 system error %3

Explanation

%1 = Channel number

%2 = Axis number

%3 = System error number

This alarm refers you to internal error conditions, which in conjunction with

the error number contained in the error message provide information on the

error cause and the error location.

Response

Alarm display.

Interface signals are set.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

6FC5598-3AA20-0BP2

1-12

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

1 017

Channel %1 axis %2 system error %3

Explanation

%1 = Channel number

%2 = Axis number

%3 = System error number

This alarm refers you to internal error conditions, which in conjunction with

the error number contained in the error message provide information on the

error cause and the error location.

Response

Alarm display.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

1 018

Floating point arithmetic error in channel %1 task %2 station %3 FPU

state: %4

Explanation

%1 = Channel number

%2 = Task ID

%3 = Station priority

%4 = FPU state

The floating point arithmetic unit of the processor has detected an error.

Response

Alarm display.

Interface signals are set.

Channel not ready for operation.

NC Stop at alarm.

NC Start inhibited.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

1 019

Floating point arithmetic error at address %3 in channel %1 task %2

FPU state %4

Explanation

%1 = Channel number

%2 = Task ID

%3 = Code address of the operation which has caused the error

%4 = FPU state

Due to a calculation error, the floating point arithmetic unit of the processor

has initiated an exception.

Response

Alarm display.

Interface signals are set.

Channel not ready for operation.

NC Stop at alarm.

NC Start inhibited.

Remedy

Please contact the hotline indicated in the beginning of this Manual and specify

the operating system error number.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-13

1 Alarms

01.02

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

2 000

Sign of life monitoring: PLC not alive

Explanation

The PLC must provide a sign of life within a certain period of time. If not, this

alarm is output. This alarm is also output as the consequence of a PLC stop

(PLC stop with programming tool, PLC stop from start-up switch, PLC stop

from alarm).

Response

NC Start inhibited.

NC not ready for operation.

Mode group ('BAG') not ready for operation.

NC Stop at alarm.

Alarm display.

Interface signals are set.

Remedy

If none of the cases mentioned above exists, please contact the hotline indicated in the beginning of this Manual and specify the operating system error

number.

Program continuation by

Power ON

2 001

PLC has not started up

Explanation

The PLC must provide at least one sign of life within the defined period of

time after Power On.

Response

NC Start inhibited.

NC not ready for operation.

Mode group ('BAG') not ready for operation.

NC Stop at alarm.

Alarm display.

Interface signals are set.

Remedy

Please contact the hotline indicated in the beginning of this Manual.

Program continuation by

Power ON

2 140

The actual service switch position forces the SRAM to be cleared at the

next Power on (general reset active)

Explanation

The initialization switch is now set to General Reset. This forces the SRAM of

the module to be cleared when the module is reset next time. As a consequence, the NC data memory gets lost.

Response

Alarm display.

Interface signals are set.

Remedy

Reset initialization switch to "1".

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

3 000

Emergency Stop

Explanation

EMERGENCY STOP request is provided at the NCK/PLC interface

(V 26000000.1).

6FC5598-3AA20-0BP2

1-14

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

Response

NC Start inhibited.

NC Stop at alarm

Alarm display.

Interface signals are set.

Remedy

Check whether an EMERGENCY STOP cam has been approached or an

EMERGENCY STOP button has been actuated. Check the PLC user program.

Eliminate the EMERGENCY STOP cause and acknowledge EMERGENCY

STOP via the PLC /NCK interface (V 26000000.2).

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

3001

Internal emergency stop

Explanation

This alarm is not displayed.

Response

NC Start inhibited.

NC Stop at alarm.

Remedy

No remedial action necessary.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

4 060

Standard machine data loaded

Explanation

Booting with standard values by:

• Operating action (e.g. start-up switch)

• MD 11200 INIT_MD

• Loss of retentive data

• Operating action "Booting with saved data", without data saving beforehand

Response

Alarm display

Remedy

The specific data of the equipment on hand must be entered/loaded after the

standard machine data (MD) have been loaded automatically.

Program continuation by

Press the Clear key to clear the alarm. Reload your own machine data.

4 062

Backup data loaded

Explanation

The user data saved to FLASH have been loaded into the SRAM.

Response

Alarm display

Remedy

Reload your own machine data.

Program continuation by

Press the RESET key to clear the alarm.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-15

1 Alarms

01.02

4065

Battery-backed memory is restored from backup copy (risk of loss

of data !)

Explanation

During power-up, it has been detected that inconsistencies are possible in the

battery-backed memory.

The battery-backed memory was initialized using the last back-up copy. As a

result, the changes in the battery-backed memory, which have been made since

the last update of the backup copy, were lost. This may be caused by the fact

that the buffer time has been exceeded. Please make sure that the appropriate

on-time of your control system complies with the on-time required by the Startup Guide.

The current backup copy of the battery-backed memory was created using the

internal data backup carried out last using the softkey "Save data" in the HMI.

Response

Alarm display

Interface signals are set.

NC Start inhibited

Remedy

Restart the control system.

Program continuation by

4 075

Machine data %1 (and may be others) not altered - permission level %2

needed

Explanation

%1 = String: MD identifier

%2 = Write protection level of the MD

When executing a TOA file, you have tried to write into data whose protection

level is higher than the right to access currently set on the control. Your value

entry will be denied.

This alarm is only set when the first violation of the right to access is detected.

Response

Alarm display.

Remedy

Enter the password to set the required access level or delete the respective

machine data from the MD file.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

4 076

%1 machine data could not be modified with permission level %2

Explanation

%1 = Number of MD

%2 = Set user class

When executing a TOA file, you have tried to write into data whose protection

level is higher than the right to access currently set on the control. Your value

entry will be denied.

This alarm is output when alarm 4075 is acknowledged. It can only be cleared

by Power On.

Response

Alarm display.

Remedy

Set the required access level either using the key-operated switch or be entering

the password and/or delete the respective machine data from the MD file.

Program continuation by

Power ON

6FC5598-3AA20-0BP2

1-16

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

4 111

PLC cycle increased to %1 ms

Explanation

The PLC cycle divider has not been set to an integer multiple of the IPO cycle

divider.

The divider (MD 10 074 PLC_IPO_TIME_RATIO) has been increased.

Response

Alarm display.

Remedy

Adapt machine data.

Program continuation by

Power ON

4 230

Channel %1 data alteration from external not possible in current channel

state

Explanation

%1 = Channel number

These data may not be entered during part program execution (e.g. setting data

for spindle speed limitation or for dry run feed).

Response

Alarm display.

Remedy

The data to be entered must be altered before starting the part program.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

4 310

Declaration in machine data %1 index %2 is not allowed

Explanation

%1 = String: MD identifier

%2 = Index in MD array

The values of the machine data in the array must be arranged in ascending

order.

Response

NC not ready for operation.

NC Stop at alarm.

NC Start inhibited.

Alarm display.

Interface signals are set.

Remedy

Correct MD

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

4 400

Machine data alteration will cause reorganization of buffered memory

(loss of data!)

Explanation

An MD has been altered which configures the buffered memory. An NCK boot

with the altered data will reorganize the buffered memory and thus result in a

loss of all buffered user data (part programs, tool data, GUD, LEC, ..).

Response

Alarm display.

Remedy

If the control system contains user data which have not yet been backed up,

these data must be saved before the next NCK boot. The reorganization of the

memory can be avoided by resetting the altered MD to the value during the last

boot manually.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-17

1 Alarms

01.02

5 000

Communication job not executed

Explanation

The communication task (data exchange between NCK and MMC), e.g. loading of an NC part program) cannot be executed due to insufficient memory.

Cause: too many parallel communication jobs.

Response

Alarm display.

Remedy

No remedial action possible - the operating action that resulted in the alarm

message must be repeated. Press Cancel to clear the alarm display.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

6 000

Memory reorganized using standard machine data

Explanation

The memory management could not realize the NC user memory mapping with

the values provided in the machine data, because the total memory is used by

the NC user both as a dynamic and a static memory (e.g. for the number of tool

offsets, number of directories and files, etc.) and is therefore not sufficient.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

NC Stop at alarm.

Remedy

Redefine NC memory mapping!

It is not possible to specify a certain MD as an alarm cause for the NC user

memory assignment. The MD that has caused the alarm must therefore be determined on the base of the default values in the machine data and by modifying the user-specific memory assignment step by step.

In most cases, not only an individual MD is selected too large, and it is therefore recommended to reduce the memory area in several MDs by a certain

fraction.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

6 020

Machine data have been altered - now memory is reorganized

Explanation

Machine data defining the NC user memory mapping have been altered. The

data management has re-mapped the memory with respect of the altered machine data.

Response

Alarm display.

Remedy

No remedial action required. Any user data needed must be re-entered.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

6 500

NC memory is full

Explanation

Too many part programs have been loaded. The job cannot be carried out.

This error may concern files of the NC file system (part of NC memory), such

as initialization files, NC programs, etc., during commissioning.

Response

Alarm display.

Remedy

Delete or unload files (e.g. part programs).

6FC5598-3AA20-0BP2

1-18

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

6 510

Too many files in the NC memory

Explanation

The number of files in the NC file system (part of NC memory has reached the

maximum.

Response

Alarm display.

Remedy

Delete or unload files (e.g. part programs).

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

6 530

Too many files in directory

Explanation

The number of files in a directory of the NC memory has reached the maximum.

Response

Alarm display.

Remedy

Delete or unload files (e.g. part programs) in the directory concerned.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

6 540

Too many directories in the NC memory

Explanation

The number of directories in the NC file system (part of NC memory) has

reached the maximum.

Response

Alarm display.

Remedy

Delete or unload directories not needed (e.g. workpiece).

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

6 560

Data format not allowed

Explanation

Invalid data have been entered in a file of the NC, e.g. binary data are loaded

into the NC as an ASCII file.

Response

Alarm display.

Remedy

Mark the file as binary data (e.g. extension: .BIN)

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

6 570

NC memory is full

Explanation

The DRAM file system of the NCK is full. The job cannot be executed. Too

many system files have been created in the DRAM.

Response

Alarm display

Remedy

Start less „Process from External“ operations.

Program continuation by

Press the Clear key to clear the alarm.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-19

1 Alarms

01.02

8 040

Machine data %1 reset, corresponding option is not set

Explanation

%1 = String: MD identifier

An MD has been set which is locked by an option.

Response

Alarm display.

Remedy

To upgrade your CNC with the required option, contact either your machine

manufacturer or a sales engineer of AUT 2 of SIEMENS AG.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

10 203

Channel %1 NC-start not possible with unreferenced axes (Cmd = %2).

Explanation

%1 = Channel number

%2 = String (event name)

NC Start has been pressed either in MDA or AUTOMATIC mode, and at least

one axis to be referenced has not reached its reference point.

Response

Alarm display.

Remedy

Referencing start can be initiated either channel or axis-specifically.

1.

Channel-specific reference-point approach: The rising edge of the

interface signal "Activate referencing" (V 32000001.0) starts an automatic cycle which start the axes of the channel in the sequence of order

specified in the axis-specific MD 34 110 REFP_CYCLE_NR (axis order

for channel-specific referencing).

-1:

0:

1-4:

2.

Axis is not involved in channel-specific referencing, but must be

referenced for NC start.

Axis is not involved in channel-specific referencing, but must be

referenced for NC start

Starting sequence for channel-specific referencing (simultaneous

start with the same number.)

Axis-specific referencing: Press the direction key corresponding to the

approach direction specified in the axis-specific MD 34 010

REFP_CAM_DIR_IS_MINUS (Approach Reference Point in Minus

Direction).

Program continuation

by

Press NC START to clear the alarm and continue program execution.

10 208

Channel %1 Continue program with NC-Start

Explanation

%1 = Channel number

After block search with calculation, the control system is in the desired state.

The program can now be started with NC Start or in the state first changed by

Overwrite/Jog.

Response

Alarm display.

NC Stop at alarm.

Remedy

Press NC Start.

Program continuation by

Press NC START to clear the alarm and continue program execution.

6FC5598-3AA20-0BP2

1-20

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

10 225

Channel %1: command % 2 refused

Explanation

%1 = Channel number

%2 = String (event name)

The channel contained a command which cannot be executed.

Response

Alarm display.

Remedy

Press RESET.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

10 600

Channel %1 block %2 auxiliary function during thread cutting active

Explanation

%1 = Channel number

%2 = Block number, label

An auxiliary function output is programmed in a thread block.

Response

Alarm display.

Remedy

Subsequent error might occur if the machining path of the thread block is too

short and further blocks (thread blocks) follow in which no machining stop

may occur.

Possible remedial actions:

•

Program longer path and/or reduce traversing speed.

•

Output auxiliary function in another block (program section).

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

10 601

Channel %1 block %2 zero-velocity at end point during thread cutting

Explanation

%1 = Channel number

%2 = Block number, label

This alarm occurs only if several blocks with G33 follow one after another.

The block end velocity in the specified block is zero although still one more

velocity block follows. Possible causes are, for example:

G09

Response

Auxiliary function after movement

Output of auxiliary function prior to the movement of the subsequent block

Alarm display.

Interface signals are set.

Interpreter stop.

NC Start inhibited.

Remedy

Modify NC part program (do not program "Stop at block end" G09)

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-21

1 Alarms

01.02

10 602

Channel %1 block %2 velocity limitation during thread cutting

Explanation

%1 = Channel number

%2 = Block number, label

The axis in the displayed thread block would exceed its maximum velocity

when the spindle override is in the maximum position.

Response

Alarm display.

Remedy

If the axis velocity is not limited (error-free thread), no remedial action is required. Otherwise, the spindle speed for the thread block must be reduced.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

10 620

Channel %1 block %3 axis %2 at software limit switch %4

Explanation

%1 = Channel number

%2 = Axis name, spindle number

%3 = Block number, label

%4 = String

During the traversing movement, it is detected that the software limit switch

has been overtraveled in the displayed direction. Overtraveling the traversing

range could not be detected during block preparation (e.g. circular interpolation), or a coordinate transformation is active.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Check set and programmed zero offsets.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 621

Channel %1 axis %2 rests on software limit switch %3

Explanation

%1 = Channel number

%2 = Axis name, spindle number

%3 = String

The axis specified is already on the displayed software limit position.

Response

Alarm display.

Remedy

Machine data:

Check the machine data POS_LIMIT_PLUS/POS_LIMIT_PLUS2 (MD 36

110/MD 36 130) and POS_LIMIT_MINUS/POS_LIMIT_MINUS2 (MD 36

100/MD 36 120) for the software limit switches.

Check the axis-specific interface signals: "2nd software limit switch plus" (V

380x1000.3) and "2nd software limit switch minus" (V 380x1000.2); make

sure that the 2nd software limit switch is selected.

Program continuation by

The alarm display disappears with the alarm cause. No further operation required.

6FC5598-3AA20-0BP2

1-22

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

10 631

Channel %1 axis %2 rests on software limit switch %3

Explanation

%1 = Channel number

%2 = Axis, spindle

%3 = String (+ or -)

IN the JOG mode, the specified axis reaches the work area limitation (positive

at "+", negative at "-").

Response

Alarm display.

Remedy

Check the work area limitation setting data

43420 WORK AREA_LIMIT_PLUS and

43430 WORK AREA_LIMIT_MINUS.

Program continuation by

The alarm display disappears with the alarm cause. No further operation required.

10 640

Channel %1 block %3 spindle %2 cannot stop during gear change

Explanation

%1 = Channel number

%2 = Spindle number

%3 = Block number, label

The spindle is in oscillation mode for gear stage change and waits for PLC

checkback that gear stage change has been carried out (interface signal: Gear

changed V 38032000.3). During this time, no spindle stop by Reset is possible

(V 30000000.7) or NC Stop axes plus spindle (V 32000007.4).

Response

Alarm display.

Remedy

No remedial action required. The spindle-specific interface signal Spindle

Reset (V 3803000.2) cancels oscillation mode V 38030002.2.

Program continuation by

The alarm display disappears with the alarm cause. No further operation required.

10 720

Channel %1 block %3 axis %2 software limit switch %4

Explanation

%1 = Channel number

%2 = Axis name, spindle number

%3 = Block number, label

%4 = String (+ or -)

The path programmed for the axis violates the currently active software limit

switch. (The 2nd software limit switch becomes active with the interface signal

"2nd software limit switch plus/minus" in V 380x1000.2 and .3). The alarm is

activated when preparing the part program block.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Check the position specified for the axis in the part program.

Check the machine data

POS_LIMIT_MINUS/POS_LIMIT_MINUS2 (MD 36 110/MD 36 130) and

POS_LIMIT_PLUS/POS_LIMIT_PLUS2 (MD 36 100/MD36 120)

for the software limit switches.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-23

1 Alarms

01.02

Check the axis-specific interface signals: "2nd software limit switch

plus/minus" (V 380x1000.2 and .3) and make sure that the 2nd software limit

switch is selected.

Check the currently active zero offsets via the current frame.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 730

Channel %1 block %3 axis %2 work area limitation %4

Explanation

%1 = Channel number

%2 = Axis name, spindle number

%3 = Block number, label

%4 = String (+ or -)

During block preparation, it has been detected that the programmed path carries the axes across the work area limitation.

Response

Remedy

Alarm display.

Interface signals are set.

Include correction block in reorganization.

NC Start inhibited.

Modify the part program.

Change the work area limitation in the setting data.

Program continuation by

Press the N C START to clear the alarm and to continue the program.

10 750

Channel %1 block %2 tool radius compensation activated without tool no.

Explanation

%1 = Channel number

%2 = Block number, label

A tool T.. must be selected so that the control system can consider the associated compensation values.

Each tool (T number) is automatically assigned a compensation data block

(D1) containing the compensation data. A tool can be assigned max. 9 compensation data blocks by specifying the desired data block with the D number.

(D1 - D9).

Response

The tool radius compensation (TRC) will be included in calculation if the

function G41 or G42 is programmed. The compensation values are contained

in the parameter P6 (geometry value) and P15 (wear value) of the active compensation data block Dx.

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Program a tool No. under address T.. with G41/G42 before calling the tool

radius compensation.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

6FC5598-3AA20-0BP2

1-24

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

10 751

Channel %1 block %2 danger of collision due to tool radius compensation

Explanation

%1 = Channel number

%2 = Block number, label

The 'bottle neck detection' (calculation of the intersection point of the following, corrected traversing blocks) was not able to calculate an intersection point

for the overviewed number of traversing blocks, resulting in the risk that one of

the equidistant paths will violate the workpiece contour.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Check the part program and modify the program (if possible) such that inner

corners with paths shorter than the compensation value are avoided. (Outer

corners are not critical, since the equidistants are elongated or intermediate

blocks are inserted so that an intersection point is always provided).

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 752

Channel %1 block %2 overflow of local block buffer with tool radius

compensation

Explanation

%1 = Channel number

%2 = Block number, label

The tool radius compensation must buffer an alternating number of intermediate blocks in order to be able to calculate the equidistant tool path for each NC

block. The size of the buffer memory cannot easily be determined. It depends

on the number of blocks without traversing information in the compensation

level and the number of contour elements to be inserted.

The size of the buffer memory is fixed by the system and cannot be altered via

MD.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Reduction of the buffer memory which has been occupied by modifying the NC

program. This can be achieved if you avoid the following:

Program continuation by

•

blocks without traversing information in the compensation level

•

blocks that contain contour elements with variable curves (e.g. ellipses)

and curve radii which are smaller than the compensation radius. (Such

blocks are split into several partial blocks).

Press the RESET key to clear the alarm. Restart part program.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-25

1 Alarms

01.02

10 753

Channel %1 block %2 activate tool radius compensation in linear block

only

Explanation

%1 = Channel number

%2 = Block number, label

Tool radius compensation with G41/G42 may only be selected on blocks with

the G function G00 (rapid traverse) or G01 (feed) active.

The block with G41/G42 must contain at least one axis of the level G17 to

G19; always both axes are recommended, since both axes are traversed when

selecting the compensation.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Correct the NC program; replace the compensation selection to a block with

linear interpolation.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 754

Channel %1 block %2 deactivate tool radius compensation in linear block

only

Explanation

%1 = Channel number

%2 = Block number, label

The deselection of the tool radius compensation by G40 may only be carried

out in blocks in which the G function G00 (rapid traverse) or G01 (feed) is

active.

The block with G40 must contain at least one axis of the plane G17 to G19;

both axes are always recommended, since usually both axes traverse when

deselecting the compensation.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Correct NC program; replace compensation deselection to a block with linear

interpolation.

Press the RESET key to clear the alarm. Restart part program.

Program continuation by

10 755

Channel %1 block %2 do not activate tool radius compensation via

KONT at the current starting point

Explanation

%1 = Channel number

%2 = Block number, label

When activating the cutter radius compensation via KONT, the start point of

the approach block is within the compensation circle, thus already violating the

contour.

6FC5598-3AA20-0BP2

1-26

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

When deselecting the cutter radius compensation with G41/G42, the approach

behavior (NORM or KONT) determines the movement along the contour if the

current actual position is behind the contour. When KONT is active, a circle

with the cutter radius is drawn around the programmed start point

(= end point of approach block). The tangent that leads through the current

actual position and that does not violate the contour is the approach movement.

If the start point is within the compensation circle and around the target point,

the tangent will lead through this point.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Place the selection of the cutter radius compensation such that the start point of

the approach movement will be outside the compensation circle around the

target point (programmed traversing movement > compensation radius). The

following possibilities are provided:

•

Selection in the preceding block

•

Insert intermediate block

•

Select approach behavior NORM

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 756

Channel %1 block %2 do not activate tool radius compensation via

KONT at the current starting point

Explanation

%1 = Channel number

%2 = Block number, label

When deselecting the cutter radius compensation, the programmed end point is

within the compensation circle. If this point would really be approached without compensation, a contour violation would be the consequence.

When the cutter radius compensation is deselected with G40, the starting behavior (NORM or KONT) will determine the movement along the contour if

the programmed end point is behind the contour. When KONT is active, a

circle with the cutter radius is drawn around the point at which the compensation is still active. The tangent that leads through the programmed end position

and that does not violate the contour is the starting movement.

If the programmed end point is within the compensation circle around the target point, no tangent will lead through this point.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Place the deselection of the cutter radius compensation such that the programmed end point is outside the compensation circle around the last active

compensation point. The following possibilities are provided:

Program continuation by

•

Deselection in the next block

•

Insert intermediate block

•

Select starting behavior NORM

Press the RESET key to clear the alarm. Restart part program.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-27

1 Alarms

01.02

10 762

Channel %1 block %2 too many empty blocks between two traversing

blocks with active tool radius compensation

Explanation

%1 = Channel number

%2 = Block number, label

The maximum admissible number of empty blocks is limited

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

1.

2.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 763

Channel %1 block %2 path component of the block in the compensation

plane becomes zero.

Explanation

%1 = Channel number

%2 = Block number, label

Modify part program:

Check whether SBL2 is selected. When SBL2 is active, a block from each

part program line is generated resulting in that the permissible number of

empty blocks between two traversing blocks can be exceeded.

Because of the collision monitoring with tool radius compensation, the path

component of the block in the compensation level becomes zero. If no movement information perpendicular to the compensation level is contained in the

original block, the block is skipped.

Response

Alarm display.

Remedy

•

The behavior at narrow places which cannot be machined with the active

tool is correct.

•

Modify part program

•

If necessary use a tool with smaller radius

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

10 764

Channel %1 block %2 discontinuous path with active tool radius compensation

Explanation

%1 = Channel number

%2 = Block number, label

This alarm occurs when tool radius compensation is active and the start point

used for the calculation of the compensation is not equal to the end point of the

preceding block.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

- Modify part program.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

6FC5598-3AA20-0BP2

1-28

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

10 777

Channel %1 block %2 tool radius compensation: too many blocks with

suppression of compensation

Explanation

%1 = Channel number

%2 = Block number, label

The maximum permissible number of blocks with active compensation suppression when tool radius compensation is active is limited.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

− Modify part program.

− Check whether SBL2 is selected. When SBL2 is active, a block from each

part program line is generated what results in that the permissible number

of empty blocks between two traversing blocks can be exceeded.

Program continuation by

Press NC START to clear the alarm and continue program execution.

10 778

Channel %1 block %2 Preparation stop with active tool radius compensation

Explanation

%1 = Channel number

%2 = Block number, label

When feed stop is detected with tool radius compensation active (either programmed by the user or generated internally), this alarm is set, since in this

situation machine movements might occur which are not intended by the user

(completing radius compensation and re-approaching the contour). Program

execution can be continued by pressing CANCEL and restart.

Response

Alarm display.

Remedy

- Continue with CANCEL and Start.

- Modify part program.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 810

Channel %1 block %2 No master spindle defined

Explanation

%1 = Channel number

%2 = Block number, label

A revolutional feedrate has been defined although no master spindle is defined.

The spindle rotation is the prerequisite to calculate the revolutional feedrate.

Response

Alarm display.

Interface signals are set.

Include the correction block into the reorganization.

NC Start inhibited.

Remedy

Define a spindle in the machine data.

Program continuation by

Press the NC START to clear the alarm and to continue the program.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-29

1 Alarms

01.02

10 860

Channel %1 block %2 feed rate not programmed

Explanation

%1 = Channel number

%2 = Block number, label

An interpolation type other than G00 (rapid traverse) is active in the displayed

block. No F value programmed.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Program the feed value with respect of the interpolation type used.

•

G94 and G97: The feed is programmed under address F in [mm/min] or

[m/min].

•

G95: The feed is programmed as a revolutional feedrate in [mm/rev] under address F.

•

G96: The feed is programmed as a cutting speed under address S in

[m/min]. It results from the current spindle speed.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 870

Channel %1 block %2 facing axis not defined

Explanation

%1 = Channel number

%2 = Block number, label

When the constant cutting speed is selected using the function G96, the spindle

speed is controlled via the position of the facing axis such that the cutting

speed programmed under S [mm/min] results at the tool edge.

In the channel-specific MD DIAMETER_AX_DEF[n,m]=x (n .. channel

index, m .. spindle index, x .. axis name), the name of the facing axis [string]

can be specified for each of the 5 spindles which is used for speed calculation.

S [1/min] =

S G96 [m / min ] ⋅ 1000

D facing axis [mm ] ⋅ π

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Enter the name of the facing axis in the channel-specific machine data

DIAMETER_AX_DEF for the spindles used.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 880

Channel %1 block %2 too many empty blocks between two traversing

blocks when inserting chamfer or radius

Explanation

%1 = Channel number

%2 = Block number, label

Too many blocks without contour information are programmed between two

blocks which contain contour elements and which are to be linked with a chamfer or a radius (CHF, RND).

6FC5598-3AA20-0BP2

1-30

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Modify part program such that the permissible number of empty blocks is not

exceeded.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 881

Channel %1 block %2 overflow of local block buffer when inserting

chamfer or radius

Explanation

%1 = Channel number

%2 = Block number, label

The number of empty blocks without contour information between two blocks

which contain contour elements and which are to be linked with a chamfer or

radius (CHF, RND) is so large that the internal buffer memory is too small..

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Modify the part program such that the number of empty blocks is reduced.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 882

Channel %1 block %2 do not activate chamfer or radius in blocks without

traversing

Explanation

%1 = Channel number

%2 = Block number, label

No chamfer or radius has been inserted between 2 linear or circle contours

(chamfer edging), because:

•

no straight line or circle contour exists in the plane

•

a movement exists outside the plane

•

the level has been changed

•

the permissible number of empty blocks without traversing information

(dummy blocks) has been exceeded

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Correct the part program with respect of the error mentioned above.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 900

Channel %1 block %2 no S value programmed for constant cutting speed

Explanation

%1 = Channel number

%2 = Block number, label

When G96 is active, the constant cutting speed under address S is missing.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-31

1 Alarms

01.02

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Program the constant cutting speed under S in [m/min] or deselect function

G96. For example, the preceding feed remains when G97 is active but the

spindle goes on rotating with the current speed.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 910

Channel %1 block %2 excessive velocity of one path axis

Explanation

%1 = Channel number

%2 = Block number, label

When transformation is selected, an extreme velocity rise in one or several

axes occurs, for example, since the path runs in the vicinity of the pole.

Response

Alarm display.

Remedy

Division of the NC block into several blocks (e.g. 3) so that the path section

with the chamfer is as small as possible and therefore short. The remaining

blocks will then be traversed with the programmed velocity.

Program continuation by

Press the Clear key to clear the alarm. No further operation required.

10 911

Channel %1 block %2 transformation prohibits to traverse the pole.

Explanation

%1 = Channel number

%2 = Block number, label

The given curve leads through the pole of the transformation.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Modify part program.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 930

Channel %1 block %2 interpolation type not allowed in stock removal

contour

Explanation

%1 = Channel number

%2 = Block number, label

The contour of the stock removal cycle (LCYC 95) contains path commands

other than G00, G01, G02 or G03. The contour program may only contain

contour elements built from these G functions (i.e. no thread blocks, no G05,

etc.).

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Program only path elements in the contour program, which consist of straight

lines and circular arcs.

6FC5598-3AA20-0BP2

1-32

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 931

Channel %1 block %2 error in programmed stock removal contour

Explanation

%1 = Channel number

%2 = Block number, label

The following errors are contained in the stock removal program (LCYC 95)

for the contour:

•

full circle

•

intersecting contour elements

•

wrong start position

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Correct the errors mentioned above in the program for the contour to be machined.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 932

Channel %1 block %2 preparation of contour has been restarted

Explanation

%1 = Channel number

%2 = Block number, label

The stock removal cycle LCYC 95 has been interrupted during the preparation

phase of the stock removal contour.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Do not admit interruption during the contour preparation in the stock removal

cycle LCYC 95.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

10 933

Channel %1 block %2 contour program contains too few contour blocks

Explanation

%1 = Channel number

%2 = Block number, label

The program in which the stock removal contour is programmed contains less

than 3 blocks with movements in both axes in the machining plane. The stock

removal cycle (LCYC 95) has been canceled.

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Enlarge the program with the stock removal contour to at least 3 NC blocks

with axis movements in both axes of the current machining plane.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-33

1 Alarms

01.02

10 934

Channel %1 block %2 array for contour segmentation is too small

Explanation

%1 = Channel number

%2 = Block number, label

The program in which the stock removal contour is programmed contains too

many blocks with movements in both axes in the machining plane (LCYC 95).

Response

Alarm display.

Interface signals are set.

NC Start inhibited.

Remedy

Reduce the number of blocks in the contour program. Check the division of the

contour into several programs.

Program continuation by

Press the RESET key to clear the alarm. Restart part program.

12 000

Channel %1 block %2 address %3 programmed repeatedly

Explanation

%1 = Channel number

%2 = Block number, label

%3 = Source string of address

Most addresses (address types) may be programmed in an NC block only once

so that the search information remains unambiguously.

(e.g. X.. T.. F.. etc. - Exception: G, M functions).

Response

Alarm display.

Interface signals are set.

Remedy

Correct block.

Program continuation by

Press NC START to clear the alarm and continue program execution.

12 010

Channel %1 block %2 address %3 address type programmed too often

Explanation

%1 = Channel number

%2 = Block number, label

%3 = Source string of address

It is defined for each address type how often it may occur in an NC block (for

example, all axes together form a address type, which is also subject to a block

limit).

Response

Alarm display.

Interface signals are set.

Remedy

Correct the block.

Program continuation by

Press NC START to clear the alarm and continue program execution.

12 050

Channel %1 block %2 DIN-address %3 is not configured

Explanation

%1 = Channel number

%2 = Block number, label

%3 = NC address in source text block

The name of the NC address (e.g. X, U, X1) is not defined in the control system.

6FC5598-3AA20-0BP2

1-34

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

Response

Alarm display.

Interface signals are set.

Corrected block.

Remedy

Study Programming Instructions and machine data with refer to the really configured addresses and their meaning and correct the NC block accordingly.

Program continuation by

Press NC START to clear the alarm and continue program execution.

12 060

Channel %1 block %2 same G group programmed repeatedly

Explanation

%1 = Channel number

%2 = Block number, label

The G functions that can be used in the part program are divided into groups

which are syntax-defining or non syntax-defining. Only one G function each

from each G group may be programmed. The functions within a group are

mutually exclusive.

The alarm concerns only the non-syntax defining G functions. If several G

functions from these groups are called in an NC block, the last function of a

group will be active (all previous functions are ignored).

G FUNCTIONS:

Syntax-defining G functions

Non-syntax defining G functions

1st to 4th G group

5th to nth G group

Response

Alarm display.

Interface signals are set.

Remedy

No remedial action necessary. However, it should be checked whether the last

programmed G function is really the desired one.

Program continuation by

Press NC START to clear the alarm and continue program execution.

12 070

Channel %1 block %2 too many syntax-defining G functions

Explanation

%1 = Channel number

%2 = Block number, label

Syntax-defining G functions define the structure of the part program block

and of the addresses contained in it. Only one syntax-defining G function may

be programmed in an NC block. The G functions of the 1st to 4th G group are

syntax-defining.

Response

Alarm display.

Interface signals are set.

Corrected block.

Remedy

Analyze the NC block and distribute the G functions over several NC blocks.

Program continuation by

Press NC START to clear the alarm and continue program execution.

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

6FC5598-3AA20-0BP2

1-35

1 Alarms

01.02

12 080

Channel %1 block %2 syntax error in text %3

Explanation

%1 = Channel number

%2 = Block number, label

%3 = Source text area

The grammar of the block has been violated at the displayed text position. The

exact error cause cannot be specified more exactly, since there are too many

possible error causes.

Example 1:

N10 IF GOTOF ..

; The condition for the jump is missing!

Example 2:

N10 R-50 =12

; Faulty arithmetic parameter number

Response

Alarm display.

Interface signals are set.

Corrected block.

Remedy

Analyze block and correct it using the Programming Instructions.

Program continuation by

Press NC START to clear the alarm and continue program execution.

12 110

Channel %1 block %2 syntax cannot be interpreted

Explanation

%1 = Channel number

%2 = Block number, label

The addresses programmed in the block are not allowed with the valid syntaxdefining G function.

Example:

G1 I10 X20 Y30 F1000; No interpolation parameter may be programmed in

the linear block.

Response

Alarm display.

Interface signals are set.

Remedy

Check block structure and correct it as required by the program.

Program continuation by

Press NC START to clear the alarm and continue program execution.

12 120

Channel %1 block %2 Write special G function in separate block

Explanation

%1 = Channel number

%2 = Block number, label

The G function programmed in this block must be written in a separate block.

No general addresses are allowed in the same block. These G functions are:

G25, G26

Spindle speed limitation

Example:

G4 F1000 M100; No M function is allowed in the G4 block.

Response

Alarm display.

Interface signals are set.

Remedy

Program the G function in a separate block.

Program continuation by

Press NC START to clear the alarm and continue program execution.

6FC5598-3AA20-0BP2

1-36

© Siemens AG 2002 All Rights Reserved

SINUMERIK 802S/802C (DG)

01.02

1 Alarms

12 140

Channel %1 block %2 expression %3 not contained in this release

Explanation

%1 = Channel number

%2 = Block number, label

%3 = Software construct in source text