- Manuals

- Brands

- SSANGYONG Manuals

- Automobile

- Korando 2010

Manuals and User Guides for SSANGYONG Korando 2010. We have 1 SSANGYONG Korando 2010 manual available for free PDF download: Manual

- Manuals

- Brands

- SSANGYONG Manuals

- Automobile

- Korando 2010

- Manual

-

Contents

-

Table of Contents

-

Bookmarks

Related Manuals for SSANGYONG Korando 2010

Summary of Contents for SSANGYONG Korando 2010

-

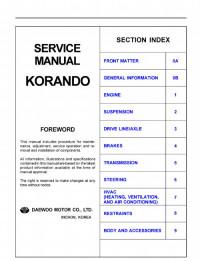

Page 1: Table Of Contents

GENERAL INFORMATION 0000-00 GENERAL INFORMATION GENERAL INFORMATION 1. MAJOR DIMENSION……2. VEHICLE IDENTIFICATION….3. EXTERIOR LAMP SYSTEM LAYOUT..4. INTERIOR LAMP SYSTEM LAYOUT..5. SWITCH SYSTEM LAYOUT….6. CAN COMMUNICATION CONFIGURATION……..ELECTRIC DEVICE GENERAL INFORMATION 1. HOW TO READ ELECTRICAL WIRING DIAGRAM……….

-

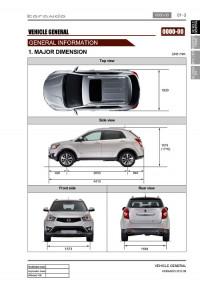

Page 2: General Information

01-2 0000-00 GENERAL INFORMATION 1. MAJOR DIMENSION 2. VEHICLE IDENTIFICATION Top View 1) The engine number (671 950 0 2 2) The chassis number 5000001) is stamped on the lower area of (KPTA0B1SSAP012345) is stamped on the cylinder block in exhaust manifold side. right side in the engine compartment (passenger side).

-

Page 3: Exterior Lamp System Layout

01-3 0000-00 3. EXTERIOR LAMP SYSTEM LAYOUT Front view Rear view High-mounted stop lamp Side repeater lamp Tail/stop lamp Puddle lamp Backup lamp Front turn signal lamp Rear turn signal lamp Position lamp Tail lamp Headlamp assembly Reflector Front fog lamp License plate lamp GENERAL INFORMATION undefined…

-

Page 4

01-4 0000-00 Headlamp Rear combination lamp Stop lamp and tail lamp Turn signal lamp Backup lamp Stop lamp (For Korea) Rear fog lamp High-beam/low-beam Turn signal lamp Position lamp Front fog lamp License plate lamp High mounted stop lamp Puddle (approach) lamp Side repeater lamp Vehicle with spoiler Vehicle without… -

Page 5: Interior Lamp System Layout

01-5 0000-00 4. INTERIOR LAMP SYSTEM LAYOUT Glove box lamp Center room lamp Luggage lamp Front room lamp Sun visor lamp Door courtesy lamp GENERAL INFORMATION undefined…

-

Page 6: Switch System Layout

01-6 0000-00 5. SWITCH SYSTEM LAYOUT Steering wheel remote Overhead console Passenger door Front seat heated wire Front seat heated wire Rear door switch (RH) control switch switch switch switch (DLX) switch (STD) Center room lamp switch Cruise control switch Luggage lamp switch Multifunction switch Lower main panel…

-

Page 7: Can Communication Configuration

01-7 0000-00 6. CAN COMMUNICATION CONFIGURATION 2) CAN Communication Wiring Diagram There are two types (P-CAN and B-CAN) of communication according to the communication speed. The instrument cluster and BCM (Body Control Module) communicate through both P- CAN and B-CAN at the same time. 1) CAN Configurations (P-CAN/B-CAN) Abbreviations Meaning…

-

Page 8: Electric Device General Information

01-8 0000-00 ELECTRIC DEVICE GENERAL INFORMATION 1. HOW TO READ ELECTRICAL WIRING DIAGRAM (1) HOW TO READ ELECTRICAL WIRING DIAGRAM GENERAL INFORMATION undefined…

-

Page 9

01-9 0000-00 (2) CONTENTS OF ELECTRICAL WIRING DIAGRAM(CIRCUIT) (4) FUNCTION OF POWER SUPPLY LINE(NUMBER) Position Emplanation Power supply NO. Power supply condition » » » » A top of horizontal line means Power supply and it is separated depending on Battery Voltage (B+) Supply in Ignition Switch ON and ST (IGN 1) -

Page 10: How To Check Terminal Number Of Connector

01-10 0000-00 (6) ELECTRIC SYMBOLS 2. HOW TO CHECK TERMINAL NUMBER OF CONNECTOR ▶ Terminal number is given based on Female Terminal Male Connector ex) Terminal Number 4 of C901 connection ▶ Terminal number of Connector Generally, the Connector terminal number is given from left to right direction of Locking upper position through the Female Terminal.

-

Page 11: Part Location According To Connector Number

01-11 0000-00 3. PART LOCATION ACCORDING TO CONNECTOR NUMBER ▶ C : Symbol Character for Connector ex) C102 Symbol Character Description Connector (Connecting part that connects two wiring harness) Diode Ground Splice pack (Joint connector that connects various wiring harness) ▶…

-

Page 12

CONNECTOR/GROUND 1413-02/8210-00/8210-01/8211-01/8212-01/8212-02 /8213-03/8213-04/8213-06/8213-09/8213-108810-22/8810-23 CONNECTOR/GROUND WIRING HARNESS 8210-00 WIRING HARNESS, COMPONENTS LOCATION..8210-00 CONNECTOR, GROUND / SPLICE PACK……CONNECTOR/GROUND 8210-01 W/H MAIN……..8212-01 W/H FLOOR(LH)……8212-02 W/H FLOOR(RH)……1413-02 W/H ENGINE MAIN….. 8211-01 W/H ENGINE EXTN….. 8213-09 W/H ROOF……… 8810-22 W/H AIR BAG……8810-23 W/H AIR BAG EXTN…. -

Page 13: Wiring Harness

02-2 8210-00 WIRING HARNESS WIRING HARNESS, COMPONENTS LOCATION 8210-00 (1) WIRING HARNESS CONNECTOR/GROUND undefined…

-

Page 14

02-3 8210-00 (2) COMPONENTS LOCATION CONNECTOR/GROUND undefined… -

Page 15: Connector, Ground / Splice Pack

02-4 8210-00 CONNECTOR, GROUND / SPLICE PACK ▶ GROUND 8210-00 (1) CONNECTOR, GROUND, SPLICE PACK ▶ CONNECTOR ▶ SPLICE PACK CONNECTOR/GROUND undefined…

-

Page 16

02-5 8210-00 (2) SPLICE PACK CIRCUIT 1) S101 (HS-CAN) 4) S202 (HS-CAN) 2) S102 (HS-CAN) 5) S203 (ILL+) 3) S201 (LS-CAN) CONNECTOR/GROUND undefined… -

Page 17

02-6 8210-00 6) S204 (GND)S301 7) S205 (HS-CAN) CONNECTOR/GROUND undefined…

-

Page 18

02-7 8210-00 (3) WIRING CONNECTOR PARTS SHAPE / NUMBERING CONNECTOR/GROUND undefined… -

Page 19

02-8 8210-00 (4) THE OTHERS PARTS SHAPE / NUMBERING ▶ UNIT PART ▶ SWITCH PART CONNECTOR/GROUND undefined… -

Page 20

02-9 8210-00 ▶ MOTOR PART ▶ SENSOR PART LAMP PART ▶ CONNECTOR/GROUND undefined… -

Page 21

02-10 8210-00 ▶ THE OTHER PART CONNECTOR/GROUND undefined… -

Page 22: Connector/Ground

02-11 8210-01 CONNECTOR/GROUND W/H MAIN 8210-01 CONNECTOR/GROUND undefined…

-

Page 23

02-12 8210-01 CONNECTOR/GROUND undefined… -

Page 24: W/H Floor(Lh)

02-13 8212-01 W/H FLOOR(LH) 8212-01 CONNECTOR/GROUND undefined…

-

Page 25

02-14 8212-01 CONNECTOR/GROUND undefined… -

Page 26: W/H Floor(Rh)

02-15 8212-02 W/H FLOOR(RH) 8212-02 CONNECTOR/GROUND undefined…

-

Page 27: W/H Engine Main

02-16 1413-02 W/H ENGINE MAIN 1413-02 ▶ TOP VIEW ▶ FRONT VIEW CONNECTOR/GROUND undefined…

-

Page 28: W/H Engine Extn

02-17 8211-01 W/H ENGINE EXTN 8211-01 CONNECTOR/GROUND undefined…

-

Page 29: W/H Roof

02-18 8213-09 W/H ROOF 8213-09 CONNECTOR/GROUND undefined…

-

Page 30: W/H Air Bag

02-19 8810-22 W/H AIR BAG W/H AIR BAG EXTN 8810-22 8810-23 CONNECTOR/GROUND undefined…

-

Page 31: W/H Driver Door

02-20 8213-03 W/H DRIVER DOOR W/H PASSENGER DOOR 8213-03 8213-04 CONNECTOR/GROUND undefined…

-

Page 32: W/H Rear Door

02-21 8213-06 W/H REAR DOOR W/H TAIL GATE 8213-06 8213-10 CONNECTOR/GROUND undefined…

-

Page 33

POWER DISTRIBUTION 8210-00/8410-04/8410-05 POWER DISTRIBUTION FUSE 8210-00 ENGINE ROOM FUSE / RELAY BOX……… 8410-04 INDOOR FUSE BOX….. 8410-05 ICM RELAY BOX…… -

Page 34

(1) ENGINE ROOM FUSE / RELAY BOX -TOP VIEW (3) ENGINE ROOM FUSE / RELAY BOX LOCATION (2) ENG ROOM FUSE / RELAY BOX -UNDER VIEW (4) BATTERY FUSE BOX LOCATION… -

Page 35

(5) USAGE OF FUSE IN ENGINE ROOM FUSE BOX (6) ENGINE ROOM FUSE BOX CONNECTOR NUMBER… -

Page 36

(7) ENGINE ROOM FUSE / RELAY BOX CIRCUIT ▶ SB1~SB6, SB10, Ef18~Ef19, START RELAY, BLOWER RELAY, DEFOGGER RELAY, DEICER RELAY… -

Page 37

▶ SB7~SB9, Ef1, Ef5, Ef9, Ef11, PTC RELAY, FUEL HEATER RELAY, HEAD LAMP RELAY(HI, LO) -

Page 38

▶ SB11~SB14, Ef12~Ef13, Ef24, ENG MAIN RELAY, C/FAN RELAY, C/FAN RELAY(HI, LO), COMP RELAY… -

Page 39

▶ Ef2~Ef4, Ef6~Ef8, Ef10, Ef14~Ef16, TAIL LAMP RELAY, FRT FOG LAMP RELAY… -

Page 40

▶ Ef17, Ef20~Ef23, Ef25~Ef26, WIPER MOTOR RELAY(HI, LO), HORN RELAY, POWER WINDOW RELAY… -

Page 41

(1) INDOOR FUSE BOX (2) POWER SUPPLY… -

Page 42

(3) INDOOR FUSE BOX CIRCUIT ▶ F27~F34… -

Page 43

▶ F35~F41… -

Page 44

▶ F42~F50… -

Page 45

▶ F51~F53… -

Page 46

▶ RR FOG LAMP RELAY, POWER OUTLET RELAY, BURGLAR HORN RELAY, RR WIPER RELAY, SHIFT LOCK RELAY… -

Page 47

▶ T/GATE OPEN RELAY, FOLDING MIRROR RELAY, IGN 1 RELAY, ACC RELAY, IGN 2 RELAY… -

Page 48

CIRCUIT 1461-01/1491-01/2112-02/2820-01/3110-17/3110-01/4610-04/4810-08/4892-01/6810-20/6810-15/7340-03/7410-02/7632-16/7770-02 /7810-01/7840-01/8010-01/8210-03/8210-01/8210-01/8310-10/8310-01/8310-01/8320-01/8510-52/8510-48/8510-05/8610-06/8620-01 /8710-03/8712-03/8790-01/8810-01/8930-40/8930-03/8930-01 CIRCUIT ENGINE 1461-01 STARTING / CHARGING….. 8610-06 HORN……….. 2820-01 GLOW CONTROL UNIT….7632-16 CIGAR LIGHTER / POWER 1491-01 ECU(D20DTF EU-V)…… OUTLET……..6810-15 PTC HEATER……. 7840-01 DEFOGGER / DEICER….8210-01 DIAGNOSIS CONNECTOR… 8710-03 DOOR LOCK CIRCUIT….7340-03 SUN ROOF……..8310-01 HEAD LAMP……… -

Page 51

(1) ENG MAIN RELAY, PEDAL MODULE, VALVE(THROTTLE, INLET METERING, EGR), SENSOR(HFM, O2, COOLANT TEMP, FUEL TEMP) -

Page 52

(2) STOP LAMP, W/SPEED SENSOR, T/PRESSURE SW, INJECTOR, SENSOR(FUEL FILTER, R/PRESSURE, CAM POSITION, MAP, KNOCK, E/GAS TEMP) -

Page 63

(1) POWER/GROUND, B/HORN, BUZZER, CLUSTER, HAZARD, ROOM LAMP, M/FUNCTION SW, IMMO, A/LIGHT… -

Page 64

(2) DR LOCK, FOLDING, DEFOG/DEICER, P/WINDOW, WIPER/WASHER, DR SWITCH… -

Page 90

VEHICLE GENERAL 0000-00 VEHICLE GENERAL SPECIFICATIONS AND CHECK ITEMS 1. VEHICLE IDENTIFICATION….2. SPECIFICATION……..3. OIL SPECIFICATIONS AND CAPACITY. -

Page 92

5000001) is stamped on the lower area of (KPTA0B1SSAP012345) is stamped on the cylinder block in exhaust manifold side. right side in the engine compartment (passenger side). 3) The certification label is affixed on the bottom of driver side B-pillar. (30 psi) VEHICLE GENERAL korando 2010.10… -

Page 93

01-4 0000-00 ▶ VIN number ▶ Engine number VEHICLE GENERAL korando 2010.10… -

Page 94

750 ± 20 rpm ← Water-cooled / forced Cooling system ← circulation Coolant capacity (ℓ) ← Gear pump, forced Lubrication type ← circulation Max. oil capacity (ℓ) ← (when shipping) Turbocharger and cooling type Turbocharger, water- ← cooled VEHICLE GENERAL korando 2010.10… -

Page 95

On demand type Clutch (M/T) Operating type Hydraulic type ← Disc type Dry single diaphragm ← type Power Type Rack and pinion (EPS, ← Steering HPS) Steering angle Inner 39.0° ← Outer 31.24° ← * ( ) Optional VEHICLE GENERAL korando 2010.10… -

Page 96

R-134a (430 ± 30g) ← Conditioner Electrical Battery type / Capacity MF / 12 — 90 ← (V-AH) Starter capacity (V-KW) 12 — 2.3 ← Alternator capacity (V-A) 12V — 140A (EPS), ← 120A (HPS) * ( ) Optional VEHICLE GENERAL korando 2010.10… -

Page 97

Ssangyong genuine oil (SAE 80W/90, ≒ 0.7 ℓ API GL-5) Brake / Clutch Fluid As required Ssangyong genuine oil (DOT4) Power Steering Fluid Ssangyong genuine oil (ATF DEXRON II) ≒ 1.0 ℓ * TOTAL FLUIDE DA (Extreme cold condition only) VEHICLE GENERAL korando 2010.10… -

Page 98

D20DTF ENGINE INFORMATION 0000-00 ENGINE GENERAL INFORMATION GENERAL INFORMATION 1. ENGINE LAYOUT……..2. MAJOR COMPONENTS……DURING SERVICE WORK 1. GUIDELINES FOR SERVICE WORK SAFETY……….2. JACK-UP POINTS……..3. STANDARD BOLTS SPECIFICATIONS.. SPECIAL TOOL 1. NEW SPECIAL TOOLS……2. NORMAL EQUIPMENTS…… -

Page 100: Engine Layout

01-3 0000-00 1. ENGINE LAYOUT Front view Rear view Right view Left view D20DTF ENGINE INFORMATION korando 2010.10…

-

Page 101: Major Components

Idler bearing 1 A/C compressor pulley Auto tensioner Idler bearing 2 Isolation damper ▶ Rear view E-EGR valve Fuel temperature sensor E-VGT actuator Fuel HP pump assembly Coolant temperature sensor Magnetic triggering Crankshaft position sensor D20DTF ENGINE INFORMATION korando 2010.10…

-

Page 102

▶ Left view Thermostat assembly Knock sensor 1 connector Oil cooler assembly Variable swirl valve assembly E-EGR valve Knock sensor 2 connector E-EGR solenoid valve EGR cooler Electronic throttle body T-MAP sensor Oil level switch D20DTF ENGINE INFORMATION korando 2010.10… -

Page 103: Guidelines For Service Work Safety

Major dedicated equipment: Engine and transmission jack (use the one for Chairman W), Engine stand, Engine crane, transmission jack, Engine hanger Engine crane Engine stand Transmission jack D20DTF ENGINE INFORMATION korando 2010.10…

-

Page 104

Coat oil or grease on the driving and sliding surfaces before installing parts. Use sealer or gasket to prevent leakage if necessary. (14) Tighten every bolt and nut with specified torque. (15) When service work is completed, check finally whether the work is performed properly or the problem is solved. D20DTF ENGINE INFORMATION korando 2010.10… -

Page 105

Replace the seals if necessary. (6) Engine oil Check the oil level and add oil if necessary. The best time to check the engine oil level is when the oil is warm. D20DTF ENGINE INFORMATION korando 2010.10… -

Page 106

0000-00 (7) Coolant Check the coolant level in the coolant reservoir and coolant condition (contamination, foreign material), coolant hose damage or leakage. Replace or add Ssangyong genuine coolant, if needed. (8) Engine drive belt Check all drive belts of the engine for wear, crack, looseness, tension. Retighten or replace the belt, if needed. -

Page 107

The HP fuel supply pipe (HP pump to fuel rail) and HP fuel pipe (Fuel rail to injector) should be replaced with new ones when removed. D20DTF ENGINE INFORMATION korando 2010.10… -

Page 108: Jack-Up Points

Stand jack-up points and installation status (front side) Stand jack-up points and installation status (front side) Mounting status Jack-up points Jack-up points for 2-post lift for 2-post lift Stand jack-up points and installation status (rear side) Mounting status D20DTF ENGINE INFORMATION korando 2010.10…

-

Page 109: Standard Bolts Specifications

Determine extra proper tightening torque if tightens with washer or packing. If tightens bolts on the below materials, be sure to determine the proper torque. Aluminum alloy: Tighten to 80 % of above torque table. Plastics: Tighten to 20 % of above torque table. D20DTF ENGINE INFORMATION korando 2010.10…

-

Page 110: New Special Tools

Used to release tension without removing belt when replacing pulley or pump. Use (Engine) Part number: T99110010A Name: Flywheel fixing device Use: Used to fix flywheel or drive shaft to prevent engine from rotating when removing crankshaft pulley. D20DTF ENGINE INFORMATION korando 2010.10…

-

Page 111: Normal Equipments

(transaxle) and can support at least 1 tone. Name: Engine crane (1 tone or more) Use: Used to move engine module (including transaxle) to working space or engine stand, and can support at least 1 tonne. D20DTF ENGINE INFORMATION korando 2010.10…

-

Page 112

Name: Oil pan gasket remover Use: Used to separate oil pan and minimize damage when removing oil pan. Name: Torque angle gauge Use: Used to angle-tighten correctly after torque- tightening Name: Fuel sender cover remover/installer D20DTF ENGINE INFORMATION korando 2010.10… -

Page 114

0.20 to 0.35 mm 2nd ring end gap 0.35 to 0.50 mm 3rd ring end gap 0.2 to 0.40 mm Offset 0.3 mm Head gasket Piston protrusion 0.475~0.540 1.2t 0.541 to 0.649 1.3t 0.650 to 0.745 1.4t ENGINE ASSEMBLY korando 2010.10… -

Page 115

30 ± 3 Nm Screw bolt 25 ± 2.5 Nm Coolant temperature 20 ± 2.0 Nm sensor Auto tensioner M7×45 (Low) 25 ± 2.5 Nm M12×90 (Up) 55 ± 5.5 Nm Coolant pump M6×50 10 ± 1.0 Nm ENGINE ASSEMBLY korando 2010.10… -

Page 116

25 ± 2.5 Nm (EGR cooler side) EGR combination bolt M6×16 10 ± 1 Nm M8×16 25 ± 2.5 Nm Tensioner pulley 45 ± 4.5 Nm Glow plug 20 ± 2 Nm Vacuum pump M8×25 25 ± 2.5 Nm ENGINE ASSEMBLY korando 2010.10… -

Page 117

(between fuel rail and injector ) Crank position sensor M5×14 8 ± 0.4 Nm Main wiring M6×16 10 ± 1 Nm Intake duct bracket M8×16 25 ± 2.5 Nm Power steering pump M8×100 25 ± 2.5 Nm ENGINE ASSEMBLY korando 2010.10… -

Page 118

Do not allow anybody to be in front of the vehicle. Warm the engine up to normal operating temperature (80°C). Disconnect the fuel rail pressure sensor connector to cut off the fuel injection. Place the diagram sheet to compression pressure tester. ENGINE ASSEMBLY korando 2010.10… -

Page 119

Perform this test in the sequence of firing order. Do not test the cylinder pressure leakage with wet type test procedure. (do not inject the engine oil into the combustion chamber) ENGINE ASSEMBLY korando 2010.10… -

Page 120

02-9 0000-00 (3) Piston protrusion check Position the piston at TDC and measure the piston protrusion from crank case mating surface. Specified value 0.541 to 0.649 mm Measure it at both ends of crankshaft. ENGINE ASSEMBLY korando 2010.10… -

Page 121

Insert the valves into the valve guides and measure the recesses. 0.1 to 0.7 mm Valve recess “a If the measured value is out of the specified range, machine the valve seat as much as necessary until the specified value is achieved. ENGINE ASSEMBLY korando 2010.10… -

Page 122

Immerse the cylinder head with the pressure plate into warm water (approx. 60°C) and pressurize with compressed air to 2 bar. Examine the cylinder head for air bubbling. If the air bubbles are seen, replace the cylinder head. ENGINE ASSEMBLY korando 2010.10… -

Page 123

While removing engine, drain engine oil, coolant and fuel in fuel system to prevent leakage. During service work of removal/installation, be sure to check each connected portions to engine not to make interference. ENGINE ASSEMBLY korando 2010.10… -

Page 124

When replacing electrical equipment, use the same genuine part and be sure to check whether ground or connecting portions are correctly connected during installation. If ground or connecting portion is loosened, there can be vehicle fire or personal injury. ENGINE ASSEMBLY korando 2010.10… -

Page 125

EPS (electric power steering) Crankshaft pulley (DDU) Auto tensioner Tensioner pulley Vacuum pulley A/C compressor pulley Alternator pulley Water pump pulley NO. 1 idler pulley NO. 2 idler pulley Power steering pump NO. 3 idler pulley ENGINE ASSEMBLY korando 2010.10… -

Page 126

-40 to 155°C Oil: 5W30 Drive type: Driven by exhaust Camshaft sprocket EGR cooler bypass valve Exhaust gas goes to combustion chamber without through EGR cooler in engine cooled, and the valve is closed by vacuum pressure. ENGINE ASSEMBLY korando 2010.10… -

Page 127

Left mounting assembly Rear mounting assembly Location: Upper side of transfer axle housing Location: Rear side of transfer axle housing and body side member and front side of sub frame Location Left mounting Location Rear mounting ENGINE ASSEMBLY korando 2010.10… -

Page 128

EGR gas mixture and turbulence in combustion chamber and to decrease the exhaust gas. ▶ Components Intake manifold 2) Exhaust Manifold Exhaust manifold is installed on the cylinder head with 10 stud bolts and nuts. EGR port is integrated in cylinder head. ▶ Components Exhaust manifold ENGINE ASSEMBLY korando 2010.10… -

Page 129

5. CYLINDER HEAD COVER AND OIL SEPARATOR The cylinder head cover is made by high strength plastic to reduce the weight. The multi twist type oil separator improves the oil consumption. ▶ Components PCV valve Oil separator ENGINE ASSEMBLY korando 2010.10… -

Page 130

Cylinder head contains cam position sensor, vacuum pump, intake manifold, exhaust manifold and valve assembly. Vacuum pump and the high pressure (HP) pump are driven by Camshaft and valves are install in vertical direction. This enables the compact layout in cylinder head assembly. ENGINE ASSEMBLY korando 2010.10… -

Page 131

02-20 0000-00 ▶ Components Finger follower & HLA Intake/exhaust Camshafts Camshaft sprocket Cylinder head Camshaft position sensor HP pump drive gear Vacuum pump drive Cylinder head gasket ENGINE ASSEMBLY korando 2010.10… -

Page 132

Mechanical type tensioner plug, spring and check valve, and operated by hydraulic pressure Operated by internal spring Crankshaft sprocket Teeth: 20 EA Chain lower bush Oil pump sprocket Chain type: single bush Teeth: 20 EA Chains: 60 EA ENGINE ASSEMBLY korando 2010.10… -

Page 133

02-22 0000-00 ▶ Components Intake/exhaust Camshaft assembly Exhaust Camshaft HP pump drive gear Connected to vacuum pump Intake Camshaft ENGINE ASSEMBLY korando 2010.10… -

Page 134

02-23 0000-00 Timing gear cover case (TGCC) TGCC Oil seal Screw plug ENGINE ASSEMBLY korando 2010.10… -

Page 135

02-24 0000-00 Mass Balance Unit (MBU) Crankshaft MBU drive gear Fuel HP pump HP pump drive gear HP pump gear ENGINE ASSEMBLY korando 2010.10… -

Page 136

And, A/C compressor bracket and the oil dipstick tube are mounted on the oil pan. Components ▶ Oil pan assembly Oil drain plug Dust cover Oil level sensor For details, refer to Chapter «Engine Control» Oil dipstick tube hole A/C compressor bracket ENGINE ASSEMBLY korando 2010.10… -

Page 137

9. MASS BALANCE SHAFT UNIT (MBU) The balance shaft in MBU (Mass Balance shaft Unit) improves the NVH performance by decreasing the unbalanced force. ▶ Components Crankshaft drive gear Mass balance shaft unit Mass balance shaft unit ENGINE ASSEMBLY korando 2010.10… -

Page 138

Drive plate receives the power from the start motor when starting the engine. With this, the drive plate initially drives the power train system. And, it is connected to the torque converter to transfer the engine torque to the power train system. Components ▶ Drive plate Trigger ring ENGINE ASSEMBLY korando 2010.10… -

Page 139

This vehicle is FF driving type and the engine is installed in lateral direction. The crankshaft and the cylinder block convert the compression pressure to the rotating energy. ▶ Components Cylinder block Piston Connecting rod Crankshaft ENGINE ASSEMBLY korando 2010.10… -

Page 140

1800 bar Operating temperature -30℃ ~ 120℃ Type Vane type Low pressure fuel Gear ratio (pump/engine) 0.5 : 1 pump Pressure 6 bar Capacity 60 L Fuel tank Material Plastic Fuel sender Dual sender type ENGINE FUEL SYSTEM korando 2010.10… -

Page 141

DI engine fuel system in this manual. At this point, thoroughly clean the related area in engine compartment. Clean the engine compartment before starting service works. Tool kit for high pressure line Took kit for low pressure line ENGINE FUEL SYSTEM korando 2010.10… -

Page 142

To supply the fuel to transfer line of HP Fuel filter assembly pump press the priming pump until it becomes hard. Priming pump Priming pump cap ENGINE FUEL SYSTEM korando 2010.10… -

Page 143

03-6 0000-00 Check the installed components again and connect the negative battery cable. Start the engine and check the operating status. With Scan Tool, check if there are current faults and erase the history faults. ENGINE FUEL SYSTEM korando 2010.10… -

Page 144

To run the system properly, the electric system must be intact but for the DI engine, the fuel pressure should be measured also when there is a malfunction even after the diagnostic test with a diagnostic device. (2) Hydraulic system ENGINE FUEL SYSTEM korando 2010.10… -

Page 145

Excessive injector backleak Occurs when the injector control valve is not sealed due to the entry of the foreign materials. ▶ Example: Entry of foreign materials Burned out and worn HP pump Mechanical damage inside the injector ENGINE FUEL SYSTEM korando 2010.10… -

Page 146

Faulty fuel supply line, or damaged or worn pump causes the lack of flow pressure and flow volume ▶ Example: Air in fuel supply line Excessive load on fuel supply line (←400 mBar) Burned out and mechanical worn pump High temperature of fuel supply (> 85℃) ENGINE FUEL SYSTEM korando 2010.10… -

Page 147

Check air in fuel supply line (bubble in fuel supply line or fuel) Check fuel supply line for leaks (low pressure and high pressure) Check that specified fuel is used Check fuel filter for contamination ENGINE FUEL SYSTEM korando 2010.10… -

Page 148

If several DTCs are output simultaneously, check the electric wiring for open or short circuit. Check the low pressure fuel system and fuel filter and confirm that there are no abnormalities. Carry out the high pressure fuel system check. ENGINE FUEL SYSTEM korando 2010.10… -

Page 149

03-12 0000-00 (4) Fuel System Check Procedure ENGINE FUEL SYSTEM korando 2010.10… -

Page 150

Crank the engine 2 times for 5 seconds. Read the highest pressure value displayed on the tester display. If the highest pressure value is 1,050 bar or less, refer to the section «Fuel System Check Process». ENGINE FUEL SYSTEM korando 2010.10… -

Page 151

«TEST?» is displayed. If the button is pressed again at 4 seconds after starting engine cranking, the highest pressure is displayed on the tester. The fuel rail pressure value can be checked using a diagnostic device. ENGINE FUEL SYSTEM korando 2010.10… -

Page 152

Start the engine and check visually for clogged low pressure fuel system, excessive air or air entry. If the fuel flow is not sufficient or air is in the fuel, repair the leak area. ENGINE FUEL SYSTEM korando 2010.10… -

Page 153

Crank the engine 2 times for 5 seconds. Check the time for flow if injector backleak and confirm that it is within the specified range. Below 20 sec. Specification If the value is out of the specified range, replace the injector. ENGINE FUEL SYSTEM korando 2010.10… -

Page 154

This test consists of 4 cycles, and the engine rpm reaches 3,500 rpm for 18 seconds in each cycle. Check the amount of backleak collected into the container and confirm that it is within the specified range. 38 ml or less Specification ENGINE FUEL SYSTEM korando 2010.10… -

Page 155

Crank the engine 2 times for 5 seconds after removing the IMV connector and fuel rail pressure sensor connector. Read the pressure value displayed on the tester display is within the specified range. 1,050 bar or more Specification ENGINE FUEL SYSTEM korando 2010.10… -

Page 156

When the water level inside water separator in fuel filter exceeds a certain level (approx. 45 cc), this warning light comes on and buzzer sounds. Also, the driving force of the vehicle decreases (torque reduction). If these conditions occur, immediately drain the water from fuel filter. ENGINE FUEL SYSTEM korando 2010.10… -

Page 157

The core elements of fuel system has very high preciseness that is easily affected by dust or very small foreign material. Therefore, make sure to keep the preliminary works and job procedures in next pages. If not, lots of system problems and claims may arise. ENGINE FUEL SYSTEM korando 2010.10… -

Page 158

Due to engine layout, a customer cannot easily drain water from fuel filter directly, so if a customer checks in to change engine oil, be sure to perform water drain from fuel filter. Water separator ENGINE FUEL SYSTEM korando 2010.10… -

Page 159

HP fuel pump Common rail and Fuel filter Injector (Priming pump) Low pressure line Fuel supply tube Fuel return tube Fuel neck Fuel tank ENGINE CONTROL SYSTEM Engine ECU (D20DTF) Fuel sender (main) Fuel sender (sub) ENGINE FUEL SYSTEM korando 2010.10… -

Page 160

Injector (C3I) Pre-injection, main injection, after-injection by signals from ECU Camshaft position sensor Fuel rail assembly Relieves the pulsation. Measures the fuel pressure. Distributes the fuel to injectors. Determines the injection order. ENGINE FUEL SYSTEM korando 2010.10… -

Page 161

Engine ECU (D20DTF) Engine control by various signals Crankshaft position sensor T-MAP sensor Measuring booster pressure Measuring intake air mass and temperature and temperature Measuring engine rpm ENGINE FUEL SYSTEM korando 2010.10… -

Page 162

(cylinder block for previous model). The fuel pressure is generated by the operation of intake camshaft and gears. The specifications for the IMV valve and the fuel temperature sensor are not changed. ENGINE FUEL SYSTEM korando 2010.10… -

Page 163

03-26 0000-00 3) Input/Output devices ENGINE FUEL SYSTEM korando 2010.10… -

Page 164

Also, the ECU uses the signals from the coolant temperature & air temperature sensors, booster pressure sensor, atmospheric pressure sensor to: a) determine injection starting point and set value for pilot injection, and b) deal with various operations and variable conditions. ENGINE FUEL SYSTEM korando 2010.10… -

Page 165

03-28 0000-00 4) Flow Diagram of Fuel Supply System ENGINE FUEL SYSTEM korando 2010.10… -

Page 166

03-29 0000-00 5) Circuit Diagram of Duel Supply System ENGINE FUEL SYSTEM korando 2010.10… -

Page 167

510 x 110 x 70 (W x H x T) Core size 510 x 110 x 63 (W x H x T) Tank material Plastic (Molding) Efficiency Shorten the service interval under severe conditions such as driving on a dusty road or off- road. INTAKE SYSTEM korando 2010.10… -

Page 168

-30 ~ 100℃ Capacity 6.5 L Intercooler Core material Aluminum Size 510 x 110 x 70 (W x H x T) Core size 510 x 110 x 63 (W x H x T) Tank material Plastic (Molding) Efficiency INTAKE SYSTEM korando 2010.10… -

Page 169

When the DI engine is running, the air entered into the engine flows in the sequence as shown above. If high intake pressure is applied to the loose or damaged part, a whistling noise may occur, the intake air volume is measured incorrectly or the engine power is derated. INTAKE SYSTEM korando 2010.10… -

Page 170

▶ Other Checks for Intake System If the intake system is free of any faults, check for EGR and PCV oil separator. INTAKE SYSTEM korando 2010.10… -

Page 171

* For more information, refer to «Engine Control» section. 1719-01 Intake manifold 1719-16 Electric throttle body Passage for variable swirl valve and for intake air * For more information, refer to «Engine Control» section. INTAKE SYSTEM korando 2010.10… -

Page 172

04-8 1719-00 2313-15 HFM sensor HFM sensor, version 6 * For more information, refer to «Engine Control» section. 2313-01 Air cleaner assembly and resonator 2330-01 Intercooler assembly INTAKE SYSTEM korando 2010.10… -

Page 173

04-9 1719-00 3. INPUT/OUTPUT DEVICES ECU (DCM 3.7) INTAKE SYSTEM korando 2010.10… -

Page 174

04-10 1719-00 4. OPERATING PROCESS ▶ Work Flow INTAKE SYSTEM korando 2010.10… -

Page 175

04-11 1719-00 5. WIRING DIAGRAM INTAKE SYSTEM korando 2010.10… -

Page 176

05-3 1729-00 1. TROUBLESHOOTING 1) Work Flow EXHAUST SYSTEM korando 2010.10… -

Page 177

Make sure that the exhaust pipe is cooled down sufficiently before working on it because it is still hot right after the engine is stopped. Wear protective gloves when removing the exhaust pipe. EXHAUST SYSTEM korando 2010.10… -

Page 178

2. COMPONENT Exhaust manifold CDPF assembly Fore details about the CDPF assembly, refer to Chapter «CDPF System». No. 1 exhaust pipe No. 2 exhaust pipe No.3 muffler pipe EXHAUST SYSTEM korando 2010.10… -

Page 179

05-6 1729-00 3. OPERATING PROCESS 1) Exhaust Gas Flow 2) Input & Output Devices EXHAUST SYSTEM korando 2010.10… -

Page 180

06-3 1914-00 1. SPECIFICATION Component Item Specification Max. expansion coefficient Max. turbine speed 213,000 rpm Turbocharger Max. temperature of turbine housing 830 ℃ Weight 7.2 kg E-Actuator Operation duty cycle 300 Hz TURBOCHARGER korando 2010.10… -

Page 181

TURBOCHARGER korando 2010.10… -

Page 182

In such case, clogging and damage of the oil drain pipe and the pressure of blow-by gas within the crank case must be inspected. Damages due to Foreign Materials When the foreign materials get into the system, it could induce inner damage as rotating balance of the turbocharger gets out of alignment. TURBOCHARGER korando 2010.10… -

Page 183

Damages by foreign materials: In case where the compressor wheel is damaged by foreign materials requires having an overhaul. At this time, it’s necessary to check whether the foreign materials have contaminated intake/exhaust manifold or inside of engine. TURBOCHARGER korando 2010.10… -

Page 184

The following tries to understand the defects that can occur with vehicle installed with the turbocharger and to manage the reasons of such defects. In case where oil pan/oil pipe has been contaminated, oil filter is defected and where adhesive of gaskets has been contaminated into the oil line. TURBOCHARGER korando 2010.10… -

Page 185

06-8 1914-00 Oil Pump Defect: Rapid over-loaded driving after replacing oil filter and oil and clogging of oil line. TURBOCHARGER korando 2010.10… -

Page 186

06-9 1914-00 Turbine Side: Inflow of foreign materials from engine Compressor Side: such as air filter, muffler and nut TURBOCHARGER korando 2010.10… -

Page 187

06-10 1914-00 Defects caused by reasons other than that of the turbocharger. TURBOCHARGER korando 2010.10… -

Page 188

— Is the rotation smooth when the rotor is rotated by hand? — Is the movement of bearing normal? — Inspect whether there has been any signs of interference between two wheels. It’s important not to drive the engine when the intake manifold hose has been removed. TURBOCHARGER korando 2010.10… -

Page 189

06-12 1914-00 2) Work Flow for Troubleshooting TURBOCHARGER korando 2010.10… -

Page 190

06-13 1914-00 TURBOCHARGER korando 2010.10… -

Page 191

06-14 1914-00 TURBOCHARGER korando 2010.10… -

Page 192

06-15 1914-00 TURBOCHARGER korando 2010.10… -

Page 193

06-16 1914-00 TURBOCHARGER korando 2010.10… -

Page 194

— At high speed: Expands the flow passage for the exhaust gas, resulting in increasing the mass flow of the exhaust gas and running the turbine more powerfully. TURBOCHARGER korando 2010.10… -

Page 195

Folding and unfolding of the vane is controlled electrically Easy to get low speed air volume Features Rapid response time Electric control Improved low speed torque and power Reduced exhaust gas Benefits Improved fuel consumption Improved acceleration performance TURBOCHARGER korando 2010.10… -

Page 197

06-20 1914-00 2. COMPONENT E-VGT For more information about control logic, refer to «Engine Control». Improves engine power T-MAP sensor For more information about control logic, refer to «Engine Control». Booster pressure and temperature TURBOCHARGER korando 2010.10… -

Page 198

Transfers driver’s will to accelerate to E-VGT duty control E-VGT For more information about control logic, refer to «Engine Control». Operates VGT by determining warming up of engine E-VGT For more information about control logic, refer to «Engine Control». Improves engine power TURBOCHARGER korando 2010.10… -

Page 199

06-22 1914-00 3. INPUT/OUTPUT DEVICES TURBOCHARGER korando 2010.10… -

Page 200

(impeller) fast. Therefore, the intake air is not compressed as needed. Because of this, it takes time for turbocharger to supply the additional power after the accelerator pedal is depressed. This is called «turbocharger lag». TURBOCHARGER korando 2010.10… -

Page 201

The flow rate is increased due to the Expands the expanded flow passage for Improved At high passage→ the exhaust gas maximum Increased turbine & speed by unfolding the power impeller speed, vanes Increased compressive force TURBOCHARGER korando 2010.10… -

Page 202

16 km when the outside temperature remains below freezing Driving in a hilly or mountainous terrain, sandy, or dusty area High load driving such as trailer towing Taxi, patrol service or delivery service (extended idling and excessive driving with low speed) LUBRICATION SYSTEM korando 2010.10… -

Page 203

Recheck the oil level after 5 minutes. Regularly check the engine oil level and add Ssangyong genuine engine oil if necessary. Clean the dipstick with clean cloth so that any foreign materials cannot get into the engine. -

Page 204

CAN communication to turn on the warning lamp. 2) Component Oil level sensor Engine oil dipstick Oil pan Oil pump Oil filter module Oil cooler LUBRICATION SYSTEM korando 2010.10… -

Page 205

The oil filter module consists of lubrication system, cooling system and some mechanical devices as below. System Components Supplementary devices Power steering pump (HPS), Alternator, A/C compressor Belt drive Belt tensioner, Idle pulley Cooling Water pump, Thermostat, Cooler housing and Pipes Lubrication Oil filter, Oil cooler (except coolant pipes) LUBRICATION SYSTEM korando 2010.10… -

Page 206

07-7 1543-00 2. OPERATING PROCESS 1) Operation Flow LUBRICATION SYSTEM korando 2010.10… -

Page 207

Series: low speed, Parallel: high speed Capacity over 2.2L Circulation Closed roof type Coolant reservoir Pressure cap Screw type, 1.4bar Vacuum valve Screw type, 1.4bar Type Wax pallet type Opening temperature 90℃ Thermostat Fully open temperature 100℃ Valve lift ENGINE COOLING SYSTEM korando 2010.10… -

Page 208

— Improper operation of cooling fan — Replace the cooling fan or repair too low the related circuit — Defective temperature sensor or — Replace the sensor or repair the faulty wiring related wiring ENGINE COOLING SYSTEM korando 2010.10… -

Page 209

Scalding hot coolant and steam could be blown out under pressure, which could cause serious injury. Never remove the coolant reservoir cap when the engine and radiator are hot. Avoid any direct contact of the coolant to the painted body of the vehicle. ENGINE COOLING SYSTEM korando 2010.10… -

Page 210

3) Thermostat Immerse the thermostat into the water. Heat the water and check the valve opening temperature. Valve opening 90±2℃ temperature ENGINE COOLING SYSTEM korando 2010.10… -

Page 211

The anti-freeze and water should be mixed in proper mixture ratio. Never add only water when adding coolant. If the anti-freeze content is too low, the coolant can be frozen while the engine can be overheated if anti-freeze content is too high. ENGINE COOLING SYSTEM korando 2010.10… -

Page 212

Thermostat When the engine coolant reaches 90℃, the thermostat starts to open (fully open at 100℃) and lets the coolant flow to the radiator to maintain the engine temperature. ENGINE COOLING SYSTEM korando 2010.10… -

Page 213

Circulates the fresh air forcibly to exchange heat with the radiator core fin. Radiator Releases heat through fins and cools down the hot coolant as the coolant passes through the tube of the radiator core. ENGINE COOLING SYSTEM korando 2010.10… -

Page 214

08-10 1520-00 2) Schematic Diagram ENGINE COOLING SYSTEM korando 2010.10… -

Page 216

08-12 1520-00 3) System Layout ENGINE COOLING SYSTEM korando 2010.10… -

Page 217

08-13 1520-00 ENGINE COOLING SYSTEM korando 2010.10… -

Page 218

70/120 A at 76/140 A at Normal output 1,800/6,500 rpm 1,800/6,500 rpm Alternator Regulator voltage 14.6 V ← Length 12.5 mm ← Brush Wear limit 7 mm ← Typ. Maintenance Free ← Battery Capacity 90 AH ← CHARGE SYSTEM korando 2010.10… -

Page 219

Measure the voltage with the engine Faulty IC regulator or field coil: L terminal voltage running. If the measured voltage is 14.5 V or higher. Disconnect the negative battery cable. Connect the negative cable again after connecting the ammeter. CHARGE SYSTEM korando 2010.10… -

Page 220

Corroded or worn battery cable Repair or replace the battery off after starting cable engine Loose alternator drive belt Replace the batteryAdjust the belt tension or replace the belt Defective wiring harness Repair or replace CHARGE SYSTEM korando 2010.10… -

Page 221

09-6 1453-00 3) Checking Battery CHARGE SYSTEM korando 2010.10… -

Page 222

Green area (③): Normal Red area on the left-hand side of OK (④ Impossible to charge with an alternator Green area with OK (⑤): Normally charged Red area on the right-hand side of OK (⑥): Overcharged by an alternator CHARGE SYSTEM korando 2010.10… -

Page 223

Try to start the discharged vehicle while accelerating the engine rpm in the booster vehicle. Attempt to start the engine with the discharged battery. After starting the engine, carefully disconnect the jumper cables in the reverse sequence of connection. CHARGE SYSTEM korando 2010.10… -

Page 224

Check the battery for crack, damage or fluid leaks. Replace it if necessary. Wipe out the battery fluid on the battery surface using a rubber glove and a clean cloth wetted with soapy water. CHARGE SYSTEM korando 2010.10… -

Page 225

It converts the chemical energy to the supplies power to each electric unit by electrical energy and supplies power to converting the mechanical energy to the the corresponding electric units when electrical energy. starting the engine. CHARGE SYSTEM korando 2010.10… -

Page 226

09-11 1453-00 2. OPERATING PROCESS CHARGE SYSTEM korando 2010.10… -

Page 227

09-12 1453-00 3. CIRCUIT DIAGRAM CHARGE SYSTEM korando 2010.10… -

Page 228

Rated voltage 12 V Operating voltage 6 to 16 V Maximum temperature 1,300°C Operating temperature 1,100°C Glow plug control unit EMS operating voltage 6 to 16 V Operating temperature -40°C to 110°C Dark current Max. 1 mA PRE-HEATING korando 2010.10… -

Page 229

10-4 0000-00 2. TIGHTENING TORQUE Glow plug GCU (Glow plug Control Unit) Name Tightening torque Glow plug 20 ± 2 Nm Glow plug control unit bolt PRE-HEATING korando 2010.10… -

Page 230

The ECU receives the information such as, engine rpm, coolant temperature, engine torque, etc., through CAN communication during pre-heating process; and the pre-heating control unit controls the pre-heating, heating during cranking and post-heating by the PWM control. Glow indicator Engine ECU (D20DTF) Glow plug Glow plug control unit (GCU) PRE-HEATING korando 2010.10… -

Page 231

10-6 0000-00 2. SYSTEM OPERATION 1) Input/Output Diagram of Glow Plug Control Unit 2) System Diagram PRE-HEATING korando 2010.10… -

Page 232

10-7 0000-00 3) Circuit Diagram PRE-HEATING korando 2010.10… -

Page 233

The total time for pre-heating should be 30 seconds or less. If this time is over, the resistor goes OFF until the post-heating is started. If the starting is failed and the engine is stopped, the start key should be turned OFF and then ON to initialize the pre-heating process. PRE-HEATING korando 2010.10… -

Page 234

If no CAN signal is received for 4 seconds from the engine ECU after the IGN ON signal is input, the GCU performs emergency preheat (Step 3) for 30 seconds. P1 to P2: Pre glow P3 to P4: Post glow PRE-HEATING korando 2010.10… -

Page 235

11-3 1461-00 1. SPECIFICATION Capacity 12V, 2.3kW Engagement Meshed type Rotating direction Clockwise Pinion gear manufacturing Cooled forging Solenoid operating voltage Max. 8 V Weight 2.5 kg Bracket manufacturing Aluminum die casting STARTING SYSTEM korando 2010.10… -

Page 236

Repair or replace Faulty starter Starter does not stop Faulty ignition switch Replace Broken pinion gear or faulty starter Replace the starter Engine cranks Broken flywheel ring gear Replace normally, but does not start Open circuit Repair STARTING SYSTEM korando 2010.10… -

Page 237

The starter (start motor) starts the engine with rotational power by converting the electric energy to the mechanical energy. When the engine is cranking, the pinion gear meshes with the ring gear. If the ring gear overruns, the pinion gear clutch overruns to protect the pinion gear. ▶ System Configuration STARTING SYSTEM korando 2010.10… -

Page 238

11-6 1461-00 2. OPERATING PROCESS 1) System Layout STARTING SYSTEM korando 2010.10… -

Page 239

11-7 1461-00 2) Circuit Diagram STARTING SYSTEM korando 2010.10… -

Page 240

The cruise control system is a supplementary system, which helps the driver to drive the vehicle at a desired speed without using the accelerator pedal under the traffic condition where the vehicle-to-vehicle distance meets the legal requirement. CRUISE CONTROL korando 2010.10… -

Page 241

Improper use of the cruise control could be dangerous. — Do not use on winding roadsyy . — Do not use in heavy traffic. — Do not use on slippery, wet roads. This could result in a loss of control, collision, and/or personal injuries. CRUISE CONTROL korando 2010.10… -

Page 242

12-5 8530-00 2. CONFIGURATION 1) Circuit Diagram CRUISE CONTROL korando 2010.10… -

Page 243

12-6 8530-00 2) Configuration CRUISE CONTROL korando 2010.10… -

Page 244

Refer to the following pages for details of operation. Never use the cruise control system until you get used to it. Improper use or not fully aware of this function could result in collision and/or personal injuries. CRUISE CONTROL korando 2010.10… -

Page 245

This is a tap-up switching. When you operate a tap-up switching, the vehicle is accelerated for 1 km/h over the previous set speed. If you want to accelerate for 10 km/h, operate the tap-up switching ten times without accelerating with the cruise control system. CRUISE CONTROL korando 2010.10… -

Page 246

40 km/h. And then release the accelerator pedal slowly. When the desired speed is reached, release the lever. But the cruise control system cannot maintain the cruise function at less than 38 km/h. CRUISE CONTROL korando 2010.10… -

Page 247

This is a tap-down switching. When you operate a tap-down switching, the vehicle is decelerated for 1 km/h below the previous set speed. If you want to decelerate for 10 km/h, operate the tap-down switching ten times without the brake pedal intervention. CRUISE CONTROL korando 2010.10… -

Page 248

But the driver should know the previous set speed to react to the changed vehicle speed properly. If the vehicle speed increases abruptly, depress the brake pedal to adjust the vehicle speed properly. CRUISE CONTROL korando 2010.10… -

Page 249

38 km/h without an acceleration intervention. In this operation, the smooth acceleration to the set cruise speed can be achieved by optimized fuel consumption. When this mode is activated, ECO indicator comes on. CRUISE CONTROL korando 2010.10… -

Page 250

When using the clutch in order to shift (M/T only). And the cruise control system can be operated again in driving state. Keep the main cruise control switch in the neutral position when not using the cruise control. CRUISE CONTROL korando 2010.10… -

Page 251

Ensure that the safe distance is maintained and use the brake pedal if needed. CRUISE CONTROL korando 2010.10… -

Page 252

Driven by DC motor Valve EGR gas flow rate 120 kg/h E-EGR cooler Cooling capacity 8.3 kW or more Cooling fin type Wavy fin Cooler type U-shaped E-EGR bypass valve Solenoid valve Drivien by Vacuum (Solenoid valve) E-EGR SYSTEM korando 2010.10… -

Page 253

CO2 content in the intake air to reduce the emission of NOx. Benefits of E-EGR valve ▶ Improved accuracy and response through electric control Feedback function (Potentiometer) Preventing chattering of EGR valve and improved durability Self-cleaning function E-EGR SYSTEM korando 2010.10… -

Page 255

(HFM: decreased at 60℃ or more), atmospheric pressure (atmospheric pressure sensor: altitude compensation) are used as auxiliary map values. EGR pipe Transports the exhaust gas from the EGR cooler and EGR bypass valve to the intake duct. E-EGR SYSTEM korando 2010.10… -

Page 256

The cooler lowers the high temperature of the exhaust gas and the bypass valve directly supplies the exhaust gas to the intake duct without passing through the EGR cooler to reduce the emission of exhaust gas before warming up the engine. E-EGR SYSTEM korando 2010.10… -

Page 257

13-8 1793-00 2. OPERATING PROCESS 1) Schematic Diagram E-EGR SYSTEM korando 2010.10… -

Page 258

The engine ECU calculates the EGR amount by adding main map value (intake air volume) and auxiliary map value and directly drives the solenoid valve in the E-EGR to regulate the opening extent of the EGR valve and sends the feedback to the potentiometer. E-EGR SYSTEM korando 2010.10… -

Page 259

(2) Shut off conditions Abrupt acceleration: with engine speed of 2600 rpm or more When the engine is idling for more than 1 minute Vehicle speed: 100 km/h or more Engine torque: 380 Nm or more E-EGR SYSTEM korando 2010.10… -

Page 261

182.41㎤ 124 X 158 X 78L Size 124 X 158 X 194 (mm) Shell SUS430J1L X 1.5t CDPF Canister End Cone SUS430J1L X 2.0t (Single) Catalyst Capacity 4.2 L CDPF Material of Filter AT (Aluminum-Titanium Alloy) CDPF SYSTEM korando 2010.10… -

Page 262

For the vehicles used in urban traffic, driving on the expressways for more than 1 hour at least once per week is needed so that the PM inside CDPF isn’t collected to one side only. CDPF SYSTEM korando 2010.10… -

Page 263

80 km/h for 15 to 20 minutes to perform the CDPF regeneration process. If the engine warning lamp on the instrument cluster blinks, the CDPF is overloaded. In this case, perform the step 2. CDPF SYSTEM korando 2010.10… -

Page 264

To solve this problem, blow soot between the engine and exhaust system several times and erase the related DTC. Then, check if the same DTC is regenerated again. If so, check the DTC related to the differential pressure sensor. CDPF SYSTEM korando 2010.10… -

Page 265

Matter) and is regenerated to reduce the quantity of particulates, HC and CO. But there is a limitation in reducing the emission of exhaust gas for each system, so the CDPF which combines these two system is applied. CDPF SYSTEM korando 2010.10… -

Page 266

Differential pressure sensor Throttle valve Engine ECU DCM 3.7 Calculates the amount of PM collected by reading the pressure difference Regulates the rate of air Post-injection between before and after intake. the CDPF. CDPF SYSTEM korando 2010.10… -

Page 267

Differential pressure sensor: This sensor checks the amount of PM collected by calculating the pressure difference between before and after the CDPF. Electric throttle valve: This valve reduces the intake air flow to raise the temperature of the exhaust gas when the CDPF is operating during idling. CDPF SYSTEM korando 2010.10… -

Page 268

When the engine is running with low load, the intake air amount is also controlled as well as fuel injection amount. This function is used to increaser the combustion temperature by increasing the amount of fuel post-injection with the lowest air amount within the specified control logic. CDPF SYSTEM korando 2010.10… -

Page 269

CDPF is measured T-MAP sensor before and after by the differential the CDPF. pressure sensor (If PM is collected in the CDPF, the pressure difference between before and after the CDPF exceeds the specified value). CDPF SYSTEM korando 2010.10… -

Page 270

CDPF, and the accumulated, the engine temperature of the exhaust ECU performs post-injection gas is increased to between to increase the exhaust gas temperature and burns the 450 and 500°C. collected PM at approx. 600°C. CDPF SYSTEM korando 2010.10… -

Page 271

14-13 2412-00 6. OPERATING TEMPERATURE CDPF SYSTEM korando 2010.10… -

Page 272

14-14 2412-00 7. ELECTRIC CIRCUIT DIAGRAM CDPF SYSTEM korando 2010.10… -

Page 273

15-3 0000-00 1. ENGINE DATA LIST Data Unit Value Coolant temperature ℃ 0.436 V (130℃) to 4.896 V (-40℃) Intake air temperature ℃ -40 to 130℃ (varies by ambient air temperature or engine mode) 780 ± 20 Idle speed 750 ± 20 Engine load 18~25% Mass air flow… -

Page 274

15-4 0000-00 1. MAJOR COMPONENT Rear exhaust gas Front exhaust gas Injector (C3I) Oxygen sensor temp. sensor temp. sensor Camshaft position sensor Glow plug Variable swirl valve Electronic throttle T-MAP sensor Knock sensor (2) Oil level sensor body (Temp.+Pres.) ENGINE CONTROL SYSTEM undefined… -

Page 275

15-5 0000-00 GCU (Glow plug Differential pres. D20DTF ECU Fuel temp. sensor control unit) sensor Coolant temp. sensor HFM (air mass/temperature) E-EGR Fuel rail pres. E-EGR valve sensor bypass valve ENGINE CONTROL SYSTEM undefined… -

Page 276

15-6 0000-00 2. SYSTEM OPERATION 1) Input/Output of ECU (1) ECU Block diagram ENGINE CONTROL SYSTEM undefined… -

Page 277

15-7 0000-00 (2) Components for ECU Input Crankshaft Accel. pedal Throttle HFM sensor posi. sensor posi. sensor posi.sensor Exhaust gas Knock sensor temp. sensor T-MAP sensor Differential pressure sensor Oxygen E-EGR valve Camshaft posi. sensor posi. sensor sensor Fuel rail pres.sensor Coolant temp. -

Page 278

15-8 0000-00 (3) Components for ECU Input Start motor Injector Variable swirl Throttle posi. compressor valve sensor E-EGR valve E-EGR cooler E-VGT bypass valve actuator Engine room PTC heater Cooling fan relay box — Glow plug unit — ABS & ESP unit — BCM — E-coupling unit — EPS… -

Page 279

15-9 0000-00 2) ECU Control (1) Function a. ECU Function ECU receives and analyzes signals from various sensors and then modifies those signals into permissible voltage levels and analyzes to control respective actuators. ECU microprocessor calculates injection period and injection timing proper for engine piston speed and crankshaft angle based on input data and stored specific map to control the engine power and emission gas. -

Page 280

15-10 0000-00 (2) Fuel Control a. Fuel Pressure Control Elements Pressure control consists of 2 principles. Determines rail pressure according to engine operating conditions. Controls IMV to make the rail pressure to reach to the required value. Pressure in the fuel rail is determined according to engine speed and load on the engine. When engine speed and load are high The degree of turbulence is very great and the fuel can be injected at very high pressure in order to optimize combustion. -

Page 281

15-11 0000-00 c. Fuel Injection Control Injection control is used in order to determine the characteristics of the pulse which is sent to the injectors. Injection control consists as below. Injection timing Injection volume Translating fuel injection timing and injection volume into values which can be interpreted by the injector driver. -

Page 282

15-12 0000-00 ▶ Pilot injection timing control The pilot injection timing is determined as a function of the engine speed and of the total flow. The elements are: A first correction is made according to the air and coolant temperatures. This correction allows the pilot injection timing to be adapted to the operating temperature of the engine. -

Page 283

15-13 0000-00 2. Driver Demand The driver demand is the translation of the pedal position into the fuel demand. It is calculated as a function of the pedal position and of the engine speed. The driver demand is filtered in order to limit the hesitations caused by rapid changes of the pedal position. -

Page 284

15-14 0000-00 3. Idle Speed Controller The idle speed controller consists of 2 principal modules: The first module determines the required idle speed according to: * The operating conditions of the engine (coolant temperature, gear engaged) * Any activation of the electrical consumers (power steering, air conditioning, others) * The battery voltage * The presence of any faults liable to interface with the rail pressure control or the injection control. -

Page 285

15-15 0000-00 5. Pilot Flow Control The pilot flow represents the amount of fuel injected into the cylinder during the pilot injection. This amount is determined according to the engine speed and the total flow. A first correction is made according to the air and water temperature. This correction allows the pilot flow to be adapted to the operating temperature of the engine. -

Page 286

15-16 0000-00 e. MDP Learning Control MDP (Minimum Drive Pulse ) refers to the minimum power supply pulse for injection which the injector can perform. It is possible to control the fuel volume for each injector accurately through correct learning for the MDP value. -

Page 287

15-17 0000-00 (3) Accelerometer Control a. Resetting the pilot injection The accelerometer is used to reset the pilot injection flow in closed loop for each injector. This method allows the correction of any injector deviations over a period of time. The principle of use of the accelerometer is based on the detection of the combustion noises. -

Page 288

15-18 0000-00 This is done periodically under certain operating conditions. When the resetting is finished, the new minimum pulse value replaces the value obtained during the previous resetting. The first MDP value is provided by the C3I. Each resetting then allows the closed loop of the MDP to be updated according to the deviation of the injector. -

Page 289

15-19 0000-00 (4) Swirl control a. Overview Variable swirl valve The strong swirl caused by intake air is important element for anti-locking function in diesel engine. The swirl control valve partially closes the intake port to generate the swirl according to the engine conditions. -

Page 290

15-20 0000-00 b. Input/Output for variable swirl valve ENGINE CONTROL SYSTEM undefined… -

Page 291

15-21 0000-00 c. Swirl control In DI type diesel engine, the liquefied fuel is injected into the cylinder directly. If the fuel is evenly distributed in short period, the combustion efficiency could be improved. To get this, there should be good air flow in cylinder. In general, there are two intake ports, swirl port and tangential port, in each cylinder. -

Page 292

15-22 0000-00 d. Features Swirl and air intake efficiency To generate the swirl, the intake port should be serpentine design. This makes the resistance in air flow. The resistance in air flow in engine high speed decreases the intake efficiency. Eventually, the engine power is also decreased, Thus, the swirl operation is deactivated in high speed range to increase the intake efficiency. -

Page 293

15-23 0000-00 (5) EGR control a. Overview The EGR (Electric-Exhaust Gas Recirculation) valve reduces the NOx emission level by recirculating some of the exhaust gas to the intake system. The major difference with the previous EURO 4 type, is that the DC motor with improved response rate according to the EURO 5 regulation. -

Page 294

15-24 0000-00 c. Input/Output of E-EGR system ENGINE CONTROL SYSTEM undefined… -

Page 295

15-25 0000-00 d. Bypass control for EGR cooler 1. Cooler temperature When the coolant temperature is below 70℃, the exhaust gas is bypassed the EGR cooler. 2. Exhaust gas temperature When the exhaust gas temperature is below 300℃, the exhaust gas is bypassed the EGR cooler. -

Page 296

15-26 0000-00 f. Features As EGR ratio goes up, smoke volume will be As EGR temperature goes up, the higher. But, this lowers the combustion concentration of NOx will be higher. Thus, it chamber temperature and accordingly the is necessary to cool down the exhaust gas. concentration of NOx is decreased. -

Page 297

15-27 0000-00 (6) E-VGT control a. Overview E-VGT (Electric-Variable Geometry Turbine) turbocharger system in D20DTF engine uses the venturi effect that controls the flow rate of exhaust gas by adjusting the passage in turbine housing. The newly adopted DC motor actuator (E-actuator) controls the E-VGT system more precisely and faster. -

Page 298

15-28 0000-00 c. Input/Output for E-VGT system ENGINE CONTROL SYSTEM undefined… -

Page 299

15-29 0000-00 d. E-VGT system control Turbocharger system operates the E-VGT actuator according to the signals for engine epm, accelerator pedal position, atmospheric pressure, T-MAP, coolant temperature and intake air temperature. Turbocharger actuator is performed PWM control by ECU. In general, the boost pressure feedbacks the turbocharger operation and the boost temperature is used for calculating the precise density. -

Page 300

15-30 0000-00 (7) Wide band oxygen sensor a. Overview For diesel engine, combustion is not performed at the optimum (theoretically correct) air-fuel ratio and the oxygen concentration is thin in most cases. So the wide-band oxygen sensor is used for this kind of engine, and this sensor is a little different from the one that used for gasoline engine. -

Page 301

15-31 0000-00 c. Input/Output for oxygen sensor ENGINE CONTROL SYSTEM undefined… -

Page 302

15-32 0000-00 d. Oxygen sensor control The wide band oxygen sensor uses ZnO2. It produces the voltage by movement of oxygen ions when there is oxygen concentration difference between exhaust gas and atmosphere. If a certain voltage is applied to the sensor, the movement of oxygen ions occurs regardless of the oxygen density. -

Page 303

15-33 0000-00 (8) Cooling fan control a. Overview of cooling fan and A/C compressor The cooling system maintains the engine temperature at an efficient level during all engine operating conditions. The water pump draws the coolant from the radiator. The coolant then circulates through water jackets in the engine block, the intake manifold, and the cylinder head. -

Page 304

15-34 0000-00 c. Input/Output for cooling fan and A/C compressor ENGINE CONTROL SYSTEM undefined… -

Page 305

15-35 0000-00 d. Cooling fan and A/C compressor control Conditions for cooling fan ▶ The cooling fan module controls the cooling fan relay, high speed relay and low speed relay. The cooling fan is controlled by the series and parallel circuits. Refrigerant pressure Cooling Coolant temperature… -

Page 306

15-36 0000-00 (9) PTC heater control a. Overview The supplementary electrical heater is installed in DI engine equipped vehicle as a basic equipment. The PTC system is operated according to two temperature values measured at the coolant temperature sensor and HFM sensor. This device is mounted in the heater air outlet and increase the temperature of air to the passenger compartment. -

Page 307

15-37 0000-00 c. Operation process The ceramic PTC has a feature that the resistance goes up very high at a certain temperature. There are three circuits in PTC heater. Only one circuit is connected when PTC1 relay is ON, and two circuits are connected when PTC2 relay is ON. Operation process: reaches at a certain temperature→high resistance→low current→less heat radiation→temperature down→high resistance→high current→temperature up ENGINE CONTROL SYSTEM… -

Page 308

15-38 0000-00 d. Control conditions Operation Operating condition PTC Heater PTC HI ON — Coolant temperature < 15℃ (PTC2) — Coolant temperature 15℃ ≤ 65℃, intake air temperature ≤ -10℃ — Coolant temperature 15℃ < 65 to 60℃, intake air PTC LO ON temperature <-10℃… -

Page 309

15-39 0000-00 (10) Immobilizer control a. Overview The Immobilizer System provides an additional theft deterrent to the vehicle in which it is installed and prevents it from being started by unauthorized persons. The transponder integrated in the key and the engine control unit have the same code. When the ignition key with the integrated transponder is turned to the ON position, the ECU (Engine Control Unit) checks the crypto code of the key and, if correct, allows the vehicle to start the engine. -

Page 310

15-40 0000-00 ▶ Key approval process When turning the ignition switch to ON position, the power is supplied to BCM and ECU. ECU communicate with the immobilizer key to check if it is valid crypto code. If it is valid, ECU start to control the engine when turning the ignition switch to START position. -

Page 311

15-41 0000-00 (11) CDPF control a. Overview As the solution for environmental regulations and PM Particle Material) of diesel engine, the low emission vehicle is getting popular. This vehicle is equipped with an extra filter to collect the soot and burn it again so that the amount of PM in the exhaust gas passed through the DOC (Diesel Oxidation Catalyst) is reduced. -

Page 312

15-42 0000-00 c. Input/Output for CDPF control ENGINE CONTROL SYSTEM undefined… -

Page 313

15-43 0000-00 d. Operation process When the differential pressure sensor detects the pressure difference between the front and the rear side of CDPF, the sensor sends signal indicating the soot is accumulated and the post injection is performed to raise the temperature of exhaust gas. The amount of fuel injected is determined according to the temperature of exhaust gas detected by the rear temperature sensor. -

Page 314

15-44 0000-00 e. Cautions Use only specified Engine Oil (approved by MB Sheet 229.51) for CDPF. 1. Use only specified engine oil (Low Ash Oil) The vehicle equipped with CDPF should use specific engine oil to improve the engine performance and fuel economy, and ensure the service life of CDPF. 2. -

Page 315

15-45 0000-00 3) Input/Output for CAN communication (1) Configuration of CAN (P-CAN/B-CAN) Abbreviation Function Glow Control Unit Electronic Power Steering Unit Body Control Module CAN Topology communicate with system units. There are two types (P-CAN and B-CAN) of communication according to the communication speed. Instrument cluster, BCM and diagnostic connector use both types of communication. -

Page 316

15-46 0000-00 (2) CAN communication flow chart Splice pack Wiring harness Location S101 Floor wiring (LH) Under fuse & relay box in engine compartment S102 Floor wiring (RH) Inside of right fender S201 Main wiring Behind meter cluster (cowl cross member) S202 Main wiring Behind meter cluster (cowl cross member) -

Page 317

15-47 0000-00 (3) Input/Output for CAN communication ENGINE CONTROL SYSTEM undefined… -

Page 318

ELECTRIC GENERAL INFORMATION 0000-01 GENERAL INFORMATION ELECTRIC GENERAL INFORMATION 1. EXTERIOR LAMP SYSTEM LAYOUT..2. INTERIOR LAMP SYSTEM LAYOUT..3. SWITCH SYSTEM LAYOUT….4. SCHEMATIC DIAGRAM FOR WIRING AND ELECTRICAL DEVICES….5. CAN COMMUNICATION CONFIGURATION…….. -

Page 320: Exterior Lamp System Layout

Side repeater lamp Puddle lamp Front turn signal lamp Position lamp Headlamp assembly Front fog lamp Rear view High-mounted stop lamp Tail/stop lamp Backup lamp Rear turn signal lamp Tail lamp Reflector License plate lamp ELECTRIC GENERAL INFORMATION korando 2010.10…

-

Page 321

01-4 0000-00 Headlamp High-beam/low-beam Turn signal lamp Position lamp Front fog lamp Puddle (approach) lamp Side repeater lamp ELECTRIC GENERAL INFORMATION korando 2010.10… -

Page 322

01-5 0000-00 Rear combination lamp Stop lamp and tail lamp Turn signal lamp Backup lamp Stop lamp (For Korea) Rear fog lamp License plate lamp High mounted stop lamp Vehicle with spoiler Vehicle without spoiler ELECTRIC GENERAL INFORMATION korando 2010.10… -

Page 323: Interior Lamp System Layout

01-6 0000-00 2. INTERIOR LAMP SYSTEM LAYOUT Glove box lamp Front room lamp Sun visor lamp ELECTRIC GENERAL INFORMATION korando 2010.10…

-

Page 324

01-7 0000-00 Center room lamp Luggage lamp Door courtesy lamp ELECTRIC GENERAL INFORMATION korando 2010.10… -

Page 325: Switch System Layout

Overhead console Passenger door control switch switch switch Cruise control switch Multifunction switch Lower main panel switch Drive door main switch & FATC switch Hazard warning switch and Outside rear view mirror bezel assembly switch ELECTRIC GENERAL INFORMATION korando 2010.10…

-

Page 326

01-9 0000-00 Front seat heated wire Rear door switch (RH) switch (STD) Center room lamp switch Luggage lamp switch Tailgate switch Driver power seat Rear door switch (LH) switch ELECTRIC GENERAL INFORMATION korando 2010.10… -

Page 327: Schematic Diagram For Wiring And Electrical Devices

01-10 0000-00 4. SCHEMATIC DIAGRAM FOR WIRING AND ELECTRICAL DEVICES 1) Wiring Harness Arrangement ELECTRIC GENERAL INFORMATION korando 2010.10…

-

Page 328

01-11 0000-00 2) Electrical devices mounting locations ELECTRIC GENERAL INFORMATION korando 2010.10… -

Page 329

01-12 0000-00 3) Connector, Ground And Splice Pack ▶ Connector ELECTRIC GENERAL INFORMATION korando 2010.10… -

Page 330

01-13 0000-00 ▶ Ground ▶ Splice pack ELECTRIC GENERAL INFORMATION korando 2010.10… -

Page 331: Can Communication Configuration

CAN and B-CAN at the same time. 1) CAN Configurations (P-CAN/B-CAN) Abbreviations Meaning Function Glow Control Unit Glow control unit Electronic Power Steering Unit Electrically driven power steering unit Body Control Module Body control module ELECTRIC GENERAL INFORMATION korando 2010.10…

-

Page 332

Floor wiring (RH) Inside of right fender S201 Main wiring Behind the instrument cluster (cowl cross member) S202 Main wiring Behind the instrument cluster (cowl cross member) S205 Floor wiring (LH) Under driver door scuff ELECTRIC GENERAL INFORMATION korando 2010.10… -

Page 334

If a fuse is blown, replace it with a rated sensors and relays. capacity fuse. If you use a fuse with capacity higher than the specification, corresponding parts can be damaged or a fire can break out. FUSE AND RELAY korando 2010.10… -

Page 335

When inspecting the airbag system, make sure to use a diagnostic device, not a circuit tester. FUSE AND RELAY korando 2010.10… -

Page 336

The rotating parts, such as fan pulley and fan belt, perturbative parts and wiring should be secured tightly at regular intervals. Wiring between fixed parts, such as the vehicle body, and vibrating parts, such as the engine, should be fixed after making it slack to afford vibration. FUSE AND RELAY korando 2010.10… -

Page 337

ICM (Integrated Control Module): Rear wiper, rear fog lamp, mirror folding, ACC, IGN1 & 2, horn, tailgate, power outlet, shift lock relay (A/T) 2. SYSTEM LAYOUT ICM box Fuse box in engine compartment Interior fuse box FUSE AND RELAY korando 2010.10… -

Page 338

1) Fuse & Relay Box in Engine Compartment The fuse & relay box is located beside the battery. It contains wiper, horn, heated wire, fog lamp, tail lamp and PTC relays. the B+ is supplied from ALT+. ▶ Fuse & relay FUSE AND RELAY korando 2010.10… -

Page 339

01-8 8410-06 ▶ Circuit diagram I FUSE AND RELAY korando 2010.10… -

Page 340

01-9 8410-06 Circuit diagram II ▶ FUSE AND RELAY korando 2010.10… -

Page 341

01-10 8410-06 ▶ Fuse & relay box III FUSE AND RELAY korando 2010.10… -

Page 342

01-11 8410-06 2) Interior Fuse Box This fuse box is located in the left side of instrument panel. ▶ Fuse & relay FUSE AND RELAY korando 2010.10… -

Page 343

01-12 8410-06 ▶ Circuit diagram I FUSE AND RELAY korando 2010.10… -

Page 344

01-13 8410-06 Circuit diagram II ▶ FUSE AND RELAY korando 2010.10… -

Page 345

01-14 8410-06 3) ICM Box ▶ Function descriptions FUSE AND RELAY korando 2010.10… -

Page 346

Rear wiper motor Multifunction switch (RH) Front & rear power outlet ACC (F47) B+ (F46) BCM (Mirror folding control) Fuse box Ground ICM «C10» BCM (Mirror unfolding control) IGN2 (F39) Mirror unfolding motor Rear wiper motor FUSE AND RELAY korando 2010.10… -

Page 347

Pin No. Function Pin No. Function Warning horn Stop lamp switch B+ (F42) Tailgate actuator IGN (F31) B+ (F45) Mirror folding motor B+ (F45) Ground Rear fog lamp ICM «C16» TGS lever B+ (F52) TGS lever FUSE AND RELAY korando 2010.10… -

Page 348

01-17 8410-06 ICM box is located behind the instrument cluster. ▶ Circuit board FUSE AND RELAY korando 2010.10… -

Page 349

The rear fog lamps do not come ON when the engine is not running or the light switch is OFF. The rear fog lamps should not automatically come on again if they have been turned OFF by any other way other than the switch. FUSE AND RELAY korando 2010.10… -

Page 350

When pressing the mirror folding/unfolding switch with IGN ON, the mirrors are folded or un- floded according to the mirror condition in 16±6 seconds. (4) Horn relay Power supply: SB1, Interior fuse box No. 45, ICM C5 Operating signal: BCM A24 (ON/OFF) FUSE AND RELAY korando 2010.10… -

Page 351

3 km/h. (6) Shift lock relay (for A/T) Power supply: SB2, Interior fuse box No. 31, ICM C1 (with stop lamp switch ON) Operating signal: No. 10 in gear selector lever connector (ON/OFF) FUSE AND RELAY korando 2010.10… -

Page 352

01-21 8410-06 (7) Power outlet relay Power supply: SB1, Interior fuse box No. 46, ICM B10 Operating signal: Interior fuse box No. 47 (with key ACC), ICM B12 (grounded) FUSE AND RELAY korando 2010.10… -

Page 353

01-22 8410-02 Fuse & Relay Box Connectors Connector C Connector B Connector D Connector A FUSE AND RELAY korando 2010.10… -

Page 354

01-23 8410-02 Function descriptions of connectors ▶ Connector A Pin No. Function Glow control FUSE AND RELAY korando 2010.10… -

Page 355

Tail lamp (LH) «2», S203 «19» (ILL+) TGS, Auto light PTC heater2 «3» DI ECU «B3» Light switch (High beam) «1» DI ECU «B1» Position lamp (LH) «2» PTC heater 1 «1» C104 «21» BCM «D3» (Low beam relay) FUSE AND RELAY korando 2010.10… -

Page 356

(driver) Outside mirror motor DI ECU «B37» (passenger) «6»(heated wire) BCM «D8» (Power window) Windshield heated wire «1» BCM «A12», Hazard & glass heated wire switch «2» HFM «1», Glow control unit «A5», VGT «1» FUSE AND RELAY korando 2010.10… -

Page 357

Rear glass heated wire «1» G101 ABS/ESP unit «1» BCM «D15″(wiper Hi) Fuel heater «2» Start motor «ST» Wiper motor (Hi) «6» G101 BCM «A25», Hazard & glass Low beam (LH) «2» heated wire switch «8» FUSE AND RELAY korando 2010.10… -

Page 358

-40 to +85°C temperature Max. humidity High resistant voltage 24 V Dark current Below 7.0 mA All switches OFF, key out, all doors LOCK and Sleep mode Voltage drop Below 1.0 V at pin B6 and all pins for IN/OUT korando 2010.10… -

Page 359

Sunroof warning display Room lamp control Door coupled room lamp and dimming control Room lamp OFF control Room lamp control display Key hole Key hole illumination illumination control Defogger (heated Front defogger timer wire) control Rear defogger timer korando 2010.10… -

Page 360

Panic alarm control by REKES signal Tailgate open Tailgate open control control Theft deterrent Theft deterrent mode control mode control Time lag power Time lag power window control window control System power System power sleep mode control sleep mode korando 2010.10… -

Page 361

Fog lamp control Auto light control Auto light control (LIN) Immobilizer function Key coding and synchronization Challenge CAN information Mirror Folding/unfolding control folding/unfolding Auto folding/unfolding control control Approach (puddle) Approach (puddle) lamp control lamp control Diagnosis function Diagnostic control korando 2010.10… -

Page 362

1) Wiper Control (1) Wiper mist & washer coupled wiper ▶ Wiper mist When turning ON the front washer switch with IGN1 ON, the front wipers operate after T1. When releasing the switch, the wipers will stop at parking positions. korando 2010.10… -

Page 363

02-8 8710-01 ▶ Front washer coupled wiper When holding the front washer switch at ON position for more than T2 with IGN1 ON, the washer fluid is sprayed onto the windshield glass and the wipers operate three times. korando 2010.10… -

Page 364

When holding it between 0.1 and 0.59 seconds, the wiper will operate only once. ▶ Rear washer motor control When turning ON the rear washer switch with key IN and IGN1 ON, the washer fluid is sprayed onto the tailgate glass. korando 2010.10… -

Page 365

When turning the wiper switch to AUTO position during the operation of auto washer, the auto washer stops its operation and the intermittent wiping mode will be started. The front and rear washer function are not available during the operation of auto washer. korando 2010.10… -

Page 366

02-11 8710-01 Rain sensor coupled wiper (LIN) ▶ System layout korando 2010.10… -

Page 367

When moving the wiper switch to «AUTO» from «OFF» position with IGN2 ON, the wipers operate one cycle through wiper low relay regardless of the communication with the rain sensor. Afterward, the wipers operate only when receiving S_RAIN (raining) signal from the rain sensor. korando 2010.10… -

Page 368

ON, wiper switch AUTO and wiper motor stop (parking), the wipers operate one cycle through the low relay. (only when the signal from rain sensor is «raining») If the volume sensitivity is changed within 2 seconds, the wipers operate only one cycle. ※ korando 2010.10… -

Page 369

When the parking terminal is fixed at IGN (HIGH) with IGN2 ON and wiper switch AUTO, the wiper system sends the wiper operating signal for 2 seconds, then continuously sends the wiper parking signal. The wiper motor runs only when the rain sensor requires the wiper operation. ※ korando 2010.10… -

Page 370

When changing the volume sensitivity to «3» from «4» with IGN2 ON and wiper switch AUTO while receiving S_COMMFAULT (communication error) signal from rain sensor, the wipers operate one cycle through the low relay. korando 2010.10… -

Page 371

Vehicle speed and volume sensitivity controls the intermittent wiping operation. The system calculates and changes the intermittent interval by using vehicle speed and volume sensitivity with IGN2 ON and wiper switch AUTO. Intermittent interval (at 0 km/h): 3±0.5 to 19±2 seconds korando 2010.10… -

Page 372

In high/low mode, the rear washer motor should operate when turning ON the rear washer switch. The auto washer function is not available during high/low mode. The wipers should go back to low parking position when turning off the ignition during high mode. korando 2010.10… -

Page 373

10 seconds with the interval of 0.02s ON/1.38s OFF. When removing the ignition key or closing the driver door during the period, the buzzer stops its operation. This function is not available when the ignition switch is in «ON» position. korando 2010.10… -

Page 374

However, the doors should not be unlocked when removing the ignition key during the locking process by door lock switch. (*1) : Driver door lock switch or passenger door lock switch (*2) : Driver door switch or passenger door switch korando 2010.10… -

Page 375