- Manuals

- Brands

- Still Manuals

- Forklifts

- FM-X-17

Manuals and User Guides for Still FM-X-17. We have 3 Still FM-X-17 manuals available for free PDF download: Original Instructions Manual

Still FM-X-17 Original Instructions Manual (380 pages)

Brand: Still

|

Category: Forklifts

|

Size: 14.74 MB

Table of Contents

-

Table of Contents

5

-

Foreword

13

-

Your Truck

14

-

General

14

-

Conformity Marking

14

-

Declaration that Reflects the Content of the Declaration of Conformity

15

-

Accessories

16

-

Labelling Points

17

-

Nameplate

18

-

Production Number

19

-

Nameplate for a 48-V Lithium-Ion Battery

20

-

Declarations of Conformity in Accordance with Directive RED 2014/53/EU

21

-

Using the Truck

22

-

Commissioning

22

-

Proper Usage

22

-

Intended Use of the Lithium-Ion Battery (Variant)

22

-

Improper Use

23

-

Place of Use

23

-

Parking in Temperatures below -10 °C

24

-

Using Working Platforms

24

-

Information about the Documentation

25

-

Documentation Scope

25

-

Supplementary Documentation

26

-

Issue Date and Topicality of the Operating Instructions

27

-

Copyright and Trademark Rights

27

-

Explanation of Information Symbols Used

27

-

List of Abbreviations

28

-

Defining Directions

30

-

Schematic Views

31

-

Environmental Considerations

32

-

Packaging

32

-

Disposal of Components and Batteries

32

-

Safety

33

-

Definition of Responsible Persons

34

-

Operating Company

34

-

Specialist

34

-

Drivers

35

-

Basic Principles for Safe Operation

37

-

Insurance Cover on Company Premises

37

-

Special Notes When Using Lithium-Ion Batteries (Variant)

37

-

Changes and Retrofitting

41

-

Modifications to the Overhead Guard and Cabs

42

-

Seat Belt

43

-

Safety Information for FM-X Wide, Extra Wide (W, EW)

43

-

Warning Regarding Non-Original Parts

44

-

Damage, Defects and Misuse of Safety Systems

44

-

Wheels and Tyres

45

-

Medical Equipment

46

-

Exercise Caution When Handling Gas Springs and Accumulators

46

-

Length of the Fork Arms

47

-

Residual Risk

48

-

Residual Dangers, Residual Risks

48

-

Special Risks Associated with Using the Truck and Attachments

49

-

Overview of Hazards and Countermeasures

52

-

Danger to Employees

54

-

Safety Tests

56

-

Carrying out Regular Inspections on the Truck

56

-

Insulation Testing

56

-

Safety Regulations for Handling Consumables

58

-

Permissible Consumables

58

-

Oils

58

-

Hydraulic Fluid

59

-

Battery Acid

60

-

Brake Fluid

61

-

Disposal of Consumables

63

-

Commissioning Fleetmanager™ (Variant)

64

-

Activating the Access Control after Delivery of the Truck

64

-

Emissions

64

-

Overviews

67

-

Overview

68

-

Overview of the Driver’s Compartment

69

-

Shelves and Cup Holders

70

-

Operating Devices and Display Elements

71

-

Display and Operating Unit

71

-

Operating Status Displays on the Display and Operating Unit

72

-

Display Messages

73

-

Entering Truck Operating Data Via the Display and Operating Unit

77

-

Lithium-Ion Battery Display

81

-

Operating Devices for Hydraulic and Traction Functions

81

-

Joystick 4Plus

82

-

Fingertip

83

-

Operating

85

-

Checks and Tasks before Daily Use

86

-

Visual Inspections and Function Checking

86

-

Climbing into and out of the Truck

89

-

Adjusting the MSG 65/MSG 75 Driver’s Seat

91

-

Adjusting the Steering Column

95

-

Filling the Washer System (Variant)

96

-

Unlocking the Emergency off Switch

97

-

Access Authorisation with PIN Code (Variant)

97

-

Operating the Signal Horn

98

-

Checking the Brake System for Correct Function

98

-

Checking the Steering System for Correct Function

100

-

Checking the Emergency off Function

100

-

Checking the «Automatic Tilting Centre Position» (Variant) for Correct Function

101

-

Switching on

102

-

Switching on the Key Switch

102

-

Lighting

105

-

STILL Safetylight (Variant)

105

-

Switching the Working Spotlights (Variant) on and off

106

-

Daytime Running Lights / Footwell Lighting (Variant)

107

-

Efficiency and Drive Modes

108

-

Blue-Q Efficiency Mode

108

-

OPTISPEED — Continuously Variable Reduction in Driving Speed or Hydraulic Functions (Variant)

108

-

Driving

111

-

Safety Regulations When Driving

111

-

Roadways

113

-

Side Chassis Supports

115

-

Enabling Truck Functions Using the Foot Switch and Seat Switch

116

-

Setting the Drive Programme

118

-

Selecting the Drive Direction

119

-

Actuating the Drive Direction Switch, Joystick 4Plus

120

-

Actuating the Drive Direction Switch, Fingertip

120

-

Starting Drive Mode, Single-Pedal Version

121

-

Starting Drive Mode, Dual-Pedal Version (Variant)

123

-

Operating the Service Brake

125

-

Applying the Electromagnetic Parking Brake

126

-

Steering

128

-

Switching between 360°/180° Steering (Variant)

130

-

Emergency Operation of the Reach Measurement System

132

-

Parking

134

-

Parking the Truck Securely

134

-

Lifting

136

-

Lifting System Variants

136

-

Lift Mast Versions

136

-

Lifting System Operating Devices

137

-

Joystick 4Plus Lifting System

138

-

Fingertip Lifting System

141

-

Electronic Lowering Stop Function

143

-

Automatic Lift Cut out (Variant)

144

-

Reach-Lower Lock (Variant)

145

-

Automatic Centre Position (Variant)

146

-

Fork Wear Protection (Variant)

147

-

Changing the Fork Arms

147

-

Speed Limitation Safety Function

149

-

Fork Extension (Variant)

151

-

Load Backrest (Variant)

153

-

Working Platforms

153

-

Malfunctions in Lifting Mode

153

-

Handling Loads

155

-

Safety Regulations When Handing Loads

155

-

Before Picking up a Load

155

-

Picking up Loads

157

-

Danger Area

159

-

Transporting Pallets

160

-

Transporting Suspended Loads

160

-

Picking up a Load

161

-

Transporting Loads

165

-

Setting down Loads

167

-

Driving on Upward and Downward Gradients

169

-

Driving Onto Lifts

169

-

Attachments

171

-

Fitting Attachments

171

-

Releasing the Pressure from the Auxiliary Hydraulics

174

-

General Instructions for Controlling Attachments

175

-

Controlling Attachments (Variant) Using the Joystick 4Plus (5Th/6Th Hydraulic Function)

177

-

Controlling Attachments (Variant) with the Fingertip (5Th/6Th Hydraulic Function)

179

-

Operating the Clamp Locking Mechanism (Variant) with a Joystick 4Plus

181

-

Operating the Clamp Locking Mechanism (Variant) with the Fingertip Switch

183

-

Picking up a Load Using Attachments

184

-

Assistance Systems

186

-

Automatic Fork Centre Position During Lowering (Variant)

186

-

Lowering Protection Assistant (Variant)

188

-

Auxiliary Equipment

190

-

Fleetmanager (Variant)

190

-

Shock Recognition (Variant)

190

-

Active Load Stabilisation als (Variant)

190

-

Optical Height Measuring System (Variant)

192

-

Load Measurement (Variant)

196

-

Speed Limitation Based on Lift Height

198

-

Button for Speed Limitation, Creep Speed (Variant)

199

-

Camera/Monitor System (Variant)

200

-

Electrical Adjustment Mechanism for the Driver’s Compartment (Variant)

200

-

Overhead Guard with Optimised Visibility (Variant)

201

-

Clipboard (Variant)

202

-

Battery Change Frame (Variant)

203

-

General

203

-

Safe Handling

203

-

Load Capacity

203

-

Area of Application

204

-

Adjusting the Transfer Height

204

-

Locking the Battery Change Frame

205

-

Battery Replacement Area

205

-

Lift Height Preselector / Easy Target (Variant)

207

-

General

207

-

Definition of Terms

208

-

AUTO MODE Function

209

-

Operating the Lift Height Preselector

212

-

Teach-In, General

215

-

Performing a Teach-In

216

-

Easy Target/Easy Target Plus (Variants)

219

-

Approaching Target Heights Using «Easy Target

221

-

Positioning the Fork Horizontally Using «Easy Target Plus

222

-

Cab (Variant)

224

-

General Information about the Cab

224

-

Opening the Cab Door

224

-

Closing the Cab Door

226

-

Cab Operating Devices

226

-

Cab Interior Lighting (Variant)

227

-

Heating System in the Cab (Variant)

228

-

Emergency Exit Window in the Cab

230

-

Cold Store Application

232

-

General

232

-

Areas of Application

232

-

Description of the Cold Store Equipment

233

-

Battery in the Cold Store

234

-

Impermissible Use of the Lithium-Ion Battery in the Shock Cold Store (-45°C)

235

-

Before Entering the Cold Store

235

-

Procedure in Emergencies

237

-

Emergency Shutdown

237

-

Procedure if Truck Tips over

238

-

Emergency Lowering

239

-

Towing

240

-

Connecting and Disconnecting the Battery Male Connector

243

-

Connecting the Battery Male Connector

243

-

Disconnecting the Battery Male Connector

243

-

Handling the Lead-Acid Battery

245

-

Safety Regulations When Handling the Battery

245

-

Maintaining the Battery

248

-

Checking the Battery Condition, Acid Level and Acid Density

249

-

Checking the Battery Charge Status

251

-

Charging the Battery

251

-

Equalising Charging to Preserve the Battery Capacity

254

-

Handling the Lithium-Ion Battery (Variant)

256

-

Safety Regulations for Handling the Lithium-Ion Battery

256

-

Approved Lithium-Ion Batteries

259

-

Lithium-Ion Batteries «GGS Li-Ion 48 V (BG4)» 9.8 Kwh and 39.2 Kwh

259

-

Regulations for Storing Lithium-Ion Batteries

260

-

Checking the Battery Charge Status (Lithium-Ion Battery)

261

-

Charging the Lithium-Ion Battery Upon Delivery

263

-

Charging the Lithium-Ion Battery

264

-

Recommissioning the Lithium-Ion Battery Following Deep Discharge

266

-

Replacing and Transporting the Battery

268

-

Commissioning Batteries that Are Delivered Separately

268

-

Alternating between a Lead-Acid Battery and a Lithium-Ion Battery

268

-

General Information on Replacing the Battery

268

-

Actuating the Battery Lock

272

-

Adjusting the Battery Lock

273

-

Special Notes for Installing the Lithium-Ion Battery

275

-

Replacing the Battery Using a Lifting Device

275

-

Changing the Battery Using the Internal Roller Channel (Variant)

280

-

Setting the Battery Data (Lead Acid Batteries)

285

-

Transporting the Battery Using a Lifting Device (Lead Acid Batteries)

286

-

Transporting the Battery Using a Lifting Device (Lithium-Ion Batteries)

288

-

Cleaning the Truck

290

-

Cleaning the Electrical System

292

-

Cleaning Load Chains

293

-

Cleaning Panes of Glass and Mirrors

293

-

After Cleaning

294

-

Transporting the Truck

295

-

Transportation

295

-

Crane Loading (Standard Truck with Overhead Guard)

298

-

Crane Loading (Trucks with a Cab)

302

-

Decommissioning

308

-

Shutting down and Storing the Truck

308

-

Re-Commissioning after Shutdown

309

-

Maintenance

311

-

Safety Regulations for Maintenance

312

-

General Information

312

-

Working on the Hydraulic Equipment

312

-

Working on the Electrical Equipment

312

-

Safety Devices

313

-

Set Values

313

-

Lifting and Jacking up

313

-

Working at the Front of the Truck

314

-

General Maintenance Information

316

-

Personnel Qualifications

316

-

Information for Carrying out Maintenance

316

-

Maintenance — 1000 Hours/Year

319

-

Maintenance — 3000 Hours/Every Two Years

325

-

Every 12 Weeks

325

-

Ordering Spare Parts and Wearing Parts

325

-

Quality and Quantity of the Required Operating Materials

326

-

Lubrication Plan

327

-

Maintenance Data Table

329

-

Preserving Operational Readiness

331

-

Checking the Driver’s Seat

331

-

Maintaining Wheels and Tyres

331

-

Checking the Hydraulic System for Leaks

333

-

Greasing the Lift Mast and Roller Tracks

334

-

Checking the Battery Change Frame (Variant)

334

-

Replacing the Heating System Filter for the Cab (Variant)

335

-

Preserving Operational Readiness for Cold Store Application

336

-

Maintenance Tasks for Lithium-Ion Batteries

336

-

Technical Data

337

-

Dimensions

338

-

VDI Datasheet for FM-X 10 / Li-Ion (N), FM-X 12 / Li-Ion (N)

339

-

VDI Datasheet for FM-X 14 / Li-Ion (N, W, EW)

344

-

VDI Datasheet for FM-X 17 / Li-Ion (N, W, EW)

349

-

VDI Datasheet for FM-X 20 / Li-Ion (N, W, EW)

354

-

VDI Datasheet for FM-X 20 HD / Li-Ion

359

-

VDI Datasheet for FM-X 25 / Li-Ion (W, EW)

363

-

Elokon Eloshield Interface (Variant)

367

-

Eco-Design Requirements for Electric Motors and Variable Speed Drives

367

-

Wheels and Tyres

368

-

Battery Specifications for Lithium-Ion Batteries

369

Advertisement

Still FM-X-17 Original Instructions Manual (360 pages)

Reach trucks

Brand: Still

|

Category: Forklifts

|

Size: 17.54 MB

Table of Contents

-

Table of Contents

5

-

1 Foreword

13

-

Your Truck

14

-

General

14

-

CE Labelling

14

-

EC Declaration of Conformity in Accordance with Machinery Directive

15

-

Accessories

16

-

Labelling Points

17

-

Nameplate

18

-

Production Number

19

-

Nameplate of a Lithium-Ion Battery

19

-

Using the Truck

20

-

Commissioning

20

-

Proper Usage

20

-

Intended Use of the Lithium-Ion Battery (Variant)

20

-

Impermissible Use

21

-

Place of Use

21

-

Parking in Temperatures below -10°C

22

-

Fm-X

22

-

Using Working Platforms

23

-

Information about the Documentation

24

-

Documentation Scope

24

-

Fm-X

24

-

Supplementary Documentation

25

-

Issue Date and Topicality of the Operating Instructions

26

-

Copyright and Trademark Rights

26

-

Explanation of Information Symbols Used

26

-

Fm-X

26

-

List of Abbreviations

27

-

Defining Directions

29

-

Fm-X

29

-

Schematic Views

30

-

Environmental Considerations

31

-

Packaging

31

-

Disposal of Components and Batteries

31

-

Fm-X

32

-

-

2 Safety

33

-

Definition of Responsible Persons

34

-

Operating Company

34

-

Specialist

34

-

Drivers

35

-

Basic Principles for Safe Operation

37

-

Insurance Cover on Company Premises

37

-

Special Notes When Using Lithium-Ion Batteries (Variant)

37

-

Changes and Retrofitting

41

-

Modifications to the Overhead Guard and Cabs

43

-

Seat Belt

43

-

Safety Information for FM-X Wide, Extra Wide (W, EW)

44

-

Warning Regarding Non-Original Parts

44

-

Damage, Defects and Misuse of Safety Systems

45

-

Wheels and Tyres

45

-

Medical Equipment

46

-

Exercise Caution When Handling Gas Springs and Accumulators

47

-

Length of the Fork Arms

47

-

Residual Risk

49

-

Residual Dangers, Residual Risks

49

-

Special Risks Associated with Using the Truck and Attachments

50

-

Overview of Hazards and Countermeasures

52

-

Danger to Employees

55

-

Safety Tests

56

-

Carrying out Regular Inspections on the Truck

56

-

Insulation Testing

56

-

Safety Regulations for Handling Consumables

57

-

Permissible Consumables

57

-

Oils

58

-

Hydraulic Fluid

59

-

Battery Acid

60

-

Brake Fluid

61

-

Disposal of Consumables

62

-

Commissioning the Fleetmanager™ (Variant)

63

-

Activating the Access Control after Delivery of the Truck

63

-

Emissions

63

-

-

3 Overviews

67

-

Overview

68

-

Overview of the Driver’s Compartment

69

-

Shelves and Cup Holders

70

-

Operating Devices and Display Elements

71

-

Display and Operating Unit

71

-

Operating Status Displays on the Display and Operating Unit

72

-

Display Messages

73

-

Entering Truck Operating Data Via the Display and Operating Unit

77

-

Lithium-Ion Battery Display

82

-

Operating Devices for Hydraulic and Traction Functions

82

-

Joystick 4Plus

83

-

Fingertip

84

-

-

4 Operation

85

-

Testing and Activities before Daily Use

86

-

Visual Inspections and Function Checking

86

-

Climbing into and out of the Truck

89

-

Adjusting the MSG 65/MSG 75 Driver’s Seat

91

-

Adjusting the Steering Column

95

-

Filling the Washer System (Variant)

96

-

Unlocking the Emergency off Switch

96

-

Switching on the Key Switch

97

-

Access Authorisation with PIN Code (Variant)

99

-

Operating the Signal Horn

100

-

Checking the Brake System for Correct Function

100

-

Checking the Steering System for Correct Function

102

-

Checking the Emergency off Function

102

-

Checking the «Automatic Tilting Centre Position» (Variant) for Correct Function

103

-

Lighting

104

-

STILL Safetylight (Variant)

104

-

Switching the Working Spotlights (Variant) on and off

105

-

Efficiency and Drive Modes

106

-

Blue-Q Efficiency Mode

106

-

OPTISPEED — Continuously Variable Reduction in Driving Speed or Hydraulic Functions (Variant)

106

-

Driving

108

-

Safety Regulations When Driving

108

-

Roadways

110

-

Side Chassis Supports

113

-

Enabling Truck Functions Using the Foot Switch and Seat Switch

113

-

Setting the Drive Programme

116

-

Selecting the Drive Direction

117

-

Actuating the Drive Direction Switch, Joystick 4Plus

118

-

Actuating the Drive Direction Switch, Fingertip

118

-

Starting Drive Mode, Single-Pedal Version

119

-

Starting Drive Mode, Dual-Pedal Version (Variant)

121

-

Operating the Service Brake

123

-

Applying the Electromagnetic Parking Brake

124

-

Steering

126

-

Emergency Operation of the Reach Measurement System

127

-

Parking

130

-

Parking the Truck Securely

130

-

Lifting

131

-

Lifting System Variants

131

-

Lift Mast Versions

131

-

Lifting System Operating Devices

132

-

Joystick 4Plus Lifting System

133

-

Fingertip Lifting System

136

-

Automatic Lift Cut out (Variant)

138

-

Reach-Lower Lock (Variant)

140

-

Automatic Centre Position (Variant)

141

-

Speed Limitation Safety Function

143

-

Changing the Fork Arms

143

-

Fork Extension (Variant)

146

-

Load Backrest (Variant)

147

-

Working Platforms

148

-

Malfunctions in Lifting Mode

148

-

Handling Loads

150

-

Safety Regulations When Handing Loads

150

-

Before Picking up a Load

150

-

Picking up Loads

152

-

Danger Area

154

-

Transporting Pallets

155

-

Transporting Suspended Loads

155

-

Picking up a Load

156

-

Transporting Loads

159

-

Setting down Loads

161

-

Driving on Upward and Downward Gradients

163

-

Driving Onto Lifts

163

-

Attachments

165

-

Fitting Attachments

165

-

Releasing the Pressure from the Auxiliary Hydraulics

167

-

General Instructions for Controlling Attachments

168

-

Controlling Attachments (Variant) Using the Joystick 4Plus (5Th/6Th Hydraulic Function

169

-

Controlling Attachments (Variant) with the Fingertip (5Th/6Th Hydraulic Function)

172

-

Operating the Clamp Locking Mechanism (Variant) with a Joystick 4Plus

174

-

Operating the Clamp Locking Mechanism (Variant) with the Fingertip Switch

176

-

Picking up a Load Using Attachments

177

-

Auxiliary Equipment

178

-

Fleetmanager (Variant)

178

-

Shock Recognition (Variant)

178

-

Active Load Stabilisation als (Variant)

178

-

Optical Height Measuring System (Variant)

180

-

Load Measurement (Variant)

185

-

Speed Limitation Based on Lift Height

187

-

Button for Speed Limitation, Creep Speed (Variant)

188

-

Camera/Monitor System (Variant)

188

-

Electrical Adjustment Mechanism for the Driver’s Compartment (Variant)

189

-

Overhead Guard with Optimised Visibility (Variant)

190

-

Clipboard (Variant)

191

-

Battery Change Frame (Variant)

191

-

General

191

-

Safe Handling

192

-

Load Capacity

192

-

Area of Application

192

-

Adjusting the Transfer Height

193

-

Locking the Battery Change Frame

193

-

Battery Replacement Area

194

-

Lift Height Preselector/Easy Target (Variant)

196

-

General

196

-

Definition of Terms

197

-

AUTO MODE Function

198

-

Operating the Lift Height Preselector

201

-

Teach-In, General

204

-

Performing a Teach-In

205

-

Easy Target/Easy Target Plus (Variants)

208

-

Approaching Target Heights Using «Easy Target

210

-

Positioning the Fork Horizontally Using «Easy Target Plus

211

-

Cab (Variant)

212

-

General Information about the Cab

212

-

Opening the Cab Door

213

-

Closing the Cab Door

214

-

Cab Operating Devices

215

-

Cab Interior Lighting (Variant)

216

-

Heating System in the Cab (Variant)

216

-

Emergency Exit Window in the Cab

219

-

Cold Store Application

219

-

General

219

-

Areas of Application

220

-

Description of the Cold Store Equipment

221

-

Battery in the Cold Store

222

-

-

Impermissible Use of the Lithium-Ion Battery in the Shock Cold Store (-45°C)

222

-

Before Entering the Cold Store

223

-

Procedure in Emergencies

224

-

Emergency Shutdown

224

-

Procedure if Truck Tips over

225

-

Emergency Lowering

226

-

Towing

227

-

Connecting and Disconnecting the Battery Male Connector

229

-

Connecting the Battery Male Connector

229

-

Disconnecting the Battery Male Connector

230

-

Handling the Lead-Acid Battery

231

-

Safety Regulations When Handling the Battery

231

-

Maintaining the Battery

234

-

Checking the Battery Condition, Acid Level and Acid Density

235

-

Checking the Battery Charge Status

237

-

Charging the Battery

237

-

Equalising Charging to Preserve the Battery Capacity

240

-

Handling the Lithium-Ion Battery (Variant)

242

-

Safety Regulations for Handling the Lithium-Ion Battery

242

-

Approved Lithium-Ion Batteries

245

-

Lithium-Ion Batteries «GGS Li-Ion 48 V (BG4)» 9.8 Kwh and 39.2 Kwh

246

-

Regulations for Storing Lithium-Ion Batteries

247

-

Checking the Battery Charge Status (Lithium-Ion Battery)

248

-

Charging the Lithium-Ion Battery Upon Delivery

250

-

Charging the Lithium-Ion Battery

251

-

Recommissioning the Lithium-Ion Battery Following Deep Discharge

253

-

Replacing and Transporting the Battery

254

-

Commissioning Batteries that Are Delivered Separately

254

-

Alternating between a Lead-Acid Battery and a Lithium-Ion Battery

255

-

General Information on Battery Replacement

256

-

Actuating the Battery Lock

258

-

Adjusting the Battery Lock

259

-

Special Notes for Installing the Lithium-Ion Battery

261

-

Replacing the Battery Using a Lifting Device

261

-

Changing the Battery Using the Internal Roller Channel (Variant)

266

-

Setting the Battery Data (Lead Acid Batteries)

271

-

Transporting the Battery Using a Lifting Device (Lead Acid Batteries)

273

-

Transporting the Battery Using a Lifting Device (Lithium-Ion Batteries)

275

-

Cleaning the Truck

276

-

Cleaning the Electrical System

279

-

Cleaning Load Chains

280

-

Cleaning Panes of Glass and Mirrors

280

-

After Cleaning

281

-

Transporting the Truck

281

-

Transportation

281

-

Crane Loading (Standard Truck with Overhead Guard)

284

-

Crane Loading (Trucks with a Cab)

288

-

Decommissioning

294

-

Shutting down and Storing the Truck

294

-

Re-Commissioning after Shutdown

295

-

-

-

5 Maintenance

297

-

Safety Regulations for Maintenance

298

-

General Information

298

-

Working on the Hydraulic Equipment

298

-

Working on the Electrical Equipment

298

-

Safety Devices

299

-

Set Values

299

-

Lifting and Jacking up

299

-

Working at the Front of the Truck

300

-

General Maintenance Information

301

-

Personnel Qualifications

301

-

Information for Carrying out Maintenance

302

-

Maintenance — 1000 Hours/Year

305

-

Maintenance — 3000 Hours/Every Two Years

309

-

Additional Maintenance Guidelines for Using the Truck in a Cold Store — 500 Hours or Every 12 Weeks

309

-

Ordering Spare Parts and Wearing Parts

310

-

Quality and Quantity of the Required Operating Materials

310

-

Maintenance Data Table

311

-

Maintaining Operational Readiness

312

-

Checking the Driver’s Seat

312

-

Maintaining Wheels and Tyres

313

-

Checking the Hydraulic System for Leaks

314

-

Greasing the Lift Mast and Roller Tracks

315

-

Checking the Battery Change Frame (Variant)

315

-

Replacing the Heating System Filter for the Cab (Variant)

316

-

Maintenance for Trucks Used in Cold Stores

317

-

Maintenance Tasks for Lithium-Ion Batteries

317

-

-

6 Technical Data

319

-

Dimensions

320

-

VDI Datasheet for FM-X 10 / Li-Ion (N), FM-X 12 / Li-Ion (N)

321

-

VDI Datasheet for FM-X 14 / Li-Ion (N, W, EW)

325

-

VDI Datasheet for FM-X 17 / Li-Ion (N, W, EW)

330

-

VDI Datasheet for FM-X 20 / Li-Ion (N, W, EW)

335

-

VDI Datasheet for FM-X 20 HD / Li-Ion

340

-

VDI Datasheet for FM-X 25 / Li-Ion (W, EW)

344

-

Wheels and Tyres

347

-

Battery Specifications for Lithium-Ion Batteries

348

-

Still FM-X-17 Original Instructions Manual (292 pages)

Reach trucks

Brand: Still

|

Category: Forklifts

|

Size: 6.02 MB

Table of Contents

-

Table of Contents

3

-

1 Foreword

11

-

Your Truck

12

-

General

12

-

CE Labelling

12

-

EC Declaration of Conformity in Accordance with Machinery Directive

13

-

Information about the Documentation

14

-

Documentation Scope

14

-

Issue Date and Topicality of the Operating Instructions

15

-

Copyright and Trademark Rights

15

-

Explanation of Information Symbols Used

15

-

List of Abbreviations

16

-

Defining Directions

19

-

Schematic Views

20

-

Environmental Considerations

21

-

Packaging

21

-

Disposal of Components and Batteries

21

-

-

2 Introduction

23

-

Using the Truck

24

-

Proper Usage

24

-

Impermissible Use

24

-

Place of Use

25

-

Parking in Temperatures below -10°C

25

-

Using Working Platforms

26

-

Residual Risk

27

-

Residual Dangers, Residual Risks

27

-

Special Risks Associated with Using the Truck and Attachments

28

-

Overview of Hazards and Countermeasures

30

-

Danger to Employees

32

-

-

3 Safety

35

-

Definition of Terms Used for Responsible Persons

36

-

Operating Company

36

-

Specialist

36

-

Drivers

37

-

Basic Principles for Safe Operation

39

-

Insurance Cover on Company Premises

39

-

Changes and Retrofitting

39

-

Modifications to the Overhead Guard and Cabs

41

-

Safety Information for FM-X Wide, Extra Wide (W, EW)

42

-

Warning Regarding Non-Original Parts

42

-

Damage, Defects and Misuse of Safety Systems

43

-

Tyres

43

-

Medical Equipment

44

-

Exercise Caution When Handling Gas Springs and Accumulators

44

-

Safety Tests

45

-

Regular Safety Inspection of the Truck

45

-

Insulation Testing

45

-

Safety Regulations for Handling Consumables

46

-

Permissible Consumables

46

-

Oils

47

-

Hydraulic Fluid

48

-

Battery Acid

49

-

Brake Fluid

50

-

Disposal of Consumables

51

-

Emissions

51

-

-

4 Overviews

55

-

Overview

56

-

Overview of the Driver’s Compartment

57

-

Operating Devices and Display Elements

58

-

Display and Operating Unit

58

-

Operating Devices for Hydraulic and Traction Functions

58

-

Joystick 4Plus

59

-

Reserved

59

-

Fingertip

60

-

Identification Points

61

-

Overview

61

-

Nameplate

62

-

Production Number

63

-

-

5 Operation

65

-

Checks and Tasks to be Carried out Prior to Commissioning

66

-

Visual Inspections

66

-

Filling the Washer System (Variant)

68

-

Checking the Condition of the Wheels and Tyres

69

-

Adjusting the MSG 65/MSG 75 Driver’s Seat

70

-

(Variant)

73

-

Electrical Driver’s Compartment Adjustment (Variant)

74

-

Compartment

74

-

Adjusting the Steering Column

75

-

Commissioning

75

-

Climbing into and out of the Truck

75

-

Shelves and Cup Holders

77

-

Connecting the Battery Male Connector

77

-

Enabling Truck Functions Using the Foot Switch and Seat Switch

78

-

Display and Operating Unit

78

-

Foot Switch

78

-

Driver’s Seat

78

-

Unlocking the Emergency off Switch

80

-

Switching on the Key Switch

80

-

Access Authorisation with PIN Code (Variant)

83

-

Entering Truck Operating Data Via the Display and Operating Unit

84

-

Operating the Signal Horn

89

-

Checking the Brake System for Correct Function

89

-

Checking the Steering System for Correct Function

91

-

Checking the Emergency off Function

91

-

Checking the «Automatic Tilting Centre Position» (Variant) for Correct Function

92

-

Setting the Drive Programme

93

-

OPTISPEED — Continuously Variable Reduction in Driving Speed or Hydraulic Functions (Variant)

94

-

Driving

95

-

Safety Regulations When Driving

95

-

Roadways

98

-

Side Chassis Supports

100

-

Selecting the Drive Direction

101

-

Actuating the Drive Direction Switch, Joystick 4Plus

102

-

Actuating the Drive Direction Switch, Fingertip

102

-

Starting Drive Mode, Single-Pedal Version

102

-

Starting Drive Mode, Dual-Pedal Version (Variant)

104

-

Operating the Service Brake

106

-

Applying the Electromagnetic Parking Brake

107

-

Steering

110

-

Lifting

112

-

Lifting System Variants

112

-

Automatic Lift Cut out (Variant)

113

-

Reach-Lower Lock (Variant)

114

-

Automatic Centre Position (Variant)

115

-

Lift Mast Versions

116

-

Malfunctions in Lifting Mode

117

-

Lifting System Operating Devices

118

-

Joystick 4Plus Lifting System

119

-

Fingertip Lifting System

122

-

Load Backrest (Variant)

124

-

Changing the Fork Arms

124

-

Fork Extension (Variant)

127

-

Working Platforms

128

-

Handling Loads

129

-

Safety Regulations When Handing Loads

129

-

Before Picking up a Load

129

-

Picking up Loads

131

-

Danger Area

132

-

Transporting Pallets

133

-

Transporting Swinging Loads

134

-

Picking up a Load

135

-

Transporting Loads

138

-

Setting down Loads

140

-

Driving on Upward and Downward Gradients

142

-

Driving Onto Lifts

142

-

Working with Attachments

144

-

Fitting Attachments

144

-

Releasing the Pressure from the Auxiliary Hydraulics

146

-

General Instructions for Controlling Attachments

147

-

Controlling Attachments (Variant) with the Fingertip (5Th/6Th Hydraulic Function)

151

-

Operating the Clamp Locking Mechanism (Variant) with a Joystick 4Plus

153

-

Operating the Clamp Locking Mechanism (Variant) with the Fingertip Switch

155

-

Picking up a Load Using Attachments

156

-

Operating Auxiliary Equipment

157

-

Switching the Working Spotlights (Variant) on and off

157

-

Clipboard (Variant)

158

-

Fleetmanager (Variant)

158

-

Accident Recorder (Variant)

158

-

Active Load Stabilisation als (Variant)

159

-

Camera/Monitor System (Variant)

160

-

Load Measurement

160

-

Battery Change Frame (Variant)

162

-

General

162

-

Safe Handling

163

-

Load Capacity

163

-

Area of Application

163

-

Adjusting the Transfer Height

164

-

Locking the Battery Change Frame

164

-

Battery Replacement Area

165

-

Lift Height Preselector (Variant)

166

-

General

166

-

Definition of Terms

167

-

AUTO MODE Function

168

-

Operating the Lift Height Preselector

171

-

Teach-In, General

175

-

Performing a Teach-In

176

-

Cab Operation (Variant)

179

-

General Information about the Cab

179

-

Opening the Cab Door

180

-

Closing the Cab Door

181

-

Emergency Exit Window in the Cab

181

-

Cab Operating Devices

182

-

Cab Interior Lighting (Variant)

183

-

Heating System in the Cab (Variant)

184

-

Cold Store Application

185

-

General

185

-

Areas of Application

186

-

Battery in the Cold Store

187

-

Description of the Cold Store Equipment

187

-

Warming up the Truck

188

-

Operating the Display and Operating Unit

188

-

Operating Status Displays on the Display and Operating Unit

188

-

Blue-Q Efficiency Mode

190

-

Functional Description

190

-

Switching the Blue-Q Efficiency Mode on and off

190

-

Fault Displays

191

-

View on the Display and Operating Unit

191

-

Operating in Special Operating Situations

191

-

Transportation

191

-

Towing

194

-

Crane Loading

196

-

Procedure in Emergencies

199

-

Emergency Shutdown

200

-

Procedure if Truck Tips over

201

-

Emergency Lowering

202

-

Handling the Battery

202

-

Safety Regulations When Handling the Battery

202

-

General Information on Battery Replacement

206

-

Actuating the Battery Lock

207

-

Disconnecting the Battery Male Connector

209

-

Battery Replacement Using a Crane

210

-

Changing the Battery Using the Internal Roller Channel (Variant)

215

-

Battery Commissioning

221

-

Adjusting the Battery Lock

221

-

Setting the Battery Data

223

-

Battery Transport with Crane

225

-

Maintaining the Battery

226

-

Decommissioning

230

-

Parking the Truck Securely

230

-

Shutting down and Storing the Truck

232

-

Re-Commissioning after Shutdown

233

-

Cleaning

234

-

Cleaning the Truck

234

-

Cleaning Load Chains

235

-

After Cleaning

236

-

-

-

6 Maintenance

237

-

General Maintenance Information

238

-

Personnel Qualifications

238

-

Information for Carrying out Maintenance

238

-

Maintenance — 1000 Hours/Year

241

-

Maintenance — 3000 Hours/Every Two Years

245

-

Additional Maintenance Guidelines for Using the Truck in a Cold Store — 500 Hours or Every 12 Weeks

248

-

Ordering Spare Parts and Wearing Parts

249

-

Quality and Quantity of the Required Operating Materials

249

-

Maintenance Data Table

250

-

Safety Regulations for Maintenance

252

-

General Information

252

-

Working on the Hydraulic Equipment

252

-

Working on the Electrical Equipment

252

-

Safety Devices

253

-

Set Values

253

-

Lifting and Jacking up

253

-

Working at the Front of the Truck

253

-

Servicing

255

-

Checking the Battery Condition, Acid Level and Acid Density

255

-

Maintaining Wheels and Tyres

256

-

Checking the Hydraulic System for Leaks

258

-

Greasing the Lift Mast and Roller Tracks

259

-

Checking the Battery Change Frame

259

-

-

7 Technical Data

261

-

Dimensions

262

-

VDI Datasheet FM-X 10 (N), FM-X 12 (N)

263

-

VDI Datasheet FM-X 14 (N), FM-X 17 (N)

267

-

VDI Datasheet FM-X 20 (N, W, EW)

271

-

VDI Datasheet FM-X 22

274

-

VDI Datasheet FM-X 25

279

-

Wheels and Tyres

282

-

Advertisement

Advertisement

Related Products

-

Still FM-X-12

-

Still FM-X-14

-

Still FM-X-10

-

Still FM-X 10 N

-

Still FMX 12 N

-

Still FM-X

-

Still FM-X-20

-

Still FM-X-25

-

Still FM-X-20 HD

-

Still FM-X W Series

Still Categories

Forklifts

Trucks

Tractor

Industrial Equipment

Lifting Systems

More Still Manuals

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Original instructions

Reach trucks

FM-X, FM-X N, FM-X W, FM-X EW,

Li-ion

FM-X-10

FM-X-12

FM-X-14

FM-X-17

FM-X-20

FM-X-20 HD

FM-X-25

1900 1901 1902 1903 1904

1905 1906 1907 1908 1909

1910 1914 1915 1916 1917

1918 1919 1920 1921 1922

50988078001 EN — 10/2018

Related Manuals for Still FM-X N Series

Summary of Contents for Still FM-X N Series

-

Page 1

Original instructions Reach trucks FM-X, FM-X N, FM-X W, FM-X EW, Li-ion FM-X-10 FM-X-12 FM-X-14 FM-X-17 FM-X-20 FM-X-20 HD FM-X-25 1900 1901 1902 1903 1904 1905 1906 1907 1908 1909 1910 1914 1915 1916 1917 1918 1919 1920 1921 1922 50988078001 EN — 10/2018… -

Page 3

• Information on transport, initial commis- sioning and storage of industrial trucks Internet address and QR code The information can be accessed at any time by pasting the address https://m.still.de/vdma in a web browser or by scanning the QR code. 50988078001 EN — 10/2018… -

Page 5: Table Of Contents

Table of contents Foreword Your truck …………2 General .

-

Page 6

Table of contents Modifications to the overhead guard and cabs ……. 31 Seat belt . -

Page 7

STILL SafetyLight (variant) …….. -

Page 8

Table of contents Parking …………118 Parking the truck securely . -

Page 9

Table of contents Shock recognition (variant) ……….166 Active Load Stabilisation ALS (variant) . -

Page 10

Table of contents Impermissible use of the lithium-ion battery in the shock cold store (-45°C) ..210 Before entering the cold store ……… . . 211 Procedure in emergencies . -

Page 11

Table of contents Cleaning the electrical system ……… . 267 Cleaning load chains . -

Page 12

Table of contents Technical data Dimensions …………308 VDI datasheet for FM-X 10 / Li-ion (N), FM-X 12 / Li-ion (N)* . -

Page 13: Foreword

Foreword…

-

Page 14: Your Truck

Foreword Your truck Your truck General The truck described in these operating instruc- These operating instructions provide the tions corresponds to the applicable standards necessary information to do this. Read and and safety regulations. observe the information provided before commissioning the truck. This will prevent The trucks have been fitted with state-of-the- accidents and ensure that the warranty art technology.

-

Page 15: Ec Declaration Of Conformity In Accordance With Machinery Directive

Foreword Your truck EC declaration of conformity in accordance with Machinery Directive Declaration STILL GmbH Berzeliusstraße 10 D-22113 Hamburg Germany We declare that the according to these operating instructions Industrial truck according to these operating instructions Model conforms to the latest version of the Machinery Directive 2006/42/EC.

-

Page 16: Accessories

Foreword Your truck Accessories • Key for key switch (2 pieces), not for trucks with the FleetManager™ or «PIN code» variants • Key for cab (variant) • Hexagon socket wrench for emergency lowering (in the driver’s compartment below the steering wheel) •…

-

Page 17: Labelling Points

Foreword Your truck Labelling points BATTERIESERVICE Nächste Prüfung Ihr STILL Service STILL GmbH Hamburg Berzeliusstraße 10 22113 Hamburg Tel.: 01804/784 55 24 400-600 1000 10200 1150 9800 1110 1300 9500 1050 1200 1400 9300 1080 1240 1450 9000 1160 1320…

-

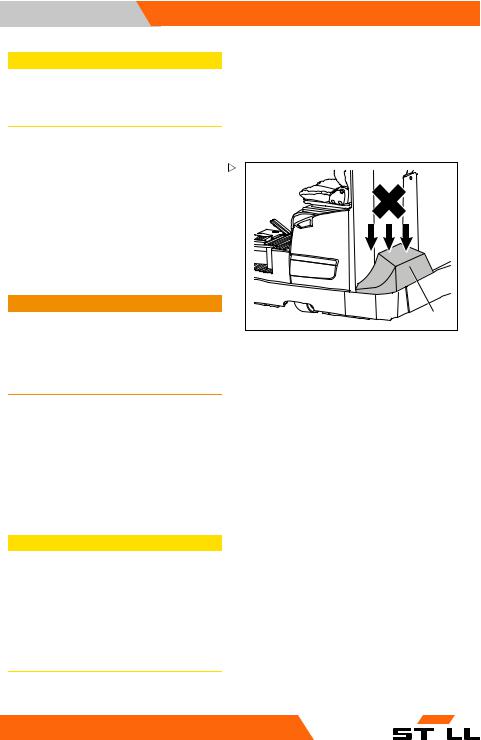

Page 18: Nameplate

Foreword Your truck Warning sign: Do not place below the fork Decal information: FEM test / Do not place on the fork / Danger due to Decal information: FEM test (inspection shearing / Danger due to high fluid pressure sticker) Warning sign: Danger due to shearing Decal information: Nameplate Decal information: Battery version…

-

Page 19: Production Number

Capacity equivalent: Weight: Manufacturer P/N: B-P/N: Address of manufacturer Custumer order no.: Still order no.: Date: Data/technical data Made in Germany Safety information Safety Advices for Lithium-Ion Batteries Do not crush. Do not heat or incinerate. Do not short-circuit. Do not dismantle.

-

Page 20: Using The Truck

Foreword Using the truck 16 «Do not dispose with household waste» 17 «Recycling — recyclable material» Using the truck Commissioning Commissioning is the initial intended use of the truck. The necessary steps for the commissioning vary depending on the model and equipment of the truck.

-

Page 21: Impermissible Use

Only lithium-ion battery chargers approved by STILL for use with this battery may be used. Impermissible use The operating company or driver, and not the manufacturer, is liable for any hazards caused by improper use.

-

Page 22: Parking In Temperatures Below -10°C

Foreword Using the truck Driving on upward and downward gradients is permitted provided the defined data and specifications are observed; see the chapter entitled «Roadways». The truck is suitable for use in many different countries, ranging from those situated in the tropics to those in Nordic regions (temperature range: -10°C to +40°C).

-

Page 23: Using Working Platforms

Foreword Using the truck Using working platforms WARNING The use of working platforms is regulated by na- tional law. The use of working platforms is only permitted by virtue of the jurisdiction in the country of use. – Observe national legislation. –…

-

Page 24: Information About The Documentation

Foreword Information about the documentation Information about the documentation Documentation scope • Original operating instructions • Original operating instructions for attach- ments (variant) • Spare parts list • Depending on the truck equipment, «UPA» operating instructions may also be provided NOTE Refer to the additional information in the section entitled «Rules for the operating…

-

Page 25: Supplementary Documentation

Foreword Information about the documentation The personnel responsible for operating and maintaining the equipment must be familiar with these operating instructions. The operating company must ensure that all users have received, read and understood these operating instructions. Safely store the complete documentation and pass on to the subsequent operating company when transferring or selling the truck.

-

Page 26: Issue Date And Topicality Of The Operating Instructions

The issue date of these operating instructions can be found on the title page. STILL is constantly engaged in the further development of trucks. These operating instructions are subject to change, and any claims based on the information and/or illustrations contained in them cannot be asserted.

-

Page 27: List Of Abbreviations

Foreword Information about the documentation NOTE For technical requirements that require special attention. ENVIRONMENT NOTE To prevent environmental damage. List of abbreviations NOTE This list of abbreviations applies to all types of operating instructions. Not all of the abbre- viations that are listed here will necessarily appear in these operating instructions.

-

Page 28

Foreword Information about the documentation Abbrevi- Meaning Explanation ation German authority for monitoring/issuing regulations for worker protection, environ- Gewerbeaufsichtsamt mental protection, and consumer protec- tion Transfer of data packets in wireless GPRS General Packet Radio Service networks ID no. ID number International Organization for Standard- International standardisation organisation ization… -

Page 29: Defining Directions

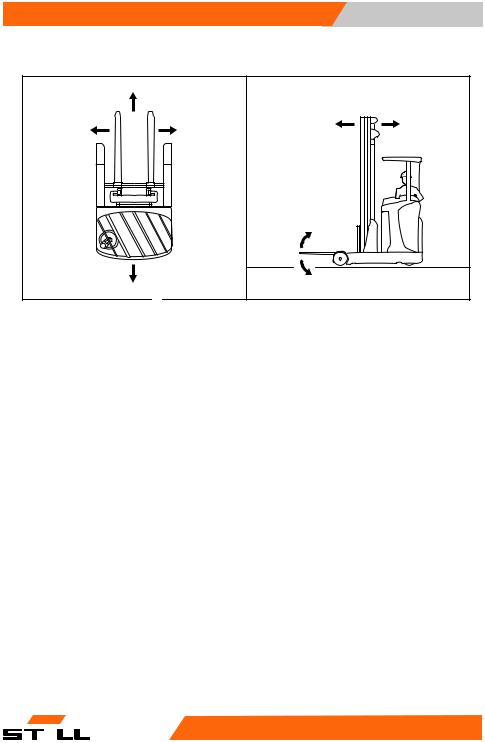

Foreword Information about the documentation Defining directions General: • left (1) • right (2) Drive directions: • Travelling in the load direction (backwards) • Travelling in the drive direction (forwards) Movements of the reach carriage: • Extending the reach carriage (in the load direction) (5) •…

-

Page 30: Schematic Views

Foreword Information about the documentation Schematic views View of functions and operating proce- dures At many points in this documentation, the operation of certain functions or operating procedures is explained. To illustrate these operations, schematic views of a reach truck are used.

-

Page 31: Environmental Considerations

Foreword Environmental considerations Environmental considerations Packaging During delivery of the truck, certain parts are packaged to provide protection during transport. This packaging must be removed completely prior to initial start-up. ENVIRONMENT NOTE The packaging material must be disposed of properly after delivery of the truck. Disposal of components and batteries The truck is composed of different materials.

-

Page 32: Fm-X

Foreword Environmental considerations 50988078001 EN — 10/2018…

-

Page 33: Safety

Safety…

-

Page 34: Definition Of Responsible Persons

Safety Definition of responsible persons Definition of responsible persons Operating company The operating company is the natural or legal person or group who operates the truck or on whose authority the truck is used. The operating company must ensure that the truck is only used for its proper purpose and in compliance with the safety regulations set out in these operating instructions.

-

Page 35: Drivers

Safety Definition of responsible persons regarding the industrial truck to be tested and the risk being assessed Drivers This truck may only be driven by suitable per- sons who are at least 18 years of age, have been trained in driving, have demonstrated their skills in driving and handling loads to the operating company or an authorised rep- resentative, and have been specifically in-…

-

Page 36

Safety Definition of responsible persons DANGER The use of drugs, alcohol or medications that affect reactions impair the ability to drive the truck! Individuals under the influence of the aforementio- ned substances are not permitted to perform work of any kind on or with the truck. Prohibition of use by unauthorised persons The driver is responsible for the truck during… -

Page 37: Basic Principles For Safe Operation

Safety Basic principles for safe operation Basic principles for safe operation Insurance cover on company premises In many cases, company premises are restricted public traffic areas. NOTE The business liability insurance should be reviewed to ensure that, in the event of any damage caused in restricted public traffic areas, there is insurance cover for the truck in respect of third parties.

-

Page 38

Safety Basic principles for safe operation Product-specific dangers posed by the lithium-ion battery Lithium-ion battery Battery group 4.1 Battery group 4.2, 4.3 Hot area on the brake resistor (position depends on the battery group; observe the warning sign Safety valve (position depends on the battery group) WARNING Risk of burns due to hot surfaces! -

Page 39

Permissible lithium-ion batteries – Use only lithium-ion batteries that have been approved by STILL for use with this truck. The dimensions of the battery must precisely correspond to the dimensions of the battery frame in the truck. The… -

Page 40

Safety Basic principles for safe operation in accordance with the manufacturer’s operating instructions for the battery. Declaring the use of lithium-ion batteries The health and safety representative and the workforce must also be informed that trucks with lithium-ion batteries are being used. We recommend that the operating company informs the local fire brigade of the planned use of trucks fitted with lithium-ion batteries. -

Page 41: Changes And Retrofitting

Additional attachments (e.g. terminals, printers, mirrors) in the driver’s compartment area can restrict the driver’s field of vision. – Only install attachments (variants) that have been specifically approved by STILL in accor- dance with the safety regulations. 50988078001 EN — 10/2018…

-

Page 42

Safety Basic principles for safe operation When carrying out welding work on the truck, it is essential that the battery and all connections to the electronic control cards are disconnected. Contact the authorised service centre on this matter. In the event of the manufacturer going into liquidation and the company not being taken over by another legal person, the operating company can make changes to the truck. -

Page 43: Modifications To The Overhead Guard And Cabs

Safety Basic principles for safe operation Modifications to the overhead guard and cabs DANGER Work on the overhead guard or on the weather protection cab/cold store cab reduces its stability. A falling load or the truck tipping over can cause the modified chassis, bodywork and fittings to fail.

-

Page 44: Safety Information For Fm-X Wide, Extra Wide (W, Ew)

STILL. CAUTION Installation and/or use of such products may there- fore have a negative impact on the design features of the truck and thus impair active and/or passive driving safety.

-

Page 45: Damage, Defects And Misuse Of Safety Systems

Safety Basic principles for safe operation Damage, defects and misuse of safety systems Damage or other defects on the truck or attachment must be reported to the supervisor or responsible fleet manager immediately so that they can have the defect rectified. Trucks and attachments that are not functional or safe to drive may not be used until they have been properly repaired.

-

Page 46: Medical Equipment

Safety Basic principles for safe operation • Only use wheels approved by the manufac- turer. • Only use high-quality products. When changing wheels, always ensure that this does not cause the truck to tilt to one side (e.g. always replace right and left wheels at the same time).

-

Page 47: Exercise Caution When Handling Gas Springs And Accumulators

Safety Basic principles for safe operation Exercise caution when handling gas springs and accumulators WARNING Gas springs are under high pressure. Improper removal results in an elevated risk of injury. For ease of operation, various functions on the truck can be supported by gas springs. Gas springs are complex components that are subject to high internal pressures (up to 300 bar).

-

Page 48

Safety Basic principles for safe operation picked up. These other loading units then fall over when the load is raised. – For help with selecting the correct fork arms, contact the authorised service centre. 50988078001 EN — 10/2018… -

Page 49: Residual Risk

Safety Residual risk Residual risk Residual dangers, residual risks Despite careful working and compliance with standards and regulations, the occurrence of other risks when using the truck cannot be entirely excluded. The truck and all other system components comply with current safety requirements. Nevertheless, even when the truck is used for its proper purpose and all instructions are followed, some residual risk cannot be…

-

Page 50: Special Risks Associated With Using The Truck And Attachments

Safety Residual risk The manufacturer is not held responsible for accidents involving the truck caused by the failure of the operating company to comply with these regulations either intentionally or carelessly. Stability The stability of the truck has been tested to the latest technological standards and is guaran- teed provided that the truck is used properly and according to its intended purpose.

-

Page 51

Safety Residual risk time the truck is used in a manner that falls outside the scope of normal use, and in cases where the driver is not certain that he can use the truck correctly and without the risk of acci- dents. -

Page 52: Overview Of Hazards And Countermeasures

Safety Residual risk Overview of hazards and counter- measures NOTE This table is intended to help evaluate the hazards in your facility and applies to all drive types. It does not claim to be complete. – Observe the national regulations for the country in which the truck is being used.

-

Page 53

Safety Residual risk Hazard Measure Check note Notes √ Complete — Not applicable Impermissible usage Issuing of operating German Ordinance on (improper usage) instructions Industrial Safety and Health (BetrSichV) and German Health and labour protection law (ArbSchG) Written notice of German Ordinance on instruction to driver Industrial Safety and… -

Page 54

Safety Residual risk Hazard Measure Check note Notes √ Complete — Not applicable When charging the Note the German Association for traction battery Ordinance on Electrical, Electronic Industrial Safety and and Information Health (BetrSichV), Technologies (VDE) the operating regulation 0510: In instructions and the particular German Engineering… -

Page 55: Danger To Employees

Safety Residual risk Danger to employees According to the German Ordinance on Indus- trial Safety and Health (BetrSichV) and labour protection law (ArbSchG), the operating com- pany must determine and assess hazards during operation, and establish the labour protection measures required for employ- ees (BetrSichVO).

-

Page 56: Safety Tests

Safety Safety tests Safety tests Carrying out regular inspections on the truck The operating company must ensure that the truck is checked by a specialist at least once a year or after particular incidents. As part of this inspection, the technical con- dition of the truck must be completely tested with regard to accident safety.

-

Page 57: Safety Regulations For Handling Consumables

Safety Safety regulations for handling consumables The exact procedure for this insulation testing is described in the workshop manual for this truck. NOTE The truck’s electrical system and drive batte- ries must be checked separately. Test values for the drive battery Recommended Nominal voltage Component…

-

Page 58: Oils

Safety Safety regulations for handling consumables Oils DANGER Oils are flammable! – Follow the statutory regulations. – Do not allow oils to come into contact with hot engine parts. – No smoking, fires or naked flames! DANGER Oils are toxic! –…

-

Page 59: Hydraulic Fluid

Safety Safety regulations for handling consumables ENVIRONMENT NOTE Oil is a water-polluting substance! Always store oil in containers that comply • with the applicable regulations. Avoid spilling oils. • Spilt oil should be removed immediately • with oil-binding agents and disposed of according to the regulations.

-

Page 60: Battery Acid

Safety Safety regulations for handling consumables ENVIRONMENT NOTE Hydraulic fluid is a water-polluting substance. Always store hydraulic fluid in containers • that comply with regulations Avoid spills • Spilt hydraulic fluid should be removed • immediately with oil-binding agents and disposed of according to the regulations Dispose of old hydraulic fluid according to •…

-

Page 61: Brake Fluid

Safety Safety regulations for handling consumables Brake fluid WARNING Brake fluid is poisonous! – Avoid swallowing. In the event of swallowing, do not induce vomiting. Rinse out your mouth thoroughly with water and ask a doctor for advice. – Avoid aerosolisation and inhala- tion.

-

Page 62: Disposal Of Consumables

Safety Safety regulations for handling consumables ENVIRONMENT NOTE Brake fluid is a water pollutant! Always store brake fluid in containers • complying with the regulations.. Do not spill brake fluid. • Spilt brake fluid must be removed immedia- • tely using an oil binding agent and disposed of in accordance with regulations Dispose of old brake fluid according to the •…

-

Page 63: Commissioning The Fleetmanager™ (Variant)

Safety Commissioning the FleetManager™ (variant) Commissioning the FleetManager™ (variant) Activating the access control after delivery of the truck CAUTION Danger associated with use by unauthorised per- sons The FleetManager™ regulates the access authori- sation to the truck. To activate the access control, the FleetManager must be put into operation im- mediately following delivery.

-

Page 64

Safety Emissions additional units etc. may produce different values. Noise emissions The values were determined using the mea- suring procedures from the EN 12053 stan- dard (noise measurement for industrial trucks based on EN 12001 and EN ISO 3744 and the requirements of EN ISO 4871). -

Page 65

– Observe the safety regulations for handling the battery. Radiation In accordance with the guidelines DIN EN 62471:2009-03 (VDE 0837-471:2009- 03), the STILL SafetyLight (variant) is as- signed to risk group 2 (medium risk) due to its photobiological hazard potential. 50988078001 EN — 10/2018… -

Page 66

Safety Emissions 50988078001 EN — 10/2018… -

Page 67: Overviews

Overviews…

-

Page 68: Overview

Overviews Overview Overview Overhead guard Battery Driver’s compartment Side support (tilt protection) Lift mast Control compartment Fork arms Drive wheel Load wheel Step Battery frame 50988078001 EN — 10/2018…

-

Page 69: Overview Of The Driver’s Compartment

Overviews Overview of the driver’s compartment NOTE The truck equipment may differ from the equipment shown. Overview of the driver’s compartment 2 3 4 Steering wheel Display and operating unit Button for speed limitation, creep speed Cup holder for max. 1.5-l bottles (variant) Operating devices for hydraulic and traction Electrical seat adjustment push button…

-

Page 70: Shelves And Cup Holders

Overviews Shelves and cup holders Shelves and cup holders WARNING Objects may fall into the footwell and obstruct the pedals, which poses a risk of accident! Objects to be stored must be of the correct size so that they do not fall from the shelves (1, 4) or out of the cup holder (2).

-

Page 71: Operating Devices And Display Elements

Overviews Operating devices and display elements Operating devices and display elements Display and operating unit Display of the operating statuses Keypad for lift height preselection (variant) or PIN code access (variant) Keypad for onboard diagnostics, parame- terising Drive programme button (P1-P4) Blue-Q button Parking brake button 50988078001 EN — 10/2018…

-

Page 72: Operating Status Displays On The Display And Operating Unit

20% of the nominal capacity, only the Battery charging state last segment will still flash. A hydraulic limitation and/or driving limitation can be implemented as an option. The hydraulic limitation and/or driving limitation must be activated by the authorised service centre.

-

Page 73: Display Messages

Overviews Operating devices and display elements Item no. Display Comment Function assistant, centre position for transition shift Function assistant, centre position for tilting — Operating hours, error messages, drive The meter displays up to 99,999.9 operat- profile, information text ing hours. Acknowledge button Actuation required for further functioning Information…

-

Page 74

LED height sensor and reflector. Remove obstacles. reflector. Then fully lower the fork to reference the system. ● If the message is still displayed after cleaning, contact your authorised service centre. ● Emergency off switch of the Switch off the truck. Unlock the truck is actuated emergency off switch. -

Page 75

● Traction dynamics and position for 2 seconds hydraulic speed are restricted ● Switch off the truck ● Lithium-ion battery is in ● If the message is still emergency operation displayed after restarting, ● Driving speed and hydraulic contact your authorised service… -

Page 76

● Check the battery cable and battery plug ● No communication with the ● Restart the truck lithium-ion battery S5951 ● If the message is still ● All truck functions are displayed after restarting, disabled contact your authorised service centre ●… -

Page 77: Entering Truck Operating Data Via The Display And Operating Unit

Overviews Operating devices and display elements Entering truck operating data via the display and operating unit Authorisation levels The authorisation levels determine which operating data and functions the user can access. The higher the authorisation level, the more comprehensive the access to truck operating data.

-

Page 78

Overviews Operating devices and display elements Level 3 (authorised service centre) Access: Press OK and ESC for 4 seconds and enter the password for level 3 Authorisations: Maintenance interval PIN for remote data transfer via SIM card Delete error list Accessing the main menu without a password (authorisation level 1) First of all, press the OK button to open the… -

Page 79

Overviews Operating devices and display elements If the password is invalid, a corresponding message appears on the display and operat- ing unit. PASSWORD NOT VALID The message appears for three seconds and then the display and operating unit shows the input screen for the password again. The password can be entered again. -

Page 80

Overviews Operating devices and display elements Entering operating data in the main menu The menus on the display and operating unit are controlled using the OK button (1), ESC button (3) and arrow buttons (2). – Press the arrow buttons to navigate through the menus –… -

Page 81

Overviews Operating devices and display elements Authori- sation Main menu Submenu (level) Edit/select Comment CONFIGU- RATION VX.XX UNITS DISTANCE miles LOAD CUSTOMER ERROR LIST MODE SERVICE A–Z, *: all DEVICE devices current error TYPE since reset since deletion Error e.g. A 12 X XX XX Teach-in… -

Page 82: Lithium-Ion Battery Display

Overviews Operating devices and display elements Lithium-ion battery display The lithium-ion battery has its own display. The display shows information about the error status (1), the temperature (2) and the charging status (3) of the lithium-ion battery. – See the «Display» chapter in the operating instructions provided by the battery manu- facturer, «BMZ».

-

Page 83: Joystick 4Plus

Overviews Operating devices and display elements Joystick 4Plus «Transition shift» slider «Transition shift/tilt centre position» push Shift button «F» (auxiliary hydraulics con- button (variant) troller) Reserve Drive direction switch Pictograms for operation of the 5th and 6th Joystick, «lifting/lowering» function hydraulic function (variant) Joystick, «shifting»…

-

Page 84: Fingertip

Overviews Operating devices and display elements Fingertip «Lift/lower» operating lever «Transition shift/tilt centre position» push «Shift» operating lever button (variant) «Tilt» operating lever Reserve «Transition shift» operating lever «Auxiliary hydraulics» push button (variant) Emergency off switch Drive direction switch «Enable» push button (variant) Signal horn button «Load measurement»…

-

Page 85: Operation

Operation…

-

Page 86: Testing And Activities Before Daily Use

Operation Testing and activities before daily use Testing and activities before daily use Visual inspections and function checking DANGER Risk of explosion if hydrogen builds up in the cab! If the truck is equipped with a cab, hy- drogen from the battery compartment can ingress into the cab through un- sealed bores.

-

Page 87

Operation Testing and activities before daily use CAUTION Risk of component damage! A deformed or damaged battery male connector can cause overheating and related consequential damage. – Check the battery male connector for damage. – If necessary, have the battery male connector replaced by the authorised service centre. -

Page 88

Operation Testing and activities before daily use Component Course of action Perform a visual inspection for wear and damage. Make sure that only approved tyre types are used (see the chapter entitled » Technical data/Wheels and tyres»). Wheels, tyres In the event of uneven tyre wear on the load wheels, change both tyres. -

Page 89: Climbing Into And Out Of The Truck

Component Course of action Perform a visual inspection for integrity. Ensure cleanliness. Make sure that the antistatic belt is still long enough Antistatic belt, corona electrode to touch the ground. The discharge wires of the corona electrode must not touch the ground. The wires discharge the energy to the air.

-

Page 90

Operation Testing and activities before daily use WARNING Risk of injury when jumping out of the truck! If the driver jumps out the truck while it is moving, he or she could fall under the truck or be crushed by an obstacle. -

Page 91: Adjusting The Msg 65/Msg 75 Driver’s Seat

Operation Testing and activities before daily use Adjusting the MSG 65/MSG 75 driver’s seat WARNING Risk of accident from sudden adjustment of the seat or of the seat backrest! If the seat or the seat backrest is adjusted uninten- tionally, it can lead to uncontrolled movements by the driver.

-

Page 92

Operation Testing and activities before daily use Moving the driver’s seat – Lift the lever (1) and hold. – Push the driver’s seat into the desired position. – Release the lever. – Ensure that the driver’s seat is securely engaged. Adjusting the seat backrest Do not put pressure on the seat backrest while disengaging it. -

Page 93

Operation Testing and activities before daily use Adjusting the seat suspension NOTE The MSG 75 seat is equipped with electric air suspension that is activated using an electric switch instead of a lever (3). The driver’s seat can be adjusted to suit the weight of the individual driver. -

Page 94

Operation Testing and activities before daily use Adjusting the backrest extension (variant) – Adjust the backrest extension (6) by pulling it out or pushing it into the desired position. To remove the backrest extension, move it past the end stop by jolting it upwards. Switching the seat heater (variant) on and off NOTE… -

Page 95: Adjusting The Steering Column

Operation Testing and activities before daily use Adjusting the horizontal suspension (variant) – Push the lever (8) in sideways and slide the driver’s seat to the locked position. To release, push the lever outwards. Using the lever (9), the driver can adjust the hardness in several levels.

-

Page 96: Filling The Washer System (Variant)