Комментарии

12

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Войти

Зарегистрироваться

Hirogaru

Я езжу на Suzuki Grand Vitara (2G)

Здоровья тебе!

1 год

leg0staev

Автор

Я езжу на Honda Accord (7G)

спасибо. и тебе)

1 год

teanovod83

Я езжу на Chery Tiggo 7 Pro

Спасибо мил человек!

1 год

leg0staev

Автор

Я езжу на Honda Accord (7G)

Не за что)

1 год

Firewool

Я езжу на Suzuki Grand Vitara (2G)

Есть на 2,4 2,7 3,2 1,9 но надо искать на внешнем диске на котором 2 Тб всякого хлама😂

1 год

leg0staev

Автор

Я езжу на Honda Accord (7G)

у меня двушка. мне этого хватит)

1 год

Firewool

Я езжу на Suzuki Grand Vitara (2G)

Могу подкинуть полный мануал на 1736 страниц с кузовщиной и т.д.

1 год

leg0staev

Автор

Я езжу на Honda Accord (7G)

давай! буду благодарен!

1 год

Firewool

Я езжу на Suzuki Grand Vitara (2G)

drive.google.com/file/d/1…SPvykk5/view?usp=drivesdk

1 год

leg0staev

Автор

Я езжу на Honda Accord (7G)

спасибо! Ссылка вечная? или скачать?

1 год

Firewool

Я езжу на Suzuki Grand Vitara (2G)

лучше скачать, я скорее всего диск снова закрою

1 год

leg0staev

Автор

Я езжу на Honda Accord (7G)

понял спасибо!

1 год

-

Engine

59

-

Precautions

69

-

Precautions for Engine (Diesel Engine Model)

69

-

Precautions for Engine (Petrol Engine Model)

69

-

Engine General Information and Diagnosis

70

-

For Petrol Engine Model

70

-

Precautions

70

-

Precautions in Diagnosing Trouble

70

-

Precautions on Engine Service

70

-

Precautions for DTC Troubleshooting

71

-

Precautions of ECM Circuit Inspection

71

-

Precautions of Electric Throttle Body System Calibration

71

-

Engine Diagnosis General Description

72

-

General Description

72

-

Statement on Cleanliness and Care

72

-

On-Board Diagnostic System Description

73

-

Engine and Emission Control System Description

76

-

Air Intake System Description

79

-

Electric Throttle Body System Description

80

-

Description of Electric Throttle Body System Calibration

81

-

Generator Control System Description

81

-

A/F Sensor Description

82

-

Electronic Control System Description

83

-

Engine and Emission Control Input / Output Table

84

-

Engine and Emission Control System Diagram

85

-

Schematic and Routing Diagram

85

-

Engine and Emission Control System Flow Diagram

87

-

ECM Input / Output Circuit Diagram

88

-

Component Location

94

-

Electronic Control System Components Location

94

-

Diagnostic Information and Procedures

96

-

Engine and Emission Control System Check

96

-

Malfunction Indicator Lamp (MIL) Check

99

-

DTC Check

100

-

DTC Clearance

101

-

DTC Table

102

-

Fail-Safe Table

108

-

Scan Tool Data

110

-

Visual Inspection

116

-

Engine Basic Inspection

117

-

Engine Symptom Diagnosis

121

-

Malfunction Indicator Lamp Does Not Come on with Ignition Switch on and Engine Stop (but Engine Can be Started)

132

-

Malfunction Indicator Lamp Remains on after Engine Starts

134

-

DTC P0010: Camshaft Position Actuator Circuit (for M16 Engine)

135

-

DTC P0011 / P0012: Camshaft Position — Timing Over-Advanced or System Performance / -Retarded (for M16 Engine)

137

-

DTC P0030: HO2S Heater Control Circuit (Sensor-1)

139

-

DTC P0031 / P0032: HO2S Heater Control Circuit Low / High (Sensor-1)

141

-

DTC P0037 / P0038: HO2S Heater Control Circuit Low / High (Sensor-2)

144

-

DTC P0101: Mass Air Flow Circuit Range / Performance

148

-

DTC P0102: Mass Air Flow Circuit Low Input

152

-

DTC P0103: Mass Air Flow Circuit High Input

153

-

DTC P0106: Manifold Absolute Pressure Range / Performance

155

-

DTC P0107: Manifold Absolute Pressure Circuit Low Input

156

-

DTC P0108: Manifold Absolute Pressure Circuit High Input

158

-

DTC P0111: Intake Air Temperature Circuit Range / Performance

160

-

DTC P0112: Intake Air Temperature Sensor Circuit Low

162

-

DTC P0113: Intake Air Temperature Sensor Circuit High

164

-

DTC P0116: Engine Coolant Temperature Circuit Range / Performance

166

-

DTC P0117: Engine Coolant Temperature Circuit Low

169

-

DTC P0118: Engine Coolant Temperature Circuit High

171

-

DTC P0122: Throttle Position Sensor (Main) Circuit Low

173

-

DTC P0123: Throttle Position Sensor (Main) Circuit High

176

-

DTC P0131 / P0132 / P0134: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage / no Activity Detected (Sensor-1)

179

-

DTC P0133: O2 Sensor (HO2S) Circuit Slow Response (Sensor-1)

181

-

DTC P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-2)

182

-

DTC P0140: O2 Sensor (HO2S) Circuit no Activity Detected (Sensor-2)

185

-

DTC P0171 / P0172 / P2195 / P2196: Fuel System too Lean / Rich / Stuck Lean / Stuck Rich

187

-

DTC P0223: Throttle Position Sensor (Sub) Circuit High

193

-

Dtc P0301, P0302, P0303, P0304

196

-

Random Misfire Detected / Cylinder 1 / Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire Detected

196

-

DTC P0327 / P0328: Knock Sensor Circuit Low / High

198

-

DTC P0335: Crankshaft Position (CKP) Sensor Circuit (for J20 Engine)

200

-

DTC P0335: Crankshaft Position (CKP) Sensor Circuit (for M16 Engine)

202

-

DTC P0340: Camshaft Position (CMP) Sensor Circuit

206

-

DTC P0401 / P0402: Exhaust Gas Recirculation Flow Insufficient Detected / Excessive Detected

209

-

DTC P0403: Exhaust Gas Recirculation Control Circuit

212

-

DTC P0420: Catalyst System Efficiency below Threshold

213

-

DTC P0443: Evaporative Emission System Purge Control Valve Circuit

215

-

DTC P0462: Fuel Level Sensor Circuit Low

217

-

DTC P0463: Fuel Level Sensor Circuit High

219

-

DTC P0480: Fan 1 (Radiator Cooling Fan) Control Circuit

221

-

DTC P0500: Vehicle Speed Sensor (VSS) Malfunction

225

-

DTC P0504: Brake Switch «A»/»B» Correlation (for J20 Engine)

227

-

DTC P0532: A/C Refrigerant Pressure Sensor Circuit Low

229

-

DTC P0533: A/C Refrigerant Pressure Sensor Circuit High

231

-

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control Module Programming Error / Control Module Performance

232

-

DTC P0616: Starter Relay Circuit Low

233

-

DTC P0617: Starter Relay Circuit High

234

-

DTC P0620: Generator Control Circuit

236

-

DTC P0625 / P0626: Generator Field Terminal Circuit Low / High

238

-

DTC P0660: Intake Manifold Tuning Valve Control Circuit / Open (for J20 Engine)

240

-

DTC P1501 / P1502: Electric Load Current Sensor Circuit Low / High

242

-

DTC P1510: ECM Back-Up Power Supply Malfunction

244

-

DTC P1603: TCM Trouble Code Detected (for J20 Engine)

245

-

DTC P1674: CAN Communication (Bus off Error)

247

-

DTC P1676: CAN Communication (Reception Error for TCM (for A/T Model))

251

-

DTC P1678: CAN Communication (Reception Error for BCM)

255

-

DTC P1685: CAN Communication (Reception Error for ABS or ESP® Control Module)

259

-

DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance

263

-

DTC P2102: Throttle Actuator Control Motor Circuit Low

265

-

DTC P2103: Throttle Actuator Control Motor Circuit High

267

-

DTC P2111: Throttle Actuator Control System — Stuck Open

268

-

DTC P2119: Throttle Actuator Control Throttle Body Range / Performance

269

-

DTC P2122: Pedal Position Sensor (Main) Circuit Low Input

271

-

DTC P2123: Pedal Position Sensor (Main) Circuit High Input

274

-

DTC P2127: Pedal Position Sensor (Sub) Circuit Low Input

276

-

DTC P2128: Pedal Position Sensor (Sub) Circuit High Input

279

-

DTC P2135: Throttle Position Sensor (Main / Sub) Voltage Correlation

281

-

DTC P2138: Pedal Position Sensor (Main / Sub) Voltage Correlation

284

-

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit Malfunction

287

-

Inspection of ECM and Its Circuits

289

-

ECM Power and Ground Circuit Check

312

-

Fuel Injector Circuit Check

316

-

Fuel Pump and Its Circuit Check

318

-

Fuel Pressure Check

321

-

A/C System Circuits Check

323

-

Electric Load Signal Circuit Check

326

-

Radiator Cooling Fan Low Speed Control System Check

328

-

Radiator Cooling Fan High Speed Control System Check

331

-

Idle Speed and IAC Throttle Valve Opening Inspection

333

-

Repair Instructions

333

-

Special Tool

334

-

Special Tools and Equipment

334

-

For Diesel Engine Model

335

-

Precautions

335

-

Precautions in Diagnosing Trouble

335

-

Precautions on Engine Service

335

-

Engine Diagnosis General Description

336

-

General Description

336

-

On-Board Diagnostic System Description

336

-

Statement on Cleanliness and Care

336

-

CAN Communication System Description

338

-

Diesel Particulate Filter Regeneration Description

340

-

Electronic Control System Diagram

340

-

Schematic and Routing Diagram

340

-

Electronic Control System Wiring Circuit Diagram

342

-

Component Location

346

-

Electronic Control System Components Location

346

-

Diagnostic Information and Procedures

347

-

Injection Warning Light (Gravity 1 Fault) Check

347

-

Malfunction Indicator Lamp (MIL) Check

347

-

Red Stop Warning Light (Gravity 2 Fault) Check

347

-

Engine and Emission Control System Check

348

-

DTC Check

350

-

DTC Clearance

350

-

DTC Table

351

-

Indicator Light Operation Table

354

-

Scan Tool Data

356

-

Engine Basic Inspection

358

-

Visual Inspection

358

-

DTC P0016: CKP — CMP Correlation

359

-

DTC P0033: Boost Pressure Control Solenoid Valve Control Circuit

360

-

DTC P0089: Fuel Flow Actuator Performance 1A-292

361

-

DTC P0100: Mass or Volume Air Flow Circuit 1A-296

365

-

DTC P0105: Barometric Pressure Circuit

367

-

DTC P0110: IAT Sensor Circuit Malfunction

367

-

DTC P0115: ECT Circuit

369

-

DTC P0190: Fuel Pressure Sensor Circuit

370

-

DTC P0201: Fuel Injector No.1 Circuit

372

-

DTC P0202: Fuel Injector No.2 Circuit

373

-

DTC P0203: Fuel Injector No.3 Circuit

374

-

DTC P0204: Fuel Injector No.4 Circuit

375

-

DTC P0225: APP Sensor (Main) Circuit

376

-

DTC P0235: Boost Pressure Sensor Circuit

378

-

DTC P0243: Boost Pressure Malfunction

379

-

DTC P0297: Vehicle Overspeed Condition

381

-

DTC P0301: Cylinder No.1 Misfire Detected

381

-

DTC P0302: Cylinder No.2 Misfire Detected

382

-

DTC P0303: Cylinder No.3 Misfire Detected

382

-

DTC P0304: Cylinder No.4 Misfire Detected

383

-

DTC P0335: CKP Sensor Circuit

383

-

DTC P0340: CMP Sensor Circuit

384

-

DTC P0380: Glow Plug Control Module Circuit

385

-

DTC P0403: EGR Control Circuit

386

-

DTC P0409: EGR Motor Malfunction

387

-

DTC P0470: Differential Sensor Circuit

388

-

DTC P0480: Radiator Fan Low Control Circuit 1A-320

389

-

DTC P0481: Radiator Fan High Control Circuit

390

-

DTC P0486: EGR Stroke Sensor Circuit

391

-

DTC P0500: VSS Malfunction

392

-

DTC P0530: A/C Refrigerant Pressure Sensor Circuit

393

-

DTC P0544: Exhaust Gas Temperature Sensor 3 Circuit

394

-

DTC P0560: System Voltage

395

-

DTC P0571: Brake Light Switch Circuit

396

-

DTC P0575: Cruise Control Input Circuit

397

-

DTC P0606: ECM Processor

397

-

DTC P0611: ECM Performance

399

-

DTC P0615: Ignition Switch Circuit

400

-

DTC P0627: Fuel Pump Control Circuit

401

-

DTC P0638: Inlet Throttle Valve Control Range / Performance

402

-

DTC P0641: Sensor Reference Voltage 1 Circuit

404

-

DTC P0645: A/C Compressor Relay Control Circuit

406

-

DTC P0651: Sensor Reference Voltage 2 Circuit

407

-

DTC P0670: Glow Plug Control Circuit

409

-

DTC P0685: Main Relay Control Circuit

410

-

DTC P0697: Sensor Reference Voltage 3 Circuit

410

-

DTC P0830: CPP Switch Circuit

412

-

DTC P1431: Clogged Diesel Particulate Filter Failures

413

-

DTC P1436: Diesel Particulate Filter Regeneration Request Failures

413

-

DTC P1480: Upstream Side Differential Pressure Sensor Failure

414

-

DTC P1641: Additional Heater Relay No.1 Control Circuit

414

-

DTC P1642: Additional Heater Relay No.2 and 3 Control Circuit

415

-

DTC P2002: Diesel Particulate Filter Efficiency below Threshold

416

-

DTC P2031: Exhaust Gas Temperature 2 Sensor Circuit

417

-

DTC P2120: APP Sensor (Sub) Circuit

418

-

DTC P2141: EGR Motor Control Circuit Low

420

-

DTC P2142: EGR Motor Control Circuit High .1A-352

421

-

DTC P2264: Fuel Filter Water Detection Sensor Circuit

422

-

DTC P2413: EGR System Performance

423

-

DTC P242A: Exhaust Gas Temperature Sensor 1 Circuit

424

-

DTC P242B: Exhaust Gas Temperature Sensor 1 Regulation Failure

425

-

DTC P2600: Turbocharger Electric Water Pump Control Circuit

426

-

DTC P3031: Exhaust Gas Temperature Sensor 2 Threshold Overshoot Failures During After-Sales Regeneration

427

-

Fault Finding-Customer Complaints

427

-

Fault Finding-Tests

436

-

Test 1: Exhaust System Check

436

-

Test 2: Low Pressure Circuit Check

438

-

Test 3: Checking the Turbocharged Air Inlet Circuit

439

-

Test 4: MAF Sensor

440

-

Test 5: Variable Geometry Turbocharger Control

440

-

Test 6: Rotating Part of a Turbocharger

441

-

Test 7: Exhaust Gas Recirculation Valve

442

-

Test 8: Injector Malfunction

443

-

Special Tool

446

-

Special Tools and Equipment

446

-

Aux. Emission Control Devices

447

-

Diagnostic Information and Procedures

447

-

EGR System Inspection

447

-

EVAP Canister Purge Inspection

447

-

For Petrol Engine Model

447

-

Repair Instructions

447

-

EVAP Canister Purge Valve and Its Circuit Inspection

448

-

EVAP Canister Purge Valve Inspection

449

-

Vacuum Hose and Purge Valve Chamber Inspection

449

-

Vacuum Passage Inspection

449

-

EGR Valve Inspection

450

-

EGR Valve Removal and Installation

450

-

EVAP Canister Inspection

450

-

PCV Hose Inspection

451

-

PCV Valve Inspection

451

-

PCV Valve Removal and Installation

451

-

Recommended Service Material

452

-

Special Tool

452

-

Special Tools and Equipment

452

-

Specifications

452

-

Tightening Torque Specifications

452

-

EGR Valve Inspection

453

-

For Diesel Engine Model

453

-

Repair Instructions

453

-

Exhaust Gas Temperature Sensor 1, 2 and 3

454

-

Removal and Installation

454

-

Exhaust Gas Temperature Sensor 1, 2 and

455

-

Installation (with Diesel Particulate Filter)

455

-

Specifications

456

-

Tightening Torque Specifications

456

-

Engine Control Module (ECM) Removal and Installation

457

-

Engine Electrical Devices

457

-

For Petrol Engine Model

457

-

Repair Instructions

457

-

Electric Throttle Body Assembly On-Vehicle Inspection

458

-

Manifold Absolute Pressure (MAP) Sensor Inspection

458

-

Electric Throttle Body System Calibration

461

-

Accelerator Pedal Position (APP) Sensor Assembly On-Vehicle Inspection

462

-

Accelerator Pedal Position (APP) Sensor Assembly Removal and Installation

462

-

Accelerator Pedal Position (APP) Sensor Assembly Inspection

463

-

Engine Coolant Temperature (ECT) Sensor Inspection

464

-

Engine Coolant Temperature (ECT) Sensor Removal and Installation

464

-

Air Fuel Ratio (A/F) Sensor On-Vehicle Inspection

465

-

Heated Oxygen Sensor (HO2S-2) Heater On-Vehicle Inspection

465

-

Air Fuel Ratio (A/F) Sensor, Heated Oxygen Sensor (HO2S-2) Removal and Installation

466

-

Camshaft Position (CMP) Sensor Removal and Installation

466

-

Camshaft Position (CMP) Sensor Inspection

467

-

Crankshaft Position (CKP) Sensor Removal and Installation

468

-

Crankshaft Position (CKP) Sensor Inspection

469

-

Control Relay Inspection

470

-

Knock Sensor Removal and Installation

470

-

Mass Air Flow (MAF) and Intake Air Temperature (IAT) Sensor On-Vehicle Inspection

471

-

Mass Air Flow (MAF) and Intake Air Temperature (IAT) Sensor Removal and Installation

472

-

Mass Air Flow (MAF) and Intake Air Temperature (IAT) Sensor Inspection

473

-

Vacuum Tank Assembly Inspection (for J20 Engine)

473

-

Electric Load Current Sensor On-Vehicle Inspection (for J20 Engine)

475

-

Electric Load Current Sensor Removal and Installation (for J20 Engine)

475

-

Specifications

476

-

Tightening Torque Specifications

476

-

Description of ECM Registration

477

-

For Diesel Engine Model

477

-

General Description

477

-

Precaution in Replacing ECM

477

-

Precautions

477

-

Engine Control Module (ECM) Removal and Installation

478

-

Idle Speed Inspection

478

-

Registration Procedure for the ECM

478

-

Repair Instructions

478

-

EGR Valve Data Initialization

479

-

Registration Procedure for the Fuel Injector Calibration Code

479

-

Diesel Particulate Filter After-Sales Regeneration Procedure

480

-

Diesel Particulate Filter Data Initialization

480

-

Inlet Throttle Valve Data Initialization

480

-

Accelerator Pedal Position (APP) Sensor Assembly On-Vehicle Inspection

482

-

Glow Plug Inspection

482

-

Glow Plug Removal and Installation

482

-

Accelerator Pedal Position (APP) Sensor Assembly Inspection

483

-

Accelerator Pedal Position (APP) Sensor Assembly Removal and Installation

483

-

Engine Coolant Temperature (ECT) Sensor Removal and Installation

484

-

Camshaft Position (CMP) Sensor Removal and Installation

485

-

Crankshaft Position (CKP) Sensor (Engine Speed Sensor) Removal and Installation

485

-

Engine Coolant Temperature (ECT) Sensor Inspection

485

-

Boost Pressure Sensor Removal and Installation

486

-

Crankshaft Position (CKP) (Engine Speed Sensor) Sensor Inspection

486

-

Boost Pressure Control Solenoid Valve Removal and Installation

487

-

Glow Plug Control Module Removal and Installation

487

-

Main Relay and Fuel Heater Relay Inspection

487

-

Boost Pressure Control Solenoid Valve Inspection

488

-

Turbocharger Electric Water Pump Removal and Installation

488

-

Inlet Throttle Valve Removal and Installation

489

-

Mass Air Flow (MAF) and Intake Air Temperature (IAT) Removal and Installation

489

-

Mass Air Flow (MAF) and Intake Air Temperature (IAT) Sensor Inspection

489

-

Turbocharger Electric Water Pump Inspection

489

-

Special Tool

490

-

Special Tools and Equipment

490

-

Specifications

490

-

Engine Construction Description

491

-

Engine Mechanical

491

-

For M16A Engine with VVT

491

-

General Description

491

-

Camshaft Position Control (VVT Variable Valve Timing) System Description

492

-

Compression Check

494

-

Diagnostic Information and Procedures

494

-

Engine Vacuum Check

495

-

Valve Lash (Clearance) Inspection

496

-

Air Cleaner Filter Inspection and Cleaning

499

-

Air Cleaner Filter Removal and Installation

499

-

Cylinder Head Cover Removal and Installation

499

-

Repair Instructions

499

-

Throttle Body and Intake Manifold Components

501

-

Electric Throttle Body Assembly Removal and Installation

502

-

Throttle Body On-Vehicle Inspection

502

-

Intake Manifold Removal and Installation

503

-

Throttle Body Cleaning

503

-

Engine Assembly Removal and Installation

504

-

Engine Mountings Components

504

-

Timing Chain Cover Components

508

-

Timing Chain Cover Removal and Installation

509

-

Oil Control Valve Removal and Installation

511

-

Timing Chain Cover Inspection

511

-

Oil Control Valve Inspection

512

-

Timing Chain and Chain Tensioner Components

513

-

Timing Chain and Chain Tensioner Removal and Installation

513

-

Timing Chain and Chain Tensioner Inspection

516

-

Camshaft, Tappet and Shim Components

517

-

Camshaft, Tappet and Shim Removal and Installation

517

-

Camshaft, Tappet and Shim Inspection

520

-

Valves and Cylinder Head Components

523

-

Valves and Cylinder Head Removal and Installation

524

-

Valves and Cylinder Head Disassembly and Assembly

525

-

Valves and Valve Guides Inspection

528

-

Cylinder Head Inspection

530

-

Valve Spring Inspection

531

-

Pistons, Piston Rings, Connecting Rods and Cylinders Components

532

-

Pistons, Piston Rings, Connecting Rods and Cylinders Removal and Installation

532

-

Pistons, Piston Rings, Connecting Rods and Cylinders Disassembly and Assembly

534

-

Cylinders, Pistons and Piston Rings Inspection

535

-

Piston Pins and Connecting Rods Inspection

537

-

Crank Pin and Connecting Rod Bearings Inspection

538

-

Main Bearings, Crankshaft and Cylinder Block Components

541

-

Main Bearings, Crankshaft and Cylinder Block Removal and Installation

542

-

Crankshaft Inspection

545

-

Main Bearings Inspection

546

-

Cylinder Block Inspection

551

-

Flywheel Inspection

551

-

Rear Oil Seal Inspection

551

-

Sensor Plate Inspection

551

-

Specifications

552

-

Tightening Torque Specifications

552

-

Recommended Service Material

553

-

Special Tool

553

-

Special Tools and Equipment

553

-

Engine Construction Description

555

-

For J20 Engine

555

-

General Description

555

-

Air Cleaner Element Introduction

557

-

Compression Check

559

-

Diagnostic Information and Procedures

559

-

Engine Vacuum Check

560

-

Valve Lash (Clearance) Inspection

561

-

Air Cleaner Assembly Removal and Installation

564

-

Air Cleaner Filter Inspection and Cleaning

564

-

Air Cleaner Filter Removal and Installation

564

-

Repair Instructions

564

-

Throttle Body and Intake Manifold Components

565

-

Electric Throttle Body Assembly Removal and Installation

566

-

Intake Manifold Removal and Installation

566

-

Throttle Body Cleaning

566

-

Throttle Body On-Vehicle Inspection

566

-

Cylinder Head Cover Removal and Installation

567

-

Engine Mountings Components

569

-

Engine Assembly Removal and Installation

570

-

Timing Chain Cover Components

573

-

Timing Chain Cover Removal and Installation

573

-

2Nd Timing Chain and Chain Tensioner Components

576

-

Timing Chain Cover Cleaning and Inspection

576

-

2Nd Timing Chain and Chain Tensioner Removal and Installation

577

-

2Nd Timing Chain and Chain Tensioner Inspection

580

-

1St Timing Chain and Chain Tensioner Components

581

-

1St Timing Chain and Chain Tensioner Removal and Installation

581

-

Inspection

583

-

Camshafts, Tappet and Shim Components

584

-

Camshafts, Tappet and Shim Removal and Installation

585

-

Camshaft, Tappet and Shim Inspection

586

-

Valves and Cylinder Head Components

589

-

Valves and Cylinder Head Removal and Installation

590

-

Valves and Cylinder Head Disassembly and Assembly

592

-

Valves and Valve Guides Inspection

595

-

Cylinder Head Inspection

597

-

Valve Spring Inspection

598

-

Pistons, Piston Rings, Connecting Rods and Cylinders Components

599

-

Pistons, Piston Rings, Connecting Rods and Cylinders Removal and Installation

599

-

Pistons, Piston Rings, Connecting Rods and Cylinders Disassembly and Assembly

600

-

Pistons, Piston Rings, Connecting Rods and Cylinders Inspection and Cleaning

602

-

Main Bearings, Crankshaft and Cylinder Block Components

609

-

Main Bearings, Crankshaft and Cylinder Block Removal and Installation

610

-

Main Bearings, Crankshaft and Cylinder Block Inspection

613

-

Specifications

619

-

Tightening Torque Specifications

619

-

Recommended Service Material

620

-

Special Tool

620

-

Special Tools and Equipment

620

-

Compression Check

623

-

Diagnostic Information and Procedures

623

-

For F9Q Engine

623

-

Valve Lash (Clearance) Inspection

624

-

Valve Lash (Clearance) Adjustment

625

-

Air Cleaner Components

626

-

Air Cleaner Filter Removal and Installation

626

-

Air Cleaner Removal and Installation

626

-

Repair Instructions

626

-

Air Cleaner Filter Inspection and Cleaning

627

-

Intercooler and Air Intake Pipe Components

627

-

Air Intake Pipe Removal and Installation

628

-

Installation

628

-

Intercooler Removal and Installation

628

-

Oil Separator Removal and Installation

632

-

Vacuum Pump Removal and Installation

632

-

Timing Belt and Belt Tensioner Components

633

-

Vacuum Pump Inspection

633

-

Timing Belt and Belt Tensioner Removal and Installation

634

-

Timing Belt and Belt Tensioner Inspection

639

-

Engine Mounting Components

640

-

EGR Valve Components

646

-

EGR Valve Removal and Installation

647

-

EGR Pipe and EGR Cooler Removal and Installation

648

-

Turbocharger Components

650

-

Turbocharger Assembly Removal and Installation

651

-

Turbocharger Assembly Inspection

653

-

Intake Manifold and Exhaust Manifold Components

654

-

Turbocharger Assembly Adjustment

654

-

Intake Manifold and Exhaust Manifold Removal and Installation

655

-

Camshaft and Tappet Components

656

-

Camshaft and Tappet Removal and Installation

657

-

Camshaft and Tappet Inspection

660

-

Valve and Cylinder Head Assembly Components

661

-

Valve and Cylinder Head Assembly Removal and Installation

662

-

Valve and Cylinder Head Assembly Inspection

664

-

Valve and Cylinder Head Disassembly and Reassembly

664

-

Valves and Valve Guides Inspection

666

-

Cylinder Head Inspection

668

-

Valve Spring Inspection

669

-

Piston, Piston Ring and Connecting Rod Removal and Installation

670

-

Piston, Piston Ring, Connecting Rod and Cylinder Components

670

-

Cylinders, Pistons and Piston Rings Inspection

673

-

Piston Pins and Connecting Rods Inspection .1D-184

674

-

Crank Pin and Connecting Rod Bearings Inspection

675

-

Main Bearing, Crankshaft and Cylinder Block Component

677

-

Main Bearing, Crankshaft and Cylinder Block Removal and Installation

678

-

Crankshaft Inspection

682

-

Main Bearings Inspection

683

-

Specifications

684

-

Tightening Torque Specifications

684

-

Recommended Service Material

685

-

Special Tool

685

-

Special Tools and Equipment

685

-

Engine Lubrication Description

688

-

Engine Lubrication System

688

-

For M16A Engine with VVT

688

-

General Description

688

-

Diagnostic Information and Procedures

690

-

Oil Pressure Check

690

-

Oil Pan and Oil Pump Strainer Components

691

-

Repair Instructions

691

-

Oil Pan and Oil Pump Strainer Removal and Installation

692

-

Oil Pan and Oil Pump Strainer Cleaning

693

-

Oil Pump Components

694

-

Oil Pump Disassembly and Reassembly

694

-

Oil Pump Removal and Installation

694

-

Oil Pump Inspection

695

-

Recommended Service Material

697

-

Special Tool

697

-

Special Tools and Equipment

697

-

Specifications

697

-

Tightening Torque Specifications

697

-

Engine Lubrication Description

698

-

For J20 Engine

698

-

General Description

698

-

Diagnostic Information and Procedures

700

-

Oil Pressure Check

700

-

Oil Pan and Oil Pump Strainer Components

701

-

Repair Instructions

701

-

Oil Pan and Oil Pump Strainer Removal and Installation

702

-

Oil Pan and Oil Pump Strainer Cleaning

703

-

Oil Pump Components

704

-

Oil Pump Removal and Installation

704

-

Oil Pump Disassembly and Assembly

705

-

Oil Pump Inspection

706

-

Recommended Service Material

707

-

Special Tool

707

-

Special Tools and Equipment

707

-

Specifications

707

-

Tightening Torque Specifications

707

-

Diagnostic Information and Procedures

708

-

Engine Lubrication Description

708

-

For F9Q Engine

708

-

General Description

708

-

Oil Pressure Check

708

-

Oil Pan and Oil Pump Strainer Components

709

-

Repair Instructions

709

-

Oil Pan and Oil Pump Strainer Removal and Installation

710

-

Oil Pump, Oil Pump Chain and Gasket Holder Plate Component

715

-

Oil Pump, Oil Pump Chain and Gasket Holder Plate Removal and Installation

715

-

Oil Pump, Oil Pump Chain and Gasket Holder Plate Inspection

717

-

Heat Exchanger Removal and Installation

718

-

Specifications

718

-

Tightening Torque Specifications

718

-

Recommended Service Material

719

-

Special Tool

719

-

Special Tools and Equipment

719

-

Coolant Description

720

-

Cooling System Description

720

-

Engine Cooling System

720

-

For Petrol Engine Model

720

-

General Description

720

-

Coolant Circulation

721

-

Schematic and Routing Diagram

721

-

Diagnostic Information and Procedures

722

-

Engine Cooling Symptom Diagnosis

722

-

Cooling System Components

723

-

Repair Instructions

723

-

Coolant Level Check

725

-

Engine Cooling System Inspection and Cleaning

725

-

Cooling System Draining

726

-

Cooling System Flush and Refill

726

-

Cooling Water Pipes or Hoses Removal and Installation

727

-

Thermostat Removal and Installation (for M16 Engine Model)

727

-

Thermostat Inspection

728

-

Thermostat Removal and Installation (for J20 Engine Model)

728

-

Radiator Cooling Fan Motor On-Vehicle Inspection

729

-

Radiator Cooling Fan Relay Inspection

729

-

Radiator Cooling Fan Assembly Removal and Installation

730

-

Radiator On-Vehicle Inspection and Cleaning

730

-

Radiator Removal and Installation

730

-

Water Pump Removal and Installation (for J20 Engine Model)

731

-

Water Pump Removal and Installation (for M16 Engine Model)

731

-

Recommended Service Material

732

-

Special Tools and Equipment

732

-

Specifications

732

-

Tightening Torque Specifications

732

-

Water Pump Inspection

732

-

Coolant Description

733

-

Cooling System Description

733

-

For Diesel Engine Model

733

-

General Description

733

-

Coolant Circulation

734

-

Schematic and Routing Diagram

734

-

Diagnostic Information and Procedures

735

-

Engine Cooling Symptom Diagnosis

735

-

Cooling System Components

736

-

Repair Instructions

736

-

Coolant Level Check

737

-

Cooling System Draining

737

-

Engine Cooling System Inspection and Cleaning

737

-

Cooling System Refilling

738

-

Cooling System Flushing

739

-

Cooling Water Pipe or Hose Removal and Installation

739

-

Thermostat Assembly Removal and Installation

739

-

Radiator Cooling Fan Motor On-Vehicle Inspection

740

-

Radiator Cooling Fan Assembly Removal and Installation

742

-

Radiator On-Vehicle Inspection and Cleaning

742

-

Radiator Removal and Installation

742

-

Water Pump Removal and Installation

742

-

Recommended Service Material

743

-

Special Tools and Equipment

743

-

Specifications

743

-

Tightening Torque Specifications

743

-

Water Pump Inspection

743

-

For Petrol Engine Model

744

-

Fuel Delivery System Description

744

-

Fuel System

744

-

Fuel System Description

744

-

General Description

744

-

Precautions

744

-

Precautions on Fuel System Service

744

-

Fuel Delivery System Diagram

745

-

Fuel Pump Description

745

-

Schematic and Routing Diagram

745

-

Diagnostic Information and Procedures

746

-

Fuel Pressure Inspection

746

-

Fuel Cut Operation Inspection

747

-

Fuel System Components

748

-

Repair Instructions

748

-

Fuel Hose Disconnecting and Reconnecting

751

-

Fuel Leakage Check Procedure

753

-

Fuel Lines On-Vehicle Inspection

753

-

Fuel Pipe Removal and Installation

753

-

Fuel Pressure Relief Procedure

753

-

Fuel Injector On-Vehicle Inspection

754

-

Fuel Injector Removal and Installation

754

-

Fuel Injector Inspection

755

-

Fuel Pressure Regulator Inspection

757

-

Fuel Pressure Regulator Removal and Installation

757

-

Fuel Filler Cap Inspection

758

-

Fuel Tank Inlet Valve Removal and Installation

758

-

Fuel Tank Inlet Valve Inspection

759

-

Fuel Tank Removal and Installation

759

-

Fuel Pump On-Vehicle Inspection

761

-

Fuel Tank Inspection

761

-

Fuel Tank Purging Procedure

761

-

Fuel Pump Assembly Removal and Installation

762

-

Fuel Pump Inspection

763

-

Main Fuel Level Sensor Removal and Installation

763

-

Sub Fuel Level Sensor Removal and Installation

763

-

Specifications

764

-

Sub Fuel Level Sensor Inspection

764

-

Tightening Torque Specifications

764

-

Recommended Service Material

765

-

Special Tool

765

-

Special Tools and Equipment

765

-

For Diesel Engine Model

766

-

Precautions

766

-

Precautions on Fuel System Service

766

-

Fuel System Description

770

-

General Description

770

-

Fuel System Components

771

-

Repair Instructions

771

-

Fuel Leakage Check Procedure

772

-

Fuel Pressure Relief Procedure

772

-

Air Bleeding of Fuel System

773

-

Fuel Filter and Fuel Heater Removal and Installation

773

-

Water Draining of Fuel Filter

773

-

Fuel Heater Inspection

774

-

Fuel Hose Disconnecting and Reconnecting

775

-

Fuel Lines Inspection

777

-

Fuel Pipe Removal and Installation

777

-

High Pressure Pipe Removal and Installation

778

-

Fuel Injector On-Vehicle Inspection

781

-

Fuel Injector Removal and Installation

781

-

Injection Pump Components

783

-

Injection Pump Removal and Installation

784

-

Fuel Flow Actuator Inspection (Type 2)

787

-

Fuel Flow Actuator Removal and Installation (Type 2)

787

-

Common Rail (High Pressure Fuel Injection Rail) Removal and Installation

788

-

Fuel Filler Cap Inspection

789

-

Fuel Rail Presser Sensor Inspection

789

-

Fuel Tank Removal and Installation

789

-

Fuel Tank Inlet Valve Removal and Installation

791

-

Fuel Tank Inspection

791

-

Fuel Tank Purging Procedure

791

-

Fuel Pump Assembly Removal and Installation

792

-

Fuel Tank Inlet Valve Inspection

792

-

Fuel Pump Inspection

793

-

Main Fuel Level Gauge Removal and Installation

793

-

Main Fuel Level Gauge Inspection

794

-

Sub Fuel Level Gauge Inspection

794

-

Sub Fuel Level Gauge Removal and Installation

794

-

Specifications

795

-

Tightening Torque Specifications

795

-

Recommended Service Material

796

-

Special Tool

796

-

Special Tools and Equipment

796

-

For Petrol Engine Model

797

-

General Description

797

-

Ignition System

797

-

Ignition System Construction

797

-

Ignition System Wiring Circuit Diagram

798

-

Schematic and Routing Diagram

798

-

Component Location

800

-

Ignition System Components Location

800

-

Diagnostic Information and Procedures

801

-

Ignition Spark Test

801

-

Ignition System Check

801

-

Ignition System Symptom Diagnosis

801

-

Reference Waveform of Ignition System

801

-

High-Tension Cord Inspection (for M16 Engine)

804

-

High-Tension Cord Removal and Installation (for M16 Engine)

804

-

Repair Instructions

804

-

Spark Plug Removal and Installation

804

-

Ignition Coil Assembly (Including Ignitor) Removal and Installation

805

-

Spark Plug Inspection

805

-

Ignition Coil Assembly (Including Ignitor) Inspection

806

-

Ignition Timing Inspection

806

-

Special Tools and Equipment

808

-

Specifications

808

-

Tightening Torque Specifications

808

-

Cranking Circuit Introduction

809

-

Cranking System Note

809

-

For Petrol Engine Model

809

-

General Description

809

-

Precautions

809

-

Starting Motor Circuit Description

809

-

Starting System

809

-

Cranking System Symptom Diagnosis

810

-

Diagnostic Information and Procedures

810

-

Starting Motor Performance Test

811

-

Repair Instructions

813

-

Starting Motor Dismounting and Remounting

813

-

Starting Motor Components

814

-

Starting Motor Inspection

815

-

Recommended Service Material

818

-

Special Tools and Equipment

818

-

Specifications

818

-

Starting Motor Specifications

818

-

Tightening Torque Specifications

818

-

Cranking Circuit Introduction

819

-

For Diesel Engine Model

819

-

General Description

819

-

Starting Motor Circuit Description

819

-

Cranking System Symptom Diagnosis

820

-

Diagnostic Information and Procedures

820

-

Starting Motor Performance Test

821

-

Repair Instructions

822

-

Starting Motor Components

822

-

Starting Motor Disassembly and Assembly

823

-

Starting Motor Dismounting and Remounting

823

-

Starting Motor Inspection

825

-

Specifications

826

-

Starting Motor Specifications

826

-

Tightening Torque Specifications

826

-

Battery Description

827

-

Charging System

827

-

For Petrol Engine Model

827

-

General Description

827

-

Generator Description

828

-

Battery Inspection

829

-

Diagnostic Information and Procedures

829

-

Generator Symptom Diagnosis

830

-

Generator Test (Undercharged Battery Check)

830

-

Generator Test (Overcharged Battery Check)

831

-

Jump Starting in Case of Emergency

832

-

Repair Instructions

832

-

Battery Dismounting and Remounting

833

-

Water Pump and Generator Drive Belt Removal and Installation (for M16 Engine)

833

-

Water Pump and Generator Drive Belt Tension Inspection and Adjustment (for M16 Engine)

834

-

Water Pump and Generator Drive Belt On-Vehicle Inspection (for J20 Engine)

835

-

Water Pump and Generator Drive Belt Removal and Installation (for J20 Engine)

836

-

Generator Dismounting and Remounting

837

-

Generator Components

838

-

Generator Inspection

839

-

Charging System Specifications

842

-

Specifications

842

-

Tightening Torque Specifications

842

-

Battery Description

843

-

For Diesel Engine Model

843

-

General Description

843

-

Generator Description

844

-

Battery Inspection

845

-

Diagnostic Information and Procedures

845

-

Generator Symptom Diagnosis

846

-

Generator Test (Undercharged Battery Check)

846

-

Generator Test (Overcharged Battery Check)

847

-

Battery Dismounting and Remounting

848

-

Jump Starting in Case of Emergency

848

-

Repair Instructions

848

-

Generator Components

849

-

Generator Disassembly and Assembly

850

-

Generator Dismounting and Remounting

850

-

Drive End Frame / Bearing Disassembly and Assembly

852

-

Generator Inspection

852

-

Accessory Drive Belt and Idler Pulley Removal and Installation

854

-

Accessory Drive Belt Inspection

855

-

Accessory Drive Belt Tensioner Removal and Installation

855

-

Charging System Specifications

855

-

Specifications

855

-

Special Tool

856

-

Special Tools and Equipment

856

-

Tightening Torque Specifications

856

-

Diagnostic Information and Procedures

857

-

Exhaust System

857

-

Exhaust System Check

857

-

Exhaust System Components

857

-

Exhaust System Description

857

-

For Petrol Engine Model

857

-

General Description

857

-

Repair Instructions

857

-

Exhaust Manifold Removal and Installation (for J20 Engine Model)

860

-

Exhaust Manifold Removal and Installation (for M16 Engine Model)

860

-

Exhaust Pipe and Muffler Removal and Installation

861

-

Specifications

862

-

Tightening Torque Specifications

862

-

Diagnostic Information and Procedures

863

-

Diesel Particurate Filter Description

863

-

Exhaust System Check

863

-

Exhaust System Description

863

-

For Diesel Engine Model

863

-

General Description

863

-

Exhaust System Components

864

-

Repair Instructions

864

-

Diesel Particulate Filter Removal and Installation

865

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобиля Suzuki Grand Vitara серии JB с 2005 года выпуска.

- Автор: —

- Издательство: Suzuki Motor Corporation

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 190,8 Mb

Сборник руководств на английском, немецком, французском и испанском языках по техническому обслуживанию и ремонту автомобилей Suzuki Grand Vitara серии SQ и Suzuki Grand Vitara XL-7 серии JA с 1997 года выпуска.

- Автор: —

- Издательство: Suzuki Motor Corporation

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 800,5 Mb

Мультимедийное руководство на 11 языках по техническому обслуживанию и ремонту автомобиля Suzuki Grand Vitara второго поколения.

- Автор: —

- Издательство: —

- Год издания: —

- Страниц: —

- Формат: MDF

- Размер: 149,5 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобилей Chevrolet Tracker и Suzuki Escudo/Grand Escudo/Grand Vitara/Grand Vitara XL-7 1997-2006 годов выпуска с бензиновыми двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 534

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобиля Suzuki Grand Vitara с 2005 года выпуска с бензиновыми двигателями объемом 1,6/2,0 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 446

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобиля Suzuki Grand Vitara с 2008 года выпуска с бензиновым двигателем объемом 2,4 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: 2015

- Страниц: 569

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобилей Suzuki Grand Vitara и Suzuki Escudo с 2005 года выпуска с бензиновыми двигателями объемом 1,6/2,0 л.

- Автор: —

- Издательство: Монолит

- Год издания: 2009

- Страниц: 386

- Формат: DjVu

- Размер: 12,3 Mb

Руководство по эксплуатации и ремонту автомобилей Suzuki Grand Vitara и Suzuki Escudo с 2005 года выпуска с бензиновыми двигателями объемом 1,6/2,0/2,4/3,2 л.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 446

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Suzuki Grand Vitara с 2005 года выпуска.

- Автор: —

- Издательство: MoToR

- Год издания: —

- Страниц: 240

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Suzuki Grand Vitara с 2005 года выпуска.

- Автор: —

- Издательство: Suzuki Motor Corporation

- Год издания: 2005

- Страниц: 261

- Формат: PDF

- Размер: 2,5 Mb

Мультимедийное руководство по техническому обслуживанию и ремонту автомобиля Suzuki Grand Vitara серии SQ с 2005 года выпуска.

- Автор: —

- Издательство: —

- Год издания: —

- Страниц: —

- Формат: —

- Размер: 174,8 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Suzuki Grand Vitara с 2008 года выпуска.

- Автор: И.А. Карпов

- Издательство: Арус

- Год издания: —

- Страниц: 227

- Формат: PDF

- Размер: 202,5 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Suzuki Escudo/Grand Escudo/Grand Vitara, Mazda Levante и Chevrolet Tracker 1997-2005 года выпуска.

- Автор: —

- Издательство: Мир Автокниг

- Год издания: —

- Страниц: 464

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Suzuki Escudo/Grand Escudo/Grand Vitara, Mazda Levante и Chevrolet Tracker 1997-2005 года выпуска.

- Автор: —

- Издательство: Мир Автокниг

- Год издания: —

- Страниц: 464

- Формат: —

- Размер: —

Сузуки Гранд Витара (JT, Escudo) руководство по эксплуатации и техническому обслуживанию с бензиновыми двигателями: M16A 1.6 л (1586 см³) 106 л.с./78 кВт, J20A 2.0 л (1995 см³) 140 л.с./104 кВт, J24B 2.4 л (2393 см³) 166-169 л.с./122-124 кВт, N32A 3.2 л (3195 см³) 233 л.с./171 кВт; Инструкция пользователя автомобиль повышенной проходимости Suzuki Grand Vitara компактный кроссовер с кузовами пяти- и трехдверный универсал повышенной вместимости передне- и полноприводные модели второго (Vitara третьего) поколения выпуска с 2005 года

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Suzuki Grand Vitara видео замена воздушного фильтра и фильтра салона, передних и задних тормозных колодок (Сузуки Гранд Витара с 05)

Suzuki Grand Vitara Mark II (Vitara III) общая информация (Сузуки Гранд Витара 2005-2015)

ВОЗДУШНЫЙ ФИЛЬТР

Если воздушный фильтр забит пылью, он создает повышенное сопротивление забору воздуха, что приводит к снижению мощности двигателя и увеличению расхода топлива.

Регулярно проверяйте фильтр и очищайте его следующим образом:

1. Снимите крышку корпуса фильтра. Выньте сменный элемент из крышки.

2. В Вашем автомобиле установлен элемент сухого типа.

Помните, что его надо чистить определенным способом:

3. Продуйте элемент изнутри сжатым воздухом. При необходимости замените элемент новым.

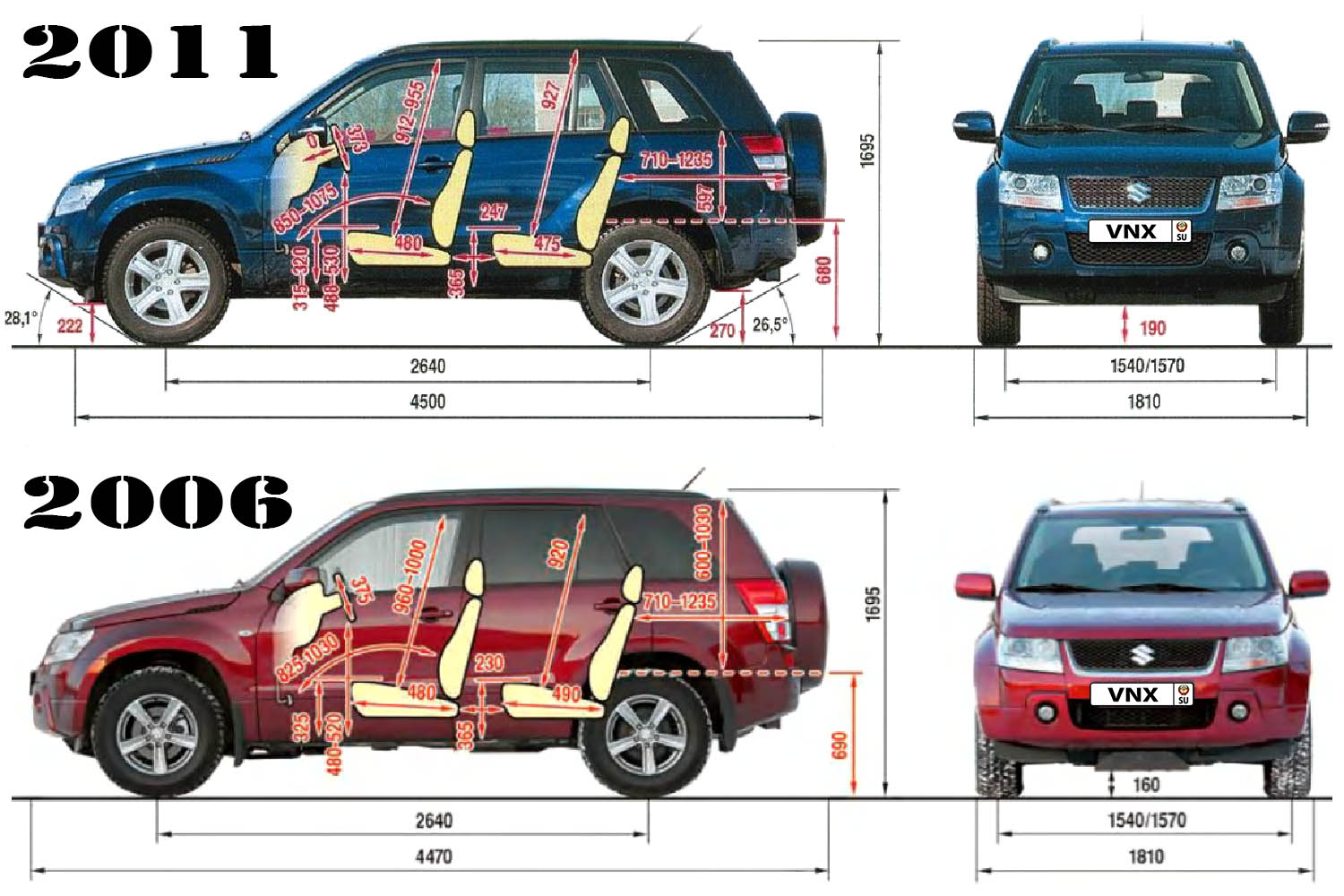

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 4500 с запасным колесом |

| 2 | Ширина (без/с зеркалами) / Width | 1810 |

| 3 | Высота (загружен/пустой) / Height | 1695 с багажником на крыше |

| 4 | Колёсная база / Wheelbase | 2640 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 190⇒160 |

| 6 | Снаряжённая масса / Total (curb) weight | 1584–1670 |

| Полная масса / Gross (max.) weight | 2100 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Бензиновый, жидкостного охлаждения, четырехтактный, J24B VVT |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 4-цилиндровый, 16V, рядный 24V, V-образный, DOHC с верхним расположением двух распределительных валов |

| 9 | Диаметр цилиндра / Bore | 92.0 мм |

| 10 | Ход поршня / Stroke | 90.0 мм |

| 11 | Объём / Engine displacement | 2393 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Многоточечный впрыск топлива MPFI |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 10.0:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 124 кВт (169 л.с.) при 6000 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 227 Нм при 3800 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | Гидротрансформатор с блокировкой / Torque Converter |

| 17 | КПП / Transmission type | АКПП 4 Автоматическая, четырёхступенчатая, гидромеханическая, адаптивная, многорежимная полноприводная трансмиссия с возможностью блокировки межосевого дифференциала и включения понижающей передачи |

О Книге

- Название: Suzuki Grand Vitara руководство по эксплуатации

- Бензиновые двигатели: M16A 1.6 л (1586 см³) 106 л.с./78 кВт, J20A 2.0 л (1995 см³) 140 л.с./104 кВт, J24B 2.4 л (2393 см³) 166-169 л.с./122-124 кВт, N32A 3.2 л (3195 см³) 233 л.с./171 кВт

- Выпуск с 2005 года

- Серия: «Owner Guide»

- Год издания: июль 2008

- Автор: Коллектив авторов

- Издательство: «Suzuki Motor Corporation»

- Формат: PDF

- Страниц в книге: 306

- Размер: 10.41 МБ

- Язык: Русский

- Количество электросхем: 0

-

-

#1

Последнее редактирование модератором: 29 Март 2015

-

-

#2

Ответ: Руководство по ремонту

спасибо большое

-

-

#3

Ответ: Руководство по ремонту

Пожалуйста!

-

-

#4

Ответ: Руководство по ремонту (на русском языке)

А про НСГВ 2008 с движками 2.4 и 3.2 нету случайно книжки?

-

-

#5

Ответ: Руководство по ремонту (на русском языке)

Ну что я могу сказатьОх ёёё, не РЕСПЕКТИЩЕ !!!!!

-

-

#6

Ответ: Руководство по ремонту (на русском языке)

А про НСГВ 2008 с движками 2.4 и 3.2 нету случайно книжки?

не интересовался. сегодня поищу.

-

-

#7

Ответ: Руководство по ремонту (на русском языке)

Спасибо большое

-

-

#8

Ответ: Руководство по ремонту (на русском языке)

Тут где то и цветое для 2.0 было…

Я скачал.

corkscrew

Guest

-

-

#9

Ответ: Руководство по ремонту (на русском языке)

не интересовался. сегодня поищу.

Видимо не нашёл . Очень жаль!!

Может есть у кого книжка на 2,4 L с 2008 года? Отсканируйте, пожалуйста, поделитесь!:whistling: можно в личку или на мыло. Заранее благодарен.

-

-

#10

Ответ: Руководство по ремонту (на русском языке)

точно, не нашел.

но, по крайней мере, убедился, что он вообще существует — электронный вариант такой книги. изредка где-то появляется, но раздачу быстро прикрывают.

-

-

#11

Ответ: Руководство по ремонту (на русском языке)

Ищется руководство по рем., экспл. и тех. обслуживанию автомобилей Suzuki G. V с 2005 г. вып. с двигателем объемом 2,4 л. Поделитесь плз у кого есть…

-

-

#13

Ответ: Руководство по ремонту (на русском языке)

smit, Фигасе, ну и цена у книжки. Хотелось бы конечно полностью, ведь сегодня нужно одно, завтра другое… Но 524 страницы сканировать это пожалуй слишком жестко. Может у кого есть в pdf или jvu? Если нет, то буду покупать книгу. И спасибо за ссылку

-

-

#14

Ответ: Руководство по ремонту (на русском языке)

я сначала тоже скачал для 2.0, но как оказалось 2.4 существенно отличается.

Добавлено через 3 минуты

Knight, кстати в ваших краях подешевле будет всяко: сама книга 1182 + доставка:

По Санкт-Петербургу и Ленинградской области до 105 км от КАД мы осуществляем курьерскую доставку.

Сроки выполнения заказа: 1-3 дня после передачи заказа в службу доставки. Если Вы делаете заказ до 13:00, и если все товары заказа есть в наличии на нашем складе, мы доставим Ваш заказ в этот же день.

Время доставки: ежедневно с 9:00 до 22:00.

Стоимость доставки:

в пределах КАД: 149 рублей;

за КАД до 5 км: 319 рублей;

за КАД до 17 км: 539 рублей;

за КАД до 30 км: 709 рублей;

за КАД до 65 км: 989 рублей;

за КАД до 105 км: 1309 рублей;

Для всех заказов свыше 2000 рублей доставка — бесплатная.

-

-

#15

Ответ: Руководство по ремонту (на русском языке)

Я тут выкладывал скан для 2л и 1.6л, 140мб http://www.suzuki-club.ru/forum/showthread.php?t=63498 — взял да сосканировал 416 стр., очень удобно бывает в электронном виде поглядеть. А купил за 1тр сразу после покупки авто год назад. Без азбуки не жизнь, сервисы обдерут как липку сразу .

-

-

#16

Ответ: Руководство по ремонту (на русском языке)

Да мне не жалко, просто особенно сейчас, в конце года цейтнот образовался. А информации много, действительно много полезной в книжке, причем там четыре модификации описаны — 1.6, 2.0, 2.4, 3.2.

-

-

#17

Ответ: Руководство по ремонту (на русском языке)

Много инфы, но часто слишком сжато изложено и многих секретов то нету, сравнивал я с заводскими мануалами на английском, немецком, французском, лежат кстати здесь на форуме в файловом архиве 200мб на все движки НСГВ

-

-

#19

Cпасибо за ув. )). Не возражаю совсем. А вот файловый архив нашего форума с заводскими мануалами чёт недоступен стал, ссылки не работают.

-

-

#21

надеюсь все, кому нужно было, уже скачали.

можно удалять?

-

-

#22

а че мешает? новичков на ветке каждый день прибывает!

книга реально хорошая!

-

-

#23

Всем привет!

Может и мне кто поможет. В поисках!

Может есть у кого книжка на 2,4 L с 2008 года?

Отсканируйте, пожалуйста, поделитесь! Можно в личку или на мыло (casim@mail.ru). Заранее благодарен.

-

-

#27

Всем привет!

скину еще такое руMazda Levante, Chevrolet Tracker, Suzuki Grand Vitara, Escudo 1997-2004. Устройство, техническое[DOUBLEPOST=1544900342,1544900299][/DOUBLEPOST]не понял как вставить.. пишет большой файл( чуть позже скину ссылку