-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for Kyocera TASKalfa 181

Summary of Contents for Kyocera TASKalfa 181

-

Page 2

A label shown in the illustration assures that the supplies are our own brand. In this Operation Guide, Taskalfa 181/221 are referred to as 18 ppm model and 22 ppm model respectively. Included Guides The following guides are supplied with the machine. -

Page 3: Safety Conventions In This Guide

Safety Conventions in This Guide The sections of this guide and parts of the machine marked with symbols are safety warnings meant to protect the user, other individuals and surrounding objects, and ensure correct and safe usage of the machine. The symbols and their meanings are indicated below.

-

Page 4: Table Of Contents

Contents Contents Part Names Operation Panel …………. 1-2 Machine.

-

Page 5

Contents Print Configuration …………5-24 Print Quality. -

Page 6

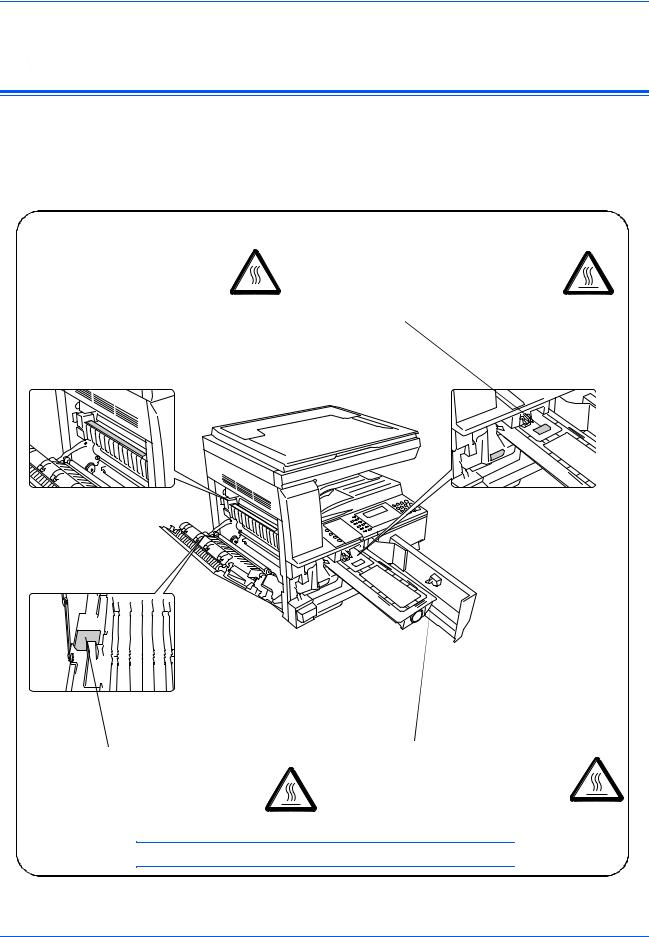

Caution / Warning Labels Caution / Warning labels have been attached to the machine at the following locations for safety purposes. Be sufficiently careful to avoid fire or electric shock when removing a paper jam or when replacing toner. Label 2 High temperature inside. -

Page 7: Installation Precautions

Installation Precautions Environment CAUTION Avoid placing the machine on or in locations which are unstable or not level. Such locations may cause the machine fall down or fall over. This type of situation presents a danger of personal injury or damage to the machine.

-

Page 8: Other Precautions

• Avoid poorly ventilated locations. If the floor is delicate against casters, when this machine is moved after installation, the floor material may be damaged. During copying, some ozone is released, but the amount does not cause any ill effect to one’s health. If, however, the machine is used over a long period of time in a poorly ventilated room or when making an extremely large number of copies, the smell may become unpleasant.

-

Page 9: Precautions For Use

Precautions for Use Cautions when using the machine WARNING Do not place metallic objects or containers with water (flower vases, flower pots, cups, etc.) on or near the machine. This type of situation presents a danger of fire or electrical shock should they fall inside. Do not remove any of the covers from the machine as there is a danger of electrical shock from high voltage parts inside the machine.

-

Page 10: Cleaning

CAUTION Do not pull the power cord when removing it from the outlet. If the power cord is pulled, the wires may become broken and there is a danger of fire or electrical shock. (Always grasp the power plug when removing the power cord from the outlet.) Always remove the power plug from the outlet when moving the machine.

-

Page 11: Machine

Cautions when handling consumables CAUTION Do not attempt to incinerate the toner container or the waste toner box. Dangerous sparks may cause burns. Keep the toner container and the waste toner box out of the reach of children. If toner happens to spill from the toner container or the waste toner box, avoid inhalation and ingestion, as well as contact with your eyes and skin.

-

Page 12: Safety Of Laser Beam

SAFETY OF LASER BEAM 1. Safety of laser beam This machine has been certified by the manufacturer to Class 1 level under the radiation performance standards established by the U.S.DHHS (Department of Health and Human Services) in 1968. This indicates that the product is safe to use during normal operation and maintenance. The laser optical system, enclosed in a protective housing and sealed within the external covers, never permits the laser beam to escape.

-

Page 13: Optical Unit

3. Optical unit When checking the optical unit, avoid direct exposure to the laser beam, which is invisible. Shown at below is the label located on the cover of the optical unit. 4. Maintenance For safety of the service personnel, follow the maintenance instructions in the other section of this manual. 5.

-

Page 14: Safety Instructions Regarding The Disconnection Of Power

Safety Instructions Regarding the Disconnection of Power Caution: The power plug is the main isolation device! Other switches on the equipment are only functional switches and are not suitable for isolating the equipment from the power source. Attention: Le débranchement de la fiche secteur est le seul moyen de mettre l’appareil hors tension. Les interrupteurs sur l’appareil ne sont que des interrupteurs de fonctionnement: ils ne mettent pas l’appareil hors tension.

-

Page 15

(1) year, or 150,000 copies/prints from date of installation, whichever first occurs. In the event the MFP or an accessory is found to be defective within the warranty period, Kyocera’s only obligation and the Customer’s exclusive remedy shall be replacement of any defective parts. -

Page 16

Legal Restriction on Copying/Scanning • It may be prohibited to copy/scan copyrighted material without permission of the copyright owner. • Copying/Scanning the following items is prohibited and may be penalized by low. It may not be limited to these items. Do not knowingly copy/scan the items that are not to be copied/ scanned. -

Page 17: Legal And Safety Information

Legal and Safety Information Please read this information before using your machine. This chapter provides information on the following topics. • Legal Information …………xvi • Regarding Trade Names……….xvii • Energy Saving Control Function ……..xix • Automatic 2-Sided Copy Function …….. xix •…

-

Page 18: Legal Information

Legal Information Copying or other reproduction of all or part of this guide without the prior written consent of Kyocera Mita Corporation is prohibited. OPERATION GUIDE…

-

Page 19: Regarding Trade Names

Regarding Trade Names • PRESCRIBE and ECOSYS are trademarks of Kyocera Corporation. • KPDL and KIR (Kyocera Image Refinement) are trademarks of Kyocera Corporation. • Diablo 630 is a product of Xerox Corporation. • IBM Proprinter X24E is a product of International Business Machines Corporation.

-

Page 20

Monotype Imaging License Agreement Software shall mean the digitally encoded, machine readable, scalable outline data as encoded in a special format as well as the UFST Software. You agree to accept a non-exclusive license to use the Software to reproduce and display weights, styles and versions of letters, numerals, characters and symbols (Typefaces) solely for your own customary business or personal purposes at the address stated on the registration card you return to Monotype Imaging. -

Page 21: Energy Saving Control Function

Energy Saving Control Function The device comes equipped with a Low Power Mode where energy consumption is reduced after a certain amount of time elapses since the device was last used, as well as a Sleep Mode where printer and fax functions remain in a waiting state but power consumption is still reduced to a minimum when there is no activity with the device within a set amount of time.

-

Page 22: About This Operation Guide

About this Operation Guide This Operation Guide contains the following chapters. Chapter 1 — Part Names Identifies machine parts and operation panel keys. Chapter 2 — Preparation before Use Explains adding paper, placing originals, connecting the machine, and necessary configurations before first use. Chapter 3 — Basic Operation Describes the basic procedures of simple copying and printing.

-

Page 23: Conventions In This Guide

Conventions in This Guide The following conventions are used depending on the nature of the description. Convention Description Example Bold Indicates the operation panel Press the Start key. keys or a computer screen. Italic Indicates a message displayed Ready to copy is displayed. on the touch panel.

-

Page 24: Originals And Paper Sizes

Originals and Paper Sizes This section explains the notation used in this guide when referring to sizes of originals or paper sizes. As with A4, B5 and Letter, which may be used either in the horizontal or vertical direction, horizontal direction is indicated by an additional letter R in order to indicate the orientation of the original/paper.

-

Page 25: Part Names

1 Part Names This chapter identifies the machine parts and operation panel keys. • Operation Panel …………1-2 • Machine …………….1-6 OPERATION GUIDE…

-

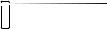

Page 26: Operation Panel

Part Names Operation Panel 12 13 Ready to copy . Auto Auto 100% 9 10 15 16 14 System Menu/Counter key and indicator Copy key and indicator Print key and indicator Scan key and indicator Fax key and indicator Combine key and indicator Border Erase key and indicator Duplex key and indicator Offset key and indicator…

-

Page 27: Initial Mode

Part Names Lighter key / Darker key Message display Ready indicator (green) Data indicator (green) Attention indicator (red) Logout key Interrupt key and indicator Energy Saver key and indicator Power key and indicator Numeric keys Reset key Stop/Clear key Start key and indicator Main power indicator Initial mode Initial mode is the state that the machine enters at the end of warm-up or when the Reset key is pressed.

-

Page 28: Message Display

Part Names Automatic Cassette Switching Function If multiple cassettes contain the same size paper and the paper in one cassette runs out during copying, the automatic cassette switching function will switch paper feed from the empty cassette to the other cassette that still contains paper.

-

Page 29

Part Names Printer Basic Screen Ready CANCEL MENU This screen is displayed when the Print key is pressed. Reference number Meaning Indicates the current status of the machine and displays the message for required operation. Select to switch between online and offline, to print/resume printing, to clear a specific error, and to begin a new page to forcibly print the last page that waits for printing. -

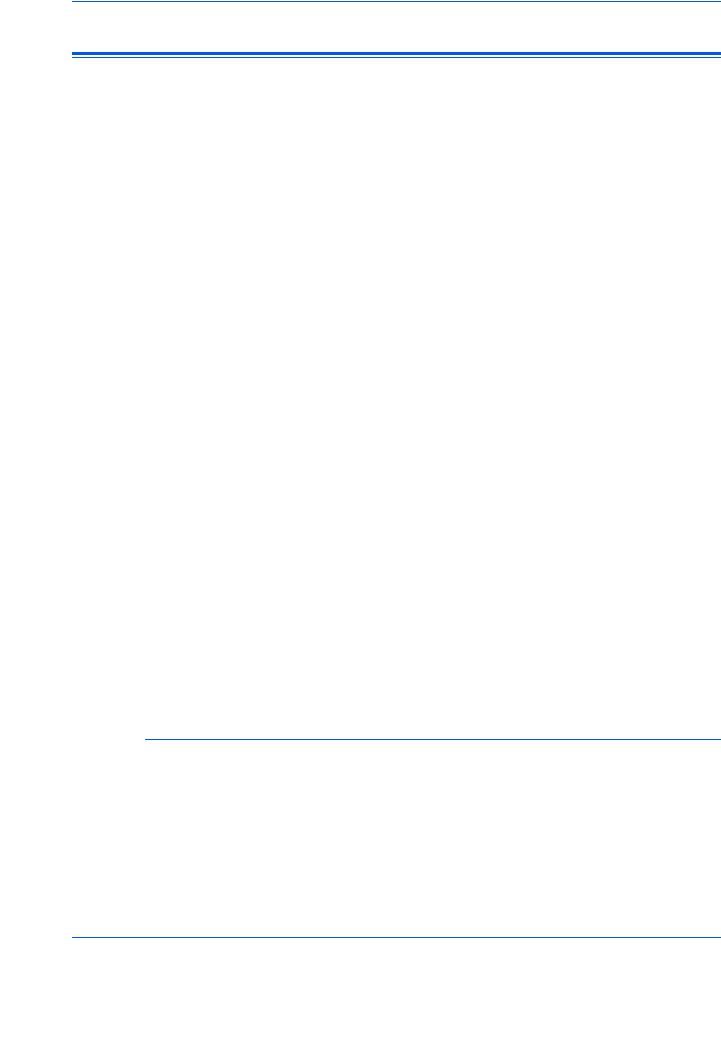

Page 30: Machine

Part Names Machine Original cover Output tray Operation panel Cassette 1 Paper width adjusting tab Paper length adjusting tab Left cover handle MP tray MP tray extension Slider OPERATION GUIDE…

-

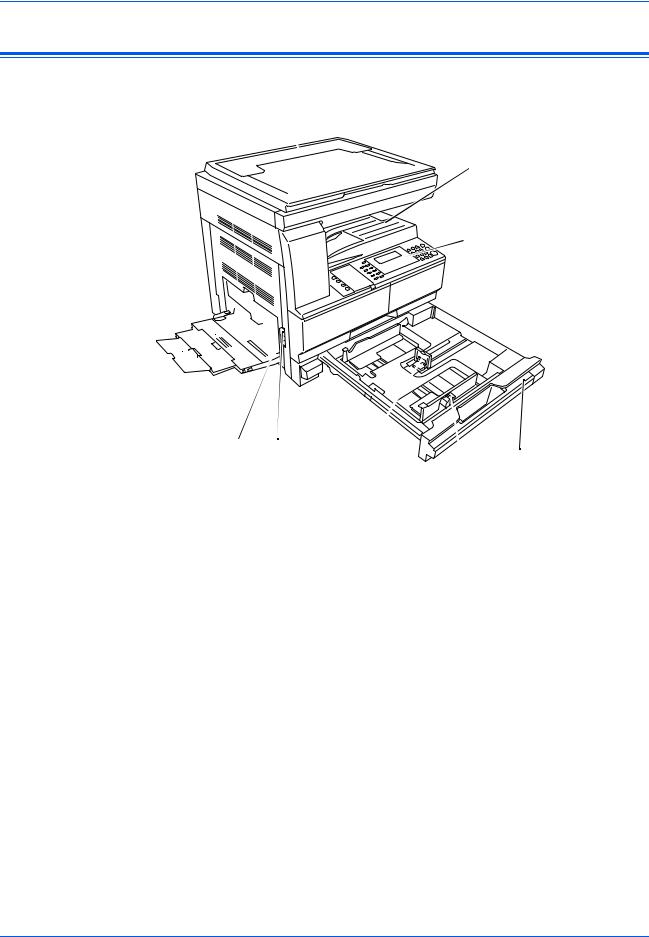

Page 31

Part Names Platen Original size indicator plates Left cover Waste toner box Toner container release lever Toner container Charger cleaner rod Front cover OPERATION GUIDE… -

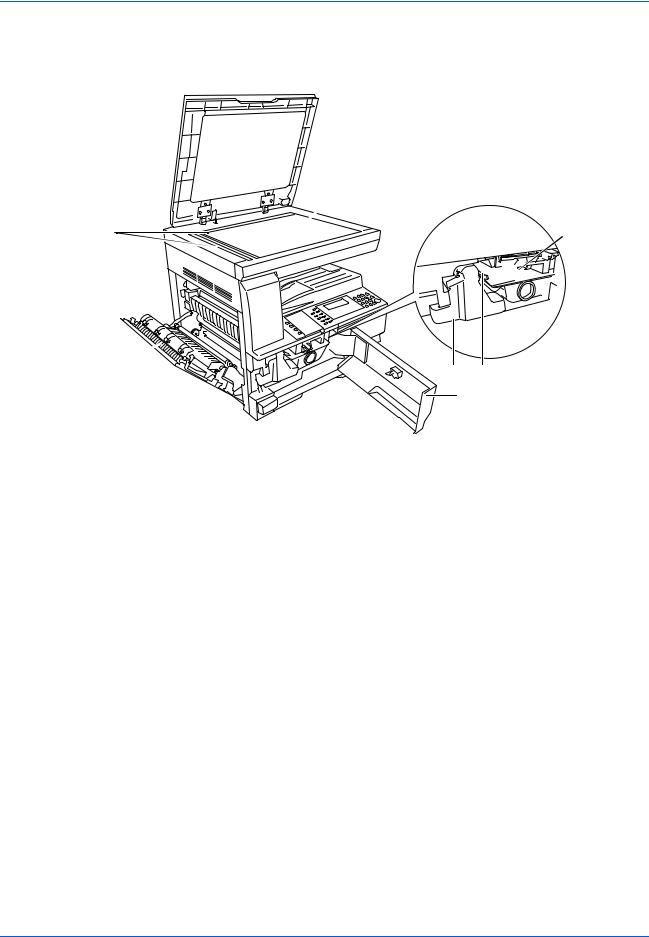

Page 32

Part Names Main power switch Main power switch cover Handles for transport USB interface connector Network interface connector Memory card slot OPERATION GUIDE… -

Page 33: Preparation Before Use

2 Preparation before Use This chapter explains the preparations before using this equipment for the first time as well as the procedures for loading papers and originals. • Check bundled items …………2-2 • Determining the Connection Method and Preparing Cables ..2-3 •…

-

Page 34: Check Bundled Items

Documents Contained in the Included CD-ROM The following documents are contained in the included CD-ROM (Product Library). Refer to them as necessary. Documents KYOCERA COMMAND CENTER Operation Guide Printer Driver User Guide Network FAX Driver Operation Guide KM-NET for Direct Printing Operation Guide…

-

Page 35: Determining The Connection Method And Preparing Cables

Preparation before Use Determining the Connection Method and Preparing Cables Check the method to connect the equipment to a PC or network, and prepare the necessary cables. Connection Example Determine the method to connect the equipment to a PC or network by referring to the illustration below. Connecting a scanner to your PC network with a network cable (100BASE-TX or 10BASE-T) COMMAND CENTER…

-

Page 36: Preparing Necessary Cables

Preparation before Use Preparing Necessary Cables The following interfaces are available to connect the equipment to a PC. Prepare the necessary cables according to the interface you use. Available Standard Interfaces Function Interface Necessary Cable Printer/Scanner* Network interface LAN (10Base-T or /Network FAX** 100Base-TX, Shielded) Printer…

-

Page 37: Connecting Cables

Preparation before Use Connecting Cables Connecting LAN Cable (Optional) Follow the steps below to connect a LAN cable to the machine. When the machine is powered up, first press the Power key on the operation panel. Check that the Power indicator and the memory indicator are off. After this, turn off the main power switch.

-

Page 38: Connecting Usb Cable

Preparation before Use Connecting USB Cable Follow the steps below to connect a USB cable to the machine. When the machine is powered up, first press the Power key on the operation panel. Check that the Power indicator and the memory indicator are off. After this, turn off the main power switch.

-

Page 39: Switching The Language For Display [Language]

Preparation before Use Switching the Language for Display [Language] Select the language displayed on the touch panel. Use the procedure below to select the language. Press the System Menu/Counter key. Press repeatedly until Language appears. System Menu / Counter: The default message language is English. Language MP Tray Setting Press the Enter key.

-

Page 40: Setting Date And Time

Preparation before Use Setting Date and Time Follow the steps below to set the local date and time at the place of installation. When you send an E-mail using the transmission function, the date and time as set here will be printed in the header of the E-mail message.

-

Page 41

Preparation before Use Press to select DST [Summertime] and Date/Time: then press to select On or Off. Time 06:33 Press to select Year and then press Date/Time: to set the current year. Time Zone GMT 00:00 Year 2009 Press to select Month and then press Date/Time: to set the current month. -

Page 42: Registering The Ip Address

Preparation before Use Network (TCP/IP) Setup Registering the IP Address Register the IP address of this machine. NOTE: Prior to the IP address entries, obtain permission from the network administrator. Press the Print key. Press to select MENU, and then press the Ready Enter key.

-

Page 43: Registering The Subnet Mask

Preparation before Use Press the Enter key. Next, set the subnet mask. Registering the Subnet Mask To register the subnet mask, continue the procedure from step 10 above. Press to select Subnet Mask, and then TCP/IP Setting press the Enter key. DHCP IP Address Subnet Mask…

-

Page 44

Preparation before Use Press to select DHCP, and then press the TCP/IP Setting Enter key. Back DHCP IP Address Press to select On, and then press the DHCP Enter key. Back 2-12 OPERATION GUIDE… -

Page 45: Installing Software

Preparation before Use Installing Software Install appropriate software on your PC from the included Product Library CD-ROM (Product Library) if you want to use the printer function of this machine or perform TWAIN transmission or FAX transmission from your PC. NOTE: Installation on Windows XP, Windows 2000, Server 2003 and Windows Vista must be done by a user logged on with administrator privileges.

-

Page 46: Optional Equipment

Preparation before Use Loading Paper Paper can be loaded standardly in a cassette (18 ppm model) or the two cassettes (22 ppm model) and the MP tray. A paper feeder is also available as an option (refer to Optional Equipment on Appendix-2). Before Loading Paper When you open a new package of paper, fan the sheets to separate them slightly prior to loading in the following…

-

Page 47: Loading Paper In The Cassettes

Preparation before Use Loading Paper in the Cassettes Standard paper, recycled paper, and colored paper can be loaded into the cassette. Up to 300 sheets of standard paper (80 g/m ) or 100 sheets of thick paper (90 to 105 g/m ) can be set.

-

Page 48

Preparation before Use Using the paper length guide, move the plate to fit the paper. IMPORTANT: • Make sure that the length guide is flush against the paper. If there is space between the guide and the paper, set the length guide again. •… -

Page 49: Loading Paper In The Mp Tray

Preparation before Use • If the length and width guides are not flush against the paper, a size that is different from the actual size may be displayed on the message display. • When the paper has become wrinkled from moisture and cannot be fed, set the paper so that the wrinkled side is toward the length guide.

-

Page 50

Preparation before Use NOTE: When you load custom size paper, enter the paper size by referring to MP Tray Settings on page 6-28. You can set the MP tray so that when you select the MP tray, the MP Tray Paper size screen is displayed. For the method of setting, refer to MP Tray Settings on page 6-28. -

Page 51

Preparation before Use Insert the paper along the paper width guides into the tray until it stops. IMPORTANT: Keep the side that was closest the package seal facing up. Put only the paper on the MP tray. Do not load more paper than the paper feed capacity of the MP tray. -

Page 52

Preparation before Use Loading Envelopes and Cardstock Up to 5 envelopes may be loaded in the MP tray. Acceptable envelope sizes are as follows. Acceptable Envelope Size Hagaki 148×100 (mm) Oufuku Hagaki 148 × 200 (mm) Youkei 2 162×114 (mm) Youkei 4 235×105 (mm) Monarch… -

Page 53

Preparation before Use When loading the cardstock, open the paper stopper shown in the figure. For landscape form envelopes, close the flap. Insert the envelope all the way along the width guides, keeping the printing side face-down and the edge with the flap facing towards you. For portrait form envelopes, close the flap. -

Page 54: Specifications

Preparation before Use MP Tray Settings Set the following items for feeding paper from the MP (multi-purpose) tray. Paper Size Set the size of paper to be used from the MP tray. You can use irregular size paper by entering the size NOTE: If the paper size is unknown or no special paper size setting is required, select Universal Size.

-

Page 55: Paper Type

Preparation before Use Press to select Other Regular Size, MP Tray Paper Size : and then press the Enter key. Other Regular Size Press to select the paper size, and then Other Regular Size : press the Enter key. The MP Tray Paper type screen is displayed. Proceed to Paper Type described below.

-

Page 56

Preparation before Use Press to select the MP tray paper type, and MP Tray Paper type : then press the Enter key. Plain Transparency The message display returns to the copier basic Preprinted screen. 2-24 OPERATION GUIDE… -

Page 57: Loading Originals

Preparation before Use Loading Originals Follow the steps below to load originals for copying or sending. Placing Originals on the Platen You may place books or magazines on the platen in addition to ordinary sheet originals. In addition, When copying from an original which cannot be set in the document processor, open the document processor and set the original directly on the platen.

-

Page 58: Loading Originals In The Document Processor

Preparation before Use Loading Originals in the Document Processor The optional document processor automatically scans each sheet of multiple originals. Both sides of two-sided originals are scanned. Originals Supported by the Document Processor The document processor supports the following types of originals. •…

-

Page 59

Preparation before Use How to Load Originals IMPORTANT: Before loading originals, be sure that there are no originals left on the original eject table. Originals left on the original eject table may cause the new originals to jam. Adjust the original width guides to fit the originals. NOTE: Before setting originals, make sure that there are no originals remaining on the original eject table. -

Page 60

Preparation before Use IMPORTANT: To keep ejected originals from falling off the machine, open the ejection extension when using large originals such as A3, B4, 11 × 17″ (Ledger), and × 14″ (Legal). When copying from 2-sided originals, the originals are temporarily ejected onto the ejection tray in order to turn them over. -

Page 61: Basic Operation

3 Basic Operation This chapter explains the following operations. • Power On/Off …………..3-2 • Low Power Mode and Auto Low Power Mode ….3-4 • Sleep and Auto Sleep ………..3-5 • Printing from Applications ……….3-6 OPERATION GUIDE…

-

Page 62: Power On/Off

Basic Operation Power On/Off Power On Turn the power of this machine on Open the main power switch cover located on the right side of the machine and turn the main power switch on ( | ). The machine starts to warm up Once warm-up is completed, the Start indicator lights up green Power Off…

-

Page 63

Basic Operation In case of not using the machine for a extended period of time CAUTION: If this machine will be left unused for an extended period (e.g. overnight), turn it off at the main power switch. If the machine will not be used for an even longer period of time (e.g. vacation), remove the power plug from the outlet as a safety precaution. -

Page 64: Low Power Mode And Auto Low Power Mode

Basic Operation Low Power Mode and Auto Low Power Mode Low Power Mode To activate Low Power Mode, press the Energy Saver key. Touch panel and all indicators on the operation panel will go out to save power except the Energy Saver, Power, and main power indicators. This status is referred to as Low Power Mode.

-

Page 65: Sleep And Auto Sleep

Basic Operation Sleep and Auto Sleep Sleep To enter Sleep, press the Power key. All indicators on the operation panel will go out to save a maximum amount of power except the Power indicator. This status is referred to as Sleep. If print data is received during Sleep, the print job is performed while the touch panel remains unlit.

-

Page 66: Printing From Applications

Basic Operation Printing from Applications Follow the steps below to print documents from applications. NOTE: To print the document from applications, install the printer driver on your computer from the supplied CD-ROM (Product Library). Create a document using an application. Click File and select Print in the application.

-

Page 67

Basic Operation NOTE: If you choose Auto Select, papers are supplied automatically from the paper source loaded with paper of optimum size and type. To print on special paper such as envelope or thick paper, place it on the MP tray and select MP Tray. Select paper orientation, either Portrait or Landscape, to match the orientation of the document. -

Page 68

Basic Operation OPERATION GUIDE… -

Page 69: Copying Functions

4 Copying Functions This chapter explains the functions available for copying. • Basic Copying Procedure …………..4-2 • Adjusting Density …………….. 4-3 • Selecting Image Quality …………… 4-4 • Zoom Copying………………4-5 • Collate Copying………………4-8 • Offset Copying ………………4-9 •…

-

Page 70: Basic Copying Procedure

Copying Functions Basic Copying Procedure Follow the steps as below for basic copying. Press the Copy key when the Copy indicator is off. NOTE: If the machine is in the sleep mode, press the Power key and wait for the machine to warm up. Place the originals on the platen or in the optional document processor.

-

Page 71: Adjusting Density

Copying Functions Adjusting Density Use this procedure to adjust the density when copying. Mode Description Auto Density mode The machine detects the density of the original and sets the optimum density. Manual Density mode Adjust the density by pressing the Lighter or Darker key.

-

Page 72: Selecting Image Quality

Copying Functions Selecting Image Quality Select image quality suited to the type of original. The table below shows the quality options. Image quality mode Description Text + Photo For originals with both text and photographs. Text For originals primarily consisting of text. Photo For photos taken with a camera.

-

Page 73: Zoom Copying

Copying Functions Zoom Copying Adjust the magnification to reduce or enlarge the original image. The following zoom options are available. NOTE: When magnification ratio is larger than 201%, the images will be rotated 90° counter-clockwise prior to copying. Auto Zoom Magnification Selection Mode Original images are reduced or enlarged according to the selected paper size.

-

Page 74: Preset Zoom Mode

Copying Functions Manually reduces or enlarges the original image in 1% 25 % increments between 25% and 400%. 200 % The procedure for zoom mode is explained below. Press the Copy key. Place the originals on the platen. Press the Zoom key. Enter the magnification using the numeric keys.

-

Page 75

Copying Functions Press the Zoom key. Press to select the desired maginification, Zoom : and then press the Enter key. 121 : 8.5×14 11×17 The zoom ratio is displayed on the message 100% 78 :8.5×14 8.5×11 display. Press the Start key to start copying. OPERATION GUIDE… -

Page 76: Collate Copying

Copying Functions Collate Copying Since copying in this mode is performed after multiple originals have been scanned and memorized, a required number of collated copy sets can be produced. NOTE: If the optional document processor is installed, you can select whether or not to turn on the collate mode at a default setting.

-

Page 77: Offset Copying

Copying Functions Offset Copying For copying of multiple sets, the orientation of the copies can be changed at the end of each set for easy classification. NOTE: If the optional document processor or finisher is not installed, use this function with collate copying. You can select whether or not to turn on the offset mode at a default setting.

-

Page 78: Staple

Copying Functions Staple Use this feature to staple your finished copies. NOTE: Stapling requires the optional document finisher. Note also that saddle stitching (center stapling) requires the folding unit. The following stapling options and orientations are available. Cassette Paper Cassette Paper Load Direction Load Direction Original Orientation:…

-

Page 79

Copying Functions The procedure for staple mode is explained below. Press the Copy key. Place the originals on the platen. Pressthe Staple key. Press to select the desired stapling Staple : position, and then press the Enter key. Left Top Right Top Press the Start key. -

Page 80: Original Size

Copying Functions Original Size Specify the size of originals being scanned. Be sure to specify the original size when copying non-standard sizes. Selecting an Original Size from Regular Size Use the procedure below to select the original size. Press the Copy key. Place the originals on the platen.

-

Page 81

Copying Functions Press to select Input Size, and then Original Size : press the Enter key. Auto Input Size Press to set the vertical size. Input Size : 2″ You can set the vertical size to 2″ to 11 5/8″ in 1/8″ 2″… -

Page 82: Paper Selection

Copying Functions Paper Selection Select the paper source (cassette or MP tray) that contains the required paper size. Press the Copy key. Place the originals on the platen. If Auto is displayed on the message display, the paper matching the size of the original is selected automatically.

-

Page 83: Mixed Sized Originals

Copying Functions Mixed Sized Originals Using the optional document processor, the originals of different sizes can be loaded in a batch and copied. In this operation, up to 30 originals of different sizes can be placed in the document processor at the same time. Supported Combinations of Originals The supported combinations of originals are as follows.

-

Page 84: Original Orientation

Copying Functions Original Orientation Select the original orientation to use the following functions. • Zoom (XY Zoom) • Duplex • Margin/Centering originals • Border erase • Combine mode • Booklets • Stapling/Punch (optional feature) When placing originals on the platen [Top Edge Top] [Top Edge Left] Original…

-

Page 85

Copying Functions Use the procedure below to select the orientation when placing the originals on the platen. Press the Copy key. Place the originals on the platen. Press the Function key. Press to select Orig. direction, and Function : then press the Enter key. Orig. -

Page 86: Ecoprint

Copying Functions EcoPrint Use EcoPrint to save toner when printing. Use this function for test copies or any other occasion where high quality print is unnecessary. NOTE: The copy exposure will be a little lighter. You can select whether or not to turn on the ecoprint mode at a default setting. Refer to EcoPrint Mode on page 6-4.

-

Page 87: Combine Mode

Copying Functions Combine Mode This mode allows you to copy 2 or 4 originals combined onto a single page. 2-in-1 mode or 4-in-1 mode. The page boundary of each original can be indicated. NOTE: Both the original size and the copy paper size must be regular sizes. 2-in-1 Mode For copying two originals onto a single sheet.

-

Page 88: Types Of Page Boundary Lines

Copying Functions 4-in-1 Mode For copying four originals onto a single sheet. This mode can be used with Duplex mode to copy eight originals onto one sheet. The following 4-in-1 options and output orientations are available. Original Copy Orientation of Original Platen Document processor NOTE:…

-

Page 89

Copying Functions Press the Combine key. Press to select the desired combine Combine : copying mode, and then press the Enter key. 2 in 1 4 in 1 (Z) 4 in 1 (N) Press to select the type of the lines to Border Line: indicate page boundaries, and then press the None… -

Page 90: Margin Mode

Copying Functions Margin Mode Shift the original image to make space on the copy for binding on the left (right) or top (bottom) side. The following margin widths are available. Input units Margin Width Inch Models 1/8 to 3/4″ (in 1/8″ increments) Metric Models 1 mm to 18 mm (in 1 mm increments) NOTE:…

-

Page 91: Border Erase

Copying Functions Border Erase Use Border Erase to remove black shadows that appear around the outside of the original when making copies. The following options can be selected. Sheet Erase Erases black borders around the single sheet original. Original Copy Book Erase Erases black borders around the edges and in the middle of the original such as a thick book.

-

Page 92

Copying Functions Press to set the border erase width, and Border Erase Width : then press the Enter key. 1/4″ 1/8″ 3/4″ You can set the width to 1/8″ to 3/4″ in 1/8″ increments [1 mm to 18 mm in 1 mm increments]. Press the Start key to start copying. -

Page 93: Duplex Copying

Copying Functions Duplex Copying Produce two-sided copies. The following duplex options are available. You can also create single-sided copies from two-sided originals or originals with facing pages such as books. The following modes are available. One-sided to Two-sided Produces two-sided copies from one-sided originals. In case of an odd number of originals, the back side of the last copy will be blank.

-

Page 94

Copying Functions Book to One-sided Produces a 1-sided copy of a 2-sided or open book original. Original Copy Book to Two-sided Produces two-sided copies from an open book original with facing pages. NOTE: The original sizes that can be used are A3, B4, A4R, B5R, A5R, 11 x 17″… -

Page 95

Copying Functions Scanning of the original is performed. After scanning all originals, press the Enter key to start copying. OPERATION GUIDE 4-27… -

Page 96: Continuous Scan

Copying Functions Continuous Scan The continuous copying function allows multiple originals to be separated into some blocks, to be scanned at more than one time, and to be copied in one batch. Since multiple originals of the same type are scanned in multiple steps to accumulate data in memory, many originals can be copied in one batch.

-

Page 97: Auto Image Rotation

Copying Functions Auto Image Rotation Automatically rotates the image when the sizes of the original and the loaded paper matches but the orientations are different. The images will be rotated 90° counter-clockwise prior to copying. NOTE: The paper sizes that can be used for auto rotation are A4/11 x 8 «…

-

Page 98: Interrupt Mode

Copying Functions Interrupt Mode This function allows you to pause the current jobs in progress when you need to make copies immediately. When interruption copy ends, the machine resumes the paused print jobs. The following modes are available for the interrupt function. Mode Description Interrupt copy…

-

Page 99

Copying Functions During Output The procedure for using Interrupt Mode during output is explained below. Press the Interrupt key during output. Select Interrupt mode is displayed. NOTE: If the machine has neither print data nor received fax data, Interrupt mode OK [Interrupt mode] is displayed. -

Page 100: Program Function

Copying Functions Program Function After registering sets of frequently used functions as a single program, you can simply press the program number as needed to recall those functions. You can also name the programs for easy identification when recalling. Registering Programs Use the procedure below to register a program.

-

Page 101: Printing Functions

5 Printing Functions This chapter explains the settings required for using the printing functions. For setting operation required for using this machine as a network printer, use the operation panel. The principal settings that can be made are shown below. •…

-

Page 102: Using This Machine As A Network Printer

Printing Functions Using This Machine as a Network Printer To use this machine as a network printer, use the procedure below for the setting Preparation of network connection environment (Assignment of IP address, etc.) Connection of network cable (Refer to Connecting Cables on page 2-5.) Setting operation from the operation panel of this machine (See this chapter.) Principal setting items •…

-

Page 103: Status Page Printing

Printing Functions Status Page Printing The printer default settings, the memory capacity, and so on are printed in a list. Use the procedure below to print the status page. Press the Print key. Press to select MENU, and then press the Ready Enter key.

-

Page 104: E-Mps Function

Printing Functions e-MPS Function The following items can be set in e-MPS function setting. • Printing Quick Copy/Proof-and-Hold • Deleting Quick Copy/Proof-and-Hold • Printing Private Print/Stored Job • Deleting Private Print/Stored Job • Printing Virtual Mailbox Accumulated Data • Printing Virtual Mailbox List •…

-

Page 105

Printing Functions Printing Quick Copy/Proof-and-Hold If you set quick copy with the printer driver when printing a document, the data is printed and stored in the hard disk. When printing is required, you can print a required number of copies from the operation panel. If you set proof-and-hold with the printer driver and set the required number of copies to execute printing, only one set is output and the document data is stored in the hard disk. -

Page 106

Printing Functions Printing Private Print/Stored Job In private printing, you can execute printing by using the operation panel to input the four-digit access code that has been set with the printer driver when printing from your computer. The data is cleared after printing is complete. -

Page 107: Printing Virtual Mailbox Accumulated Data

Printing Functions Press to select Delete, and then press the Select User Name Enter key. Copies Delete Printing Virtual Mailbox Accumulated Data With the virtual mailbox function, a job is stored in the virtual mailbox. If you use the virtual mailbox function to print a document with the printer driver, the job is stored and is not printed until you execute printing from the operation panel.

-

Page 108: Printing Code Job List

Printing Functions Press to select Print, and then press the List of VMB Enter key. Print The virtual mailbox list is printed. Printing Code Job List Permanent code jobs in the hard disk can be printed. Display the e-MPS screen. (See How to Display the e-MPS Screen on page 5-4.) Press to select List of code Job, and…

-

Page 109

Printing Functions Capacity for Storage of Temporary Code Jobs Set the total capacity (upper limit) for storage of temporary code jobs in the hard disk. The actual maximum size, however, is the size of available hard disk space. Display the e-MPS screen. (See How to Display the e-MPS Screen on page 5-4.) Press to select e-MPS Configuration,… -

Page 110

Printing Functions Total Capacity for Storage of Virtual Mailboxes Set the total capacity (upper limit) for storage of virtual mailboxes in the hard disk. The actual maximum size, however, is the size of available hard disk space. Display the e-MPS screen. (See How to Display the e-MPS Screen on page 5-4.) Press to select e-MPS Configuration,… -

Page 111: Interface

Printing Functions Interface This machine is equipped with a USB interface and network interface as standard components. How to Display the Interface Screen Press the Print key. Press to select MENU, and then press the Ready Enter key. CANCEL MENU Press to select Interface, and then Menu…

-

Page 112

Printing Functions Press to select Change #, and then press NetWare the Enter key. Change # Press to select the frame mode, and then NetWare Frame press the Enter key. Back Auto 802.3 Press the Reset key. The message display returns to the printer basic screen. -

Page 113

Printing Functions Press to select Network, and then press Interface the Enter key. Back Network Press to select TCP/IP, and then press the Network Setting Enter key. Back NetWare TCP/IP Press to select On, and then press the TCP/IP Enter key. Back DHCP This machine supports DHCP (Dynamic Host Configuration Protocol). -

Page 114

Printing Functions Press to select Change #, and then press TCP/IP the Enter key. Change # Press to select IP Address, and then TCP/IP Setting press the Enter key. Back DHCP IP Address Enter the IP address using the numeric keys. IP Address Enter the first block of 3 digits of the address in the highlighted area. -

Page 115

Printing Functions Use the same procedure as steps 4 to 6 of IP Gateway Address setting to input the address, and then press the Enter key. When you finish making all of the setting, press the Reset key. The message display returns to the printer basic screen. -

Page 116: Emulation

Printing Functions Emulation NOTE: You can set the emulation for each interface. Emulation Mode Selection Emulation modes that can be used with this machine: PCL6, KC-GL, KPDL, KPDL (AUTO), Line Printer, IBM Proprinter, Diablo 630, EPSON LQ-850 If you set KC-GL, you can set the thickness of the pen and the page size. If you set KPDL (AUTO), switching between KPDL and an alternative emulation mode will be automatically performed according to the print data.

-

Page 117

Printing Functions KC-GL Pen Thickness If you have selected the KC-GL emulation, you can set the thicknesses of the eight pens and the page size. Continue the procedure from step 5 of Emulation Mode Selection to set these items as shown below. Press to select KC-GL Pen Adjust, and KC-GL… -

Page 118

Printing Functions Press to select On or Off, and then press Print KPDL Errs the Enter key. Back If you set On, the details of any error will be printed. Press the Reset key. The message display returns to the printer basic screen. -

Page 119: Font

Printing Functions Font You can select the default font for the current interface. The default font can be one of the internal fonts or a font stored in the optional memory card. You can set the following items for fonts. •…

-

Page 120: Font Size

Printing Functions Press to select the font ID, and then press Select Font the Enter key. Back I000 Detail The font number is displayed. Font ID I000 Characters displayed before font numbers indicate the following items. Display Description Internal font Downloaded fonts Fonts in memory card Fonts in RAM disk or optional hard disk…

-

Page 121

Printing Functions Press to select Detail, and then press the Select Font Enter key. I000 Back I000 Detail Press to enter the character size, and then Font Size Setting press the Enter key. 8.50 Point (4.00 999.75) You can set the character size to 4.00 to 999.75 point. -

Page 122: Code Set Selection

Printing Functions Courier/Letter Gothic Font Setting You can select the thickness of the Courier or Letter Gothic font from two types. An example of changing the Courier font thickness is described below. Display the Font screen. (See How to Display the Font Screen on page 5-19.) Press to select Select Font, and then…

-

Page 123: Font List Printing

Printing Functions Press the Reset key. The message display returns to the printer basic screen. Font List Printing Display the Font screen. (See How to Display the Font Screen on page 5-19.) Press to select List of Inter. Fonts, Font and then press the Enter key.

-

Page 124: Print Configuration

Printing Functions Print Configuration You can set the following items for print configuration. • Number of Copies • Reduction Printing • Print Orientation • Page Protect Mode • Line Feed (LF) Action • Carriage Return (CR) Action • Wide A4 NOTE: You can set the print configuration for each interface.

-

Page 125: Reduction Printing

Printing Functions Press to enter the number of copies, and Copies then press the Enter key. You can set any number from 1 to 999. Press the Reset key. The message display returns to the printer basic screen. Reduction Printing If you specify the paper size (original size) and the output size, the machine reduces the image at a preset magnification ratio to print onto the specified output size paper.

-

Page 126: Page Protect Mode

Printing Functions Press to select Portrait or Landscape, Orientation and then press the Enter key. Back Portrait Landscape Press the Reset key. The message display returns to the printer basic screen. Page Protect Mode To maintain the printer memory efficiently, the default setting of this mode is Auto. Normally, this menu is not displayed.

-

Page 127: Carriage Return (Cr) Action

Printing Functions return. Ignore LF: Does not perform a line feed. Press the Reset key. The message display returns to the printer basic screen. Carriage Return (CR) Action Set the action of the machine to be executed when it receives a carriage return code (0DH). Display the Page Set screen.

-

Page 128

Printing Functions Press the Reset key. The message display returns to the printer basic screen. 5-28 OPERATION GUIDE… -

Page 129: Print Quality

Printing Functions Print Quality You can set the following items for print quality. • KIR Mode • EcoPrint Setting • Resolution Setting • Print Density How to Display the Print Quality Screen Press the Print key. Press to select MENU, and then press the Ready Enter key.

-

Page 130: Ecoprint Setting

Printing Functions EcoPrint Setting The ecoprint mode allows printing with less toner consumption. Use this mode when high quality printing is not necessary, for example, for trial printing. Display the Print Quality screen. (See How to Display the Print Quality Screen on page 5-29.) Press to select EcoPrint Mode, and then Print Quality…

-

Page 131

Printing Functions Press to select Print Density, and then Print Quality press the Enter key. EcoPrint Mode Resolution Print Density Press to set the print density, and then Print Density press the Enter key. Press the Reset key. The message display returns to the printer basic screen. -

Page 132: Memory Card Operation

Printing Functions Memory Card Operation If the optional memory card is installed in this machine, the following operations are available. • Reading Font Data • Reading Macro Data • Reading Data • Reading Program • Writing Data • Deleting Data •…

-

Page 133: Reading Macro Data

Printing Functions Press the Reset key. The message display returns to the printer basic screen. Reading Macro Data Display the Memory Card screen. (See How to Display the Memory Card Screen on page 5-32.) Press to select Read Macro, and then Memory Card press the Enter key.

-

Page 134: Writing Data

Printing Functions Press to select the program to read, and then press the Enter key. The selected program is read from the memory card. Press the Reset key. The message display returns to the printer basic screen. Writing Data Display the Memory Card screen. (See How to Display the Memory Card Screen on page 5-32.) Press to select Write Data, and then…

-

Page 135: Deleting Font Data

Printing Functions The selected data is deleted from the memory card. Press the Reset key. The message display returns to the printer basic screen. Deleting Font Data Display the Memory Card screen. (See How to Display the Memory Card Screen on page 5-32.) Press to select Delete Font, and then Memory Card…

-

Page 136: Deleting Language Data

Printing Functions Press to select Delete Macro, and then Memory Card press the Enter key. Delete Font Delete Program Delete Macro Press to select the macro data to delete, and then press the Enter key. The selected macro data is deleted from the memory card.

-

Page 137: Printing A Partition List

Printing Functions Press to select OK, and then press the Enter key. Formatting of the memory card starts. When formatting is complete, format information is output. Printing a Partition List Display the Memory Card screen. (See How to Display the Memory Card Screen on page 5-32.) Press to select List of Partitions, Memory Card…

-

Page 138: Hard Disk Operation

Printing Functions Hard Disk Operation If the optional hard disk is installed in this machine, the following operations are available. • Reading Data • Reading Program • Writing Data • Deleting Data • Deleting Font Data • Deleting Program Data •…

-

Page 139: Ram Disk Operation

Printing Functions RAM Disk Operation RAM Disk Functions This machine is equipped with RAM disk functions. The RAM disk is a virtual disk unit that uses a part of the memory. If you assign a certain size of the memory to the RAM disk, you can use the RAM disk for electronic sorting (for reduction of total print time) and storage and reading of data.

-

Page 140: Ram Disk Size

Printing Functions Press to select RAM Disk Mode, and then Menu press the Enter key. Page Set Print Quality RAM Disk Mode Press to select Change #, and then press RAM Disk Mode the Enter key. The operation procedure of each item is the same Change # as that of the memory card operation.

-

Page 141: Paper Handling

Printing Functions Paper Handling You can set the following items for paper. • MP Tray Mode • Paper Source • Duplex Print Mode • Output Destination • Override A4/Letter How to Display the Paper Handling Screen Press the Print key. Press to select MENU, and then press the Ready…

-

Page 142: Paper Source

Printing Functions Paper Source Set the paper source to be selected first. Display the Paper Handling screen. (See How to Display the Paper Handling Screen on page 5-41.) Press to select Feed Select, and then Paper Handling press the Enter key. Back MP Tray Mode Feed Select…

-

Page 143: Output Destination

Printing Functions Display the Paper Handling screen. (See How to Display the Paper Handling Screen on page 5-41.) Press to select Duplex Mode, and then Paper Handling press the Enter key. MP Tray Mode Feed Select Duplex Mode Press to select Short edge bind or Duplex Mode Long edge bind, and then press the Enter key.

-

Page 144

Printing Functions Override A4/Letter The A4 and Letter sizes can be regarded as a size that can be used in common. Display the Paper Handling screen. (See How to Display the Paper Handling Screen on page 5-41.) Press to select Override A4/LT, and Paper Handling then press the Enter key. -

Page 145: Other Settings

Printing Functions Other Settings You can set the following items for other settings. • Form Feed Timeout • Received Data Dump • Printer Function Resetting • Resource Protect Mode • Auto Continue • Duplex Printing Error Detection • Stapling Error Detection •…

-

Page 146: Received Data Dump

Printing Functions Press the Reset key. The message display returns to the printer basic screen. Received Data Dump You can print data received by this machine as hexadecimal codes for debugging programs and files. Display the Others screen. (See How to Display the Others Screen on page 5-45.) Press to select Print HEX-DUMP, and…

-

Page 147: Resource Protect Mode

Printing Functions Press to select OK, and then press the Printer Reset Enter key. Back The printer functions are reset. Resource Protect Mode The resource protect mode protects the resource data such as downloaded fonts and macros and memorizes the PCL resources even if the emulation mode is switched. If you select Permanent, temporary resources are not protected.

-

Page 148: Auto Continue

Printing Functions Auto Continue If any of the following error messages appears, the error can be cleared and printing can be continued after the preset recovery time elapses (auto continue). • Memory Overflow/Press GO • Print overrun Press GO • KPDL error Press GO •…

-

Page 149: Duplex Printing Error Detection

Printing Functions Press the Reset key. The message display returns to the printer basic screen. Duplex Printing Error Detection This setting is available if the optional duplex unit is installed. You can select whether or not to display Duplex disabled Press GO when you select duplex printing and specify a paper type that cannot be used for duplex printing such as label.

-

Page 150: Stapling Error Detection

Printing Functions Stapling Error Detection You can select whether or not to display Add Staples and Press GO when staples have run out while stapling is performed. Setting Processing • If you select GO, printing is performed without stapling. • If you select CANCEL, printing is cancelled.

-

Page 151

Printing Functions Press to select Service, and then press Others the Enter key. Auto Continue Finishing Error Service Press to select Print Status Page, and Service then press the Enter key. Back Print Status Page Paper Feed Press to select Print, and then press the Print Status Page Enter key. -

Page 152

Printing Functions 5-52 OPERATION GUIDE… -

Page 153: System Menu

6 System Menu This chapter explains the system settings concerning the general operation of this machine. The principal settings that can be made are shown below. • Default Setting Mode …………6-2 • Machine Default Settings ……….6-13 • MP Tray Settings …………6-28 •…

-

Page 154: Default Setting Mode

System Menu Default Setting Mode For this machine, the state that the machine enters at the end of warm-up or when the Reset key is pressed is called initial mode. The settings of this machine that are made automatically in the initial mode are called default settings.

-

Page 155

System Menu Enter the four-digit management code using the Enter Pin Code using # key. numeric keys. The management code at the factory default setting is 1800 for the 18 ppm model and 2200 for the 22 ppm model. NOTE: The four-digit management code can be changed. -

Page 156

System Menu Press to select Orig Image, and then Copy Default : press the Enter key. Density Mode Manual Original Image Txt+Phto Press to select Text+Photo, Text or Original Image : Photo, and then press the Enter key. Text+Photo Text Photo Press the Reset key. -

Page 157

System Menu Press to adjust the background color, and Background Adjustment : then press the Enter key. Moving right darkens the background color, and moving left lightens it. Press the Reset key. The message display returns to the copier basic screen. -

Page 158

System Menu Press to select Off or On, and then press Paper Type(Auto): the Enter key. If you have selected On, press to select the Paper Type(Auto): desired paper type, and then press the Enter key. Plain Preprinted Press the Reset key. The message display returns to the copier basic screen. -

Page 159

System Menu Press to select Default Magnif, and Copy Default : then press the Enter key. Paper Type(Auto ) Plain Default Cassette Casset.1 Default Magnif . 100% Press to select 100% or Auto %, and then Default Magnification : press the Enter key. 100% Auto % Press the Reset key. -

Page 160

System Menu Press to adjust the density, and then press Adjust Auto OCR Density : the Enter key. Moving right darkens the density, and moving left lightens it. Press the Reset key. The message display returns to the copier basic screen. -

Page 161

System Menu Press the Reset key. The message display returns to the copier basic screen. Density Adjustment for Photo Originals Adjust the density of the central value in the manual density mode for photo originals. Display the Copy Default screen. (See How to Display the Copy Default Screen on page 6-2.) Press to select Photo Ori Dnsity, and… -

Page 162

System Menu Offset Copying Select whether or not to set the offset copy mode as a default setting. Display the Copy Default screen. (See How to Display the Copy Default Screen on page 6-2.) Press to select Offset, and then press the Copy Default : Enter key. -

Page 163

System Menu Press to select Margin Width, and then Copy Default : press the Enter key. Offset Auto Rotation Margin Width 1/4″ Press to set the default value of margin Margin Width : width, and then press the Enter key. 1/4″… -

Page 164

System Menu Enter the maximum number of copies (1 to 999) Copy Limit: using the numeric keys, and then press the Enter key. Sets # keys Press the Reset key. The message display returns to the copier basic screen. Black Streaking Reduction Processing If black streaks (streaks that are not contained in the original image) appear on copies from the optional document processor, you can make black streaking less noticeable. -

Page 165: Machine Default Settings

System Menu Machine Default Settings You can set the following items as machine default settings. • Auto Cassette Switching • Paper Size (cassettes 1 to 4) • Paper Type (cassettes 1 to 4) • MP Tray Confirmation Display • Paper Weight for Paper Type •…

-

Page 166

System Menu NOTE: The four-digit management code can be changed. (See Administrator Management Code Change on page 6-24.) If the management code is accepted, the Machine Machine Default : Default screen is displayed. Auto Cassette SW Next, perform the setting referring to the following Paper Size(1st) Auto I description of each setting item. -

Page 167

System Menu NOTE: For the 18 ppm model, cassettes 2 to 4 are included in the optional paper feeder. For the 22 ppm model, cassettes 3 and 4 are included in the optional paper feeder. This setting is displayed only if the optional paper feeder is installed. -

Page 168

System Menu Press the Reset key. The message display returns to the copier basic screen. MP Tray Confirmation Display Select whether or not to display the MP Tray Paper size screen when pressing the Paper Selection key to select the multi-purpose tray. Display the Machine Default screen. -

Page 169

System Menu Press to select the paper weight, and then Plain: press the Enter key. Heavy 1 Middle 3 Middle 2 When all setting is complete, press to select Paper type (Paper Weight ): End, and then press the Enter key. Plain Middle 2 Transparency… -

Page 170

System Menu Custom Paper Type Printing onto prepunched paper, preprinted paper or letterhead in the one-sided mode and the two-sided mode from the same paper source may cause displacement of hole positions or reverse orientations on both sides in two-sided printing. Set Match Print Direction to match the orientation in one-sided printing and two-sided printing. -

Page 171

System Menu Original Orientation Set the default original orientation. Display the Machine Default screen. (See How to Display the Machine Default Screen on page 6-13.) Press to select Orig. direction, and Machine Default : then press the Enter key. P. Type (2sided) Specific P . -

Page 172: Top Tray

System Menu Press the Reset key. The message display returns to the copier basic screen. Auto Low Power Time Set the time that elapses before the low power mode is automatically activated. Time that can be set: Inch Specification— 1 to 240 minutes (in 1 minute increments) Metric Specification—…

-

Page 173: Job Separator

System Menu Press to select Copy Otput Destn, and Machine Default : then press the Enter key. Sleep Mode Time 1 Min. Low Power Time 1 Min. Copy Otput Destn Top Tray Press to select the desired output Copy Output Destination : destination, and then press the Enter key.

-

Page 174

System Menu Default Operation Mode Select the default screen to be displayed when the power is turned on from the copy screen or the fax screen. NOTE: This item is displayed only if the optional fax kit is installed. Display the Machine Default screen. (See How to Display the Machine Default Screen on page 6-13.) Press to select Main mode, and then press… -

Page 175

System Menu Date and Time Set the current date and time, time difference from the Greenwich Mean Time (GMT), and summer time. Display the Machine Default screen. (See How to Display the Machine Default Screen on page 6-13.) Press to select Date/Time, and then press Machine Default : the Enter key. -

Page 176

System Menu Press the Reset key. The message display returns to the copier basic screen. Display Contrast Adjustment Adjust the display contrast if the message display is indistinct. Display the Machine Default screen. (See How to Display the Machine Default Screen on page 6-13.) Press to select Display Contrast Machine Default :… -

Page 177

System Menu Press the Reset key. The message display returns to the copier basic screen. Auto Sleep The machine enters automatically the sleep mode when the preset time elapses without any operation if this setting is turned On. NOTE: This setting is displayed only on the inch specification machine. You can disable the auto sleep function if this function causes inconvenience. -

Page 178

System Menu Press the Reset key. The message display returns to the copier basic screen. Auto Clear Time Set the time that elapses from completion of copying to activation of the auto clear function if you have turned On the auto clear function (see page 6-25.) Time that can be set: 10 to 270 seconds (in 10 second increments) NOTE: This item is not displayed if the auto clear function is off. -

Page 179

System Menu Press the Reset key. The message display returns to the copier basic screen. Machine Administrator Management Code Change You can change the four-digit management code for the security administrator of the other machine. IMPORTANT: If you change the management code, be sure to note it. If you should forget the management code, contact your service representative. -

Page 180: Mp Tray Settings

System Menu MP Tray Settings Set the following items for feeding paper from the MP tray. Paper Size Set the size of paper to be used from the MP tray. You can use irregular size paper by entering the size. NOTE: If the paper size is unknown or no particular paper size setting is required, select Universal Size.

-

Page 181

System Menu Press to select Other Regular Size, MP Tray Paper Size : and then press the Enter key. Other Regular Size Press to select the paper size, and then Other Regular Size : press the Enter key. The MP Tray Paper type screen is displayed. Proceed to MP Tray Paper Type described below. -

Page 182

System Menu Paper Type To set the paper type to be used in the MP tray, continue the procedure from Paper Size setting. Paper types that can be set: Plain, Transparency, Preprinted, Labels, Bond, Recycled, Vellum, Rough, Letterhead, Color [Colour], Prepunched, Envelope, Cardstock, Thick paper, High quality, Custom 1 (toPress to select the paper type, and then press…

-

Page 183: Browsing And Printing The Total Counter

System Menu Browsing and Printing the Total Counter You can browse the total count on the operation panel. Also you can output it as a counter report. Browsing the Total Counter NOTE: You can browse the output counter and the scanning counter. Press the System Menu/Counter key.

-

Page 184

System Menu Press the Reset key. The message display returns to the copier basic screen. 6-32 OPERATION GUIDE… -

Page 185: Report Output

System Menu Report Output You can output the following reports from the operation panel. Copy status report Machine status report Coverage report NOTE: Ensure that A4/11 » paper is set in the cassette when printing a report. × A coverage report is a report on which the number of printed sheets and the average of blackness ratio for each paper size are written.

-

Page 186: Language Setting

System Menu Language Setting You can select the language to be used on the message display. Languages that can be selected: Inch Specification — English, French (Français), Spanish (Español), and Japanese ( Metric Specification — English, German (Deutsch), French (Français), Spanish (Español) and Italian (Italiano) Press the System Menu/Counter key.

-

Page 187: Job Accounting

7 Job Accounting This chapter explains the job accounting functions of this machine. The principal functions that can be set are shown below. • Job Accounting Mode ………..7-2 • All Account Management ……….7-10 • Individual Account Management……… 7-11 • Enabling Job Accounting ……….7-12 •…

-

Page 188: Job Accounting Mode

Job Accounting Job Accounting Mode Use the job accounting mode to control the total number of copies and prints by setting an ID-code for each account. The job accounting mode of this machine has the following features. • Controls the copier functions, printer functions, and optional scanner/fax functions using the same ID- codes.

-

Page 189: Managing Accounts

Job Accounting How to Display the Job Accounting Screen Use the following procedure to display the Job Accounting screen. Press the System Menu/Counter key. Press to select Job Accounting, and System Menu / Counter: then press the Enter key. Counter Check Print Report Job Accounting Enter the four-digit management code using the…

-

Page 190: Setting Limit Of Use

Job Accounting Enter a one- to eight-digit ID-code using the New registration : numeric keys. Account ID A code from 0 to 99999999 can be input. NOTE: If you try to register an ID-code that has been already input, an error occurs. Enter another ID-code. Press the Enter key.

-

Page 191

Job Accounting Item Description of limit Reference page Fax transmission Set the limit of count of fax transmission if the optional fax kit is limit installed. No limit: Does not set the limit of count of fax transmission. Counter limit: Set the limit of count of fax transmission (0 to 999,999). -

Page 192

Job Accounting Press to select Able to use or Unable Printer: to use, and then press the Enter key. Able to use Unable to use The message display returns to the Limit in use screen. Output Limit You can set the limit of total count of copying and printing. NOTE: This item is not displayed if both Copy Restriction and Print Restriction are set to Unable to use. -

Page 193

Job Accounting Press to select No limit or Counter Scanner Transmitting : limit or Is not permitted, and then press the No Limit Enter key. Counter Limit Is not permitted If you have selected Counter limit, the Counter limit Default Value screen is displayed. Proceed to the next step. -

Page 194: Deleting An Account

Job Accounting Deleting an Account Delete a registered account. Display the Job Accounting screen. (See How to Display the Job Accounting Screen on page 7-3.) Press to select Edit Job Accounting, Job Accounting : and then press the Enter key. Each Job Accounting TL Edit Job Accounting Job Accountg Def .

-

Page 195

Job Accounting Press to select Edit Job Accounting, Job Accounting : and then press the Enter key. Each Job Accounting TL Edit Job Accounting Job Accountg Def . Set. Press to select Change limit in use, Edit Job Accounting : and then press the Enter key. -

Page 196: All Account Management

Job Accounting All Account Management You can browse the total output count, output the job accounting report, and clear the counter for all accounts. Display the Job Accounting screen. (See How to Display the Job Accounting Screen on page 7-3.) Press to select Job Accounting Total, Job Accounting :…

-

Page 197: Individual Account Management

Job Accounting Individual Account Management You can see the output count and clear the counter for individual accounts. Display the Job Accounting screen. (See HHow to Display the Job Accounting Screen on page 7-3.) Press to select Each Job Accounting Job Accounting : TL, and then press the Enter key.

-

Page 198: Enabling Job Accounting

Job Accounting Enabling Job Accounting Turn on or off the job accounting function. Display the Job Accounting screen. (See How to Display the Job Accounting Screen on page 7-3.) Press to select Job Accounting On/ Job Accounting : Off, and then press the Enter key. Edit Job Accounting Job Accountg Def .

-

Page 199: Default Settings

Job Accounting Default Settings Adjust the default settings for job accounting. You can set the following items in default settings. • Copier Job Accounting (page 7-13) • Printer Job Accounting (page 7-14) • Scanner Job Accounting (page 7-14) • Fax Job Accounting (page 7-15) •…

-

Page 200: Printer Job Accounting

Job Accounting Printer Job Accounting You can select whether or not to enable job accounting for the printer functions. Display the Job Accounting screen. (See How to Display the Job Accounting Screen on page 7-3.) Press to select Job Accounting Def. System Menu / Counter: Set, and then press the Enter key.

-

Page 201: Fax Job Accounting

Job Accounting Press to select Off or On, and then press Scanner Job Accounting : the Enter key. Press to select End, and then press the Job Accounting Default Setting Enter key. Copy Job Account . : On Prnt Job Account . : On Fax Job Accounting You can select whether or not to enable job accounting for the fax functions.

-

Page 202

Job Accounting Press to select Job Accounting Def. Job Accounting : Set, and then press the Enter key. Each Job Accounting TL Edit Job Accounting Job Accountg Def . Set. Press to select Excess limit Set, and Job Accounting Default Setting then press the Enter key. -

Page 203: Using Job Accounting

Job Accounting Using Job Accounting Copier Operation Under job accounting, you can perform copier operation only by entering your ID-code using the numeric keys. IMPORTANT: Be sure to press the Job Accounting key after completing copying. The ID-code input screen is displayed.

-

Page 204

Job Accounting 7-18 OPERATION GUIDE… -

Page 205: Maintenance

8 Maintenance This chapter describes cleaning and toner replacement. • Cleaning…………….8-2 • Toner Container and Waste Toner Box Replacement …8-6 OPERATION GUIDE…

-

Page 206: Cleaning

Maintenance Cleaning Clean the machine regularly to ensure optimum output quality. CAUTION: For safety, always unplug the power cord before cleaning the machine. Original Cover / Glass Platen Wipe the backside of the original cover and the glass platen with a soft cloth dampened with alcohol or mild detergent.

-

Page 207

Maintenance Open the document processor and wipe the slit glass (a). Wipe the white guide (b) on the document processor. Separator Clean the separator regularly (at least monthly) to ensure optimum output quality. Open the front cover. Remove cleaning brush (blue colored). OPERATION GUIDE… -

Page 208: Transfer Roller

Maintenance Pull up and open left cover. As shown in the figure, clean dirt from the separator by moving the brush from side to side along the separator. Put away the cleaning brush, press the specified position of the front cover and left cover to close. Transfer Roller Open the front cover.

-

Page 209

Maintenance Pull up and open left cover. As shown in the figure, clean dirt from the transfer roller by moving the brush from side to side along the roller while rotating the roller by turning the gear at the left end of the roller. Put away the cleaning brush, press the specified position of the front cover and left cover to close. -

Page 210: Toner Container And Waste Toner Box Replacement

Maintenance Toner Container and Waste Toner Box Replacement When the touch panel displays Add toner, replace the toner. Every time you replace the toner container, be sure to clean the parts as instructed below. Dirty parts may deteriorate output quality. CAUTION: Do not attempt to incinerate the toner container or the waste toner box.

-

Page 211

Maintenance WARNING: High voltage is present in the charger section. Take sufficient care when working in this area, as there is a danger of electrical shock. IMPORTANT: Do not invert the old waste toner box. Use the cap attached to the center of the old waste toner box to cover the opening. -

Page 212: Cleaning Electrical Charge Section

Maintenance Place the old toner container in the plastic bag provided for disposal. Cleaning Electrical Charge Section While holding the charger cleaner rod, gently pull it out as far as it will go and push it in again. Repeat this operation two or three times. NOTE: Do not use excessive force to pull the rod or attempt to pull it out completely.

-

Page 213

Maintenance When the electrical charge section is pulled out approximately 5 cm (2 inches), remove the grid cleaner and then push back the electrical charge section all the way into the main body. IMPORTANT: After you use the grid cleaner to clean the electrical charge section, the machine can be used again after more than 5 minutes have elapsed. -

Page 214

Maintenance Insert the new toner container, and push it with both hands until it is locked. Install the new waste toner box. Close the front cover. NOTE: Return the exhausted toner container and waste toner box to your dealer or service representative. -

Page 215: Troubleshooting

9 Troubleshooting This chapter explains how to solve problems with the machine. • Solving Malfunctions ………….9-2 • Responding to Error Messages ……..9-5 • Clearing Paper Jams ……….9-12 OPERATION GUIDE…

-

Page 216: Solving Malfunctions

Troubleshooting Solving Malfunctions The table below provides general guidelines for problem solving. If a problem occurs with your machine, look into the checkpoints and perform procedures indicated on the following pages. If the problem persists, contact your Service Representative. Reference Symptom Checkpoints Corrective Actions…

-

Page 217

Troubleshooting Reference Symptom Checkpoints Corrective Actions Page Printouts are too dark. Is the machine in Auto Set the correct density level for — Density mode? auto density. Is the machine in Manual Use the Image Quality key to set Density mode? the correct density level. -

Page 218

PC set application software settings are properly? set properly. While the operation Is the operation panel Check the panel lock setting in KYOCERA panel was being used, locked? COMMAND CENTER and change COMMAND the keys locked up the setting if necessary. -

Page 219: Responding To Error Messages

Troubleshooting Responding to Error Messages If the touch panel displays any of these messages, follow the corresponding procedure. Alphanumeric Reference Error Message Checkpoints Corrective Actions Page Print data does not match To change the paper source, press — Add paper in the size or type of paper in the Paper Selection key to select the cassette.

-

Page 220

Troubleshooting Reference Error Message Checkpoints Corrective Actions Page The slit glass is dirty. Clean the slit glass because black — Clean the slit lines may be copied when the glass for optional document processor is used. original fed from [Clean the slit glass original fed from DP.]… -

Page 221

Troubleshooting Reference Error Message Checkpoints Corrective Actions Page Current copying cannot be Select Copy Scanned Image to — Memory is full. processed because the output the pages that have been memory for copying is full scanned or select Cancel to delete or the number of originals scanned data. -

Page 222

Troubleshooting Reference Error Message Checkpoints Corrective Actions Page The memory card is Insert the memory card. — Memory card error accidentally removed Insert again. during printer setting. NOTE: When inserting the memory card, turn the main power switch off. Originals have jammed in Leave the main power switch on ( | ) —… -

Page 223

Troubleshooting Reference Error Message Checkpoints Corrective Actions Page Printing has not been Press the Print key to display the — Print overrun Press performed properly following messages. because of insufficient GO: Continues printing. memory. CANCEL: Cancels printing. RESET: Resets the printer board. In this case, only the printer functions will be reset. -

Page 224

Troubleshooting Reference Error Message Checkpoints Corrective Actions Page The output tray capacity is Remove the paper. — Remove paper from exceeded during printing. Top tray. Press GO There are already 250 Press the Print key. Press sheets of paper stored in select GO, and then press the Enter the output tray. -

Page 225

Troubleshooting Reference Error Message Checkpoints Corrective Actions Page The toner container is not Set the toner container properly. Set toner set properly. container. The toner container is not Tap and shake the new toner Shake the toner tapped or shaked properly. container without spilling the toner, container. -

Page 226: Clearing Paper Jams

Troubleshooting Clearing Paper Jams If a paper jam occurs, copying or printing stops. At this Paper misfeed in time, jam location indicators are displayed as well as an cassette 1. error message indicating a paper jam. Leave the main Remove paper . power switch on ( | ) and remove the jammed paper.

-

Page 227

Troubleshooting After you remove the jam, the machine will warm up again and the error message will be cleared. The machine resumes with the page which jam has occurred. Precautions with Paper Jams • Do not reuse jammed papers. • If the paper tears during removal, be sure to remove any loose scraps of paper from inside the machine. -

Page 228

Troubleshooting Push cassette 1 back in place securely. NOTE: Check to see if paper is out of position in the cassette. If the paper is out of position, set the paper properly. If JAM21 is displayed, remove the jammed paper referring to Left Cover on page 9-17. -

Page 229

Troubleshooting Cassette 2 to 4 If Paper misfeed in cassette 2 (to 4). Remove paper [Misfeed in paper cassette 2 (to 4). Remove paper] and Paper misfeed. Open left cover 2 (to 4) and remove paper appears and the jam location indicator shown in the illustration blinks, a paper jam has occurred in the optional paper feeder. -

Page 230

Troubleshooting Pull out the cassette. Remove the jammed paper without tearing it. NOTE: If the paper does happen to tear, remove any loose scraps from inside the machine. Push cassette back in place securely. MP Tray (JAM 10) If Paper misfeed in stack bypass. Remove paper appears and the jam location indicator shown in the illustration blinks, a paper jam has occurred in the MP tray. -

Page 231: Left Cover

Troubleshooting Reset the paper in the MP tray. The error message disappears. MP Tray (except JAM10) IMPORTANT: If JAM20 is displayed, remove the jammed paper referring to Paper Jam in the Left Cover. If JAM40 is displayed, remove the jammed paper referring to Paper Jam in the Left Cover. When removing jammed paper, do not pull it out from the MP tray side.

-

Page 232

Troubleshooting Remove the jammed paper without tearing it. If the optional duplex unit is installed, raise the duplex unit and remove any paper. NOTE: If the paper does happen to tear, remove any loose scraps from inside the machine. Close the left cover. 9-18 OPERATION GUIDE… -

Page 233

Troubleshooting Paper Output Slot If Paper misfeed in Eject section Remove paper appears and the jam location indicator shown in the illustration blinks, a paper jam has occurred in the paper output slot. Follow the steps below to clear paper jams in the paper output slot. -

Page 234: Optional Document Processor

Troubleshooting Optional Document Processor If Misfeed in DP. Remove original(s) appears and the jam location indicator shown in the illustration blinks, a paper jam has occurred in the optional document processor. Perform the following procedure to remove the jammed original(s). Misfeed in DP .

-

Page 235

Troubleshooting Remove the jammed originals without tearing them. NOTE: If the original does happen to tear, remove any loose scraps from inside the document processor. Turn the dial as shown in the illustration to remove the jammed original. Close the left cover to its original position. Reset all the originals and start copying again. -

Page 236: Optional Finisher

Troubleshooting Optional Finisher If Paper misfeed in Finisher, lower Process Tray and remove paper appears and the jam location indicator shown in the illustration blinks, a paper jam has occurred in the optional finisher. Follow the steps below to clear paper jams in the optional finisher.

-

Page 237