Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобиля Toyota Avensis 1998-2002 годов выпуска.

- Автор: —

- Издательство: Toyota Motor Corporation

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 651,2 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобиля Toyota Avensis 2003-2009 годов выпуска.

- Автор: —

- Издательство: Toyota Motor Corporation

- Год издания: —

- Страниц: —

- Формат: PDF, ISO

- Размер: 659,3 Mb

Руководство по техническому обслуживанию и ремонту автомобиля Toyota Avensis 1998-2003 годов выпуска.

- Автор: —

- Издательство: Алфамер

- Год издания: —

- Страниц: 336

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Toyota Avensis 2005 года выпуска.

- Автор: —

- Издательство: Toyota Motor Corporation

- Год издания: 2004

- Страниц: 364

- Формат: PDF

- Размер: 66,4 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобиля Toyota Avensis 1997-2003 годов выпуска с бензиновыми двигателями объемом 1,6/1,8/2,0 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 456

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобиля Toyota Avensis 2003-2008 годов выпуска с бензиновыми двигателями объемом 1,6/1,8/2,0/2,4 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 456

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Toyota Avensis с 2003 года выпуска.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 268

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобилей Toyota Avensis с 2003 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Гуси-Лебеди

- Год издания: —

- Страниц: 404

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобиля Toyota Avensis с 2009 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 428

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Toyota Avensis с 2002 года выпуска.

- Автор: —

- Издательство: MoToR

- Год издания: —

- Страниц: 372

- Формат: —

- Размер: —

Toyota Avensis T250 с бензиновыми двигателями: 3ZZ-FE 1.6 л (1598 см³) 108 л.с./79,4 кВт, 1ZZ-FE 1.8 л (1794 см³) 129 л.с./95 кВт, 1AZ-FE LG 2.0 л (1998 см³) 135 л.с./99 кВт, 1AZ-FSE 2.0 л D-4 (1998 см³) 147 л.с./108 кВт, 2AZ-FSE 2.4 л D-4 (2362 см³) 163 л.с./120 кВт; Руководство по эксплуатации, техническому обслуживанию и ремонту, технические характеристики, электросхемы, контрольные размеры кузова, устройство, диагностика. Тойота Авенсис модели второго поколения с кузовами пятидверный хэтчбек/liftback, универсал/estate и седан/saloon выпуска с 2003 по 2009 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео Toyota Avensis замена салонного фильтра и передних тормозных колодок, дисков/ how to replace disc brakes (Тойота Авенсис 03-09)

Toyota Avensis T250 Mark II общая информация (Тойота Авенсис 2003-2009)

В 2003 году компания Toyota Motor Corporation выпустила второе поколение автомобиля среднего класса D Toyota Avensis. Автомобиль был спроектирован во французском дизайн-центре Toyota. В самом начале продаж автомобиль был представлен с тремя бензиновыми и одним дизельным моторами. Бензиновые двигатели объемом 1.6, 1.8 и 2.0 л развивали мощность 110, 129 и 147 л.с. соответственно и оснащались механизмом изменяемых фаз газораспределения VVТ-i.

В 2006 году был представлен обновленный Toyota Avensis. Автомобиль получил новую решетку радиатора, новые фары и задние фонари. Небольшие изменения произошли и в интерьере. Линейка моторов пополнилась бензиновым двигателем объемом 2,4 л, мощностью 163 л.с. На автомобили устанавливали 5-ступенчатые механические и 4-ступенчатые автоматические коробки передач. Автомобили Toyota Avensis выпускались с кузовами седан, хэтчбек и универсал.

Автомобиль поставлялся на российский рынок с четырехцилиндровыми рядными 16-клапанными бензиновыми двигателями объемом 1,8 л (129 л.с.), 2,0 л (147 л.с.) и 2,4 л (163 л.с.) с механизмом изменяемых фаз газораспределения VVT-i и предлагался в трех комплектациях с кузовом седан и универсал:

— Terra (только двигатель 1,8 л, МКП, кузов седан, ABS+EBD, система курсовой устойчивости (VSC), система автоматического противопробуксовывания колес (TRC), система помощи при экстренном торможении (ВА), кондиционер, электроусилитель руля, рулевая колонка с регулировкой по высоте и вылету, 6 подушек безопасности, система подсветки приборов Optitron, боковые зеркала заднего вида со встроенными указателями поворотов и электроприводом, радио/ СD-аудиосистема с 8 динамиками и возможностью воспроизведения файлов в формате МР3 и WMA, стальные диски колес 205/55 R16, электростеклоподъемники на всех дверях, складывающиеся задние сиденья, иммобилизатор, система дистанционного управления замками дверей);

— Sol (двигатель 1,8 и 2,0 л с механической или автоматической коробкой переключения передач, кузов седан или универсал, дополнительно к оборудованию Terra — раздельный климат-контроль, 9 подушек безопасности, гидроусилитель (с двигателем 2,0 л) руля, круиз — контроль, мультиинформационный дисплей, обогрев передних сидений и боковых зеркал, электропривод складывания боковых зеркал, противотуманные фары, омыватели фар, датчик дождя, обтянутое кожей рулевое колесо, регулировка положения передних сидений по 6 направлениям);

— Lux (двигатель 2,0 и 2,4 л с автоматической коробкой передач, кузов — седан, дополнительно к оборудованию Sol — кожаный салон, ксеноновые фары, электрические регулировки передних сидений, CD-чейнджер на 6 дисков, электрическая шторка заднего окна, регулировка положения поясничного подпора на сиденье водителя). В комплектацию автомобилей Toyota Avensis для российского рынка входят: защита картера двигателя и порогов, брызговики всех колес и полноразмерное запасное колесо.

Кузова всех модификаций автомобилей Toyota Avensis несущие, цельнометаллические, сварной конструкции с навесными передними крыльями, дверьми, капотом и крышкой багажника. Ветровое и заднее стекла вклеенные. Сиденье водителя регулируется в продольном направлении, по наклону спинки и высоте, сиденье переднего пассажира — в продольном направлении и по наклону спинки. Передние и задние сиденья оборудованы регулируемыми по высоте подголовниками. Спинка заднего сиденья может быть сложена по частям в пропорции 40:60.

Трансмиссия выполнена по переднеприводной схеме с приводами колес, оснащенными шарнирами равных угловых скоростей. Передняя подвеска независимая, пружинная, на поперечных рычагах, со стабилизатором поперечной устойчивости, с гидравлическими амортизаторными стойками. Задняя подвеска независимая, многорычажная, с гидравлическими амортизаторными стойками и стабилизатором поперечной устойчивости. Тормозные механизмы передних колес дисковые, вентилируемые, с плавающей скобой, задних колес — дисковые, с плавающей скобой. Тормозная система оснащена вакуумным усилителем и системой помощи при экстренном торможении.

Рулевое управление травмобезопасное, с рулевым механизмом типа шестерня-рейка, с гидроусилителем или электроусилителем. Рулевая колонка регулируется по вылету и углу наклона. В ступице рулевого колеса расположена фронтальная подушка безопасности. Все автомобили оснащены инерционными диагональными ремнями безопасности для водителя, переднего пассажира и пассажиров на заднем сиденье. Для переднего пассажира предусмотрена фронтальная подушка безопасности.

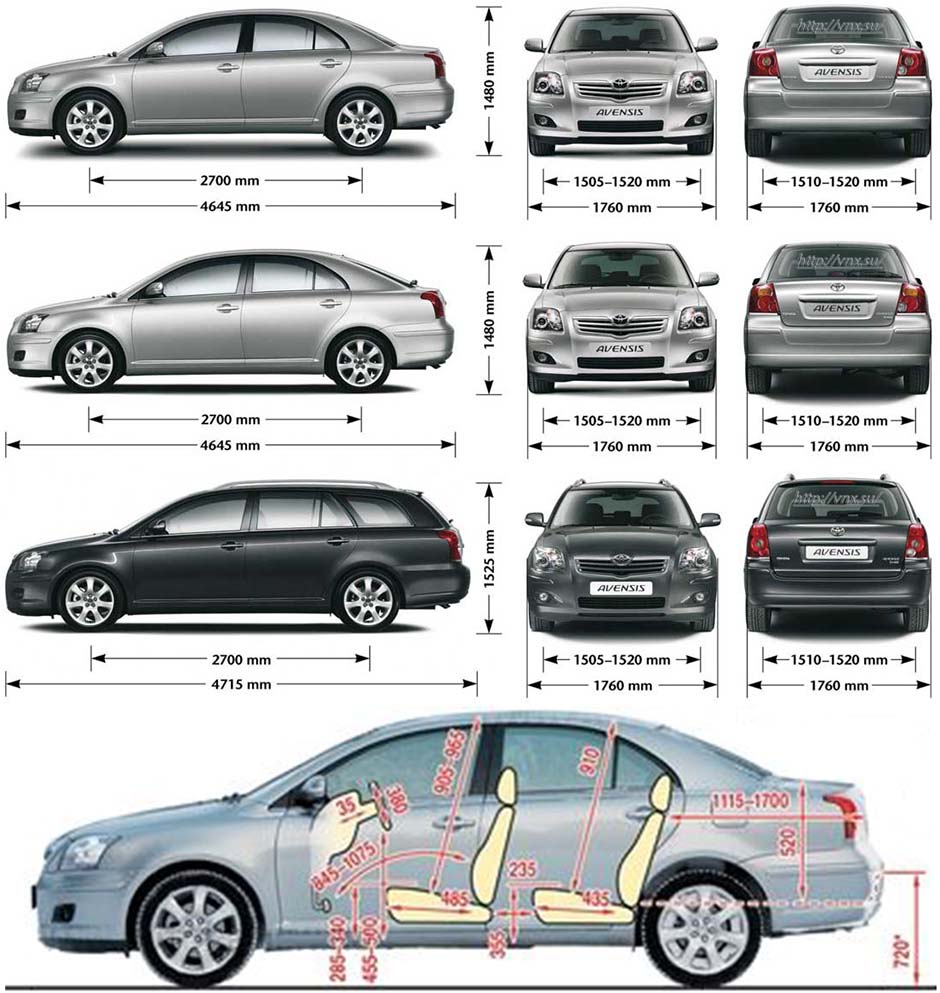

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 4645 |

| 2 | Ширина (без/с зеркалами) / Width | 1760 |

| 3 | Высота (загружен/пустой) / Height | 1480 |

| 4 | Колёсная база / Wheelbase | 2700 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 140 |

| 6 | Снаряжённая масса / Total (curb) weight | 1410 |

| Полная масса / Gross (max.) weight | 1900 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Бензиновый, жидкостного охлаждения, четырехтактный, 2AZ-FSE D-4 |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 4-цилиндровый, 16V, рядный, DOHC с верхним расположением двух распределительных валов, VVT-i |

| 9 | Диаметр цилиндра / Bore | 88.5 мм |

| 10 | Ход поршня / Stroke | 96.0 мм |

| 11 | Объём / Engine displacement | 2362 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Распределенный впрыск топлива MPI — Toyota TCCS |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 11.0:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 120 кВт (163 л.с.) при 5800 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 230 Нм при 3800 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | Гидротрансформатор |

| 17 | КПП / Transmission type | U151E АКПП 5 Автоматическая, пятиступенчатая, гидромеханическая, адаптивная |

О Книге

- Название: Toyota Avensis T250 Руководство по эксплуатации, техническому обслуживанию и ремонту

- Бензиновые двигатели: 3ZZ-FE 1.6 л (1598 см³) 108 л.с./79,4 кВт, 1ZZ-FE 1.8 л (1794 см³) 129 л.с./95 кВт, 1AZ-FE LG 2.0 л (1998 см³) 135 л.с./99 кВт, 1AZ-FSE 2.0 л D-4 (1998 см³) 147 л.с./108 кВт, 2AZ-FSE 2.4 л D-4 (2362 см³) 163 л.с./120 кВт

- Выпуск с 2003 года

- Серия: «Ремонт Автомобилей»

- Год издания: 2007

- Автор: Коллектив авторов

- Издательство: «Ассоциация независимых издателей»

- Формат: PDF

- Страниц в книге: 519

- Размер: 162.51 МБ

- Язык: Русский

- Количество электросхем: 93

-

nekesha

- Администратор

- Сообщения: 1668

- Зарегистрирован: 17 дек 2014, 03:43

- Благодарил (а): 2 раза

- Поблагодарили: 6 раз

Toyota Avensis 1997-2003 / Тайота Авенсис 1997-2003

Руководство по эксплуатации, техобслуживанию и ремонту Toyota Avensis / Тайота Авенсис

Operation, Maintenance and Repair Manual Toyota Avensis

- Года выпуска: 1997-2003

Бензиновые двигатели: 4A-FE, 7A-FE, 3S-FE, 1ZZ-FE, 3Z-FE

Year of release: 1997-2003

Gasoline engines: 4A-FE, 7A-FE, 3S-FE, 1ZZ-FE, 3Z-FE

- Язык: Русский

Формат: PDF

Размер: 187,7 Мб

Russian language

Format: PDF

Size: 187.7 MB

Скачать документацию Toyota Avensis / Тайота Авенсис

Download the documentation of Toyota Avensis

для распаковки используйте пароль — avtoproblem-net.ru

use the password to unpack — avtoproblem-net.ru

В данном руководстве для владельца Toyota Avensis 2003 модельного года, приведены поясненения по эксплуатации автомобиля. Следование инструкциям позволит вам долгие годы наслаждаться безопасным вождением без проблем.

Год выпуска: 2003

Автор: Toyota

Формат: PDF

Язык: Русский

Количество страниц: 364

размер : 68 мб.

Скачать руководство по эксплуатации Toyota Avensis 2003

Внимание! У Вас нет прав для просмотра скрытого текста.

Для скачивания введите код с картинки

- Manuals

- Brands

- Toyota Manuals

- Automobile

- Avensis ZZT251 2003

- Service and repair manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for Toyota Avensis ZZT251 2003

Summary of Contents for Toyota Avensis ZZT251 2003

-

Page 2

MO-2 NEW MODEL OUTLINE EXTERIOR APPEARANCE 4-Door Sedan 240MO01 240MO02 http://vnx.su… -

Page 3

MO-3 NEW MODEL OUTLINE 5-Door Liftback 240MO03 240MO04 http://vnx.su… -

Page 4

MO-4 NEW MODEL OUTLINE 5-Door Wagon 240MO05 240MO06 http://vnx.su… -

Page 5: Model Code

MO-5 NEW MODEL OUTLINE MODEL CODE ZZT250 L – A E M N K W BASIC MODEL CODE GEAR SHIFT TYPE ZZT250 : With 3ZZ FE Engine M : 5 Speed Manual, Floor ZZT251 : With 1ZZ FE Engine P : 4 Speed Automatic, Floor AZT250 : With 1AZ FSE Engine : With 1AZ FE Engine GRADE…

-

Page 6

MO-6 NEW MODEL OUTLINE MODEL LINE-UP EUROPE TRANSAXLE BODY BODY ENGINE GRADE 5-Speed Manual TYPE TYPE C250 E354 E357 ENTRY ZZT250L(R)-AEMNKW — — — Sedan MID TECHNICAL ZZT250L-AEMEKW — — — 3ZZ-FE MID ELEGANT ZZT250L-AEMGKW — — — Liftback ENTRY ZZT250L(R)-ALMNKW —… -

Page 7: Front View

MO-7 NEW MODEL OUTLINE EXTERIOR Front View D The front view is dynamically expressive, with innovative headlights and a front bumper design that has a sense of stability with upper and lower thickness. D The headlight low beams feature projectors and have an innovative shape. Sedan and Liftback Models 240MO07 Headlight…

-

Page 8: Rear View

MO-8 NEW MODEL OUTLINE Rear View D The rear combination lens features an elegant, innovative shape. D The luggage compartment door and back door were given a greater sense of volume for a high-quality feel. 4-Door Sedan Taillight Stop Light 240MO11 Back Up or Turn Signal Light…

-

Page 9: Side View

MO-9 NEW MODEL OUTLINE Side View D The side view communicates a sense of balance, with a large cabin structure that expresses a sense of stability and elegance. D The side view has an elegant and dynamic shape thanks to two character lines. 4-Door Sedan 240MO16 5-Door Liftback…

-

Page 10

MO-10 NEW MODEL OUTLINE Tire & Disc Wheel Tire Size 195 / 65 R15 205 / 55 R16 Size 15 x 6 J 16 x 6 1 / 2 J 16 x 6 1 / 2 JJ Disc Wheel Material Steel Steel Aluminum… -

Page 11

MO-11 NEW MODEL OUTLINE INTERIOR 240MO24 Sedan Model 240MO25 240MO26 Liftback Model Wagon Model http://vnx.su… -

Page 12

MO-12 NEW MODEL OUTLINE Instrument Panel D The instrument panel’s design, composed of smooth curving lines, expresses the cabin’s spaciousness. D The use of painted, surface-treated, and chrome plated parts, as well as the greatest possible minimization of openings and break lines, express a sense of quality. Chrome plated parts Painted parts and surface-treated parts… -

Page 13: Steering Wheel

MO-13 NEW MODEL OUTLINE Steering Wheel D ENTRY grade models feature a urethane 4-spoke type steering wheel, and MID TECHNICAL and MID ELEGANT grade models feature a leather 4-spoke type steering wheel. D Europe models feature a steering pad switch that enables drivers to operate the audio system, switch to trip information display, and turn the navigation system’s voice recognition function on and off without removing their hands from the steering wheel.

-

Page 14: Front Seat

MO-14 NEW MODEL OUTLINE Seat D The seat features a high-quality finish with an elegant stitch. D Leather seats are available as an option for MID TECHNICAL and MID ELEGANT grade with the 1AZ-FSE or 1CD-FTV engine models. 240MO34 Front Seat D Power seats are available as a set option with leather seats.

-

Page 15: Rear Seat

MO-15 NEW MODEL OUTLINE Rear Seat D ENTRY grade sedans feature a fixed seat; other models feature seats with a 60:40 separate seat back. D Liftback and wagon models feature a 60:40 separate seat. 240MO40 240MO41 240MO43 Fixed Seat 60:40 Separate Seat Back 60:40 Separate Seat D CRS (Child Restraint System) ISO-FIX bar and CRS tether anchor bracket for securing child seats have been provided on all the vehicle.

-

Page 16

MO-15 NEW MODEL OUTLINE Rear Seat D ENTRY grade sedans feature a fixed seat; other models feature seats with a 60:40 separate seat back. D Liftback and wagon models feature a 60:40 separate seat. 240MO40 240MO41 240MO43 Fixed Seat 60:40 Separate Seat Back 60:40 Separate Seat D CRS (Child Restraint System) ISO-FIX bar and CRS tether anchor bracket for securing child seats have been provided on all the vehicle. -

Page 17: Luggage Cover

MO-16 NEW MODEL OUTLINE 5-Door Wagon The luggage room features an abundance of items for ease of use. Grocery Bag Hook (Both Side) Auxiliary Box Tie-down Hook (Right / Left) Deck Under Tray Tool Box Tie-down Hook Auxiliary Box CRS Tether Anchor Bracket Auxiliary Box CRS Tether…

-

Page 18: Trip Information

MO-17 NEW MODEL OUTLINE EQUIPMENT Multi Display A multi display is available as an option for MID TECHNICAL and MID ELEGANT grade Europe models. Navigation and trip information can be displayed on the multi display. Navigation System D Through the use of the GPS (Global Positioning System) and map data in a DVD (Digital Versatile Disc), the navigation system analyzes the position of the vehicle and indicates that position on the map that is displayed on this screen.

-

Page 19: Audio System

MO-18 NEW MODEL OUTLINE Audio System D The audio system has a head unit with three built-in functions: CD player, cassette player, and radio. D By adopting new digital sound processing program, this unit can emphasize sound faithfully without phase distortion, and produce extremely clear and powerful sound. Figure for image No distortion Original…

-

Page 20

MO-19 NEW MODEL OUTLINE Location Front Door Speaker Front Tweeter Glass Antenna Rear Tweeter Rear Door Speaker Rear Door Speaker Rear Tweeter Front Door Speaker 240MO69 Sedan Model Glass Antenna Glass Antenna 240MO70 240MO71 Liftback Model Wagon Model Multi-information Display D A multi-information display is standard equipment on MID TECHNICAL and MID ELEGANT grade Europe models… -

Page 21

MO-19 NEW MODEL OUTLINE Location Front Door Speaker Front Tweeter Glass Antenna Rear Tweeter Rear Door Speaker Rear Door Speaker Rear Tweeter Front Door Speaker 240MO69 Sedan Model Glass Antenna Glass Antenna 240MO70 240MO71 Liftback Model Wagon Model Multi-information Display D A multi-information display is standard equipment on MID TECHNICAL and MID ELEGANT grade Europe models… -

Page 22: Air Conditioner System

MO-20 NEW MODEL OUTLINE Air Conditioner System D A manual air conditioner is standard equipment on ENTRY grade models and an automatic air conditioner on MID TECHNICAL and MID ELEGANT grade models. 240MO95 240MO96 Manual Air Conditioner Control Panel Automatic Air Conditioner Control Panel for LHD model for LHD model D The automatic air conditioner employs a left/right independent temperature control system.

-

Page 23

MO-21 NEW MODEL OUTLINE Windshield & Door Glass Dark gray privacy glass is available as an option for the rear door glass, rear quarter glass, and back door glass of wagon models. Windshield Back Window Front Door Glass Glass Glass Rear Door 240MO73 240MO74… -

Page 24: Rear Sunshade

MO-22 NEW MODEL OUTLINE Rear Sunshade A hand-operated rear sun shade is available as an option for Europe sedans and liftback models and is standard equipment on General Countries sedan models. 240MO82 240MO81 Sedan Model Liftback Model Power Outlet The back surface of the console is equipped with a 12V-120W power outlet for MID TECHNICAL and MID ELEGANT grade only.

-

Page 25

MO-23 NEW MODEL OUTLINE PERFORMANCE Power Train Engine Engine 240MO100 Type 1ZZ-FE 3ZZ-FE Valve Mechanism 16-Valve DOHC with VVT-i 16-Valve DOHC with VVT-i Displacement 1794 cm (109.5 cu. in.) 1598 cm (97.5 cu. in.) Max. Output 95 kW / 6000 rpm 81 kW / 6000 rpm Max. -

Page 26

MO-24 NEW MODEL OUTLINE Transaxle 240MO101 Transaxle Manual Transaxle Type C250 E354 E357 Combination with Engine 3ZZ-FE 1ZZ-FE 1AZ-FE & 1AZ-FSE 1CD-FTV Gear Ratio 1st 3.545 3.545 3.538 3.538 1.904 1.904 2.045 1.913 1.310 1.310 1.333 1.258 0.969 1.031 1.028 0.918 0.815 0.815… -

Page 27

MO-25 NEW MODEL OUTLINE Chassis Front Suspension Rear Suspension MacPhason Strut Type Double Wishbone Type Type Type Type Independent Suspension Type Suspension 240MO99 EPS Model Steering EPS (Electoronic Power Steering) (for 1ZZ-FE and 3ZZ-FE) Type Ty e Hydraulic Type Power Steering (for 1AZ-FSE, 1AZ-FE and 1CD-FTV) Brake for 15-inch Wheel (for 1ZZ-FE, 3ZZ-FE and 1AZ-FE) Front Brake Type… -

Page 28

MO-26 NEW MODEL OUTLINE SAFETY SRS (Supplemental Restraint System) Airbag System D A newly developed SRS knee airbag is standard equipment for the driver’s seat on the new Avensis. D The SRS knee airbag is positioned in the lower part of the instrument panel on the driver’s side to receive the impact of the driver’s lower body when he or she shifts forward in the event of a frontal collision, contributing to prevention of secondary impact to the lower body. -

Page 29

MO-27 NEW MODEL OUTLINE DIMENSIONS mm (in.) 4-Door Sedan 1760 1480 2700 1025 Front: 1505* , 1515* Rear: 1500* , 1515* 240MO92 5-Door Liftback 1760 1480 2700 1025 Front: 1505* , 1515* Rear: 1500* , 1515* 240MO93 5-Door Wagon 1760 1525 2700 1095… -

Page 30

MO-28 NEW MODEL OUTLINE EQUIPMENT LIST F: Standard OP: Option Europe General General Countries ENTRY TECHNICAL ELEGANT Exterior Rear Spoiler Wagon — Side Protection Moulding Windshield Green — Front Side Green Green Glass Glass Rear Side & Back Rear Side & Back Wagon Privacy —… -

Page 31

MO-29 NEW MODEL OUTLINE F: Standard OP: Option Europe General General Countries ENTRY TECHNICAL ELEGANT Body Electrical Projector Headlight Headlight HID (High lntensity Discharge) — — Manual — Headlight Beam Level Control System Automatic — — Headlight Cleaner System — Except for 1AZ-FE —… -

Page 32

MO-30 – MEMO – http://vnx.su… -

Page 33

AP-2 APPENDIX MAJOR TECHNICAL SPECIFICATIONS Area EUROPE Item Body Type 4-Door Sedan Vehicle Grade ENTRY MID TECHNICAL MID ELEGANT Model Code ZZT250R-AEMNKW ZZT250L-AEMNKW ZZT250L-AEMEKW ZZT250L-AEMGKW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) -

Page 34

AP-3 APPENDIX EUROPE 4-Door Sedan ENTRY MID TECHNICAL ZZT251R-AEMNKW ZZT251L-AEMNKW ZZT251R-AEPNKW ZZT251L-AEPNKW ZZT251R-AEMEKW ZZT251L-AEMEKW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) -

Page 35

AP-4 APPENDIX Area EUROPE Item Body Type 4-Door Sedan Vehicle Grade MID TECHNICAL MID ELEGANT Model Code ZZT251R-AEPEKW ZZT251L-AEPEKW ZZT251R-AEMGKW ZZT251L-AEMGKW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) Height… -

Page 36

AP-5 APPENDIX EUROPE 4-Door Sedan MID ELEGANT MID TECHNICAL MID ELEGANT ZZT251R-AEPGKW ZZT251L-AEPGKW AZT250L-AEMEKW AZT250L-AEPEKW AZT250L-AEMGKW AZT250L-AEPGKW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) -

Page 37

AP-6 APPENDIX Area EUROPE Item Body Type 4-Door Sedan Vehicle Grade MID TECHNICAL Model Code AZT250R-AEMEHW AZT250L-AEMEHW AZT250R-AEPEHW AZT250L-AEPEHW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) Height mm (in.) -

Page 38

AP-7 APPENDIX EUROPE 4-Door Sedan MID ELEGANT ENTRY AZT250R-AEMGHW AZT250L-AEMGHW AZT250R-AEPGHW AZT250L-AEPGHW CDT250R-AEMNYW CDT250L-AEMNYW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) -

Page 39

AP-8 APPENDIX Area EUROPE Item Body Type 4-Door Sedan Vehicle Grade MID TECHNICAL MID ELEGANT Model Code CDT250R-AEMEYW CDT250L-AEMEYW CDT250R-AEMGYW CDT250L-AEMGYW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) Height… -

Page 40

AP-9 APPENDIX EUROPE 5-Door Liftback ENTRY ZZT250R-ALMNKW ZZT250L-ALMNKW ZZT251R-ALMNKW ZZT251L-ALMNKW ZZT251R-ALPNKW ZZT251L-ALPNKW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) -

Page 41

AP-10 APPENDIX Area EUROPE Item Body Type 5-Door Liftback Vehicle Grade MID TECHNICAL Model Code ZZT251R-ALMEKW ZZT251L-ALMEKW ZZT251R-ALPEKW ZZT251L-ALPEKW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) Height mm (in.) -

Page 42

AP-11 APPENDIX EUROPE 5-Door Liftback MID ELEGANT MID TECHNICAL ZZT251R-ALMGKW ZZT251L-ALMGKW ZZT251R-ALPGKW ZZT251L-ALPGKW AZT250R-ALMEHW AZT250L-ALMEHW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) -

Page 43

AP-12 APPENDIX Area EUROPE Item Body Type 5-Door Liftback Vehicle Grade MID TECHNICAL MID ELEGANT Model Code AZT250R-ALPEHW AZT250L-ALPEHW AZT250R-ALMGHW AZT250L-ALMGHW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) Height… -

Page 44

AP-13 APPENDIX EUROPE 5-Door Liftback MID ELEGANT ENTRY MID TECHNICAL AZT250R-ALPGHW AZT250L-ALPGHW CDT250R-ALMNYW CDT250L-ALMNYW CDT250R-ALMEYW CDT250L-ALMEYW 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 4630 (182.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1480 (58.3) 1480 (58.3) 1480 (58.3) -

Page 45

AP-14 APPENDIX Area EUROPE Item Body Type 5-Door Liftback 5-Door Wagon Vehicle Grade MID ELEGANT ENTRY Model Code CDT250R-ALMGYW CDT250L-ALMGYW ZZT250L-AWMNKW ZZT251R-AWMNKW 4630 (182.3) 4630 (182.3) 4700 (185.0) 4700 (185.0) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) Height… -

Page 46

AP-15 APPENDIX EUROPE 5-Door Wagon ENTRY MID TECHNICAL MID ELEGANT ZZT251L-AWMNKW ZZT251L-AWPNKW ZZT251R-AWMEKW ZZT251L-AWMEKW ZZT251L-AWPEKW ZZT251R-AWMGKW 4700 (185.0) 4700 (185.0) 4700 (185.0) 4700 (185.0) 4700 (185.0) 4700 (185.0) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1525 (60.0) 1525 (60.0) 1525 (60.0) -

Page 47

AP-16 APPENDIX Area EUROPE Item Body Type 5-Door Wagon Vehicle Grade MID ELEGANT MID TECHNICAL MID ELEGANT Model Code ZZT251L-AWMGKW ZZT251L-AWPGKW AZT250L-AWPEKW AZT250L-AWPGKW 4700 (185.0) 4700 (185.0) 4700 (185.0) 4700 (185.0) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) -

Page 48

AP-17 APPENDIX EUROPE 5-Door Wagon MID TECHNICAL MID ELEGANT AZT250R-AWMEHW AZT250L-AWMEHW AZT250R-AWPEHW AZT250L-AWPEHW AZT250R-AWMGHW AZT250L-AWMGHW 4700 (185.0) 4700 (185.0) 4700 (185.0) 4700 (185.0) 4700 (185.0) 4700 (185.0) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1525 (60.0) 1525 (60.0) 1525 (60.0) 1525 (60.0) -

Page 49

AP-18 APPENDIX Area EUROPE Item Body Type 5-Door Wagon Vehicle Grade MID ELEGANT ENTRY Model Code AZT250R-AWPGHW AZT250L-AWPGHW CDT250R-AWMNYW CDT250L-AWMNYW 4700 (185.0) 4700 (185.0) 4700 (185.0) 4700 (185.0) Length mm (in.) Overall Width mm (in.) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) Height mm (in.) -

Page 50

AP-19 APPENDIX EUROPE GENERAL COUNTRIES 5-Door Wagon 4-Door Sedan MID TECHNICAL MID ELEGANT ENTRY CDT250L-AWMEYW CDT250L-AWMGYW AZT250L-AEMNK AZT250R-AEPNK AZT250L-AEPNK 4700 (185.0) 4700 (185.0) 4630 (182.3) 4630 (182.3) 4630 (182.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1760 (69.3) 1525 (60.0) 1525 (60.0) 1480 (58.3) 1480 (58.3) -

Page 51

The connector with a lock should be securely con- nected until it makes a ”click” sound. When checking the connector with a Toyota electri- WRONG cal tester, check it from the backside (harness side) of the connector using a mini test lead. -

Page 52

01–33 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS Checking of the contact pressure of the terminal: Prepare a spare male terminal. Insert it into a female terminal, check the engaged condition and sliding resistance. Same terminal as a male terminal D25088 REPAIR METHOD OF CONNECTOR TERMINAL If there is on the contact point, clean the contact… -

Page 53

01–34 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS Check the continuity. Fig. 2 Disconnect connectors A and C and measure the resistance between them. Resistance: 1 f or less HINT: Sensor Measure the resistance while lightly shaking the wire harness vertically and horizontally. -

Page 54

01–35 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS CHECK SHORT CIRCUIT Fig. 5 If the wire harness is ground shorted as shown in Fig. 5, C SHORT locate the section by conducting a continuity check with the body ground in step (b). Z17008 Check the continuity with the body ground. -

Page 55

01–36 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS CHECK AND REPLACE ECU NOTICE: Start an inspection of the connector from the back- side of the connector on the wire harness side with the connector connected to the ECU. When no measurement condition is specified, per- form the inspection with the engine stopped and also the ignition switch ON. -

Page 56: Table Of Contents

01–21 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS 010B6–13 GENERAL INFORMATION There are many ECU controlled systems used in the AVENSIS. In general, ECU controlled system are con- sidered to be very intricate and require a high level of technical knowledge and expert skill to troubleshoot. The fact is, however, that if you proceed by inspecting the circuits one by one, troubleshooting of these sys- tems is not complex.

-

Page 57: Introduction – How To Troubleshoot Ecu Controlled

01–22 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS 010B7–13 HOW TO PROCEED WITH TROUBLESHOOTING HINT: Carry out troubleshooting in accordance with the procedures on the following page. Here, only the basic procedures are shown. Details are provided in the Diagnostics Section, showing the most effective methods for each circuit.

-

Page 58

01–23 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS Confirmation test After completing repairs, confirm that the problem has been solved (If the problem does not recur, per- form a confirmation test under the same conditions and in the same environment as when it occurred for the first time). -

Page 59

01–24 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS CUSTOMER PROBLEM ANALYSIS HINT: In troubleshooting, the problem symptoms must be confirmed accurately, meaning that all preconcep- tions must be set aside in order to make an accurate judgement. To ascertain what the problem symp- toms are, it is extremely important to ask the customer about the problem and conditions when it oc- curred. -

Page 60: Abs With Ebd System

01–25 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS SYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE HINT: The diagnostic system in AVENSIS has various functions. The first function is the Diagnostic Trouble Code (DTC) Check, in which a malfunction in the signal circuits to the ECU is stored in code form in the ECU memory.

-

Page 61

01–26 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS Symptoms exist No symptoms exist Go to step 5 Simulation test using the symptom simulation methods DTC check DTC displayed Normal code displayed Troubleshooting of problem indicated by DTC Symptom confirmation No symptoms exist Symptoms exist If a DTC is displayed in the initial DTC check, it indicates that… -

Page 62

01–27 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS SYMPTOM SIMULATION HINT: The most difficult case in troubleshooting is when no symptoms occurs. In such cases, a thorough customer problem analysis must be carried out. Then the same or similar conditions and environment in which the problem occurred in the customer’s vehicle should be simulated. -

Page 63

01–28 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS Do not apply heat directly to the parts in the ECU. WATER SPRINKLING METHOD: When the malfunc- tion seems to occur on a rainy day or in high–humid- ity. Sprinkle water onto the vehicle and check if the malfunc- tion occurs. -

Page 64

01–29 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS DIAGNOSTIC TROUBLE CODE CHART The inspection procedures are shown in the table below. This table allows efficient and accurate trouble- shooting using the diagnostic trouble codes displayed in the diagnostic trouble code chart. Proceed with troubleshooting in accordance with the inspection procedures listed in the diagnostic chart corresponding to the diagnostic trouble codes displayed. -

Page 65

01–30 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS PROBLEM SYMPTOMS TABLE The suspected circuits or parts for each problem symptom are shown in the table below. Use this table to troubleshoot the problem when a Normal code is displayed in the diagnostic trouble code chart but the prob- lem is still occurring. -

Page 66: Circuit Inspection

01–31 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS CIRCUIT INSPECTION How to read and use each page is shown below. Y Circuit Description Y Inspection Procedures The major role and, operation of the circuit Use the inspection procedures to determine and its component parts are explained.

-

Page 67

01–1 INTRODUCTION – HOW TO USE THIS MANUAL HOW TO USE THIS MANUAL 010B2–13 GENERAL INFORMATION GENERAL DESCRIPTION This manual is made in accordance with SAE J2008. Generally, repair operations can be separated in the following 3 main processes: 1. Diagnosis 2. -

Page 68

01–2 INTRODUCTION – HOW TO USE THIS MANUAL Tightening torque, grease application area, and non–reusable parts are described as important points in the procedures. NOTICE: There are cases where such information can only be explained by using an illustration. In these cases, all the information such as torque, oil, etc. -

Page 69

01–3 INTRODUCTION – HOW TO USE THIS MANUAL SI UNIT The units given in this manual are primarily expressed according to the SI UNIT (International System of Units), and alternately expressed in the metric system and in the English System. Example: Torque: 30 N m (310 kgf cm, 22 ft lbf) AVENSIS REPAIR MANUAL (RM1018E) -

Page 70: Identification Information

01–4 INTRODUCTION – IDENTIFICATION INFORMATION IDENTIFICATION INFORMATION 010LE–01 VEHICLE IDENTIFICATION AND SERIAL NUMBERS VEHICLE IDENTIFICATION NUMBER The vehicle identification number is stamped in the en- gine compartment, as shown in the illustration. This num- ber has also been stamped on the manufacturer’s plate. D30402 ENGINE SERIAL NUMBER AND TRANSAXLE SERIAL NUMBER…

-

Page 71

01–5 INTRODUCTION – REPAIR INSTRUCTION REPAIR INSTRUCTION 010LF–01 PRECAUTION BASIC REPAIR HINT HINTS ON OPERATIONS D25016 Y Always wear a clean uniform. Looks Y Hat and safety shoes must be worn. Y Set a grill cover, fender cover, seat cover and floor mat before starting operation. Vehicle protection Y When working with 2 or more persons, be sure to check the safety of one another. -

Page 72

01–6 INTRODUCTION – REPAIR INSTRUCTION JACKING UP AND SUPPORTING VEHICLE Care must be taken when jacking up and supporting the vehicle. Be sure to lift and support the vehicle at the proper locations (See page 01–19). PRECOATED PARTS Precoated parts such as bolts, nuts, etc., are coated with a seal lock adhesive at the factory. -

Page 73

01–7 INTRODUCTION – REPAIR INSTRUCTION CLIPS The removal and installation methods of typical clips used in body parts are shown in the table below. HINT: If the clip is damaged during the operation, always replace it with a new clip. Shape (Example) Removal/Installation Clip… -

Page 74

01–8 INTRODUCTION – REPAIR INSTRUCTION Shape (Example) Removal/Installation Removal Installation Removal Installation V00012 REMOVAL AND INSTALLATION OF VACUUM HOSES To disconnect vacuum hoses, pull them by holding the end, not the middle of the hose. CORRECT WRONG D25063 When disconnecting vacuum hoses, use tags to identify where they should be reconnected. -

Page 75

01–9 INTRODUCTION – REPAIR INSTRUCTION TORQUE WHEN USING TORQUE WRENCH WITH EX- TENSION TOOL When the torque wrench is combined with SST or an extension tool to extend the length, and you tighten until the torque wrench reads the specified torque value, the actual torque becomes excessive. -

Page 76

01–10 INTRODUCTION – REPAIR INSTRUCTION Even in the case of a minor collision where the SRS does not deploy, the horn button assembly, instrument panel passenger airbag assembly and seat belt pretensioner should be inspected (See pages 60–19, 60–19 61–9). Never use the SRS related parts from another vehicle. -

Page 77

01–11 INTRODUCTION – REPAIR INSTRUCTION When disposing the vehicle or the horn button assembly alone, the airbag should be inflated us- ing an SST before disposal (See page 60–19). Perform the operation in a safe place away from electrical noise. Example: CORRECT WRONG… -

Page 78

01–12 INTRODUCTION – REPAIR INSTRUCTION Example: Z13951 FRONT SEAT AIRBAG ASSEMBLY Always store a removed or new front seat airbag assembly with the airbag inflating direction fac- ing upward. Placing the airbag assembly with the airbag inflation direction facing downward could cause a serious accident if the airbag inflates. -

Page 79

01–13 INTRODUCTION – REPAIR INSTRUCTION INSTRUMENT PANEL LOWER AIRBAG ASSEMBLY Always store a removed or new instrument panel lower airbag assembly with the airbag inflating direction facing upward. Placing the airbag assembly with the airbag inflation direction facing downward could cause a serious accident if the airbag inflates. -

Page 80

01–14 INTRODUCTION – REPAIR INSTRUCTION Grease should not be attached to the curtain shield airbag assembly, and the surface should not be cleared with detergents of any kind. Store the airbag assembly where the ambient temperature remains below 93°C (200°F), without high humidity and away from electrical noise. -

Page 81

01–15 INTRODUCTION – REPAIR INSTRUCTION Oil or water should not be put on the front seat outer belt and the front seat outer belt should be cleaned with the appropriate detergents. Example: D26613 AIRBAG SENSOR ASSEMBLY Never reuse the airbag sensor assembly involved in a collision where the SRS has deployed. The connectors to the airbag sensor assembly should be connected or disconnected with the sensor mounted on the floor. -

Page 82

01–16 INTRODUCTION – REPAIR INSTRUCTION (–) terminal cable is disconnected. If necessary, be sure to initialize the system. HANDLING OF ELECTRONIC PARTS Do not open the cover or case of the ECU unless absolutely necessary (If the IC terminals are touched, the IC may be rendered inoperative by static electricity). -

Page 83

01–17 INTRODUCTION – REPAIR INSTRUCTION HANDLING OF HOSE CLAMPS Spring Type Clamp Before removing the hose, check the depth of the insert- ing portion and the clamp position to restore it surely. Change a deformed or dented clamp for a new one. In case of reusing a hose, attach the clamp on the clamp track portion of the hose. -

Page 84

01–18 INTRODUCTION – REPAIR INSTRUCTION NOTICE: Confirm that the VSC warning light blinks. VSC system will be reset when the engine is re- started. Fasten the vehicle with lock chains. NOTICES OF RELATED OPERATIONS TO VSC Do not carry out unnecessary installation and re- moval as it might disorder the adjustment of related parts to VSC. -

Page 85

01–19 INTRODUCTION – REPAIR INSTRUCTION 010B5–11 VEHICLE LIFT AND SUPPORT LOCATIONS NOTICE ABOUT VEHICLE CONDITION WHEN JACKING UP As a rule, the vehicle must be unloaded when jacking up. Never jack up or lift up the vehicle loaded with things of heavy weight. When removing any parts of heavy weight like the engine and transmission, the center of gravity of the vehicle moves. -

Page 86

01–20 INTRODUCTION – REPAIR INSTRUCTION NOTICE FOR USING SWING ARM TYPE LIFT Follow the instruction manual of the lift for a safe operation. Use a cradle with a rubber attachment, as shown in the illustration. Set in the vehicle so as to make its center of gravity as close as possible to the center of the lift. (”L” becomes short.) Place the vehicle horizontally by adjusting the height of the cradle, and match the groove of the cradle and the safety stand support location accurately. -

Page 87

01–37 INTRODUCTION – TERMS TERMS 010B9–11 ABBREVIATIONS USED IN THIS MANUAL Abbreviations Meaning Anti–Lock Brake System Air Conditioner Alternating Current Accessory ACIS Acoustic Control Induction System ACSD Automatic Cold Start Device A.D.D. Automatic Disconnecting Differential Air–Fuel Ratio Active Height Control Suspension Automatic Locking Retractor Alternator Amplifier… -

Page 88

01–38 INTRODUCTION – TERMS Abbreviations Meaning Defogger Deflector DIFF. Differential DIFF. LOCK Differential Lock D/INJ Direct Injection Data Link Connector Distributorless Ignition DOHC Double Overhead Camshaft Dash Pot Dead Soak Digital Signal Processor Diagnostic Trouble Code Digital Versatile Disc Electric Brake Force Distribution ECAM Engine Control And Measurement System Electronic Controlled Diesel… -

Page 89

01–39 INTRODUCTION – TERMS Abbreviations Meaning H–FUSE High Current Fuse High High Intensity Discharge (Head Lamp) Housing Hard Top Heated Windshield System Integrated Circuit Indirect Diesel Injection Independent Front Suspension Ignition Integrated Ignition Assembly Intake (Manifold, Valve) Intermittent Instrument Panel Independent Rear Suspension Idle Speed Control Junction Block… -

Page 90

Special Service Tools Standard Cold–Start Fuel Injection Switch System Transaxle TACH Tachometer Throttle Body Electronic Fuel Injection Turbocharger TCCS TOYOTA Computer–Controlled System Timing Control Valve Top Dead Center TEMP. Temperature TEMS TOYOTA Electronic Modulated Suspension AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 91

INTRODUCTION – TERMS Abbreviations Meaning Toyota Free–Tronic Total Information System For Vehicle Development Transmission TOYOTA Motor Corporation TMMK TOYOTA Motor Manufacturing Kentucky, Inc. Traction Control System TURBO Turbocharge Three–Way Catalyst Underdrive Undersize Vacuum Control Valve VENT Ventilator Vehicle Identification Number… -

Page 92

– TERMS 010BA–14 GLOSSARY OF SAE AND TOYOTA TERMS This glossary lists all SAE–J1930 terms and abbreviations used in this manual in compliance with SAE rec- ommendations, as well as their TOYOTA equivalents. TOYOTA TERMS SAE TERMS ABBREVIATIONS ( )––ABBREVIATIONS… -

Page 93

01–43 INTRODUCTION – TERMS HO2S Heated Oxygen Sensor Heated Oxygen Sensor (HO Idle Air Control Idle Speed Control (ISC) Intake Air Temperature Intake or Inlet Air Temperature Ignition Control Module – Indirect Fuel Injection Indirect Injection (IDL) Inertia Fuel–Shutoff – Idle Speed Control –… -

Page 94

01–44 INTRODUCTION – TERMS Transmission Control Module Transmission ECU, ECT ECU Throttle Position Throttle Position Transmission Range – Bimetallic Vacuum Switching Valve (BVSV) Thermal Vacuum Valve Thermostatic Vacuum Switching Valve (TVSV) Three–Way Catalytic (TWC) Three–Way Catalytic Converter Manifold Converter TWC+OC Three–Way + Oxidation Catalytic Converter + CCo Volume Air Flow… -

Page 95

02–55 PREPARATION – AUDIO & VISUAL SYSTEM AUDIO & VISUAL SYSTEM 022KX–01 PREPARATION Recomended Tools 09042–00010 Torx Socket T30 NAVIGATION ANTENNA ASSY 09042–00030 Torx Socket T20 CIGARETTE LIGHTER ASSY 09050–00032 Air Drill FRONT NO.1 SPEAKER ASSY REAR SPEAKER ASSY Chuck Set FRONT NO.1 SPEAKER ASSY (09050–00210) REAR SPEAKER ASSY… -

Page 96

02–36 PREPARATION – AUTOMATIC TRANSMISSION / TRANS AUTOMATIC TRANSMISSION / TRANS 022L4–02 PREPARATION 07110–58060 Air Conditioner Service Tool Set TRANSMISSION CONTROL CABLE ASSY (07117–58060) Refrigerant Drain Service Valve TRANSMISSION CONTROL CABLE ASSY (07117–58070) T–Joint TRANSMISSION CONTROL CABLE ASSY Quick Disconnect Adapter TRANSMISSION CONTROL CABLE (07117–58080) ASSY… -

Page 97

02–37 PREPARATION – AUTOMATIC TRANSMISSION / TRANS (09316–00011) Replacer Pipe FRONT DIFFERENTIAL SEAL(U241E) TOYOTA Automatic Transmission TORQUE CONVERTER CLUTCH 09350–32014 Tool Set AND DRIVE PLATE(ATM) AUTOMATIC TRANSAXLE ASSY(U241E) AUTOMATIC TRANSAXLE ASSY(U341E) (09351–32010) One–way Clutch Test Tool TORQUE CONVERTER CLUTCH AND DRIVE PLATE(ATM) -

Page 98

02–38 PREPARATION – AUTOMATIC TRANSMISSION / TRANS (09726–02041) Replacer FRONT DIFFERENTIAL SEAL(U341E) Drive Shaft Nut Chisel AUTOMATIC TRANSAXLE 09930–00010 ASSY(U241E) AUTOMATIC TRANSAXLE ASSY(U341E) FRONT DIFFERENTIAL SEAL(U341E) 09950–70010 Handle Set FRONT DIFFERENTIAL SEAL(U241E) FRONT DIFFERENTIAL SEAL(U341E) (09951–07150) Handle 150 FRONT DIFFERENTIAL SEAL(U241E) Handle 200 FRONT… -

Page 99

02–39 PREPARATION – AUTOMATIC TRANSMISSION / TRANS 09090–04020 Engine Sling Device AUTOMATIC TRANSAXLE ASSY(U241E) AUTOMATIC TRANSAXLE ASSY(U341E) Gas Leak Detector TRANSMISSION CONTROL CABLE 95416–00140 (Halogen Leak Detector) ASSY (DENSO Part No.) Belt Tension Gauge AUTOMATIC TRANSAXLE 09216–00021 ASSY(U151E/U151F) 08833–00080 Adhesive 1344 TRANSMISSION WIRE(U241E) THREE BOND 1344 TRANSMISSION… -

Page 100

02–33 PREPARATION – BRAKE BRAKE 022KS–01 PREPARATION 09023–00100 Union Nut Wrench 10 mm BRAKE FLUID BRAKE MASTER CYLINDER SUB–ASSY FRONT BRAKE REAR BRAKE BRAKE BOOSTER ASSY(LHD) BRAKE BOOSTER ASSY(RHD) BRAKE ACTUATOR ASSY(W/ VSC) BRAKE ACTUATOR ASSY(W/O VSC) Union Nut Wrench 14mm BRAKE FLUID 09023–38400 BRAKE… -

Page 101

02–34 PREPARATION – BRAKE Equipment Micrometer Dial indicator w/ magnetic base Brake drum gauge Slide calipers Torque wrench Lubricant Item Capacity Classification Brake fluid – SAE J1704 or FMVSS No. 116 DOT4 AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 102

02–43 PREPARATION – CLUTCH CLUTCH 022KZ–01 PREPARATION 09023–00100 Union Nut Wrench 10 mm CLUTCH ACCUMULATOR ASSY(1CD–FTV) CLUTCH RELEASE CYLINDER ASSY(MTM) CLUTCH MASTER CYLINDER ASSY(MTM) 09301–00220 Clutch Guide Tool CLUTCH UNIT(MTM) 09333–00013 Universal Joint Bearing Remover CLUTCH UNIT(MTM) & Replacer Recomended Tools Hexagon Wrench Set CLUTCH PEDAL SUB–ASSY(MTM) 09040–00011… -

Page 103

02–56 PREPARATION – COMMUNICATION SYSTEM COMMUNICATION SYSTEM 022L2–01 PREPARATION Recomended Tools 09082–00050 TOYOTA Electrical Tester Set HORN SYSTEM AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 104

02–18 PREPARATION – COOLING COOLING 022KA–01 PREPARATION 09023–12700 Union Nut Wrench 17mm WATER PUMP ASSY(1CD–FTV) 09213–54015 Crankshaft Pulley Holding Tool WATER PUMP ASSY(1CD–FTV) (90105–08076) Bolt WATER PUMP ASSY(1CD–FTV) Torque Wrench Adaptor WATER PUMP ASSY(1AZ–FE) 09249–63010 THERMOSTAT(1AZ–FE) WATER PUMP ASSY(1AZ–FSE) THERMOSTAT(1AZ–FSE) Companion Flange Holding Tool WATER PUMP ASSY(1CD–FTV) 09330–00021… -

Page 105

WATER PUMP ASSY(1CD–FTV) Coolant Item Capacity Classification Engine coolant (3ZZ–FE) TOYOTA long life coolant Left–hand drive vehicles 5.8 liters (6.1 US qts, 5.1 lmp. qts) Right–hand drive vehicles 5.9 liters (6.2 US qts, 5.2 lmp. qts) Engine coolant (1ZZ–FE) TOYOTA long life coolant Left–hand drive vehicles… -

Page 106

POWER STEERING SYSTEM SUPPLEMENTAL RESTRAINT SYSTEM SFI SYSTEM(1AZ–FE) ECD SYSTEM(1CD–FTV) SFI SYSTEM(1ZZ–FE/3ZZ–FE) 09992–00242 Turbocharger Pressure Gauge ECD SYSTEM(1CD–FTV) Recomended Tools TOYOTA Electrical Tester COMBINATION METER 09082–00040 SFI SYSTEM(1AZ–FE) SFI SYSTEM(1AZ–FSE) ECD SYSTEM(1CD–FTV) SFI SYSTEM(1ZZ–FE/3ZZ–FE) ELECTRONIC CONTROLLED AUTOMATIC TRANSAXLE [ECT](U241E(1AZ–FE)) ELECTRONIC… -

Page 107: Abs With Ebd & Ba & Trc & Vsc System

TRANSAXLE [ECT](U241E(1AZ–FE)) ELECTRONIC CONTROLLED AUTOMATIC TRANSAXLE [ECT](U241E(1AZ–FSE)) ELECTRONIC CONTROLLED AUTOMATIC TRANSAXLE [ECT](U341E) 09082–00050 TOYOTA Electrical Tester Set POWER DOOR LOCK CONTROL SYSTEM Test Lead Set AIR CONDITIONING SYSTEM (09083–00150) ABS WITH EBD SYSTEM ELECTRONIC MOTOR POWER STEERING SYSTEM MULTIPLEX COMMUNICATION…

-

Page 108

02–29 PREPARATION – DRIVE SHAFT / PROPELLER SHAFT DRIVE SHAFT / PROPELLER SHAFT 022KL–01 PREPARATION 09240–00020 Wire Gauge Set FRONT DRIVE SHAFT 09520–00031 Rear Axle Shaft Puller FRONT AXLE HUB SUB–ASSY LH 09520–01010 Drive Shaft Remover Attachment FRONT DRIVE SHAFT Differential Side Gear Shaft FRONT DRIVE SHAFT 09520–24010… -

Page 109

02–30 PREPARATION – DRIVE SHAFT / PROPELLER SHAFT 09610–20012 Pitman Arm Puller REAR AXLE CARRIER SUB–ASSY Ball Joint Puller REAR AXLE LH HUB BOLT 09628–10011 FRONT AXLE LH HUB BOLT Boll Joint Puller FRONT AXLE HUB SUB–ASSY LH 09628–62011 REAR AXLE CARRIER SUB–ASSY FRONT DRIVE SHAFT 09710–04081 Base… -

Page 110

02–31 PREPARATION – DRIVE SHAFT / PROPELLER SHAFT (09955–04061) Claw No.6 FRONT AXLE HUB SUB–ASSY LH Attachment FRONT AXLE HUB SUB–ASSY LH (09957–04010) Holder (J) FRONT AXLE HUB SUB–ASSY LH (09958–04010) 09950–60010 Replacer Set FRONT AXLE HUB SUB–ASSY LH (09951–00370) Replacer 37 FRONT AXLE HUB SUB–ASSY LH (09951–00600) -

Page 111

02–32 PREPARATION – DRIVE SHAFT / PROPELLER SHAFT 09040–00011 Hexagon Wrench Set FRONT AXLE HUB SUB–ASSY LH FRONT DRIVE SHAFT Socket Hexagon Wrench 6 FRONT AXLE HUB SUB–ASSY LH (09043–20060) FRONT DRIVE SHAFT Expander Set FRONT DRIVE SHAFT 09904–00010 (09904–00050) No. -

Page 112

PREPARATION – ENGINE CONTROL SYSTEM ENGINE CONTROL SYSTEM 022J5–01 PREPARATION 09268–21010 Fuel Hose Puller KNOCK SENSOR(1AZ–FE) Recomended Tools 09082–00040 TOYOTA Electrical Tester SFI SYSTEM(1AZ–FE) SFI SYSTEM(1AZ–FSE) SFI SYSTEM(1ZZ–FE/3ZZ–FE) (09083–00150) Test Lead Set SFI SYSTEM(1AZ–FE) SFI SYSTEM(1AZ–FSE) SFI SYSTEM(1ZZ–FE/3ZZ–FE) Equipment Ohmmeter… -

Page 113

02–61 PREPARATION – ENGINE HOOD/DOOR ENGINE HOOD/DOOR 022K8–01 PREPARATION 09812–00010 Door Hinge Set Bolt Wrench FRONT DOOR 09812–00020 Door Hinge Set Bolt Wrench FRONT DOOR Recomended Tools 09042–00010 Torx Socket T30 FRONT DOOR REAR DOOR 09042–00020 Torx Socket T40 FRONT DOOR REAR DOOR LUGGAGE COMPARTMENT DOOR BACK DOOR(LIFTBACK MODELS) -

Page 114

02–8 PREPARATION – ENGINE MECHANICAL ENGINE MECHANICAL 022KB–01 PREPARATION 09023–00100 Union Nut Wrench 10 mm PARTIAL ENGINE ASSY(1CD–FTV) 09023–12700 Union Nut Wrench 17mm VALVE CLEARANCE(1CD–FTV) CAMSHAFT(1CD–FTV) CYLINDER HEAD GASKET(1CD–FTV) PARTIAL ENGINE ASSY(1CD–FTV) 09023–12900 Union Nut Wrench 19mm VALVE CLEARANCE(1AZ–FSE) PARTIAL ENGINE ASSY(1AZ–FSE) CHAIN SUB–ASSY(1AZ–FSE) CAMSHAFT(1AZ–FSE) CYLINDER… -

Page 115

02–9 PREPARATION – ENGINE MECHANICAL (91651–60855) Bolt PARTIAL ENGINE ASSY(1AZ–FE) CHAIN SUB–ASSY(1AZ–FE) CYLINDER HEAD GASKET(1AZ–FE) ENGINE REAR OIL SEAL(1AZ–FE) TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL(1AZ–FE) PARTIAL ENGINE ASSY(1AZ–FSE) CHAIN SUB–ASSY(1AZ–FSE) CYLINDER HEAD GASKET(1AZ–FSE) ENGINE REAR OIL SEAL(1AZ–FSE) TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL(1AZ–FSE) 09223–15020… -

Page 116

02–10 PREPARATION – ENGINE MECHANICAL 09249–63010 Torque Wrench Adaptor GENERATOR BELT(1AZ–FE) CHAIN SUB–ASSY(1AZ–FE) CYLINDER HEAD GASKET(1AZ–FE) TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL(1AZ–FE) GENERATOR BELT(1AZ–FSE) CHAIN SUB–ASSY(1AZ–FSE) CYLINDER HEAD GASKET(1AZ–FSE) TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL(1AZ–FSE) 09268–21010 Fuel Hose Puller CYLINDER… -

Page 117

02–11 PREPARATION – ENGINE MECHANICAL (09330–00030) PARTIAL ENGINE ASSY(1AZ–FE) PARTIAL ENGINE ASSY(1AZ–FSE) Drive Shaft Remover Attachment ENGINE REAR OIL SEAL(1CD–FTV) 09520–01010 Differential Side Gear Shaft ENGINE REAR OIL SEAL(1CD–FTV) 09520–24010 Puller (09520–32040) Shocker Set ENGINE REAR OIL SEAL(1CD–FTV) 09628–62011 Boll Joint Puller ENGINE REAR OIL SEAL(1CD–FTV) PARTIAL ENGINE ASSY(1CD–FTV) PARTIAL… -

Page 118

02–12 PREPARATION – ENGINE MECHANICAL 09950–50013 Puller C Set CHAIN SUB–ASSY(1AZ–FE) CYLINDER HEAD GASKET(1AZ–FE) TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL(1AZ–FE) CHAIN SUB–ASSY(1AZ–FSE) CYLINDER HEAD GASKET(1AZ–FSE) TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL(1AZ–FSE) TIMING BELT(1CD–FTV) CAMSHAFT(1CD–FTV) CYLINDER HEAD GASKET(1CD–FTV) -

Page 119

02–13 PREPARATION – ENGINE MECHANICAL (09953–05020) Center Bolt 150 CHAIN SUB–ASSY(1AZ–FE) CYLINDER HEAD GASKET(1AZ–FE) TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL(1AZ–FE) CHAIN SUB–ASSY(1AZ–FSE) CYLINDER HEAD GASKET(1AZ–FSE) TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL(1AZ–FSE) TIMING BELT(1CD–FTV) CAMSHAFT(1CD–FTV) CYLINDER HEAD GASKET(1CD–FTV) -

Page 120

02–14 PREPARATION – ENGINE MECHANICAL (09962–01000) Variable Pin Wrench Arm Assy TIMING BELT(1CD–FTV) CAMSHAFT(1CD–FTV) CYLINDER HEAD GASKET(1CD–FTV) CRANKSHAFT SEAL(1CD–FTV) PARTIAL ENGINE ASSY(1CD–FTV) PARTIAL ENGINE ASSY(1ZZ–FE/3ZZ–FE) CHAIN SUB–ASSY(1ZZ–FE/3ZZ–FE) CYLINDER HEAD GASKET(1ZZ–FE/3ZZ–FE) TIMING CHAIN OR BELT COVER OIL SEAL(1ZZ–FE/3ZZ–FE) ENGINE REAR SEAL(1ZZ–FE/3ZZ–FE) Pin 10 TIMING BELT(1CD–FTV) (09963–01000) -

Page 121

02–15 PREPARATION – ENGINE MECHANICAL Recomended Tools Socket Wrench 30 mm ENGINE REAR OIL SEAL(1CD–FTV) 09011–12301 PARTIAL ENGINE ASSY(1CD–FTV) PARTIAL ENGINE ASSY(1ZZ–FE/3ZZ–FE) ENGINE REAR SEAL(1ZZ–FE/3ZZ–FE) Deep Socket Wrench 12 mm PARTIAL ENGINE ASSY(1CD–FTV) 09017–38120 09040–00011 Hexagon Wrench Set PARTIAL ENGINE ASSY(1ZZ–FE/3ZZ–FE) Socket Hexagon Wrench 5 PARTIAL… -

Page 122

02–16 PREPARATION – ENGINE MECHANICAL Vernier calipers Tire pressure gauge Alignment tester Toe–in gauge OBD II scan tool Deep socket wrench 24 mm Slide calipers Sand paper (#400) Wooden block Chain block Spark plug cleaner Angle gauge Universal engine lifter 08826–00080 Seal Packing Black or equivalent VALVE CLEARANCE(1AZ–FE) -

Page 123

02–17 PREPARATION – EXHAUST EXHAUST 022J7–01 PREPARATION Equipment Torque wrench Vernier calipers Wooden block AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 124

02–62 PREPARATION – EXTERIOR/INTERIOR TRIM EXTERIOR/INTERIOR TRIM 022KP–01 PREPARATION Recomended Tools 09070–20010 Moulding Remover FRONT DOOR BELT MOULDING ASSY LH REAR DOOR BELT MOULDING ASSY LH ROOF HEADLINING ASSY(LIFTBACK MODELS) ROOF HEADLINING ASSY(SEDAN MODELS) ROOF HEADLINING ASSY(WAGON MODELS) Equipment Adhesive tape To avoid surface damage. -

Page 125

02–25 PREPARATION – FRONT SUSPENSION FRONT SUSPENSION 022KF–01 PREPARATION 09628–62011 Boll Joint Puller LOWER BALL JOINT ASSY FRONT STABILIZER BAR FRONT FRONT SUSPENSION SUB–ASSY LOWER NO.1 LH(ATM) 09727–30021 Coil Spring Compressor FRONT SHOCK ABSORBER WITH COIL SPRING 09729–22031 Front Spring Upper Seat Holder FRONT SHOCK ABSORBER WITH COIL SPRING 09930–00010… -

Page 126

02–4 PREPARATION – FUEL FUEL 022J6–01 PREPARATION 09023–12700 Union Nut Wrench 17mm INJECTOR ASSY(1CD–FTV) INJECTION OR SUPPLY PUMP ASSY(1CD–FTV) COMMON RAIL ASSY(1CD–FTV) 09213–54015 Crankshaft Pulley Holding Tool INJECTION SUPPLY PUMP ASSY(1CD–FTV) (90105–08076) Bolt INJECTION SUPPLY PUMP ASSY(1CD–FTV) Fuel Filter Wrench FUEL FILTER ASSY(1CD–FTV) 09228–64030 Fuel Hose Puller… -

Page 127

02–5 PREPARATION – FUEL 09808–14010 Fuel Sender Gauge Tool Assy FUEL TANK ASSY(DIESEL) FUEL PUMP ASSY(GASOLINE) FUEL TANK ASSY(GASOLINE) Wire ”H” EFI Inspection FUEL SYSTEM(1AZ–FE) 09842–30080 FUEL SYSTEM(1ZZ–FE/3ZZ–FE) Puller C Set INJECTION OR SUPPLY PUMP 09950–50013 ASSY(1CD–FTV) (09951–05010) Hanger 150 INJECTION OR SUPPLY PUMP ASSY(1CD–FTV) (09952–05010) -

Page 128

02–6 PREPARATION – FUEL 09082–00040 TOYOTA Electrical Tester FUEL SYSTEM(1CD–FTV) FUEL SYSTEM(1ZZ–FE/3ZZ–FE) Test Lead Set FUEL SYSTEM(1AZ–FE) (09083–00150) FUEL SYSTEM(1AZ–FSE) FUEL SYSTEM(1ZZ–FE/3ZZ–FE) Water Pump Pliers FUEL FILTER ASSY(1CD–FTV) 09130–00150 09216–00021 Belt Tension Gauge INJECTION OR SUPPLY PUMP ASSY(1CD–FTV) Equipment Clip… -

Page 129

02–47 PREPARATION – HEATER & AIR CONDITIONER HEATER & AIR CONDITIONER 022KJ–01 PREPARATION 07110–58060 Air Conditioner Service Tool Set REFRIGERANT CONDITIONING RADIATOR ASSY W/RECEIVER CONDENSER ASSY W/PULLEY COMPRESSOR ASSY(1AZ–FE) W/PULLEY COMPRESSOR ASSY(1AZ–FSE) W/PULLEY COMPRESSOR ASSY(1CD–FTV) W/PULLEY COMPRESSOR ASSY(1ZZ–FE) W/PULLEY COMPRESSOR ASSY(2AZ–FSE) W/PULLEY COMPRESSOR… -

Page 130

02–48 PREPARATION – HEATER & AIR CONDITIONER (07117–58080) Quick Disconnect Adapter REFRIGERANT CONDITIONING RADIATOR ASSY W/RECEIVER CONDENSER ASSY W/PULLEY COMPRESSOR ASSY(1AZ–FE) W/PULLEY COMPRESSOR ASSY(1AZ–FSE) W/PULLEY COMPRESSOR ASSY(1CD–FTV) W/PULLEY COMPRESSOR ASSY(1ZZ–FE) W/PULLEY COMPRESSOR ASSY(2AZ–FSE) W/PULLEY COMPRESSOR ASSY(3ZZ–FE) Quick Disconnect Adapter REFRIGERANT (07117–58090) CONDITIONING RADIATOR… -

Page 131

02–49 PREPARATION – HEATER & AIR CONDITIONER (07117–88060) Refrigerant Charging Hose REFRIGERANT CONDITIONING RADIATOR ASSY W/RECEIVER CONDENSER ASSY W/PULLEY COMPRESSOR ASSY(1AZ–FE) W/PULLEY COMPRESSOR ASSY(1AZ–FSE) W/PULLEY COMPRESSOR ASSY(1CD–FTV) W/PULLEY COMPRESSOR ASSY(1ZZ–FE) W/PULLEY COMPRESSOR ASSY(2AZ–FSE) W/PULLEY COMPRESSOR ASSY(3ZZ–FE) Refrigerant Charging Hose REFRIGERANT (07117–88070) CONDITIONING RADIATOR… -

Page 132

02–50 PREPARATION – HEATER & AIR CONDITIONER 09870–00025 A/C Quick Joint Puller No.2 CONDITIONING RADIATOR ASSY Puller C Set CONDITIONING RADIATOR 09950–50013 ASSY BLOWER ASSY Hanger 150 CONDITIONING RADIATOR (09951–05010) ASSY BLOWER ASSY (09952–05010) Slide Arm CONDITIONING RADIATOR ASSY BLOWER ASSY (09953–05020) Center Bolt 150 CONDITIONING… -

Page 133

02–51 PREPARATION – HEATER & AIR CONDITIONER 95416–00140 Gas Leak Detector REFRIGERANT (Halogen Leak Detector) CONDITIONING RADIATOR (DENSO Part No.) ASSY W/PULLEY COMPRESSOR ASSY(1AZ–FE) W/PULLEY COMPRESSOR ASSY(1AZ–FSE) W/PULLEY COMPRESSOR ASSY(1CD–FTV) W/PULLEY COMPRESSOR ASSY(1ZZ–FE) W/PULLEY COMPRESSOR ASSY(2AZ–FSE) W/PULLEY COMPRESSOR ASSY(3ZZ–FE) Equipment Voltmeter Anmeter Ohmmeter… -

Page 134

PREPARATION – IGNITION IGNITION 022J8–01 PREPARATION 09249–63010 Torque Wrench Adaptor CRANKSHAFT POSITION SENSOR (1AZ–FE/1AZ–FSE) Recomended Tools 09082–00040 TOYOTA Electrical Tester IGNITION SYSTEM(1AZ–FE) IGNITION SYSTEM(1AZ–FSE) IGNITION SYSTEM (1ZZ–FE/3ZZ–FE) (09083–00150) Test Lead Set IGNITION SYSTEM(1AZ–FE) IGNITION SYSTEM(1AZ–FSE) IGNITION SYSTEM (1ZZ–FE/3ZZ–FE) 09200–00010 Engine Adjust Kit IGNITION SYSTEM(1AZ–FE) -

Page 135

Center Bolt 150 INSTRUMENT PANEL SUB–ASSY (09953–05020) LOWER Claw No.2 INSTRUMENT PANEL SUB–ASSY (09954–05021) LOWER Recomended Tools 09082–00040 TOYOTA Electrical Tester COMBINATION METER (09083–00150) Test Lead Set COMBINATION METER Torx Driver T30 INSTRUMENT PANEL SUB–ASSY 09041–00030 LOWER Torx Socket T30 INSTRUMENT PANEL SUB–ASSY… -

Page 136

PREPARATION – INTAKE INTAKE 022KR–01 PREPARATION 09992–00242 Turbocharger Pressure Gauge TURBO CHARGER SYSTEM (1CD–FTV) Recomended Tools 09082–00040 TOYOTA Electrical Tester TURBO CHARGER SYSTEM (1CD–FTV) (09083–00150) Test Lead Set TURBO CHARGER SYSTEM (1CD–FTV) Equipment Vacuum gauge Voltmeter Ohmmeter Service wire harness… -

Page 137

02–20 PREPARATION – LUBRICATION LUBRICATION 022K9–01 PREPARATION 09023–12900 Union Nut Wrench 19mm OIL PUMP ASSY(1AZ–FSE) 09032–00100 Oil Pan Seal Cutter OIL PUMP ASSY(1AZ–FE) OIL PUMP ASSY(1AZ–FSE) OIL PUMP ASSY(1CD–FTV) 09213–54015 Crankshaft Pulley Holding Tool OIL PUMP ASSY(1AZ–FE) OIL PUMP ASSY(1AZ–FSE) OIL PUMP ASSY(1CD–FTV) Bolt OIL PUMP ASSY(1CD–FTV) -

Page 138

02–21 PREPARATION – LUBRICATION 09330–00021 Companion Flange Holding Tool OIL PUMP ASSY(1AZ–FE) OIL PUMP ASSY(1AZ–FSE) OIL PUMP ASSY(1CD–FTV) Puller C Set OIL PUMP ASSY(1AZ–FE) 09950–50013 OIL PUMP ASSY(1AZ–FSE) OIL PUMP ASSY(1CD–FTV) Hanger 150 OIL PUMP ASSY(1AZ–FE) (09951–05010) OIL PUMP ASSY(1AZ–FSE) OIL PUMP ASSY(1CD–FTV) (09952–05010) Slide Arm… -

Page 139

02–22 PREPARATION – LUBRICATION Seal Packing Black or equivalent OIL PUMP ASSY(1CD–FTV) 08826–00080 (FIPG) Lubricant Item Capacity Classification Oil grade (gasoline engine) API grade SJ ”Energy–Conserving”, SL ”Energy– – Conserving” multigrade engine oil or ILSAC multi- grade engine oil Oil grade (Diesel engine) ACEA B1, API CF–4 or CF –… -

Page 140

02–40 PREPARATION – MANUAL TRANSMISSION/TRANSAXLE MANUAL TRANSMISSION/TRANSAXLE 022KY–01 PREPARATION 09023–00100 Union Nut Wrench 10 mm MANUAL TRANSAXLE ASSY(1CD–FTV) 09023–12700 Union Nut Wrench 17mm MANUAL TRANSAXLE ASSY(1AZ–FE/1AZ–FSE) MANUAL TRANSAXLE ASSY(1CD–FTV) 09308–00010 Oil Seal Puller FRONT DIFFERENTIAL SEAL(C50/C250) FRONT DIFFERENTIAL SEAL(E354/E357) Drive Shaft Remover Attachment MANUAL TRANSAXLE 09520–01010… -

Page 141

02–41 PREPARATION – MANUAL TRANSMISSION/TRANSAXLE 09608–32010 Steering Knuckle Oil Seal FRONT DIFFERENTIAL Replacer SEAL(E354/E357) Boll Joint Puller MANUAL TRANSAXLE 09628–62011 ASSY(1AZ–FE/1AZ–FSE) MANUAL TRANSAXLE ASSY(1CD–FTV) MANUAL TRANSAXLE ASSY(1ZZ–FE/3ZZ–FE) FRONT DIFFERENTIAL SEAL(C50/C250) FRONT DIFFERENTIAL SEAL(E354/E357) 09670–00010 Front Crossmember Guide Tool MANUAL TRANSAXLE ASSY(1AZ–FE/1AZ–FSE) MANUAL TRANSAXLE… -

Page 142

02–42 PREPARATION – MANUAL TRANSMISSION/TRANSAXLE Equipment Torque wrench Hexagon wrench (6 mm) Lubricant Item Capacity Classification C50, C250 API GL–4 or GL–5 Manual Transaxle oil 1.9 litters (2.0 US qts, 1.7 Imp. qts) SAE 75W–90 (w/ Differential oil) E354, E357 API GL–4 or GL–5 Manual Transaxle oil 2.5 litters (2.6 US qts, 2.2 Imp. -

Page 143

02–35 PREPARATION – PARKING BRAKE PARKING BRAKE 022JT–01 PREPARATION 09718–00010 Shoe Hold Down Spring Driver PARKING BRAKE ASSY PARKING BRAKE CABLE ASSY NO.3 Recomended Tools 09070–20010 Moulding Remover PARKING BRAKE CABLE ASSY NO.1 PARKING BRAKE LEVER SUB–ASSY Equipment Torque wrench Slide calipers AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 144

02–45 PREPARATION – POWER STEERING POWER STEERING 022KE–01 PREPARATION 09023–12700 Union Nut Wrench 17mm RACK & PINION POWER STEERING GEAR ASSY VANE PUMP ASSY(1CD–FTV) 09249–63010 Torque Wrench Adaptor VANE PUMP ASSY(AZ Series) 09521–24010 Rear Axle Shaft Puller STEERING GEAR ASSY RACK &… -

Page 145

02–46 PREPARATION – POWER STEERING Recomended Tools Torque Wrench (30 kgf–cm) STEERING GEAR ASSY 09025–00010 RACK & PINION POWER STEERING GEAR ASSY VANE PUMP ASSY(1CD–FTV) VANE PUMP ASSY(AZ Series) 09090–04020 Engine Sling Device STEERING GEAR ASSY RACK & PINION POWER STEERING GEAR ASSY Snap Ring No.1 Expander VANE PUMP ASSY(1CD–FTV) -

Page 146

02–26 PREPARATION – REAR SUSPENSION REAR SUSPENSION 022L8–01 PREPARATION 09610–20012 Pitman Arm Puller REAR SUSPENSION ARM ASSY NO.1 LH LOWER CONTROL ARM ASSY LH 09628–62011 Boll Joint Puller REAR SUSPENSION ARM ASSY NO.1 LH 09632–36010 Steering Vane Pump Bearing REAR SUSPENSION ARM ASSY Replacer NO.1 LH Coil Spring Compressor… -

Page 147

02–27 PREPARATION – REAR SUSPENSION (09955–04051) Claw No.5 REAR SUSPENSION ARM ASSY NO.1 LH Attachment REAR SUSPENSION ARM ASSY (09957–04010) NO.1 LH Holder REAR SUSPENSION ARM ASSY (09958–04011) NO.1 LH Recomended Tools 09040–00011 Hexagon Wrench Set REAR SHOCK ABSORBER WITH COIL SPRING REAR SUSPENSION ARM ASSY NO.1 LH… -

Page 148

02–59 PREPARATION – SEAT SEAT 022L6–01 PREPARATION Recomended Tools 09082–00050 TOYOTA Electrical Tester Set FRONT POWER SEAT CONTROL SYSTEM SEAT HEATER SYSTEM 09082–00040 TOYOTA Electrical Tester FRONT POWER SEAT CONTROL SYSTEM SEAT HEATER SYSTEM Equipment Hog ring Hog ring pliers… -

Page 149

02–60 PREPARATION – SLIDING ROOF/CONVERTIBLE SLIDING ROOF/CONVERTIBLE 022KO–01 PREPARATION Recomended Tools 09041–00020 Torx Driver T25 SLIDING ROOF 09082–00040 TOYOTA Electrical Tester SLIDING ROOF SYSTEM Equipment Torque wrench AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 150

– STARTING & CHARGING STARTING & CHARGING 022J9–01 PREPARATION 09249–63010 Torque Wrench Adaptor GENERATOR ASSY(1AZ–FE/1AZ–FSE) Recomended Tools 09082–00040 TOYOTA Electrical Tester STARTING SYSTEM(1AZ–FE) STARTING SYSTEM(1AZ–FSE) STARTING SYSTEM (1ZZ–FE/3ZZ–FE) (09083–00150) Test Lead Set STARTING SYSTEM(1AZ–FE) STARTING SYSTEM(1AZ–FSE) STARTING SYSTEM (1ZZ–FE/3ZZ–FE) 09216–00021 Belt Tension Gauge GENERATOR ASSY(1CD–FTV) -

Page 151

02–44 PREPARATION – STEERING COLUMN STEERING COLUMN 022JS–01 PREPARATION 09616–00011 Steering Worm Bearing Adjusting STEERING COLUMN ASSY Socket 09950–50013 Puller C Set STEERING COLUMN ASSY (09951–05010) Hanger 150 STEERING COLUMN ASSY Slide Arm STEERING COLUMN ASSY (09952–05010) Center Bolt 150 STEERING COLUMN ASSY (09953–05020) (09954–05021) -

Page 152

02–52 PREPARATION – SUPPLEMENTAL RESTRAINT SYSTEM SUPPLEMENTAL RESTRAINT SYSTEM 022L5–01 PREPARATION 09082–00700 SRS Airbag Deployment Tool HORN BUTTON ASSY CURTAIN SHIELD AIR BAG ASSY LH FRONT SEAT AIRBAG ASSY LH INSTRUMENT PANEL PASSENGER AIR BAG ASSY INSTRUMENT PANEL ASSY Airbag Deployment Wire FRONT SEAT AIRBAG ASSY LH 09082–00750 Sub–harness No.3… -

Page 153

02–53 PREPARATION – SUPPLEMENTAL RESTRAINT SYSTEM Recomended Tools Torx Socket T30 HORN BUTTON ASSY 09042–00010 SPIRAL CABLE SUB–ASSY Moulding Remover AIR BAG SENSOR ASSY CENTER 09070–20010 Equipment Torque wrench Bolt Length: 35.0 mm (1.378 in.) Pitch: 1.0 mm (0.039 in.) Airbag disposal Diam.: 6.0 mm (0.236 in.) Tire… -

Page 154

02–28 PREPARATION – TIRE & WHEEL TIRE & WHEEL 022KG–01 PREPARATION Equipment Tire pressure gauge Dial indicator with magnetic base Wheel balancer AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 155

02–63 PREPARATION – VEHICLE CONTROL SYSTEM VEHICLE CONTROL SYSTEM 022L3–01 PREPARATION Recomended Tools 09082–00040 TOYOTA Electrical Tester IGNITION OR STARTER SWITCH ASSY 09082–00050 TOYOTA Electrical Tester Set IGNITION OR STARTER SWITCH ASSY AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 156

02–57 PREPARATION – WINDSHIELD/WINDOWGLASS/MIRROR WINDSHIELD/WINDOWGLASS/MIRROR 022L7–01 PREPARATION Recomended Tools 09070–20010 Moulding Remover WINDSHIELD GLASS 09082–00040 TOYOTA Electrical Tester POWER WINDOW CONTROL SYSTEM WINDOW DEFOGGER SYSTEM POWER MIRROR CONTROL SYSTEM (09083–00150) Test Lead Set POWER WINDOW CONTROL SYSTEM (09083–00350) AC/DC 400 A Probe… -

Page 157

Diagnosis Check Wire No.2 WIPER AND WASHER SYSTEM Recomended Tools 09042–00010 Torx Socket T30 WINDSHIELD WIPER MOTOR ASSY 09082–00040 TOYOTA Electrical Tester WIPER AND WASHER SYSTEM (09083–00150) Test Lead Set WIPER AND WASHER SYSTEM Equipment Torque wrench AVENSIS REPAIR MANUAL (RM1018E) -

Page 158

03–67 SERVICE SPECIFICATIONS – AUDIO & VISUAL SYSTEM AUDIO & VISUAL SYSTEM 031HB–01 TORQUE SPECIFICATION Part Tightened kgf cm ft lbf Amplifier antenna assy x Body 62 in. lbf Antenna cord sub–assy x Body 62 in. lbf Antenna cord sub–assy No.3 x Body 62 in. -

Page 159

03–45 SERVICE SPECIFICATIONS – AUTOMATIC TRANSMISSION / TRANSAXLE AUTOMATIC TRANSMISSION / TRANSAXLE 030A9–10 SERVICE DATA U341E (RHD) Line pressure (Wheel locked) Engine idling D range 370 – 410 kPa (3.8 – 4.2 kgf@cm , 54 – 60 psi) R range 540 –… -

Page 160

03–46 SERVICE SPECIFICATIONS – AUTOMATIC TRANSMISSION / TRANSAXLE Shift schedule D range (Throttle valve fully opened) 53 – 59 km/h (33 – 37 mph) 100 – 108 km/h (62 – 67 mph) 156 – 165 km/h (97 – 103 mph) 119 –… -

Page 161

03–47 SERVICE SPECIFICATIONS – AUTOMATIC TRANSMISSION / TRANSAXLE Shift schedule D range (Throttle valve fully opened) 53 – 62 km/h (33 – 39 mph) 102 – 111 km/h (63 – 69 mph) 158 – 173 km/h (98 – 108 mph) 150 –… -

Page 162

03–48 SERVICE SPECIFICATIONS – AUTOMATIC TRANSMISSION / TRANSAXLE Shift schedule(When kick down switch turns ON) D range (Throttle valve fully opened) 53 – 62 km/h (33 – 39 mph) 102 – 111 km/h (63 – 69 mph) 158 – 173 km/h (98 – 108 mph) 150 –… -

Page 163

03–49 SERVICE SPECIFICATIONS – AUTOMATIC TRANSMISSION / TRANSAXLE U241E (1AZ–FE) (LHD) Line pressure (Wheel locked) Engine idling D range 372 – 412 kPa (3.8 – 4.2 kgf@cm , 53 – 60 psi) R range 672 – 742 kPa (6.9 – 7.6 kgf@cm , 97 –… -

Page 164

03–50 SERVICE SPECIFICATIONS – AUTOMATIC TRANSMISSION / TRANSAXLE 030AA–10 TORQUE SPECIFICATION U341E Part Tightened kgf cm ft lbf Park/neutral position switch x Transaxle Bolt 48 in. lbf 61 in. lbf Control shaft lever x Park/neutral position switch Battery carrier x Body Engine hanger x Engine Drain plug x Oil pan Transaxle x Engine… -

Page 165

03–51 SERVICE SPECIFICATIONS – AUTOMATIC TRANSMISSION / TRANSAXLE U241E Part Tightened kgf cm ft lbf Park/neutral position switch x Transaxle Bolt 48 in. lbf 61 in. lbf Control shaft lever x Park/neutral position switch Battery carrier x Body Engine hanger x Engine Drain plug x Oil pan Transaxle x Engine Bolt A:… -

Page 166

03–41 SERVICE SPECIFICATIONS – BRAKE BRAKE 030MU–02 SERVICE DATA Brake pedal height (from asphalt sheet) RHD: 142.5 – 152.5 mm (5.610 – 6.004 in.) LHD: 148.1 – 158.1 mm (5.831 – 6.224 in.) 149.9 – 159.9 mm (5.902 – 6.295 in.) Brake Pedal free play 1 –… -

Page 167

03–42 SERVICE SPECIFICATIONS – BRAKE 030MV–02 TORQUE SPECIFICATION Part Tightened kgf cm ft lbf Wheel nut 1,050 Brake line union nut 10 mm 14 mm Brake booster clevis lock nut Brake master cylinder sub–assy x Brake booster assy Charcoal canister bracket x Body 48 in. -

Page 168

03–55 SERVICE SPECIFICATIONS – CLUTCH CLUTCH 030L1–03 SERVICE DATA Pedal height from asphalt sheet LHD steering position type 1CD–FTV engine type w/ intercooler 154.0 – 164.0 mm (6.063 – 6.457 in.) Others 139.6 – 149.6 mm (5.496 – 5.890 in.) Pedal height from asphalt sheet RHD steering position type 1CD–FTV engine type w/ intercooler… -

Page 169

03–56 SERVICE SPECIFICATIONS – CLUTCH 030L2–04 TORQUE SPECIFICATION Part Tightened kgf cm ft lbf Clutch pedal support x Stopper bolt Clutch pedal sub–assy x Clutch pedal support Clutch pedal support x Body Clutch pedal support x Clutch start switch assy Clutch master cylinder push rod clevis lock nut Clutch master cylinder x Flexible hose tube Clutch master cylinder x Body… -

Page 170

03–68 SERVICE SPECIFICATIONS – COMMUNICATION SYSTEM COMMUNICATION SYSTEM 031HJ–01 TORQUE SPECIFICATION Part Tightened kgf cm ft lbf HIGH PITCHED HORN ASSY High pitched horn assy x Body LOW PITCHED HORN ASSY Low pitched horn assy x Body AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 171

03–24 SERVICE SPECIFICATIONS – COOLING COOLING 031H3–01 SERVICE DATA 1ZZ–FE/3ZZ–FE: Thermostat Valve opening temperature 86 to 90YC (187 to 198YF) Valve lift at 95YC (203YF) 10 mm (0.394 in.) or more Radiator cap sub–assy Standard opening pressure 74 to 103 kPa (0.75 to 1.05 kgf/cm2, 10.7 to 14.9 psi) Minimum opening pressure 59 kPa (0.6 kgf/cm2, 8.6 psi) Cooling fan… -

Page 172

03–25 SERVICE SPECIFICATIONS – COOLING Cooling fan Standard amperage at 20YC (68YF) 5.2 to 8.2 A (M/T) 8.3 to 11.3 (A/T) Standard amperage (No.2 (With Air Conditioner)) at 20YC (68YF) 5.2 to 8.2 A (M/T) 8.3 to 11.3 (A/T) Cooling fan relay Specified condition Between terminals 1 and 2 Continuity… -

Page 173

03–26 SERVICE SPECIFICATIONS – COOLING 031H4–01 TORQUE SPECIFICATION 1ZZ–FE/3ZZ–FE: Part Tightened kgf cm ft lbf Radiator drain plug Water pump x Cylinder block Bolt A 8.0 in.lbf Bolt B Water inlet x Cylinder block sub–assy Radiator x Radiator support upper 1AZ–FE: Part Tightened kgf cm… -

Page 174

03–39 SERVICE SPECIFICATIONS – DRIVE SHAFT / PROPELLER SHAFT / AXLE DRIVE SHAFT / PROPELLER SHAFT / AXLE 030KB–05 SERVICE DATA Front axle hub bearing Backlash Maximum: 0.05 mm (0.0020 in.) Front axle hub sub–assy Deviation Maximum: 0.05 mm (0.0020 in.) Rear axle hub &… -

Page 175

03–40 SERVICE SPECIFICATIONS – DRIVE SHAFT / PROPELLER SHAFT / AXLE 030KC–06 TORQUE SPECIFICATION Part Tightened kgf cm ft lbf Front wheel set nut 1,050 Rear wheel set nut 1,050 Manual transaxle oil drain plug C50/C250: E354/E357: Lower ball joint assy front x Suspension arm sub–assy lower No.1 Tie rod end sub–assy x Steering knuckle Flexible hose and speed sensor front x Shock absorber assy front Speed sensor front x Steering knuckle… -

Page 176: Emission Control

03–10 SERVICE SPECIFICATIONS – EMISSION CONTROL EMISSION CONTROL 031FP–01 SERVICE DATA 1ZZ–FE/3ZZ–FE: Heated oxygen sensor Resistance Bank 1 sensor 1 5 to 10 ( at 20YC (68YF) 1 (HT1A) – 2 (+B) 1 (HT1A) – 4 (E1) No continuity Heated oxygen sensor Resistance Bank 1 sensor 2 5 to 10 ( at 20YC (68YF)

-

Page 177

03–4 SERVICE SPECIFICATIONS – ENGINE CONTROL SYSTEM ENGINE CONTROL SYSTEM 031DY–01 SERVICE DATA 1ZZ–FE/3ZZ–FE: Power steering oil pressure switch Voltage EMPS – E2 Not spin the steering wheel at engine idling 8 to 14 V 0 to 1.5 V Spin the steering wheel at engine idling Idle air control valve Half open @ fully close @ fully open @ half open Movement… -

Page 178

03–5 SERVICE SPECIFICATIONS – ENGINE CONTROL SYSTEM 1CD–FTV: Mass air flow meter Resistance 2 (THA) – 1 (E2) at –20YC (–4YF) 12.5 to 16.9 kW at 20YC (68YF) 2.19 to 2.67 kW at 60YC (140YF) 0.50 to 0.68 kW Intake shutter assy Resistance at 20YC (68YF) 18 to 22 W… -

Page 179

03–6 SERVICE SPECIFICATIONS – ENGINE CONTROL SYSTEM 031DZ–02 TORQUE SPECIFICATION 1ZZ–FE/3ZZ–FE: Part Tightened kgf cm ft lbf Throttle position sensor x Throttle body assy 18 in. lbf ISC valve x Throttle body assy 33 in. lbf Accelerator control cable bracket x Throttle body assy Throttle body assy x Intake manifold Throttle body bracket x Cylinder block sub–assy (1ZZ–FE) Manifold stay No. -

Page 180

03–73 SERVICE SPECIFICATIONS – ENGINE HOOD/DOOR ENGINE HOOD/DOOR 031GG–01 TORQUE SPECIFICATION Part Tightened kgf@cm ft@lbf HOOD Hood hinge x Hood Hood hinge x Body 49 in.@lbf Hood lock x Hood 71 in.@lbf FRONT DOOR Door check x Body Door check x Door panel 46 in.@lbf Door frame sub–assy rear lower x Door panel 71 in.@lbf… -

Page 181

03–74 SERVICE SPECIFICATIONS – ENGINE HOOD/DOOR Part Tightened kgfVcm ftVlbf Back door stay sub–assy x Door panel Center stop lamp assy x Door panel 49 in.Vlbf AVENSIS REPAIR MANUAL (RM1018E) http://vnx.su… -

Page 182

03–13 SERVICE SPECIFICATIONS – ENGINE MECHANICAL ENGINE MECHANICAL 031H1–01 SERVICE DATA 1ZZ–FE/3ZZ–FE: Ignition timing w/ Terminal TC and CG of DLC3 connected 8 to 12YBTDC W/ Terminal TC and CG of DLC3 disconnected 10 to 18YBTDC (1ZZ–FE) 3.5 to 11.5YBTDC (3ZZ–FE) Idle speed 600 to 700 rpm Compression… -

Page 183

03–14 SERVICE SPECIFICATIONS – ENGINE MECHANICAL 1CD–FTV: New drive belt deflection Pressing force: 98 N (10 kgf, 22 lbf) For vane pump V belt (A/C equipped) 9.5 to 11.5 mm (0.37 to 0.45 in.) For vane pump V belt (A/C not equipped) 10 to 12 mm (0.39 to 0.47 in.) Used drive belt deflection Pressing force: 98 N (10 kgf, 22 lbf) -

Page 184

03–15 SERVICE SPECIFICATIONS – ENGINE MECHANICAL 031H2–01 TORQUE SPECIFICATION 1ZZ–FE/3ZZ–FE: Part Tightened kgf cm ft lbf Camshaft bearing cap No. 3 x Cylinder head sub–assy Camshaft bearing cap No. 1 x Cylinder head sub–assy Camshaft timing gear or sprocket x Camshaft No. 2 Chain tensioner assy No. -

Page 185

03–16 SERVICE SPECIFICATIONS – ENGINE MECHANICAL Part Tightened kgf cm ft lbf Floor panel brace front x Body Battery carrier x Body 12.8 Battery x Body 44 in. lbf Air cleaner case x Body 44 in. lbf Air cleaner case x Transverse engine engine mounting bracket LH 44 in. -

Page 186

03–17 SERVICE SPECIFICATIONS – ENGINE MECHANICAL Part Tightened kgf cm ft lbf Engine mounting bracket x No, 2 RH x Transverse engine engine mounting insulator 1,152 Clutch release cylinder x manual transaxle Bolt A Bolt B 80 in. lbf Bolt C 44 in. -

Page 187

03–18 SERVICE SPECIFICATIONS – ENGINE MECHANICAL Part Tightened kgf cm ft lbf Knock sensor x Cylinder block Engine oil pressure switch assy x Cylinder head Water by–pass pipe No.1 x Cylinder block 80 in. lbf Drive shaft bearing bracket x Cylinder block Oil level gauge guide x Cylinder block 80 in. -

Page 188

03–19 SERVICE SPECIFICATIONS – ENGINE MECHANICAL Part Tightened kgf cm ft lbf Camshaft timing sprocket x Camshaft Camshaft bearing cap No. 1 x Cylinder head Camshaft bearing cap No. 2 x Cylinder head Camshaft bearing cap No. 3 x Cylinder head 80 in. -

Page 189

03–20 SERVICE SPECIFICATIONS – ENGINE MECHANICAL Part Tightened kgf cm ft lbf Injection pipe, Fuel inlet pipe x Common rail Used pipe using SST Used pipe not using SST New pipe using SST New pipe not using SST Injection pipe x Injector Used pipe using SST Used pipe not using SST New pipe using SST… -

Page 190

03–21 SERVICE SPECIFICATIONS – ENGINE MECHANICAL Part Tightened kgf cm ft lbf Air cleaner assy x Body x Engine mounting bracket LH 62 in. lbf Engine cover No.1 x Cylinder head cover sub–assy 71 in. lbf Engine cover No. 1 x Intake manifold 71 in. -

Page 191

03–22 SERVICE SPECIFICATIONS – EXHAUST EXHAUST 031E2–02 SERVICE DATA 1ZZ–FE/3ZZ–FE: Compression spring Free length Minimum Front x Manifold 41.5 mm (1.634 in.) Front x Tail 38.5 mm (1.516 in.) 1AZ–FE/1AZ–FSE: Compression spring Free length Minimum Front x Manifold 41.5 mm (1.634 in.) Center x Tail 38.5 mm (1.516 in.) 1CD–FTV:… -

Page 192

03–23 SERVICE SPECIFICATIONS – EXHAUST 031E3–02 TORQUE SPECIFICATION 1ZZ–FE/3ZZ–FE: Part Tightened kgf cm ft lbf Exhaust pipe assy front x Exhaust manifold Exhaust pipe assy front x Exhaust pipe assy tail Heated oxygen sensor x Exhaust pipe assy front Floor panel brace front x Body 1AZ–FE/1AZ–FSE: Part Tightened kgf cm… -

Page 193

03–75 SERVICE SPECIFICATIONS – EXTERIOR/INTERIOR TRIM EXTERIOR/INTERIOR TRIM 031GY–01 TORQUE SPECIFICATION Part Tightened kgf cm ft lbf FUEL LID CONTROL ASSY Fuel lid control assy x Body 71 in. lbf REAR BUMPER COVER Rear bumper cover x Body 49 in. lbf Rear bumper reinforcement No. -

Page 194

03–34 SERVICE SPECIFICATIONS – FRONT SUSPENSION FRONT SUSPENSION 0313B–05 SERVICE DATA Vehicle height (Normal package) Front: A – B 92 mm (3.62 in.) Rear: D – C 61 mm (2.40 in.) (Rough road package) Front: A – B 72 mm (2.83 in.) Rear: D –… -

Page 195