• YaleStop automatic park brake eliminates uncontrolled

roll-back on ramps

• Oil-immersed brakes

• CAN bus and high-performance AC motor technology

• E-steering to increase productivity while maintaining

excellent battery life

Electric forklift trucks

VF

series

1,600kg / 1,800kg / 2,000kg

• New 180° fold back door and fork pockets allow

completing horizontal battery exchange in 3 min

• 2 battery choices: DIN and BS.

VDI 2198 — General Specifications

* Standard / Wide tread

** 60 minute rating

*** 5 minute rating

**** 30 minute rating

n Max. battery.

t Bottom of forks.

: Without load backrest.

m h6 subject to +/- 5mm tolerance.

8 Full suspension seat at midpoint of

suspension travel. Standard hood

specified. 1051mm with raised hood.

w Add 32mm with load backrest.

4 HiP performance setting.

◊ Maximum flow set through dash display.

] HiP performance.

l Min./max.

q With manual hydraulic controls; 155 bar with

e-hydraulic controls.

(A)

Overall width 1116mm with required

200/50-10 tyres fitted for masts 5000mm and over.

(B)

With vertical battery removal; add 34mm with

horizontal removal.

Distinguishing markWeightsTyres/chassis

Dimensions

Performance data Electric-engine

Addition data

VF series

2

Manufacturer (abbreviation)

Manufacturer’s type designation

Drive: electric (battery or mains), diesel, petrol, fuel gas

Operator type: hand, pedestrian, standing, seated, order-picker

Rated capacity/rated load

Load centre distance

Load distance, centre of drive axle to fork

Wheelbase

Service weight n

Axle loading, laden front/rear n

Axle loading, unladen front/rear n

Tyres: P=pneumatic, C=cushion, SE=superelastic

Tyre size, front

Tyre size, rear

Wheels, number front/rear (x = driven wheels)

Tread, front

Tread, rear

Tilt of mast/fork carriage forward/backward

Height, mast lowered

Free lift t

Lift t

Height, mast extended :

Height of overhead guard (cabin) m

Cab height (open cab)

Seat height relating to SIP/stand height 8

Coupling height

Overall length

Length to face of forks

Overall width

(8)

Fork dimensions ISO 2331

Fork carriage ISO 2328, class/type A, B

Fork carriage width :

Ground clearance, laden, below mast

Ground clearance at centre of wheelbase

(C)

Load dimension b

12

× l

6

crossways

Aisle width predetermined load dimensions

Aisle width for pallets 1000 × 1200 crossways

Aisle width for pallets 800 × 1200 lengthways

Turning radius

Internal turning radius

90° intersecting aisle (With pallet W = 1200mm, L = 1000mm)

Step Height (from ground to running board)

(B)

Step Height

Travel speed, laden/unladen ]

Travel speed, laden/unladen, backwards

Lift speed, laden/unladen

Lowering speed, laden/unladen

Drawbar pull, laden/unladen **

Max. drawbar pull, laden/unladen ***

Gradeability, laden/unladen ****

Max. gradeability, laden/unladen ***

Acceleration time, laden/unladen ]

Service brake

Drive motor rating S2 60 min

Lift motor rating at S3 15%

Battery according to DIN 43531/35/36 A, B, C, no

Battery voltage/nominal capacity K5

Battery weight l

Energy consumption according to VDI cycle ]

Type of drive unit

Operating pressure for attachments q

Oil volume for attachments ◊

Hydraulic oil tank, capacity

Sound pressure level at the driver’s seat LPAZ H

Towing coupling, type DIN

1.1

1.2

1.3

1.4

1.5

1.6

1.8

1.9

2.1

2.2

2.3

3.1

3.2

3.3

3.5

3.6

3.7

4.1

4.2

4.3

4.4

4.5

4.7

4.7.1

4.8

4.12

4.19

4.20

4.21

4.22

4.23

4.24

4.31

4.32

4.33

4.34

4.34.1

4.34.2

4.35

4.36

4.41

4.42

4.43

5.1

5.1.1

5.2

5.3

5.5

5.6

5.7

5.8

5.9

5.10

6.1

6.2

6.3

6.4

6.5

6.6

8.1

10.1

10.2

10.3

10.7

10.8

Yale

ERP16VF (LWB)

Electric (battery)

Seated

1.6

500

326

1539

3209

3992 / 817

1533 / 1676

SE

18 x 7-8

140 / 55-9

2X / 2

889

918

5 / 5

2230

100

3320

3868

2070

2087

1017

360

3088

2088

1050

(A)

40 / 80 / 1000

2A

907

70

100

1000 x 1200

3417

3417

3540

1762

0

1824

526

484

16 / 16

16 / 16

0.43 / 0.59

0.50 / 0.47

3406 / 3680

11415 / 11690

11 / 16

25 / 35

4.6 / 4.1

Electric

2x 5.0

12.0

DIN 43531-A

48 / 750

962 / 1064

5.1

AC Induction

180

40

19

69

Pin

Yale

ERP18VF (MWB)

Electric (battery)

Seated

1.8

500

321

1431

3288

4435 / 653

1601 / 1687

SE

200 / 50-10

140 / 55-9

2X / 2

908

918

5 / 5

2180

100

3390

4006

2070

2087

1017

360

2975

1975

1116

40 / 80 / 1000

2A

977

70

100

1000 x 1200

3305

3305

3427

1654

0

1800

526

484

16 / 16

16 / 16

0.41 / 0.60

0.46 / 0.40

3337 / 3646

11355 / 11664

10 / 15

23 / 35

4.6 / 4.1

Electric

2x 5.0

12.0

DIN 43531-A

48 / 625

813 / 899

5.3

AC Induction

180

40

19

69

Pin

Yale

ERP16VF (MWB)

Electric (battery)

Seated

1.6

500

326

1431

3036

3986 / 650

1461 / 1575

SE

18 x 7-8

140 / 55-9

2X / 2

889

918

5 / 5

2230

100

3320

3868

2070

2087

1017

360

2980

1980

1050

(A)

40 / 80 / 1000

2A

907

70

100

1000 x 1200

3309

3309

3432

1654

0

1778

526

484

16 / 16

16 / 16

0.43 / 0.59

0.50 / 0.47

3406 / 3680

11415 / 11690

11 / 16

25 / 35

4.6 / 4.1

Electric

2x 5.0

12.0

DIN 43531-A

48 / 625

813 / 899

5.1

AC Induction

180

40

19

69

Pin

Q (t)

c (mm)

x (mm)

y (mm)

kg

kg

kg

b

10

(mm)

b

11

(mm)

α /β (°)

h

1

(mm)

h

2

(mm)

h

3

(mm)

h

4

(mm)

h

6

(mm)

h

7

(mm)

h

10

(mm)

l

11

(mm)

l

2

(mm)

b

1

/b

2

(mm)

s/e/l (mm)

b

3

(mm)

m

1

(mm)

m

2

(mm)

b

12

× l

6

(mm)

A

st

(mm)

A

st

(mm)

A

st

(mm)

W

a

(mm)

b

13

(mm)

mm

mm

mm

km/h

km/h

m/s

m/s

N

N

%

%

s

kW

kW

(V)/(ah)

kg

kWh/h @No. of Cycles

bar

l/min

l

dB(A)

VDI 2198 — General Specifications

(C)

90mm with horizontal battery removal.

H LPAZ, measured according to the test

cycles and based on the weighting values

contained in EN12053.

Spec sheet truck based on:

3360mm (Clear View) and 3430mm (Hi-Vis) to

top of fork, 2 stage LFL mast with standard

carriage and 1000mm forks, with HiP

performance setting, DIN battery configuration.

Distinguishing markWeightsTyres/chassis

Dimensions

Performance data Electric-engine

Addition data

All values are nominal values and they are

subject to tolerances. For further

information, please contact the

manufacturer.

Yale products might be subject to change

without notice.

Lift trucks illustrated may feature optional

equipment.

Values may vary with alternative configurations.

3

Manufacturer (abbreviation)

Manufacturer’s type designation

Drive: electric (battery or mains), diesel, petrol, fuel gas

Operator type: hand, pedestrian, standing, seated, order-picker

Rated capacity/rated load

Load centre distance

Load distance, centre of drive axle to fork

Wheelbase

Service weight n

Axle loading, laden front/rear n

Axle loading, unladen front/rear n

Tyres: P=pneumatic, C=cushion, SE=superelastic

Tyre size, front

Tyre size, rear

Wheels, number front/rear (x = driven wheels)

Tread, front

Tread, rear

Tilt of mast/fork carriage forward/backward

Height, mast lowered

Free lift t

Lift t

Height, mast extended :

Height of overhead guard (cabin) m

Cab height (open cab)

Seat height relating to SIP/stand height 8

Coupling height

Overall length

Length to face of forks

Overall width

(8)

Fork dimensions ISO 2331

Fork carriage ISO 2328, class/type A, B

Fork carriage width :

Ground clearance, laden, below mast

Ground clearance at centre of wheelbase

(C)

Load dimension b

12

× l

6

crossways

Aisle width predetermined load dimensions

Aisle width for pallets 1000 × 1200 crossways

Aisle width for pallets 800 × 1200 lengthways

Turning radius

Internal turning radius

90° intersecting aisle (With pallet W = 1200mm, L = 1000mm)

Step Height (from ground to running board)

(B)

Step Height

Travel speed, laden/unladen ]

Travel speed, laden/unladen, backwards

Lift speed, laden/unladen

Lowering speed, laden/unladen

Drawbar pull, laden/unladen **

Max. drawbar pull, laden/unladen ***

Gradeability, laden/unladen ****

Max. gradeability, laden/unladen ***

Acceleration time, laden/unladen ]

Service brake

Drive motor rating S2 60 min

Lift motor rating at S3 15%

Battery according to DIN 43531/35/36 A, B, C, no

Battery voltage/nominal capacity K5

Battery weight l

Energy consumption according to VDI cycle ]

Type of drive unit

Operating pressure for attachments q

Oil volume for attachments ◊

Hydraulic oil tank, capacity

Sound pressure level at the driver’s seat LPAZ H

Towing coupling, type DIN

Yale

ERP20VF (LWB)

Electric (battery)

Seated

2.0

500

321

1539

3386

4719 / 668

1652 / 1734

SE

200 / 50-10

140 / 55-9

2X / 2

908

918

5 / 5

2180

100

3390

4006

2070

2087

1017

360

3083

2083

1116

40 / 100 / 1000

2A

977

70

100

1000 x 1200

3413

3413

3535

1762

0

1846

526

484

16 / 16

16 / 16

0.40 / 0.58

0.47 / 0.40

3294 / 3637

11304 / 11647

9 / 15

22 / 36

4.6 / 4.1

Electric

2x 5.0

12.0

DIN 43531-A

48 / 750

962 / 1064

5.5

AC Induction

180

40

19

69

Pin

Q (t)

c (mm)

x (mm)

y (mm)

kg

kg

kg

b

10

(mm)

b

11

(mm)

α /β (°)

h

1

(mm)

h

2

(mm)

h

3

(mm)

h

4

(mm)

h

6

(mm)

h

7

(mm)

h

10

(mm)

l

11

(mm)

l

2

(mm)

b

1

/b

2

(mm)

s/e/l (mm)

b

3

(mm)

m

1

(mm)

m

2

(mm)

b

12

× l

6

(mm)

A

st

(mm)

A

st

(mm)

A

st

(mm)

W

a

(mm)

b

13

(mm)

mm

mm

mm

km/h

km/h

m/s

m/s

N

N

%

%

s

kW

kW

(V)/(ah)

kg

kWh/h @Nn. of Cycles

bar

l/min

l

dB(A)

Yale

ERP20VF (MWB)

Electric (battery)

Seated

2.0

500

321

1539

3565

4892 / 673

1743 / 1822

SE

200 / 50-10

15 x 4.5-8

2X / 2

906

918

5 / 5

2180

100

3390

4006

2070

2087

1017

360

2975

1975

1116

40 / 100 / 1000

2A

977

70

100

1000 x 1200

3305

3305

3427

1654

0

1800

526

484

16 / 16

16 / 16

0.40 / 0.58

0.47 / 0.40

3260 / 3603

11269 / 11612

9 / 14

31 / 34

4.6 / 4.1

Electric

2x 5.0

12.0

DIN 43531-A

48 / 625

813 / 899

5.5

AC Induction

180

40

19

69

Pin

Yale

ERP18VF (LWB)

Electric (battery)

Seated

1.8

500

321

1539

3282

4368 / 714

1608 / 1674

SE

200 / 50-10

140 / 55-9

2X / 2

908

918

5 / 5

2180

100

3390

4006

2070

2087

1017

360

3083

2083

1116

40 / 80 / 1000

2A

977

70

100

1000 x 1200

3413

3413

3535

1762

0

1846

526

484

16 / 16

16 / 16

0.41 / 0.60

0.46 / 0.40

3337 / 3646

11346 / 11655

10 / 15

23 / 36

4.6 / 4.1

Electric

2x 5.0

12.0

DIN 43531-A

48 / 750

962 / 1064

5.4

AC Induction

180

40

19

69

Pin

1.1

1.2

1.3

1.4

1.5

1.6

1.8

1.9

2.1

2.2

2.3

3.1

3.2

3.3

3.5

3.6

3.7

4.1

4.2

4.3

4.4

4.5

4.7

4.7.1

4.8

4.12

4.19

4.20

4.21

4.22

4.23

4.24

4.31

4.32

4.33

4.34

4.34.1

4.34.2

4.35

4.36

4.41

4.42

4.43

5.1

5.1.1

5.2

5.3

5.5

5.6

5.7

5.8

5.9

5.10

6.1

6.2

6.3

6.4

6.5

6.6

8.1

10.1

10.2

10.3

10.7

10.8

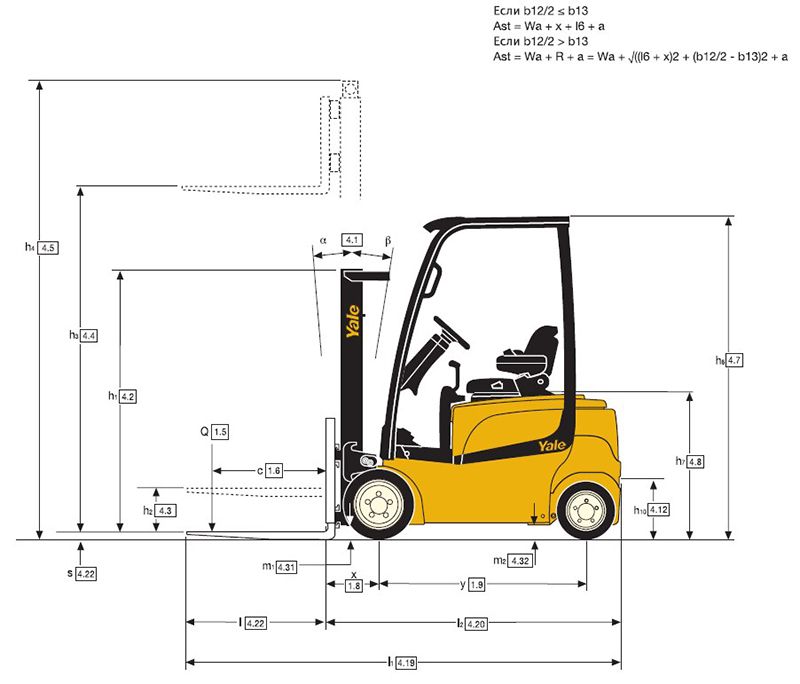

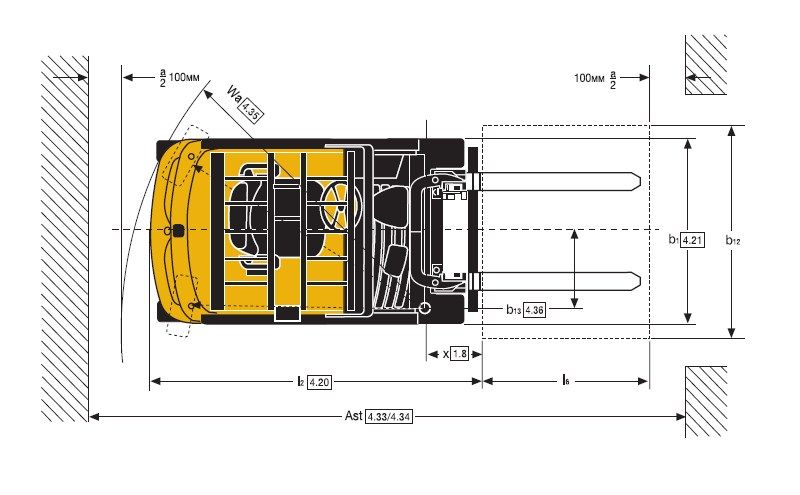

Ast = Wa + R + a = Wa + √((l6 + x)2 + (b12/2 — b13)2) + a

Truck Dimensions

4.20

12

4.21

b1

b12

l6

1.8

x

4.34.1/4.34.2

Ast

4.35

Wa

100mm

a

2

100mm

a

2

4.5

h4

4.4

h3

4.2

h1

1.6

c

4.3

h2

4.22

s

4.1

a

4.22

l

1.8

x

4.19

l1

Q

1.9

y

4.20

l2

4.12

h10

4.8

h7

4.7

h6

4.32

m2

4.31

m1

b

1.5

4.36

b13

VF series

4

ERP16VF MWB mast details and capacity ratings (kg) — Superelastic tyres

h1

(mm)

h2+ s

(mm)

h3+s

(mm)

h4

(mm)

Tilt

F B

Mast

2 Stage

LFL

Clear

View

2 Stage

LFL

Hi-Vis

2 Stage

FFL

Hi-Vis

3 Stage

FFL

Clear

View

3 Stage

FFL

Hi-Vis

Model

Tyre size, front

Overall width, front

E RP 16 V F M W B

18 x 7—8

1050mm

Forks Integral sideshift

500 500600 600700 700

Load centre (kg) Load centre (kg)

2230

2580

2830

3180

2180

2530

2780

3130

2080

2330

2680

1980

2080

2180

2330

2430

1930

2030

2130

2280

2380

140

140

140

140

140

140

140

140

1505

1755

2105

1472

1572

1672

1822

1922

1355

1455

1555

1705

1805

3360

3860

4360

4860

3432

3932

4432

4932

3218

3718

4338

4300

4600

4900

5200*

5500*

4300

4600

4900

5200*

5500*

3868

4368

4868

5368

4006

4506

5006

5506

3728

4228

4847

4808

5108

5408

5708

6008

4875

5175

5375

5775

6075

1600

1600

1580

1490

1600

1600

1580

1490

1600

1600

1600

1600

1500

1350

1220

1090

1600

1570

1460

1320

1190

1450

1450

1430

1350

1450

1450

1430

1350

1450

1450

1450

1450

1400

1350

1220

1090

1450

1420

1370

1320

1190

1350

1340

1330

1250

1350

1340

1330

1240

1340

1340

1330

1340

1300

1250

1190

1090

1340

1320

1270

1220

1160

1600

1590

1570

1480

1580

1570

1550

1450

1570

1560

1550

1570

1480

1320

1190

1060

1570

1540

1420

1290

1160

1430

1430

1410

1320

1410

1410

1390

1300

1410

1400

1390

1410

1360

1310

1190

1060

1410

1380

1330

1270

1160

1300

1290

1270

1200

1280

1270

1260

1180

1270

1270

1260

1270

1230

1190

1140

1060

1270

1250

1200

1150

110 0

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

Note that the capacities are given in

kilograms.

All ratings with DIN Battery.

All ratings with 1000mm forks and less load

backrest.

Note that the capacities are given in

kilograms.

All ratings with DIN Battery.

All ratings with 1000mm forks and less load

backrest.

* Tilt speed reduced to 1° per second by

mechanical tilt speed restictors for mast

heights 5000mm and above.

* Tilt speed reduced to 1° per second by

mechanical tilt speed restictors for mast

heights 5000mm and above.

All values are nominal values and they are

subject to tolerances. For further

information, please contact the

manufacturer.

Yale products might be subject to change

All values are nominal values and they are

subject to tolerances. For further

information, please contact the

manufacturer.

Yale products might be subject to change

without notice.

Lift trucks illustrated may feature optional

equipment.

Values may vary with alternative

configurations.

without notice.

Lift trucks illustrated may feature optional

equipment.

Values may vary with alternative

configurations.

ERP16VF LWB mast details and capacity ratings (kg) — Superelastic tyres

h1

(mm)

h2+ s

(mm)

h3+s

(mm)

h4

(mm)

Tilt

F B

Mast

2 Stage

LFL

Clear

View

2 Stage

LFL

Hi-Vis

2 Stage

FFL

Hi-Vis

3 Stage

FFL

Clear

View

3 Stage

FFL

Hi-Vis

Model

Tyre size, front

Overall width, front

E R P 1 6 V F LW B

18 x 7—8

1050mm

Forks Integral sideshift

500 500600 600700 700

Load centre (kg) Load centre (kg)

2230

2580

2830

3180

2180

2530

2780

3130

2080

2330

2680

1980

2080

2180

2330

2430

1930

2030

2130

2280

2380

140

140

140

140

140

140

140

140

1505

1755

2105

1472

1572

1672

1822

1922

1355

1455

1555

1705

1805

3360

3860

4360

4860

3432

3932

4432

4932

3218

3718

4338

4300

4600

4900

5200*

5500*

4300

4600

4900

5200*

5500*

3868

4368

4868

5368

4006

4506

5006

5506

3728

4228

4847

4808

5108

5408

5708

6008

4875

5175

5375

5775

6075

1600

1600

1580

1500

1600

1600

1580

1500

1600

1600

1600

1600

1510

1360

1230

110 0

1600

1570

1450

1330

1200

1450

1450

1430

1360

1450

1450

1430

1360

1450

1450

1450

1450

1400

1360

1230

110 0

1450

1420

1380

1320

1200

1350

1340

1330

1250

1350

1340

1330

1250

1340

1340

1330

1340

1300

1250

1200

110 0

1340

1320

1270

1220

1170

1600

1590

1570

1480

1580

1570

1550

1460

1570

1560

1550

1570

1470

1320

1190

1060

1570

1540

1430

1290

1160

1430

1430

1410

1330

1410

1410

1390

1310

1410

1400

1390

1410

1360

1310

1190

1060

1410

1380

1330

1280

1160

1300

1290

1270

1200

1280

1270

1260

1180

1270

1270

1260

1270

1230

1190

1140

1060

1270

1250

1210

1160

1110

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

ERP18VF MWB mast details and capacity ratings (kg) — Superelastic tyres

h1

(mm)

h2+ s

(mm)

h3+s

(mm)

h4

(mm)

Tilt

F B

Mast

2 Stage

LFL

Hi-Vis

2 Stage

FFL

Hi-Vis

3 Stage

FFL

Hi-Vis

Model

Tyre size, front

Overall width, front

E R P 1 8 V F M W B

2 0 0 / 5 0 — 10

1116mm

Forks Integral sideshift

500 500600 600700 700

Load centre (kg) Load centre (kg)

2180

2530

2780

3130

2080

2330

2680

1930

2030

2130

2280

2380

140

140

140

140

1505

1755

2105

1355

1455

1555

1705

1805

3432

3932

4432

4932

3218

3718

4338

4300

4600

4900

5200*

5500*

4006

4506

5006

5506

3728

4228

4847

4875

5175

5375

5775

6075

1800

1800

1780

1580

1800

1800

1800

1800

1770

1710

1650

1590

1740

1740

1720

1540

1750

1750

1740

1740

1710

1650

1590

1520

1600

1600

1580

1500

1600

1600

1600

1600

1570

1520

1470

1410

1560

1560

1540

1450

1570

1560

1560

1560

1530

1480

1420

1360

1490

1480

1470

1380

1500

1490

1480

1490

1460

1410

1360

1300

1420

1410

1390

1310

1420

1420

1410

1410

1390

1340

1290

1230

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

Note that the capacities are given in kilograms.

All ratings with DIN Battery.

All ratings with 1000mm forks and less load backrest. * Tilt speed reduced to 1° per second by mechanical

tilt speed restictors for mast heights 5000mm and above.

ERP18VF LWB mast details and capacity ratings (kg) — Superelastic tyres

h1

(mm)

h2+ s

(mm)

h3+s

(mm)

h4

(mm)

Tilt

F B

Mast

2 Stage

LFL

Hi-Vis

2 Stage

FFL

Hi-Vis

3 Stage

FFL

Hi-Vis

Model

Tyre size, front

Overall width, front

E R P 1 8 V F LW B

2 0 0 / 5 0 — 10

1116mm

Forks Integral sideshift

500 500600 600700 700

Load centre (kg) Load centre (kg)

2180

2530

2780

3130

2080

2330

2680

1930

2030

2130

2280

2380

140

140

140

140

1505

1755

2105

1355

1455

1555

1705

1805

3432

3932

4432

4932

3218

3718

4338

4300

4600

4900

5200*

5500*

4006

4506

5006

5506

3728

4228

4847

4875

5175

5375

5775

6075

1800

1800

1780

1580

1800

1800

1800

1800

1770

1710

1600

1470

1740

1740

1720

1540

1750

1750

1740

1740

1710

1650

1580

1440

1600

1600

1580

1500

1600

1600

1600

1600

1570

1520

1470

1410

1560

1560

1540

1450

1570

1560

1560

1560

1530

1480

1420

1360

1490

1480

1470

1380

1500

1490

1480

1490

1460

1410

1360

1300

1420

1410

1390

1310

1420

1420

1410

1410

1380

1340

1290

1230

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

Note that the capacities are given in kilograms.

All ratings with DIN Battery.

All ratings with 1000mm forks and less load backrest. * Tilt speed reduced to 1° per second by mechanical

tilt speed restictors for mast heights 5000mm and above.

ERP20VF MWB/LWB mast details and capacity ratings (kg) — Superelastic tyres

h1

(mm)

h2+ s

(mm)

h3+s

(mm)

h4

(mm)

Tilt

F B

Mast

2 Stage

LFL

Hi-Vis

2 Stage

FFL

Hi-Vis

3 Stage

FFL

Hi-Vis

Model

Tyre size, front

Overall width, front

E R P 2 0 V F LW B

2 0 0 / 5 0 — 10

1116mm

Forks Integral sideshift

500 500600 600700 700

Load centre (kg) Load centre (kg)

2180

2530

2780

3130

2080

2330

2680

1930

2030

2130

2280

2380

140

140

140

140

1505

1755

2105

1355

1455

1555

1705

1805

3432

3932

4432

4932

3218

3718

4338

4300

4600

4900

5200*

5500*

4006

4506

5006

5506

3728

4228

4847

4875

5175

5375

5775

6075

2000

2000

1980

1570

2000

2000

2000

2000

1960

1910

1670

1540

1800

1800

1780

1570

1800

1800

1800

1800

1770

1710

1660

1530

1640

1630

1620

1530

1650

1640

1630

1640

1610

1560

1500

1440

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

1920

1910

1890

1520

1930

1920

1910

1910

1880

1770

1640

1500

1720

1720

1700

1520

1730

1720

1720

1710

1690

1630

1570

1500

1560

1550

1540

1450

1570

1560

1550

1550

1530

1480

1420

1370

Note that the capacities are given in kilograms.

All ratings with DIN Battery.

All ratings with 1000mm forks and less load backrest.

* Tilt speed reduced to 1° per second by mechanical

tilt speed restictors for mast heights 5000mm and above.

VF series

6

77

VF series

Models: ERP16VF MWB/LWB, ERP18VF MWB/LWB, ERP20VF MWB/LWB

AC Technology

Yale AC technology Class H traction

motors are suitable for the most arduous

applications. Smooth forward and

reverse directional changes providing

seamless driving action. In the high-

performance or ‘HiP’ setting,

AC technology provides increased speed

and acceleration, even when fully laden,

and increased speed on grade. As well

as improving performance,

AC technology reduces maintenance and

allows service intervals of 1000 hours for

most components.

Brakes

Yale has replaced the previous hydraulic

service brake system with ‘E-braking’,

which uses the regenerative braking

principle. The brake pedal position is

monitored by a sensor whose voltage

output determines the amount of braking

torque provided by the motors. Yale’s

E-braking system is self-calibrating and

requires no maintenance.

The truck is equipped with and automatic

YaleStop park brake: spring applied,

electro magnetically released park brakes

are mounted at the end of both motors.

The park brake is automatically set by the

control system, so that the brake is

always set whenever the truck is not

moving, and no traction has been

requested. Moreover the park brake

provides controllability on ramp

applications.

Steering

E-steering eliminates the hydraulic

steering lines from the steer column

which is infinitely adjustable in a range of

26º. The E-steering also incorporates the

synchronous steering function so the

steer knob always returns to the home

position which can be selected via the

dash display. During cornering the speed

of the drive motors is continuously

adjusted independently by the traction

controller ensuring smooth operation.

The Yale VF features a state-of-the-art

new customised steer-axle that has

increased articulation of the steer wheels,

allowing it to turn in smaller spaces than

a conventional 4-wheel steer-axle.

Performance modes

Performance of the truck can be tailored

via the enhanced overhead display, with

4 performance modes available to suit

the requirements of the application or the

preferences of the driver. For maximum

speed and acceleration, choose mode 4,

or for more delicate manoeuvring and

extended battery life, mode 1 is ideal.

Your service technician can alter the top

speed and acceleration of mode 4, with

modes 1, 2 and 3 being automatically

adjusted as percentages of setting 4.

‘eLo’ and ‘HiP’ Settings

Yale VF trucks feature an ‘eLo’ energy

saving setting (accessible via the dash

display with service password), which

provides exceptional energy efficient

performance for when you require

continuous operation over longer periods

without recharging the battery. You can

choose the ‘HiP’ high performance

setting for higher top speeds and

acceleration for the most demanding

applications.

Improved ergonomics

The VF is designed for optimum operator

comfort. The operator is seated in an

ergonomically designed position for

maximum safety, comfort, visibility and

ease of operation. The truck features a

very low step height, generous floor and

storage space, standard grab handle for

ease of entry and standard reverse grab

handle. The full suspension seat has

80mm of adjustment. A swivel seat

option for a superior reverse driving

position is available. Both the mini-lever

module and the manual levers have an

integrated direction switch. Clear footwell

allows easy access from both sides.

Masts

A full range of Yale Hi-Vis 2 stage LFL and

2 and 3 stage FFL masts are available.

Yale Hi-Vis masts are designed for

maximum visibility, with widely spaced

channels, lift chains and main lift

cylinders. The Yale Clear View Mast with

class-leading visibility is offered on the

1.6 Ton capacity.

Battery

Choice of 2 battery sizes:

DIN and BS.

Choice of 2 wheelbases:

Depending on the capacity, there is a

choice of Medium Wheelbase (MWB),

and Long Wheelbase (LWB). The LWB

versions provide extra battery space and

longer shift life. MWB versions offer

improved maneuverability and reduced

stacking aisle dimensions. Battery

discharge indicator and lift interrupt are

standard on all trucks.

Battery Exchange

There are several different methods

available to exchange the battery (should

this be necessary), using either a crane, a

2nd fork lift tuck or the Yale purpose

designed pallet truck.

Battery exchange can be accomplished

in under 3 minutes keeping truck

downtime to a minimum.

Low lifetime costs

Lower maintenance costs as a result of

less maintenance by E- brakes, electric

park brake, E-steering, CAN bus and AC

technology. Transmission is sealed for life,

eliminating the need for service. LED light

packages are offered as an option.

1000 hours service interval for most

components.

Auto Regen Braking optimises the shift

life of the battery and contributes to an

increase in the life of parts.

Options

l AccuTouch mini-levers

l Foot directional control

l Lighting kits, including LED lights

l Reverse alarm

l Integrated sideshift

l DIN and BS battery

l Side battery extraction.

HYSTER-YALE UK LIMITED

trading as Yale Europe Materials Handling

Centennial House, Frimley Business Park,

Frimley, Surrey GU16 7SG, United Kingdom.

Tel: +44 (0) 1276 538500

Fax: +44 (0) 1276 538559

www.yale-forklifts.eu

Publication part no. 220990041 Rev.10 Printed in The Netherlands (1118HG) EN.

Safety: This truck conforms to the current EU requirements. Specification is subject to change

without notice.

Yale, VERACITOR and are registered trademarks. “PEOPLE, PRODUCTS, PRODUCTIVITY”,

PREMIER, Hi-Vis, and CSS are trademarks in the United States and certain other jurisdictions.

MATERIALS HANDLING CENTRAL and MATERIAL HANDLING CENTRAL are Service Marks in

the United States and certain other jurisdictions. is a Registered Copyright.

© Yale Europe Materials Handling 2018. All rights reserved. Truck shown with optional equipment.

Country of Registration: England and Wales. Company Registration Number: 02636775

VF series

Models: ERP16VF MWB/LWB, ERP18VF MWB/LWB, ERP20VF MWB/LWB

Welcome to ManualMachine

You have been successfully registered

We have sent a verification link to to complete your registration.

If you can’t find the email, check your Junk/Spam folder.

- Buy Points

- How it Works

- FAQ

- Contact Us

- Questions and Suggestions

- Users

You can only view or download manuals with

Sign Up and get 5 for free

Upload your files to the site. You get 1 for each file you add

Get 1 for every time someone downloads your manual

Buy as many as you need

View and download manuals available only for

Register and get 5 for free

Upload manuals that we do not have and get 1 for each file

Get 1 for every download of your manual

Buy as much as you need

- Manuals

- Brands

- Yale Manuals

- Forklifts

ManualsLib has more than 123 Yale Forklifts manuals

Click on an alphabet below to see the full list of models starting with that letter:

A

B

C

D

E

F

G

J

M

N

O

S

T

Z

Models

Document Type

A

A245

Operating Manual

A283

Service Manual

A372

Service Manual

A474

Maintenance Manual

A497

Maintenance Manual

A7S1

Service Manual

A895

Operating Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

B

B295

Manual

B802

Maintenance Manual • Manual • Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

B827

Manual • Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

B895

Operating Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

B974

Service Manual

C

C801

Maintenance Manual

C802

Maintenance Manual • Manual • Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

C902

Service Manual

C903

Service Manual

D

D801

Maintenance Manual

D826

Maintenance Manual

D861

Manual

E

E815

Manual

E826

Maintenance Manual

EMS 10-16

Operation And Parts Manual

ERC030VA

Manual

ERC040VA

Manual

ERC045VG

Manual

ERC070VG

Manual

ERC100VHS

Manual

ERC120VH

Manual

ERC16VA

Manual

ERC20VA

Manual

ERC22VG

Manual

ERC35VG

Manual

ERC40VH

Manual

ERC50VHS

Manual

ERC55VH

Manual

ERC80VH

Manual

ERP025VC

Manual

ERP030VC

Manual

ERP030VT

Manual

ERP040VT

Manual

ERP045VL

Manual

ERP070VL

Manual

ERP080VM

Manual

ERP100VML

Manual

ERP120VM

Manual

ERP13VC

Manual

ERP15-20VT

Service Manual

ERP15VC

Manual

ERP15VT

Manual

ERP16VF

Manual

ERP170VNL

Manual

ERP190VNL

Manual

ERP20VF

Manual

ERP20VT

Manual

ERP22VL

Manual

ERP30VF

Manual

ERP35VL

Manual

ERP40VF

Manual

ERP40VM

Manual

ERP50VM

Manual

ERP50VM6

Manual

ERP55VM6

Manual

ERP80VNL6

Manual

ERP80VNL9

Manual

ERP90VNL

Manual

F

FS030BF

Maintenance Manual

G

G807

Service Manual

GDP100VX

Service Manual

GDP110VX

Service Manual

GDP120VX

Service Manual • Maintenance Manual

GDP20LX

Service Manual

GDP20UX

Service Manual

GDP25LX

Service Manual

GDP25UX

Service Manual

GDP30UX

Service Manual

GDP35UX

Service Manual

GDP80VX

Service Manual • Maintenance Manual

GDP90VX

Service Manual • Maintenance Manual

GLP100VX

Service Manual

GLP110VX

Service Manual

GLP120VX

Service Manual • Maintenance Manual

GLP20LX

Service Manual

GLP20UX

Service Manual

GLP25LX

Service Manual

GLP25UX

Service Manual

GLP30UX

Service Manual

GLP35UX

Service Manual

GLP80VX

Service Manual • Maintenance Manual

GLP90VX

Service Manual • Maintenance Manual

GP100VX

Service Manual

GP110VX

Service Manual

GP120VX

Service Manual • Maintenance Manual

GP80VX

Service Manual

GP90VX

Service Manual

J

J813

Service Manual • Maintenance Manual

M

MPB040-E

Manual • Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

MPB045VG

Operating Manual • Maintenance Manual

MPC060-VG

Service Manual

MPC080-VG

Service Manual

MSW020-E

Operating Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

MSW025-E

Operating Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

MSW025-F

Operating Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

MSW030-F

Operating Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

MTR005-F

Service Manual

MTR007-F

Service Manual

N

NDR030DB

Manual

NDR030EB

Manual

NDR035EB

Manual

NR035DB

Manual

NR035EB

Manual

NR040DB

Manual

NR040EB

Manual

NR045EB

Manual

O

OS030BE

Maintenance Manual

OS030BF

Maintenance Manual

OS030EC

Maintenance Manual

OS030EF

Maintenance Manual

S

SS030BE

Maintenance Manual

SS030BF

Maintenance Manual

T

Tigrip TKG vh

Operating Instructions Manual

Z

ZAPI MPW045-E

Maintenance Manual • Manual • Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

ZAPI MPW050-E

Maintenance Manual • Manual • Manual • Maintenance Manual • Maintenance Manual • Maintenance Manual

|

Title |

File Size |

Download Link |

|

YALE B974 GDP25LX LIFT TRUCK Service Repair Manual.pdf |

3.4Mb |

Download |

|

Yale Electric Forklift ERC040-065GH (A908), ERC030-040AH (B814), ERP040-060DH(D216) Operating Manual.pdf |

19.2Mb |

Download |

|

Yale Electric Forklift Maintenance Manual.pdf |

990.7kb |

Download |

|

Yale Forklift ERC040RG Service Manual.pdf |

7.5Mb |

Download |

|

Yale Forklift ERC040ZG Service Manual.pdf |

7.5Mb |

Download |

|

Yale Forklift ERC050RG Service Manual.pdf |

7.5Mb |

Download |

|

Yale Forklift ERC050ZG Service Manual.pdf |

7.5Mb |

Download |

|

Yale Forklift ERC060RG Service Manual.pdf |

7.5Mb |

Download |

|

Yale Forklift ERC060ZG Service Manual.pdf |

7.5Mb |

Download |

|

Yale Forklift ERC065RG Service Manual.pdf |

7.5Mb |

Download |

|

Yale Forklift ERC065ZG Service Manual.pdf |

7.5Mb |

Download |

|

Yale Forklift ERC070HG Service Manual.pdf |

2.2Mb |

Download |

|

Yale Forklift ERC080HG Service Manual.pdf |

2.2Mb |

Download |

|

Yale Forklift ERC100HG — 39 Service Manual.pdf |

2.2Mb |

Download |

|

Yale Forklift ERC100HG — 45 Service Manual.pdf |

2.2Mb |

Download |

|

Yale Forklift ERC120HG Service Manual.pdf |

2.2Mb |

Download |

|

Yale Forklift ERP15VT, 16VT, 18VT, 20VT(G807) Parts Manual.pdf |

14.2Mb |

Download |

|

Yale Forklift GLP050LX, GDP50LX(A974) Parts Manual.pdf |

7.4Mb |

Download |

|

Yale Forklift GLP050LX(A974) Parts Manual.pdf |

5.4Mb |

Download |

|

Yale Forklift GLP050TG, GLP060TG, GP050TG, GP060TG Parts Manual.pdf |

9.4Mb |

Download |

|

Yale Forklift GP-GTP-GDP 050-055-060 RL-TL Parts Manual.pdf |

36.8Mb |

Download |

|

Yale Forklift GP080-120VX, GLP080-120VX,GDP080-120VX VERACITOR(G813) Parts Manual.pdf |

13.3Mb |

Download |

|

Yale Forklift Project Report — 1.pdf |

1010.8kb |

Download |

|

YALE G807 ERP18VT LIFT TRUCK (EUROPE) Service Repair Manual.pdf |

6.3Mb |

Download |

|

Yale j813gp-glp-gdp110vx lift truck service repair manual.pdf |

2.8Mb |

Download |

все категории

Вилочный электрический погрузчик Yale ERP16VF MWB со средней колесной базой обеспечивает высокую маневренность и позволяет работать в узких проходах.

Для наибольшей эффективности работы вилочного погрузчика предусмотрены два режима — режим максимальной мощности (HiPP) и экономии энергии (eLo). Интервал между техническим обслуживанием увеличен до 1000 моточасов.

Рабочее место оператора обеспечивает максимальный уровень комфорта и безопасности. Погрузчик отличается отличной обзорностью и легкостью управления.

Особенности

Характеристики

Файлы для скачивания

Галерея

Видео

Особенности конструкции электрического погрузчика Yale ERP16VF MWB

- Тяговый электродвигатель переменного тока Yale обладает электростойкостью изоляционных материалов класса H и приспособлен для работы в особо тяжелых условиях.

- Установки производительности eLo (экономичный режим для эксплутуации погрузчика в течение длительного периода времени без подзарядки) и HiP (режим максимальной мощности)

- Автоматический стояночный тормоз YaleStop имеет пружинный привод и электромагнитные выключатели, которые установлены на оба электродвигателя. Стояночный тормоз включается автоматически с помощью системы управления и всегда включен во время остановки погрузчика.

- Погруженные в масло тормоза

- Средняя колесная база для быстрого маневрирования даже в узких проездах.

- Извлечение аккумуляторной батареи сверху и сбоку (опция)

- Четыре рабочие программы на выбор: максимальные скорость и ускорение при выборе программы 4, более точное маневрирование и увеличение времени работы аккумуляторной батареи без подзарядки с программой 1.

- Система повышенной устойчивости CSE.

- Мачта Hi-Vis™: 2-х секционные мачты без свободного хода вил (LFL) или 2-х и 3-х-секционные мачты со свободным ходом вил (FFL).

- Интервал между техническим обслуживанием большинства узлов и агрегатов погрузчика составляет 1000 моточасов.

- Большое пространство для ног оператора, интуитивно понятное расположение органов управления и низкая высота ступеней обеспечивают комфортные рабочие условия для оператора.

- Удобный доступ к электродвигателю, насосу, контроллеру и гидравлическому баку. Полное техническое обслуживания погрузчика возможно без демонтажа батареи.

Габаритная схема*

*Информацию о габаритах см. во вкладке Характеристики.

| Грузоподъемность, кг | 1600 |

| Высота подъема, мм | 3320 |

| Ast, для паллета 800х1200, мм | 3432 |

| Скорость движения с грузом/без груза, км/ч | 16.0 / 16.0 |

| Скорость подъема вил с грузом/без груза, мм/с | 430 / 590 |

| Общая масса, кг | 3190 |

| Нагрузка на переднюю/заднюю ось с грузом, кг | 4050 / 532 |

| Нагрузка на переднюю/заднюю ось без груза, кг | 1525 / 1657 |

| Шины | Суперэластик |

| Размер шин, передние (стандартный протектор) | 18 x 7-8 |

| Размер задних шин | 140 / 55-9 |

| Количество передних/задних колес (x = ведущие колеса) | 2X / 2 |

| Колея задних колес, мм | 918 |

| Колея передних колес, мм | 889 |

| Преодолеваемый наклон с грузом/без груза, % | 11 / 16 |

| Рабочие тормоза | Гидравлический |

| Рабочее давление для навесного оборудования, бар | 180 |

| Привод | Электрический |

| Скорость опускания, с грузом/без груза, м/с | 0.50 / 0.47 |

| Тяговое усилие, с грузом/без груза, кН | 3406 / 3680 |

| Мощность тягового электродвигателя S2 60 мин, кВт | 2 x 5.0 |

| Мощность двигателя привода гидромотора при S3 15%, кВт | 12 |

| Аккумуляторная батарея по DIN 43531/35/36 A, B, C, не DIN | DIN 43531-A |

| Напряжение аккумулятора/номинальная емкость, (В)/(Ач) | 48 / 625 |

| Вес батареи, кг | 813 / 899 |

| Энергопотребление в соответствии с циклом VDI, кВтч/ч * кол. циклов | 5.1 |

| Общая длина, l1 (мм) | 2981 |

| Общая ширина, b1/b2 (мм) | 1076 |

| Высота с опущенной мачтой, h1 (мм) | 2230 |

| Свободный ход подъема, h2 (мм) | 100 |

| Высота подъема по нижней кромке вил, h3 (мм) | 3320 |

| Высота с выдвинутой мачтой, h4 (мм) | 3868 |

| Высота защитного ограждения (кабины), h6 (мм) | 2070 |

| Высота кресла относительно SIP/высота стойки, h7 (мм) | 919 |

| Высота буксировочного крюка, h10 (мм) | 360 |

| Длина до спинок вил, l2 (мм) | 1981 |

| Габариты вил ISO 2331 (длина х ширина х толщина), s/e/l (мм) | 40 / 80 / 1000 |

| Каретка ISO 2328, класс/тип A, B | IIA |

| Ширина каретки вил, b3 (мм) | 907 |

| Клиренс под мачтой с грузом, m1 (мм) | 88 |

| Клиренс по центру колесной базы, m2 (мм) | 100 |

| Ширина рабочего коридора для паллет 1000х1200, в ширину, Ast (мм) | 3309 |

| Ширина рабочего коридора для паллет 800х1200, вдоль (мм) | 3432 |

| Внешний радиус разворота, Wa (мм) | 1654 |

| Наклон мачты/каретки вперед/назад, α / β (o) | 5 / 5 |

| Центр загрузки, мм | 500 |

| Колесная база, мм | 1431 |

| Расстояние от оси передних колес до спинки вил, мм | 326 |