-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

SMART POSITIONER

PRODUCT MANUAL

YT-2500 / 2550 / 2501 SERIES

Rotork YTC Limited

VERSION 1.34

Related Manuals for rotork YT-2500 Series

Summary of Contents for rotork YT-2500 Series

-

Page 1

SMART POSITIONER PRODUCT MANUAL YT-2500 / 2550 / 2501 SERIES Rotork YTC Limited VERSION 1.34… -

Page 2: Table Of Contents

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Contents Introduction …………………………5 General Information for the users ………………….5 Manufacturer Warranty …………………….5 Explosion Proof Warning (Only for Intrinsic safety type positioners) …………6 Product Description ………………………7 General …………………………7 Main Features and Functions …………………..7 Label Description ……………………..8 Product Code ………………………..

-

Page 3

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Safety …………………………34 Connection ……………………….34 Ground …………………………. 36 Adjustments ……………………….. 37 Limit Switch Adjustment ……………………37 Variable Orifice Adjustment ………………….. 38 Optional Sub-PCB Installment ………………….. 39 Installation steps ……………………..39 Maintenance ……………………….. -

Page 4

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual 9.8.6 Split Range Mode (SPLIT) ………………….54 View Mode (VIEW) ……………………..55 Error and Warning Code ……………………. 57 10.1 Error code which is displayed during Auto calibration …………… 57 10.2 Error code which is displayed while using the product ………….. -

Page 5: Introduction

Introduction General Information for the users Thank you for purchasing Rotork YTC Limited products. Each product has been fully inspected after its production to offer you the highest quality and reliable performance. Please read the product manual carefully prior to installing and commissioning the product.

-

Page 6: Explosion Proof Warning (Only For Intrinsic Safety Type Positioners)

➢ For detailed warranty information, please contact the corresponding local Rotork YTC Limited office or main office in South Korea. Explosion Proof Warning (Only for Intrinsic safety type positioners) Please ensure the unit is being used and installed in conformity with local, regional, and national explosion proof within the proper safety barrier environment.

-

Page 7: Product Description

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Product Description General YT-2500 / 2550 / 2501 series Smart Valve Positioner accurately controls valve stroke in response to an input signal of 4~20mA from the controller. Built-in micro-processor optimizes the positioner’s performance and provides unique functions such as Auto-Calibration, PD Control, and HART Protocol Communications.

-

Page 8: Label Description

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Label Description • MODEL : Indicates the model number and additional options. • EXPLOSION PROOF : Indicates certified explosion proof grade. • INGRESS PROTECTION : Indicates enclosure protection grade. • INPUT SIGNAL : Indicates input signal range.

-

Page 9

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Fig. L-3: YT-2500 Intrinsic safety type (KCs, NEPSI, ATEX, IECEx) Fig. L-4: YT-2500 Intrinsic safety type (TRCU) Fig. L-5: YT-2500 Intrinsic safety type (CCC) Ver. 1.34… -

Page 10

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Fig. L-6: YT-2550 Non-explosion proof Fig. L-7: YT-2550 Intrinsic safety type (KCs, ATEX, IECEx) Fig. L-8: YT-2550 Intrinsic safety type (CCC) Fig. L-9: YT-2501 Non-explosion proof Ver. 1.34… -

Page 11

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Fig. L-10: YT-2501 Intrinsic safety type (KCs, ATEX, IECEx) Fig. L-11: YT-2501 Intrinsic safety type (CCC) Ver. 1.34… -

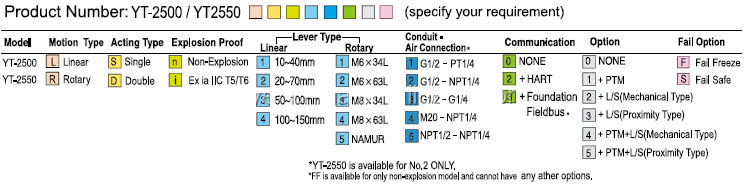

Page 12: Product Code

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Product Code YT-2500 / 2550 series follows suffix symbols as follows. 2.4.1 YT-2500 / 2550 1 Linear Motion Type Rotary Single Acting type Double Non-Explosion Intrinsic safety : YT-2500 → KCs, NEPSI, ATEX, IECEx YT-2550 →…

-

Page 13: Yt-2501 Series Follows Suffix Symbols As Follows

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Fail Freeze Fail Option Fail Safe Operating temp. of inductive proximity limit switch is from -25°C~ . YT-2501 series follows suffix symbols as follows. 2.4.2 YT-2501 1 Linear Motion Type Rotary Single Acting type…

-

Page 14: Product Specification

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Product Specification YT-2500 / 2550 Specification 2.5.1 Model YT-2500 YT-2550 Housing Material Aluminum Stainless steel 316 Motion Type Linear Rotary Linear Rotary Acting Type Single / Double Input Signal 4~20mA DC Minimum Current Signal 3.5mA(Standard), 3.8mA(HART Included) Supply Pressure…

-

Page 15

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Tested under ambient temperature of 20°C, absolute pressure of 760mmHg, and humidity of 65% Please contact Rotork YTC Limited for detailed testing specification. Ver. 1.34… -

Page 16: Yt-2501 Specification

0.6 kg (1.2 lb) 1.0 kg (2.1 lb) Cable(5M) 0.6 kg (1.3 lb) Painting Polyester Powder Coating Tested under ambient temperature of 20°C, absolute pressure of 760mmHg, and humidity of 65% Please contact Rotork YTC Limited for detailed testing specification. Ver. 1.34…

-

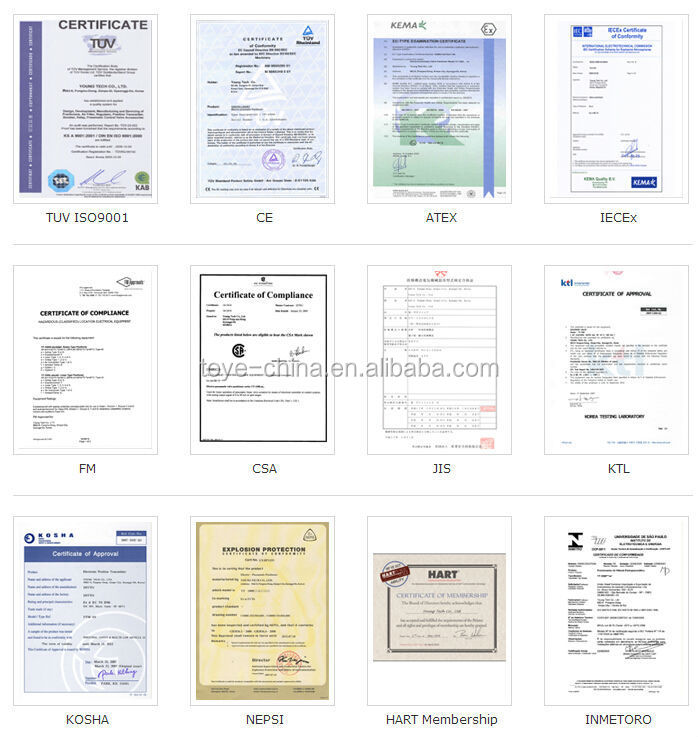

Page 17: Certifications

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Certifications ※ All certifications below are posted on Rotork YTC Limited homepage(www.ytc.co.kr). KCs (Korea) ➢ Type : Intrinsic safety Rating : Ex ia IIC T5/T6, Ex iaD IIIC T100°C/T85°C Certification No. : 11-KB2BO-0163X(YT-2500)

-

Page 18: Parts And Assembly

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Parts and Assembly Fig. 2-1: YT-2500 / 2550 series exploded view 1. Base Cover 6. Potentiometer 2. Option PCB 7. Main shaft 3. Main PCB 8. Base body 4. Pressure Gauge 9.

-

Page 19

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Positioner Rotary Remote Sensor Linear Remote Sensor Fig. 2-2: YT-2501 exploded view 1. Base cover of Remote sensor 10. Base cover of Positioner 2. Terminal of Remote sensor 11. PCB of Positioner 3. -

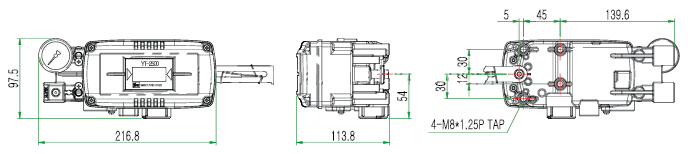

Page 20: Product Dimension

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Product Dimension YT-2500 2.8.1 Fig. 2-3: YT-2500L Fig. 2-4: YT-2500R (Fork Lever Type) Fig. 2-5: YT-2500R (Namur Type) Fig. 2-6: YT-2500R (L/S Option) Ver. 1.34…

-

Page 21

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual YT-2550 2.8.2 Fig. 2-7: YT-2550L Fig. 2-8: YT-2550R YT-2501 2.8.3 Fig. 2-10: Rotary Remote Sensor Fig. 2-9: Linear Remote Sensor Fig. 2-11: YT-2501 Positioner Ver. 1.34… -

Page 22: Installation

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Installation Safety When installing a positioner, please ensure to read and follow safety instructions. ➢ Any input or supply pressures to valve, actuator, and / or to other related devices must be turned off.

-

Page 23: Linear Positioner Installation

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Linear positioner Installation Linear positioner should be installed on linear motion valves such as globe or gate type which uses spring return type diaphragm or piston actuators. Fig. 3-2: YT-2500L / 2550L installation example Fig.

-

Page 24: Linear Positioner Installation Steps

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Linear positioner Installation Steps 3.3.2 1) Assemble the positioner with the bracket made in previous step by fastening the bolts. The bolt size is M8 x 1.25P. Fig. 3-4: Attaching to bracket Fig.

-

Page 25

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual 5) Insert the connection bar between the feedback lever and lever spring. The connection bar must be located upward from the lever spring as shown below left figure. If it is located downward from the lever spring as shown below right figure, the connection bar or the lever spring will be worn out quickly because of excessive strong tension. -

Page 26

Fig. 3-9: Feedback lever and location of the connection bar ※ The effective linear lever angle of YT-2500 series is 30 degree.After installing the positioner, operate the valve from 0% to 100% stroke by using direct air to the actuator.

-

Page 27: Rotary Positioner Installation

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Rotary positioner Installation Rotary positioner should be installed on rotary motion valve such as ball or butterfly type which uses rack and pinion, scotch yoke or other type of actuators which its stem rotates 90 degrees. Before proceeding with the installation, ensure following components are available.

-

Page 28: Rotary Bracket Information (Only Yt-2500 / 2550)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Rotary Bracket information (Only YT-2500 / 2550) 3.4.3 The rotary bracket set (included with the positioner) contains two components. The bracket is designed to fit onto the actuator with 20mm, 30mm and 50mm stem height (H) according to VDI/VDE 3845 standard.

-

Page 29: Rotary Positioner Installation Steps

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Rotary positioner Installation Steps 3.4.4 1) Please check the actuator’s stem height and adjust the brackets by referring to the above bracket table. 2) Attached the brackets onto the actuator. It is recommended to use spring washer so the bolts will not be loosen from vibration.

-

Page 30

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual 6) Attach the positioner to the bracket. <Only fork lever type of YT-2500 / 2550: Fix the clamping pin (5mm Dia.) into the fork lever slot and insert center pin (2mm Dia.) of the main shaft of the positioner into the hole of center of the fork lever. -

Page 31: Connection — Air

➢ Always recommended to use air filter regulator (i.e. YT-200 series). ➢ Rotork YTC Limited has not tested positioner’s operation with any other gases other than clean air. Please contact Rotork YTC Limited for any questions. Supply Pressure Condition ➢…

-

Page 32: Connection — Piping With Actuator

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Connection – Piping with actuator Single acting actuator 4.4.1 Singe acting type positioner is set to use only OUT1 port. OUT1 port of positioner should be connected with supply port of actuator when using spring return actuator of single acting type. Fig.

-

Page 33: Double Acting Actuator

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Double acting actuator 4.4.2 Double acting type positioner is set to use OUT1 and OUT2 port. As input signal increases, the supply pressure will be supplied through OUT1 port. Fig. 4-5: Double acting linear actuator (YT-2500L / 2550L) Fig. 4-6: Double acting rotary actuator (YT-2500R / 2550R) Fig.

-

Page 34: Connection — Power

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Connection – Power Safety ➢ There are two conduit entries on the product. See “2.4 Product Code” for conduit entry threads. ➢ Before connecting terminal, ensure that the power is off completely. ➢…

-

Page 35

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Fig. 5-2: Mechanical Limit Switch Terminal (Only YT-2500 / 2550) Fig. 5-3: Inductive Proximity Limit Switch Terminal (Only YT-2500 / 2550) Ver. 1.34… -

Page 36: Ground

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Fig. 5-4: Remote sensor and cables (Only YT-2501) Ground 1) Ground must be done before operating the positioner. 2) Open base cover and there is an internal ground “F.G” on the left hand. An external ground bolt is located next to the conduit entry.

-

Page 37: Adjustments

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Adjustments Limit Switch Adjustment YT-2500 / 2550 can have limit switch option. If user wants to adjust the sensing position, please loosen bolts and adjust cam. Fig. 6-1: Mechanical Type Fig.

-

Page 38: Variable Orifice Adjustment

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Variable Orifice Adjustment Hunting can be occurred when the actuator’s volume is too small. In order to prevent hunting, orifice can be adjusted. By adjusting the orifice, the flow rate of the supply pressure to actuator can be adjusted.

-

Page 39: Optional Sub-Pcb Installment

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Optional Sub-PCB Installment By adding sub-PCB, the positioner can have additional functions. There are 3 types of sub-PCB. Hart Only Ptm Only Ptm+Hart Fig. 7-1: Types of Sub-PCB When purchasing option sub-PCBs separately, 4 Bolts and 2 supports (3 at Limit switch internal option) are supplied together with sub-PCB.

-

Page 40: Maintenance

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Maintenance Supply air If Supply air pressure is not stable or Supply air is not clean, the positioner may not function properly. Air quality and pressure should be checked regularly to see if the air is clean and pressure set is normal. Seals Once a year, it is recommend to check if there are any damaged parts of the positioner.

-

Page 41: Auto Calibration And Pcb Operation

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Auto Calibration and PCB Operation Warning Following process will operate valve and actuator. Before proceeding with any Auto Calibration, please separate valve from the entire system by using bypass valve, so Auto Calibration will not affect entire valve process.

-

Page 42: Run Mode (Run)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Run Mode (RUN) After power connection to the positioner, Run Mode will be appeared on positioner’s LCD screen in about 4 seconds. “RUN” indicates that the positioner adjusts the valve stroke according to the receiving signal. There are six types of display message in “RUN”…

-

Page 43: Auto1 Calibration (Auto1)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual AUTO1 Calibration (AUTO1) 9.4.1 AUTO1 changes only zero and end points; however other parameters(P, D etc.) will not be adjusted. It is recommended to perform AUTO1 when the positioner has been set by the valve manufacturer already, and the field user wants to re-calibrate the positioner.

-

Page 44: Manual Mode (Manual)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Manual Mode (MANUAL) Manual mode is used to maneuver valve stem manually. In Manual mode, the positioner does not control the valve by the signal received from outside, but it could be controlled to move up and down by pressing <UP>…

-

Page 45: Dead-Zone (Deadzone, %)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Dead-Zone (dEAdZONE, %) 9.6.1 Dead-Zone indicates the percentage of error allowance. When AUTO 2 or AUTO 3 calibration are done, this value would be set automatically and moderately. But if hunting still occur after AUTO 2 or AUTO 3 calibration for the reason such as high level of packing friction, increasing the value of Dead-Zone can stable the valve operation.

-

Page 46: D1 Value (Kd1)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual D1 Value (Kd1) 9.6.3 D value indicates the derivative value of the compensation signal based on the percentage of error allowance. As the value increase, it is more likely to have hunting. As the value decreases, it can have poor linearity or dynamic characteristic.

-

Page 47: Period T (Period T)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Period T (PERIOd T) 9.6.7 Period T indicates the positioner’s internal control time interval. As default, positioner will check current position respective to current input signal in every 100 msec. Auto DZ (AUTO dZ) 9.6.8 After the auto calibration, the positioner will create deadzone automatically.

-

Page 48: Hand Calibration Mode (Hand Cal)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Hand Calibration Mode (HAND CAL) Hand Calibration mode is used when zero-point and end-point require re-adjustment to use partial range of total strokes after Auto Calibration has been performed. Below are the list of features which could be set from Hand CAL mode. 1) Zero-Point (PV_ZERO) and End-Point (PV_END) for Valves 2) Zero-Point (TR_ZERO) and End-Point (TR_END) for Transmitter 3) Normal / Reverse Feedback Signal (TR NORM / REVS)

-

Page 49: Zero-Point (Tr_Zero) And End-Point (Tr_End) For Transmitter

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Zero-Point (TR_ZERO) and End-Point (TR_END) for Transmitter 9.7.2 TR_ZERO adjusts the zero point of the transmitter (4mA feedback), and TR_END adjusts the end point of the transmitter (20mA feedback). This is used when output signal becomes unstable and requires re-adjustment or when feedback output signal and actual stroke need to be used differently.

-

Page 50: Normal / Reverse Feedback Signal (Tr Norm / Revs)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Normal / Reverse Feedback Signal (TR NORM / REVS) 9.7.3 The feedback signal from the positioner can be changed to normal or reverse. <ENTER> <ENTER> <DOWN> → → → Press <UP> or <DOWN>…

-

Page 51: Acting Adjustment (Act Ra / Da)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Acting Adjustment (ACT RA / dA) 9.8.1 RA & DA are automatically set by performing “AUTO 2” from Auto Calibration. However, this function is used when the user wants to change RA & DA. The positioner can be set as Direct Action (DA) or Reverse Action (RA).

-

Page 52: User Defining Flow Characteristics (User Set)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual User defining flow Characteristics (USER SET) 9.8.3 User can make its own flow characteristic curve with this mode. USER SET can be set in two ways, 5 points and 18 points. User can choose whichever is more suitable for their application. 1) 5 points setting can be set with 4mA intervals.

-

Page 53: Tight Shut Open (Tshut Op)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual 2) 18 points setting can be set with 1mA intervals. The initial positions are P0(4mA=0%), P1(5mA=6.25%), P2(6mA=12.5%), … P16(20mA=100%) and P17(21mA=106.25%) but user can change the % values to different values. User can change all 18 points or only change partially and exit the menu by pressing <ESC>…

-

Page 54: Tight Shut Close (Tshut Cl)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Tight Shut Close (TSHUT CL) 9.8.5 Tight shut close shows the current value in percentage (%). Input current of 4mA is 0%, 20mA is 100%. If temporary Tight shut close value (≤100%) is set and input current value is below the set % value, the valve’s position is immediately moved to 0%.

-

Page 55: View Mode (View)

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual View Mode (VIEW) Displays various information of the positioner. <ENTER> <ENTER> <DOWN> 3 seconds → → → Press <UP> or <DOWN> button if the above is not displayed. <DOWN> <DOWN> <DOWN>…

-

Page 56

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual ITEM Description 1’st row→FF: Fail Freeze / FS: Fail Safe. FF / FS 2’nd row→Positioner model. YT-2500L 1’st row→version number of firmware. 1.6.03 2’nd row→VERSION: Main software version / VERSION / 2020DC31 2020-12(DC)-31: loading date of software. -

Page 57: Error And Warning Code

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Error and Warning Code Error or Warning code occur if there is a problem during Auto calibration or using the product. ➢ Error code : These are indicated if the positioner cannot be controlled, malfunctions or becomes imprecise.

-

Page 58: Error Code Which Is Displayed While Using The Product

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual ➢ Indicated when the feedback lever’s angle used is excessively small ➢ Re-install the positioner by during auto calibration. moving it towards the actuator RNG ERR ➢ When this error is detected, auto stem so that the angle use of the calibration is aborted and this feedback lever becomes larger.

-

Page 59: Warning Code Which Can Be Checked From View Mode

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual ➢ Accumulated I value is I max or min’s limit. ➢ Degree of precision is low. ➢ Re-perform auto-calibration. ➢ Indicated if valve’s friction is ➢ Check air regulator’s set extremely high or set pressure of air pressure and re-adjust to regulator has been changed.

-

Page 60: Main Software Map

Smart Positioner YT-2500 / 2550 / 2501 Series Product Manual Main Software Map Ver. 1.34…

-

Page 61

Product Manual Manufacturer: Rotork YTC Limited Address: 81, Hwanggeum-ro, 89 Beon-gil, Yangchon-eup, Gimpo-si, Gyeonggi-do, South Korea Postal code: 10048 Tel: +82-31-986-8545 Fax: +82-70-4170-4927 Email: ytc.sales@rotork.com Homepage : http://www.ytc.co.kr Issued : 2021-03-17 Copyright © Rotork YTC Limited. All Rights Reserved. Ver. 1.34…

Умные позиционеры YTC

Smart Valve Positioner контролирует ход клапана

входной сигнал с контроллера 4 ~ 20 мА

Комплектация:

- Автоматическая калибровка

- Автоматический и ручной переключатель

- Коммуникация HART

- ЖК-дисплей

- ПИД-регулирование

- 4 кнопки локального управления

- Сигнал обратной связи

- Предельный выключатель

|

Искробезопасный позиционер YT-3300 |

|||

|

Искробезопасный позиционер из нержавеющей стали YT-3350 |

|

||

|

YT-3303 |

|

||

|

Удаленный позиционер YT-3301 |

|

||

|

Взрывозащищенный позиционер YT-3400 |

|

||

|

Взрывозащищенный позиционер из нержавеющей стали YT-3450 |

|||

|

YT-2500 Fail Freeze или Fail Safe Type Функция блокировки останова Почти нулевой уровень потребления воздуха

|

|

||

|

Позиционер из нержавеющей стали YT-2550 Fail Freeze или Fail Safe Type Функция блокировки останова Почти нулевой уровень потребления воздуха |

|||

|

Удаленный позиционер YT-2501 дистанционное управление работа в условиях высокой температуры и вибрации Отдельный модуль обратной связи Почти нулевой уровень потребления воздуха Fail freeze / safe function |

|||

|

Взрывозащищенный позиционер YT-2600 Fail Freeze / Fail Safe Type Функция блокировки останова Почти нулевой уровень потребления воздуха |

|||

|

Компактный позиционер YT-2700 встроенный оператор микрообработки |

|||

|

Позиционер ТМП-3000 для углового клапана Взаимозаменяемое действие отказа Почти нулевой уровень потребления |

Электропневматический позиционер

Управление приводами пневматических поворотных клапанов.

Электрический контроллер или система управления с аналоговым выходным сигналом постоянного тока: 4 — 20 мА или диапазоном разделения

- Простая настройка нуля и диапазона

- Без резонанса между 5-200 Гц

- Автоматический и ручной переключатель

- RA vs DA и 1/2 сплит-диапазона

- Внутренний сигнал обратной связи для защиты от дождя (опция)

|

Линейный позиционер YT-1000L |

|||

|

Ротационный позиционер YT-1000R |

|||

|

Позиционер YT-1050 из нержавеющей стали |

Пневматический позиционер

Пневматический позиционер YTC применяется для пневматических приводов линейных клапанов.

Пневматический контроллер или система управления с выходным сигналом: 3 — 15 фунтов на квадратный дюйм или диапазоном разделения.

- Простая настройка нуля и диапазона

- Без резонанса между 5 ~ 200 Гц

- Автоматический и ручной переключатель

- RA vs DA и 1/2 сплит-диапазона

|

Линейный позиционер YT-1200L |

|||

|

Ротационный позиционер YT-1200R |

На все вопросы по подбору и приобретению позиционеров YTC ответят специалисты «УралКомплектЭнергоМаш», коммерческий отдел (343) 222-79-77 либо заполните заявку он-лайн…

- 458 Reviews

- 12 Questions

- Категории: >>>

- Поставщик: Toye,Measurement,&,Control,Equipment,Co.,Ltd.,[Shannxi,China]Toye

Цена:5 273,66 ₽ — 113 006,85 ₽*

Стоимость в USD:Показать (текущая цена)

-

В избранное

Описание и отзывы

Характеристики

Смарт-устройство для позиционирования

1. характеристики

YT-2500 умный позиционер клапана точно контролирует ход клапана, в соответствии с входным сигналом 4-20мА, доставляемым от контроллера.

-Не функция замораживания

Автоматическая машина для упаковки в калибровке

-ЖК-дисплей

-Отзывы сигнала

-Почти нулевой уровень потребления воздуха

-PD управления

-Концевые выключатели

-HART коммуникации

-4 кнопки для локального управления

2. Спецификация

|

Товар. Тип |

YT-2500 |

YT-2550 |

|

Входной сигнал |

4-20mA постоянного тока |

|

|

Давление подачи |

0,14-0.7MPa (1.4-7bar) |

|

|

Ход |

Линейный тип |

10-150 мм |

|

Щит роторного типа |

0-90 ° |

|

|

Импеданс |

Max.500 Ω @ 20mA постоянного тока |

|

|

Воздушное соединение |

PT (NPT) 1/4 |

NPT1/4 |

|

Датчик соединение |

PT (NPT) 1/8 |

NPT1/8 |

|

Кабелепровода |

G (PF, NPT) 1/2, M20 |

Г (ПФ) 1/2 |

|

Температура окружающей среды |

Рабочая температура |

(-30℃ ~80℃)/(-22~176 °F) |

|

Взрыва темп |

(-40℃ ~60℃T5)/(-40℃ ~40℃T6) |

|

|

Линейность |

±0. 5%; f |

|

|

Гистерезиса |

±0. 5%; f |

|

|

Чувствительность |

±0. 2%; f |

|

|

Точность повторяемости |

±0. 3%; f |

|

|

Расход воздуха |

Не замораживать |

0.01LPM (sup = 0.14MPa) |

|

Замок-электрозащелка |

6 ЛПМ (sup = 0,14 МПа) |

|

|

Пропускная способность |

Не замораживать |

60 ЛПМ (sup = 0,14 МПа) |

|

Замок-электрозащелка |

40 ЛПМ (sup = 0,14 МПа) |

|

|

Выходные характеристики |

Линейный, эквалайзер %, быстрый открытый пользовательский набор (16 точек) |

|

|

Материал |

Алюминиевое литье под давлением |

Нержавеющая Steel316 |

|

Корпус |

IP66 |

|

|

Защита от взрыва |

Exia IIC T5/T6 |

|

|

L/S рейтинг |

Механический тип (Omron) |

Переменный ток: 125 В, 3 А; Постоянный ток: 30 в, 2 А |

|

Тип приближения (P & F) |

Постоянный ток: 8,2 В, 8,2 мА |

|

|

Вес |

1,5 кг (3.3Ib) |

2,9 кг (6.4Ib) |

3. Изображение товара

3,1 Размер

3,2 выбора типа

3,3 изображение

4. Сертификация

Упаковка & Доставка

Информация об упаковке: Стандартная (экспортная) упаковка или по требованию заказчика

Сведения о доставке: Доставка в течение 30 дней после получения оплаты./после получения оплаты

Доставка: Морской, воздушный и другие виды транспорта

Наши услуги

Наше преимущество:

А. опытный поставщик товары.

B. Профессиональный и отдел продаж для вашего обслуживания.

C. Alibaba Золотой Поставщик.

D. 7/24 обслуживание для вас, все вопросы будут иметь дело в течение 24 часов.

Преимущества которые вы получите:

A. стабильное качество

B. Низкая цена-не самая дешевая, но такое же качество.

С. Хорошее обслуживание-удовлетворительное обслуживание до и после продажи.

D. Срок поставки-от 30 до 45 дней для массового производства.

Заказ наш продукт

1. клиенты предлагают Подробные параметры и модель продукта.

2. Мы постараемся отправить предложение после того, как информация и последним требованиям рассчет стоимости.

Информация о компании

Toye измерения и контроля equipment co., Ltd, размещает на NO.5 Южная лиственницаRoad, Yanta District, Xi’an, является высокотехнологичным предприятием, которое интегрирует разработку, дизайн, производство, агенты по продажам и системную интеграцию. Товары включают в биологической, химической, военной промышленности, производство, научно-исследовательских институтах, контроля за состоянием окружающей среды, химическая промышленность, фармацевтическая отрасли, сельского хозяйства и других областях. Компания стремится к введению международных известных брендов высококачественных инструментов промышленной автоматизации и метров и передовых технологий, опираясь на свои мощные ресурсы, чтобы предоставить клиентам комплексные товары в области автоматизации, и удовлетворить клиента для тестирования, обслуживания, требования инженерной технологии и других запасных частей.

Основные товары, включая передатчик давления, расходомер, интеллектуальный детектор радаров, позиционер клапана, переключатель давления, манометр.

Мы стремимся создать самую профессиональную команду, чтобы обеспечить клиентам оптимальные решения и бизнес-услуги, обратить внимание на все требования клиентов, полностью рассмотреть каждую деталь, благодаря неустанным усилиям и развитию в течение многих лет, завоевала хорошую репутацию в отрасли, Мы рассчитываем на сотрудничество с вами для установления долгосрочных и стабильных отношений сотрудничества.

Toye Measurement and Control equipment co., Ltd

№ 5 Южная лиственница Road, Yanta District, Сиань, Шэньси, Китай (материк). 710065

Тел: 86-29-84504648/89286267/88234682 факс: 86-29-84504648

Skype: cherise1196

Http://www.toye-china.com

After installing the positioner, operate the valve from 0% to 100% stroke by using direct air to the actuator.

After installing the positioner, operate the valve from 0% to 100% stroke by using direct air to the actuator.